Patents

Literature

39results about How to "Avoid manual flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

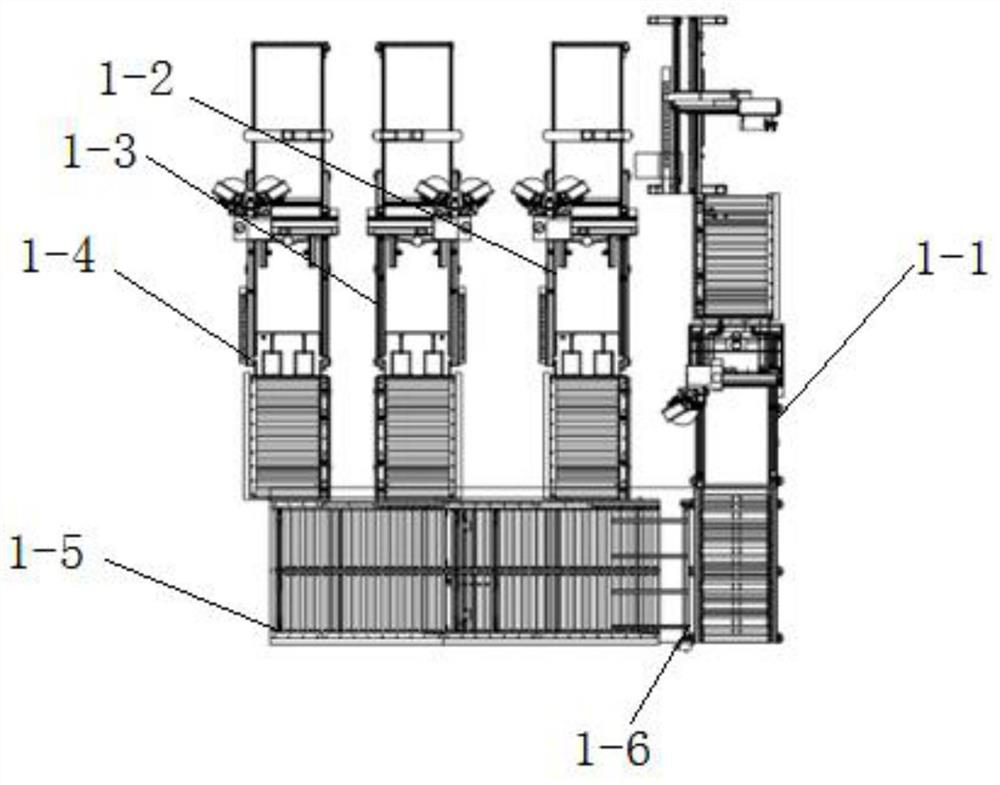

