Wet automatic grinding and polishing machine

A polishing machine and grinding machine technology, applied in the direction of grinding/polishing equipment, grinding machine parts, grinding machines, etc., can solve the problems of low efficiency of grinding fluid use, poor manual replacement efficiency, and affecting processing quality, etc., to achieve fixture The effect of high utilization rate, short workpiece clamping time, and shortened processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described now in conjunction with accompanying drawing.

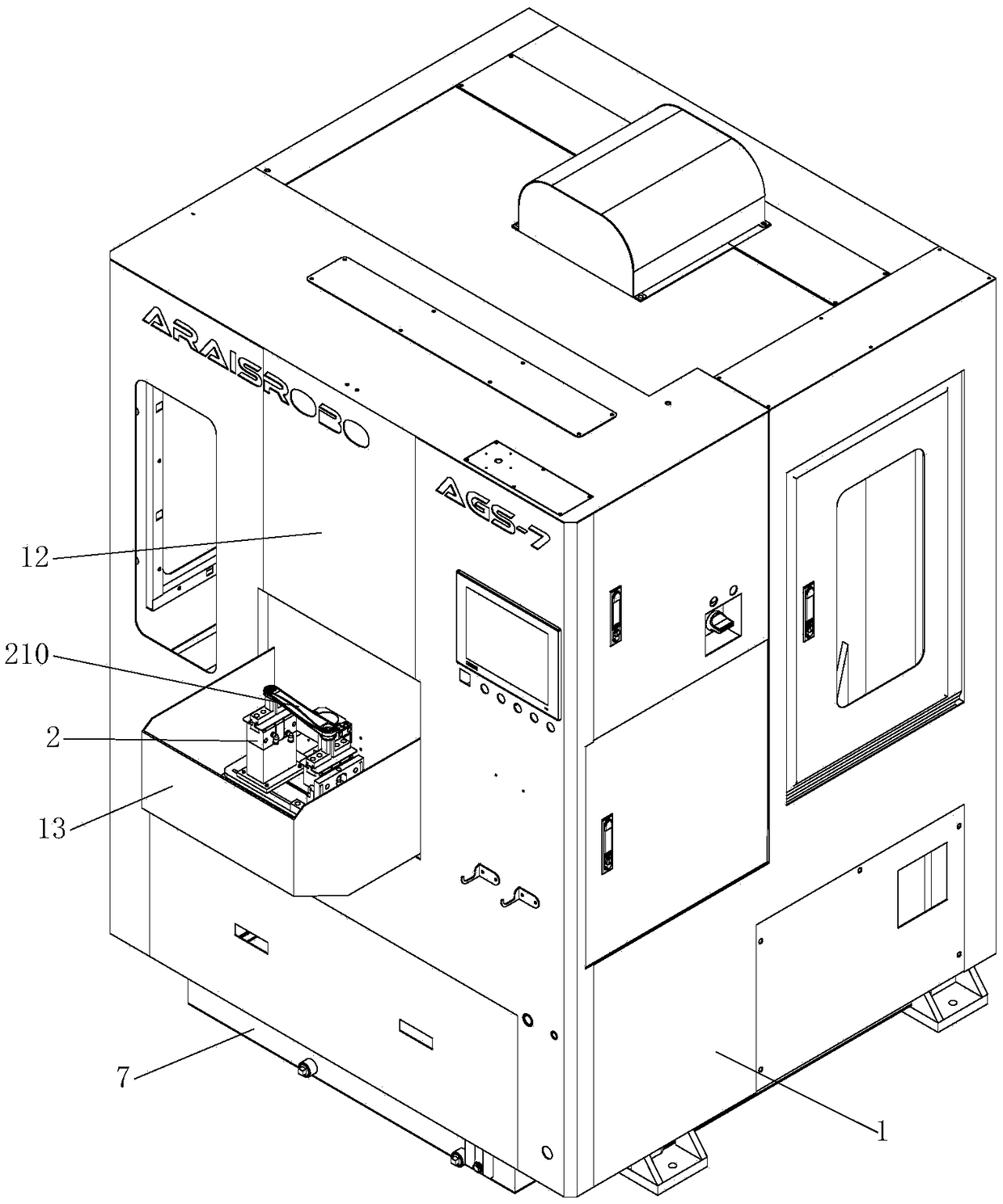

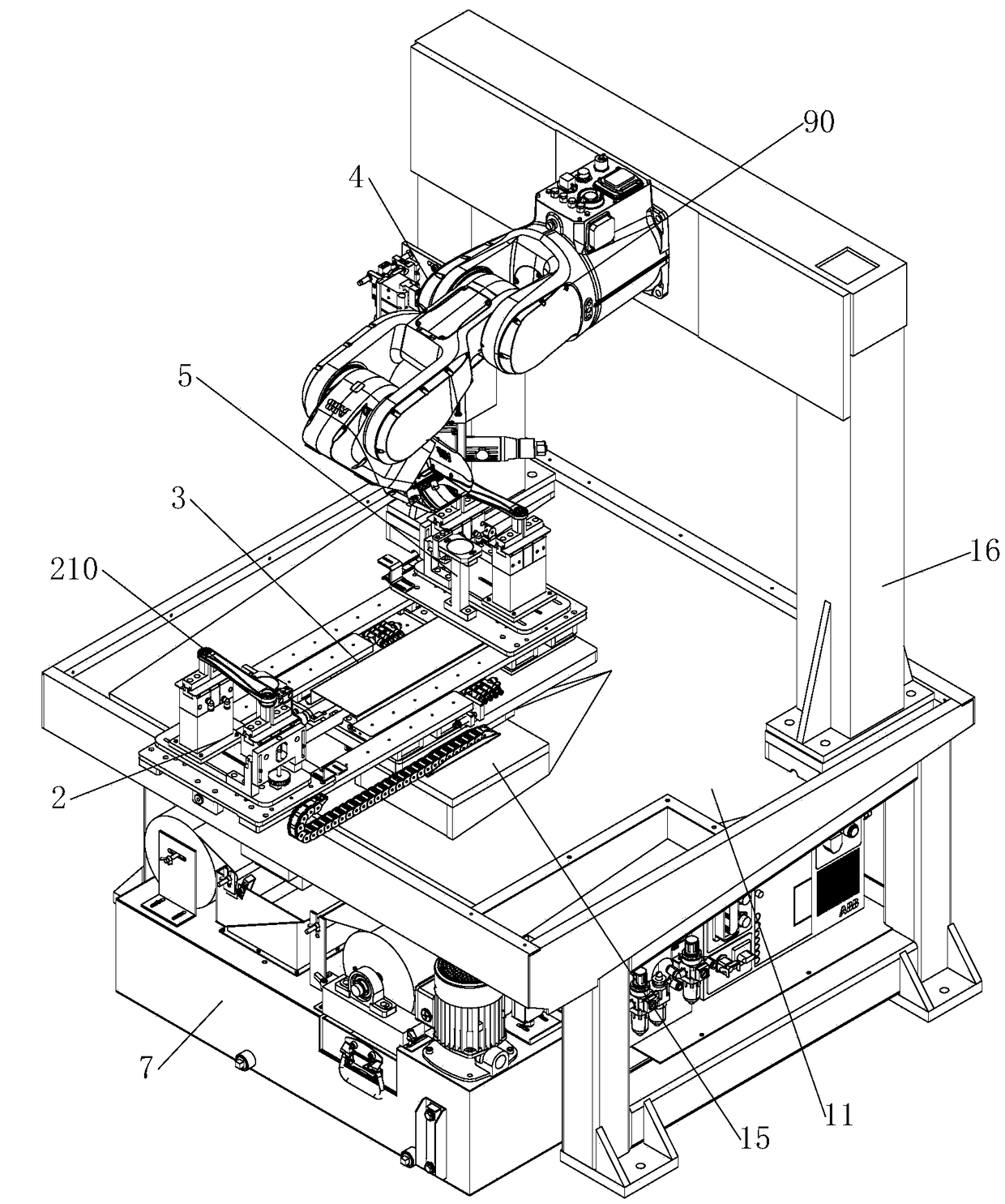

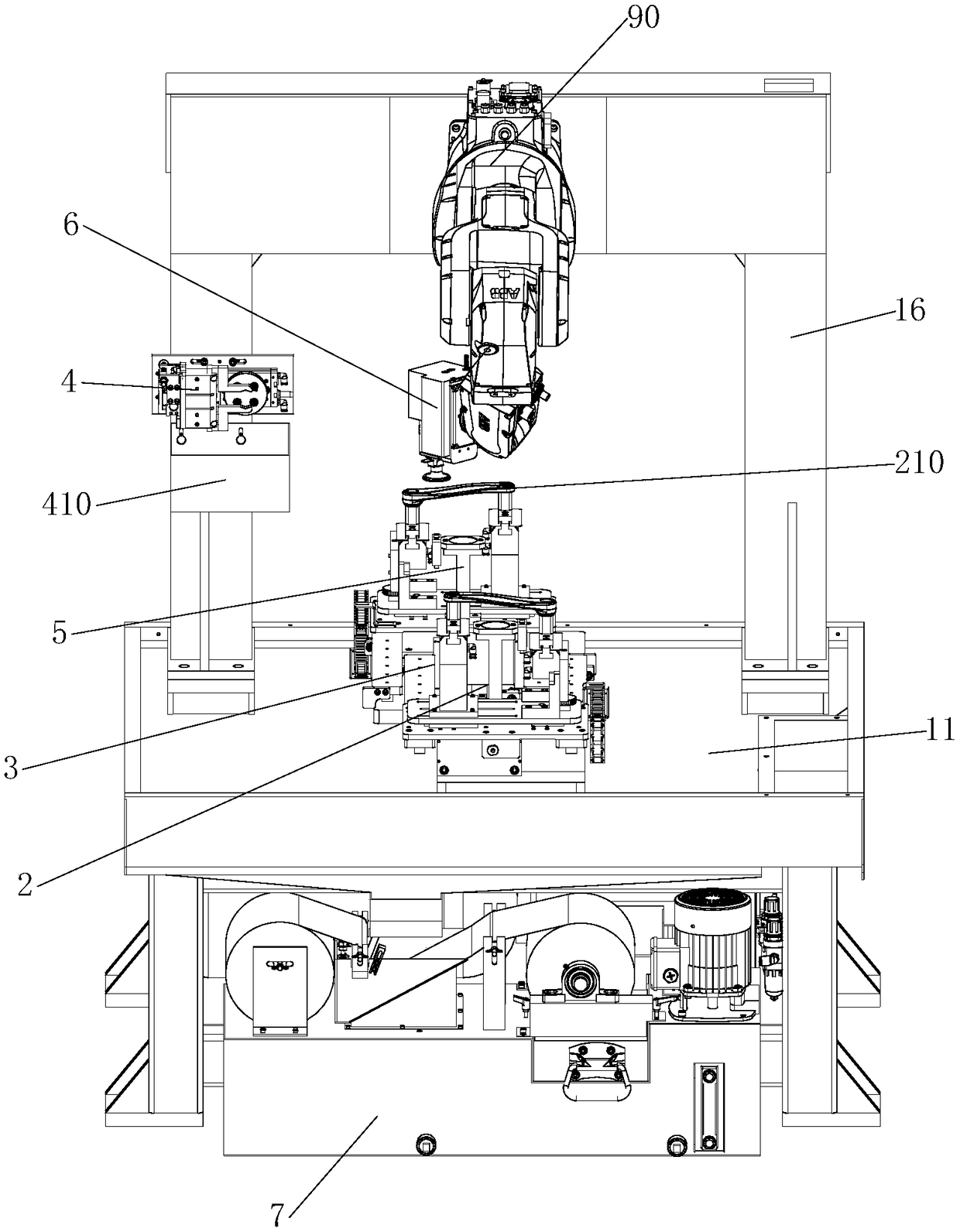

[0046] Such as Figure 1 to Figure 19 As shown, a wet automatic grinding and polishing machine includes a grinding machine 80, a mobile device 90 and a casing 1, the grinding machine 80 is equipped with a grinding disc 801, the grinding machine 80 is installed on the mobile device 90, and the mobile device 90 is installed on the top of the base 11 On the column 16, the mobile device 90 and the grinding machine 80 are all located in the casing 1, and the casing 1 is provided with an automatic door 12; it also includes a workpiece fixing device 2, a double-station rotary exchange table 3, a sand disc removal device 4, The sand disc loading device 5, the grinding control device 6 and the circulating filter device 7; the workpiece fixing device 2 and the sand disc loading device 5 are installed at both ends of the double-station rotary exchange table 3, and the double-station rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com