Flexible and adjustable automobile maintenance grinding wagon

A technology for car maintenance and grinding cars, which is applied in vehicle maintenance/repair, grinding machines, trolleys, etc., and can solve the problems of narrow adjustment and adaptable range, inconvenient operation of grinding cars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

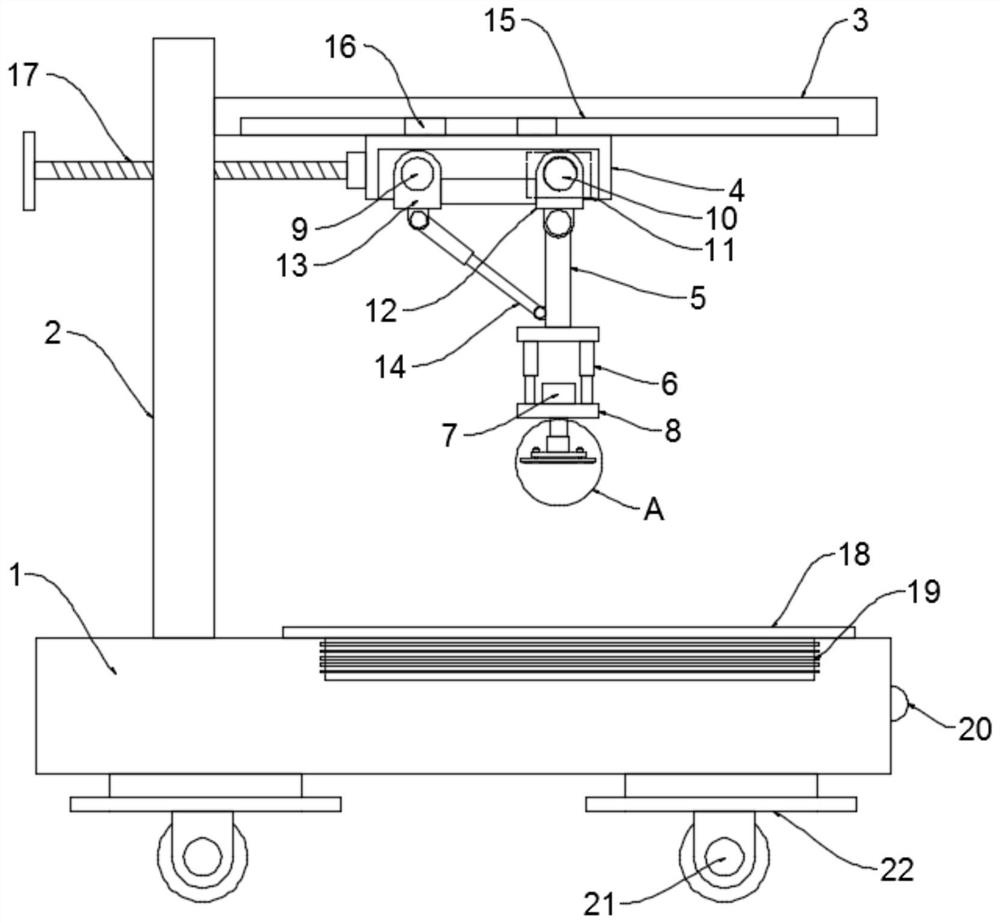

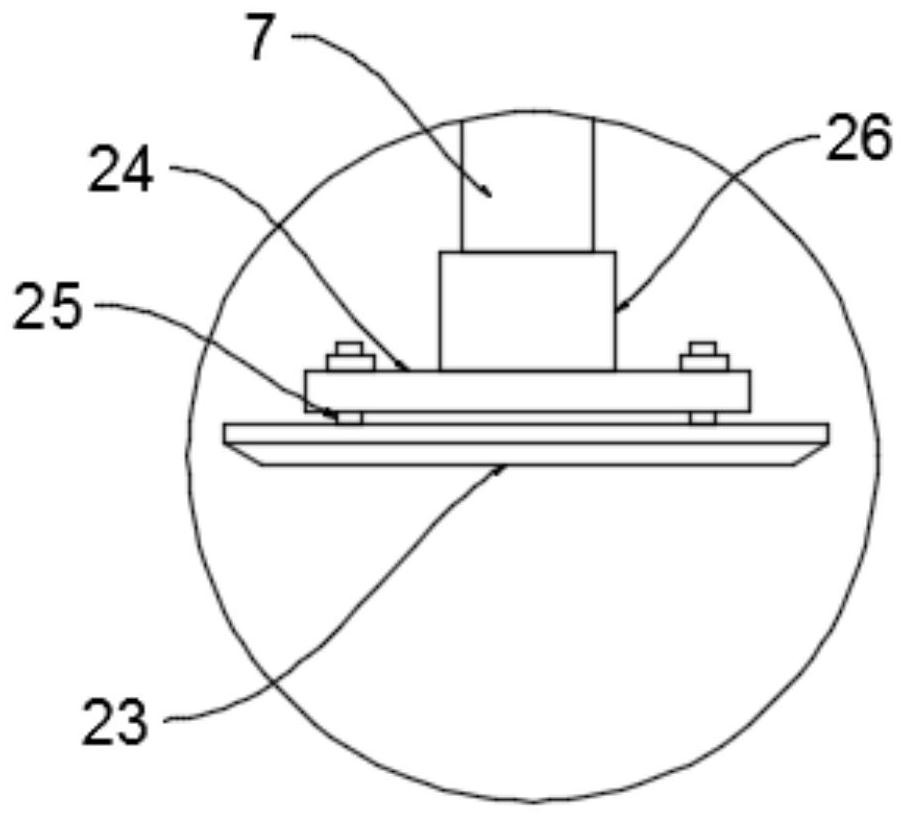

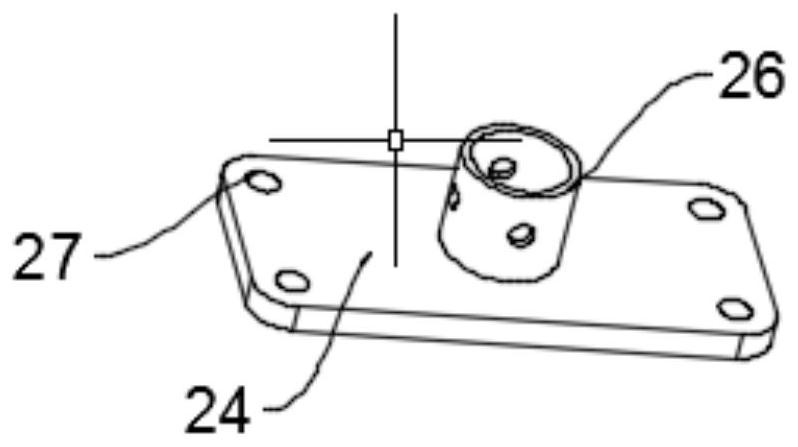

[0024] See Figure 1~3 In the embodiment of the present invention, a flexibly adjustable automobile maintenance and polishing vehicle includes a polishing box 1, a polishing mechanism, and an adjustment assembly for adjusting the orientation of the polishing mechanism. The top side of the polishing box 1 is fixed with a support stand. A horizontal frame 3 is fixed at the top end of the supporting stand 2. The polishing mechanism is suspended and mounted on the horizontal frame 3. The polishing mechanism includes a fixed boom 5 and a polishing sheet 23. The bottom end of the fixed boom 5 is provided with two The two fixed plates 8 are connected by a telescopic cylinder 6. A grinding motor 7 is provided on the fixed plate 8 at the bottom. The grinding plate 23 is installed at the output end of the grinding motor 7, and the adjustment assembly includes a horizontal The mounting crossbar frame 4 on the lower end of the frame 3 is provided with a parallel limiting slide 9 and an adj...

Embodiment 2

[0029] See figure 1 with 4 The difference between the embodiment of the present invention and the embodiment 1 is that: the four corners of the bottom of the polishing box 1 are equipped with universal rollers 21, and the rod frame of the universal roller 21 penetrates the bottom wall of the polishing box 1. The through hole extends to the inside of the polishing box 1 and is fixedly connected to the top wall of the polishing box 1. The universal roller 21 is covered with an outer cover 22 that passes through the through hole and slides with the side wall Cooperate, the polishing box 1 is provided with a double-ended screw 28 and the two ends of the double-ended screw 28 have opposite spiral directions. Both ends of the double-ended screw 28 are equipped with a screw-fitting push sleeve 29. The sleeve 29 is respectively connected with the side wall of the outer cover 22 on the same side by pushing the hinge rod 30, the outer cover 22 is provided with an extension plate 31 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com