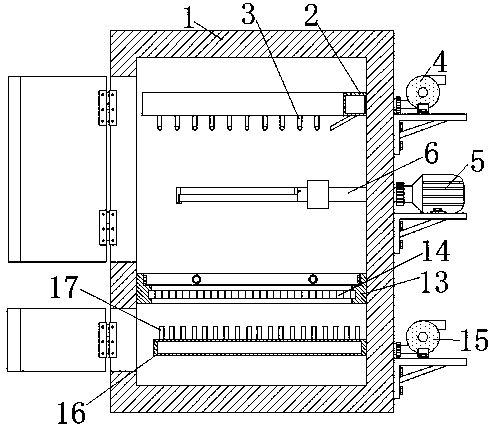

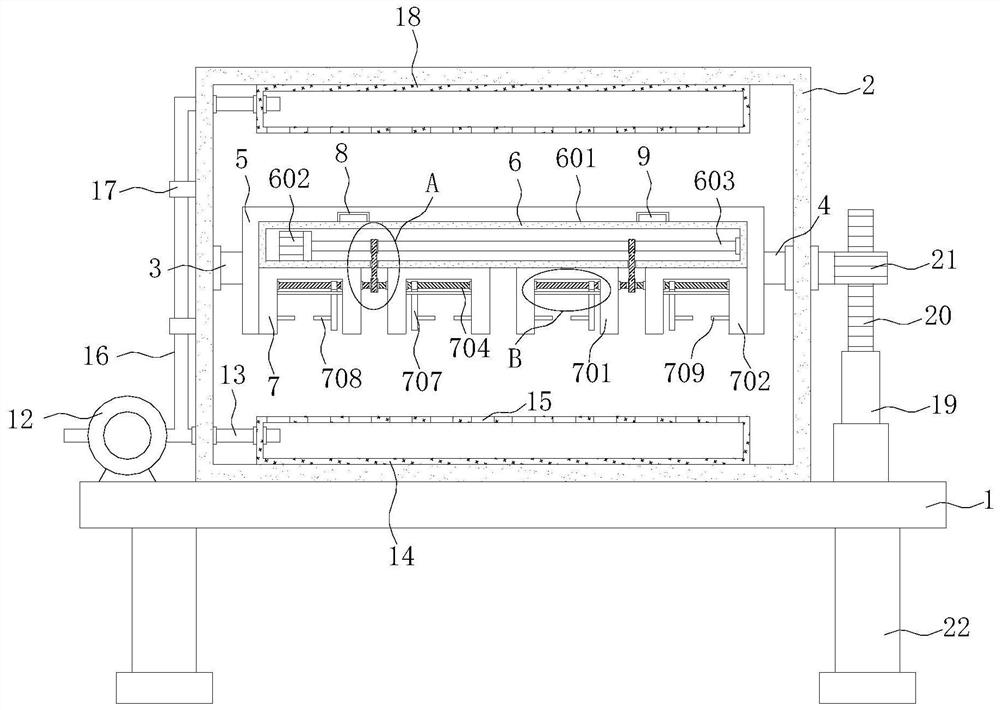

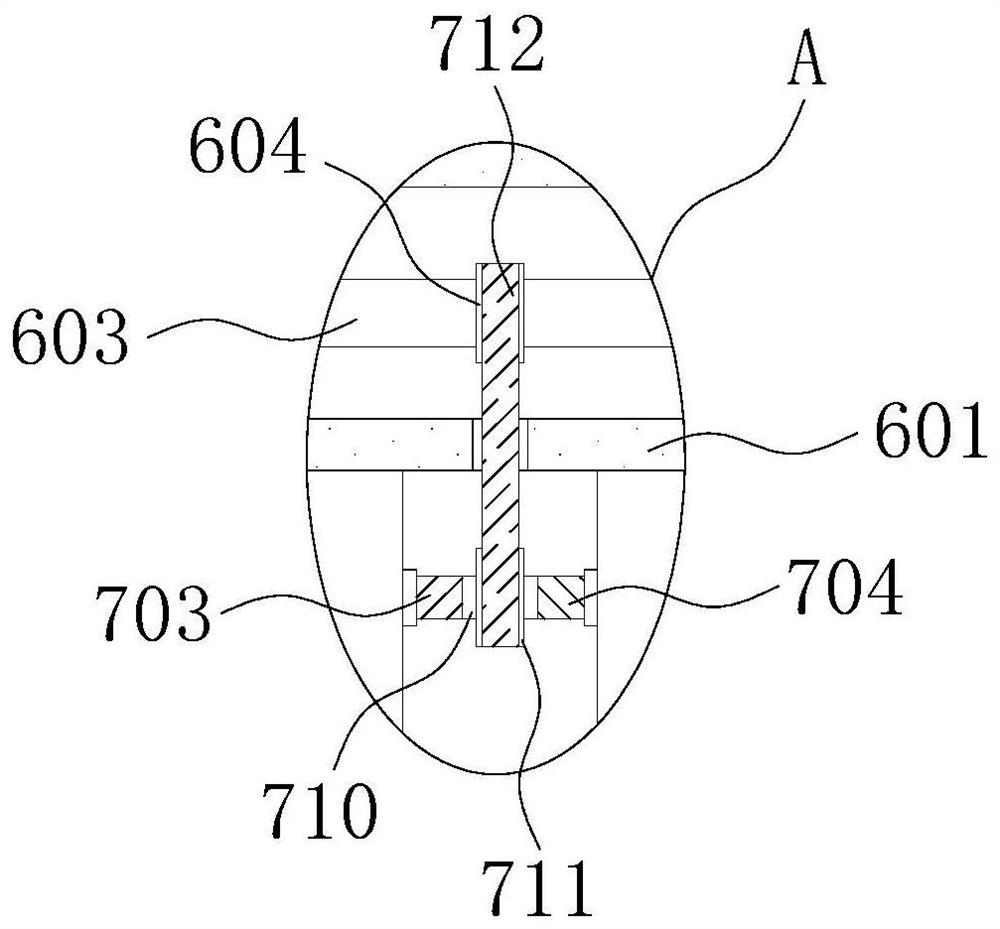

Safety device for formation and sub-capacity of lithium ion battery

