Production process and production equipment of stainless steel seamless steel pipe for ship

A technology for seamless steel pipes and production equipment, used in metal processing equipment, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of long operation time, high labor cost, uneven grinding, etc. , to achieve the effect of low labor intensity, efficient and comprehensive grinding, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] A production process of stainless steel seamless steel pipes for ships, comprising the following steps:

[0047] S1: Tube billet preparation: round tube billets are made through ironmaking, steelmaking, ingot casting, blooming, rolling round steel and other processes;

[0048] S2: Tube billet inspection, fixed cutting: inspect the round steel billet, confirm that the tube billet has no obvious trauma or surface depression and other raw material problems, and then perform fixed cutting treatment;

[0049] S3: tube billet heating, hot-rolled piercing: the cut tube material is sent to the furnace for heating through the conveyor belt, and the heated tube material is hot-rolled and pierced through pressure piercing machine and other equipment;

[0050] S4: pickling: immerse the pipe material in an acid solution to produce a chemical reaction, and then clean it with pressure water;

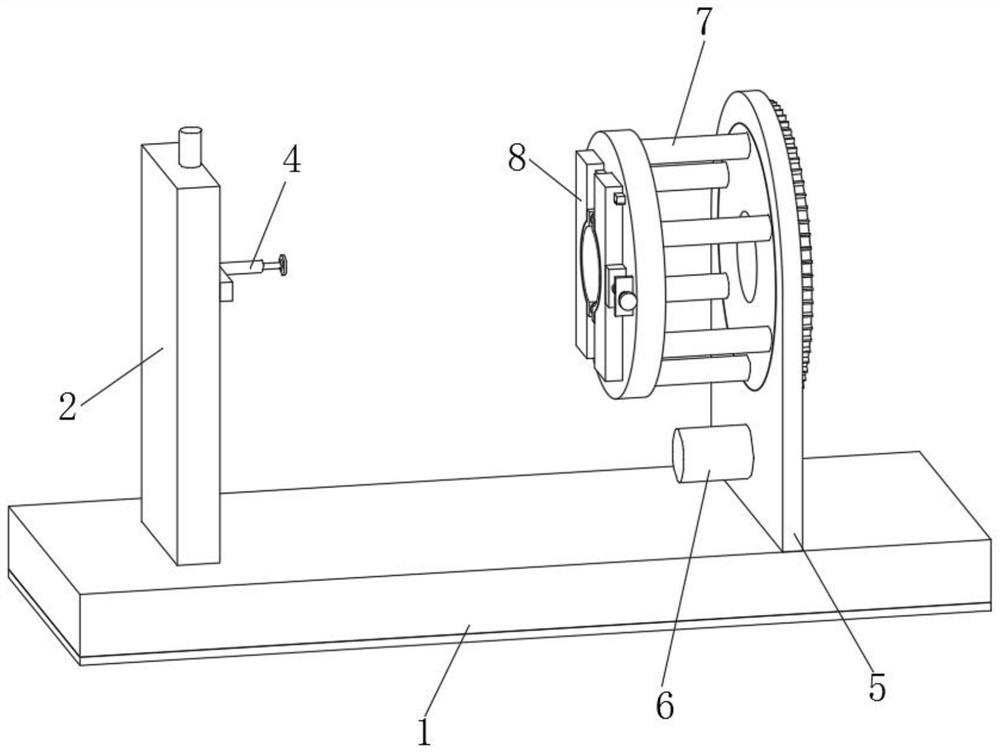

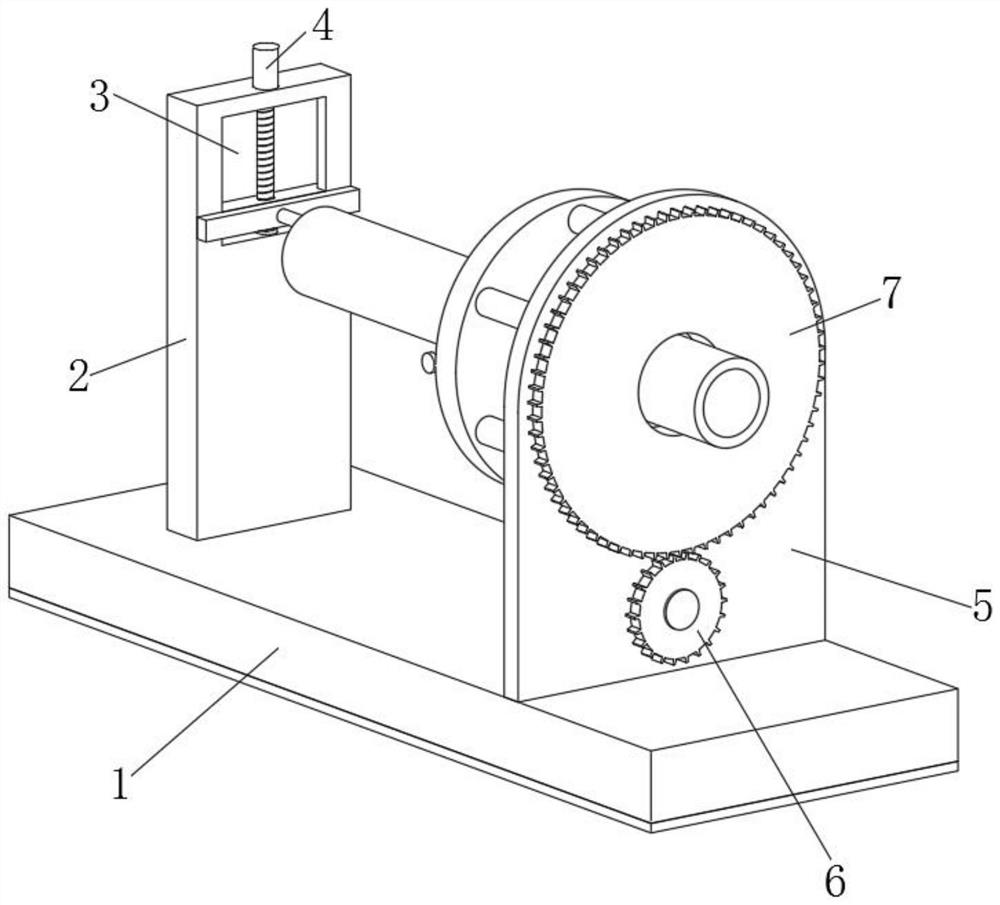

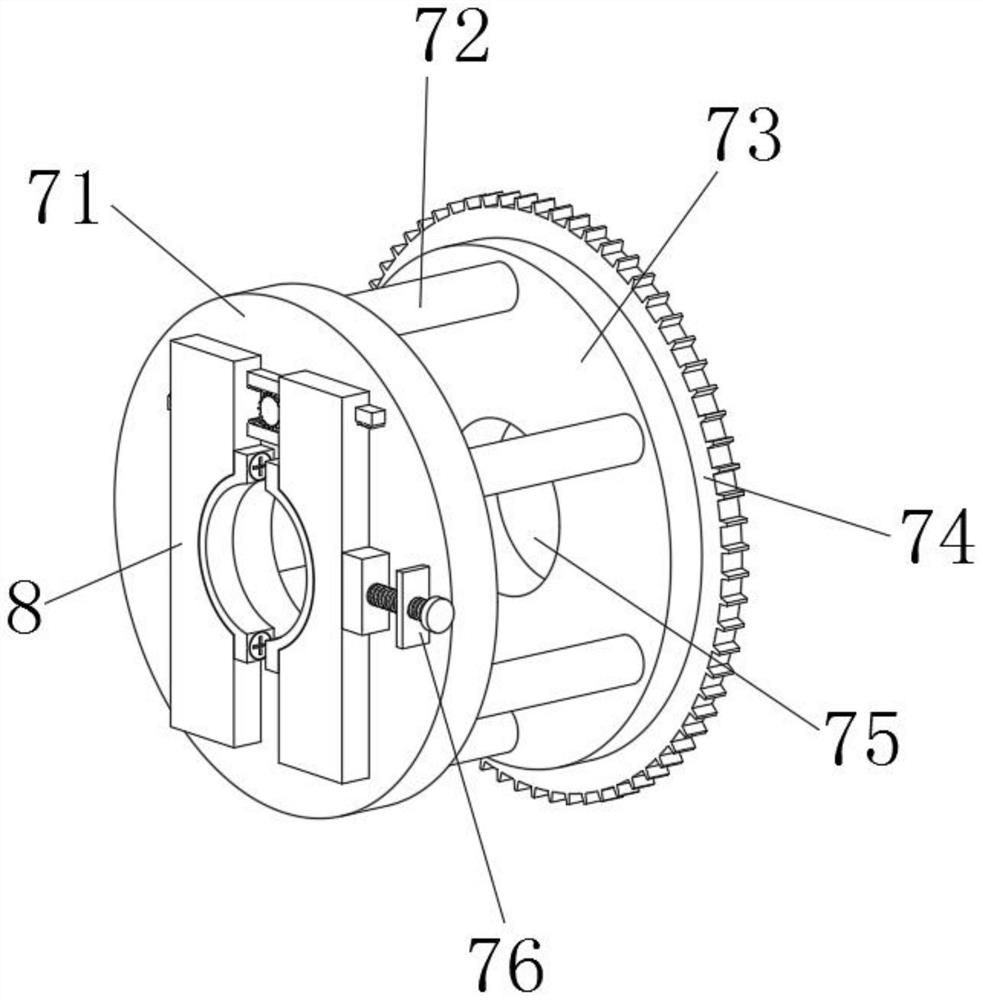

[0051] S5: Surface polishing: send the pickled pipe material into the equipment for surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com