ActiveCN102881942AAvoid short circuitAvoid manual flippingFinal product manufactureCell component detailsElectrical batteryEngineering

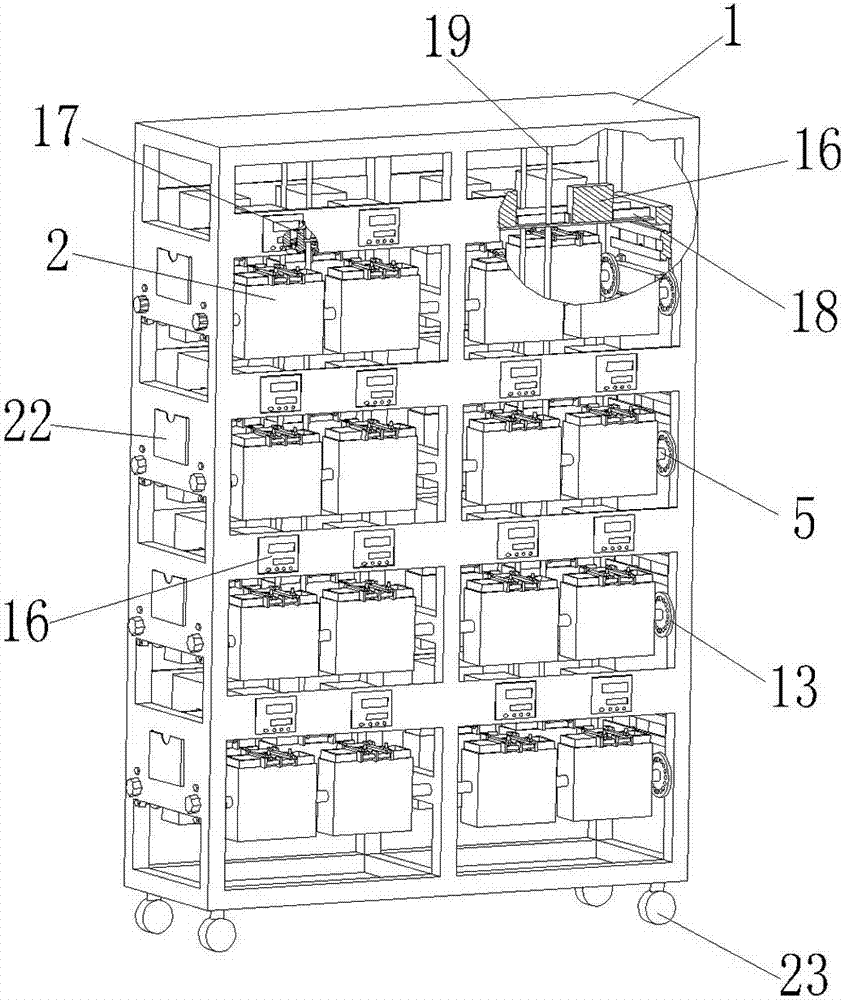

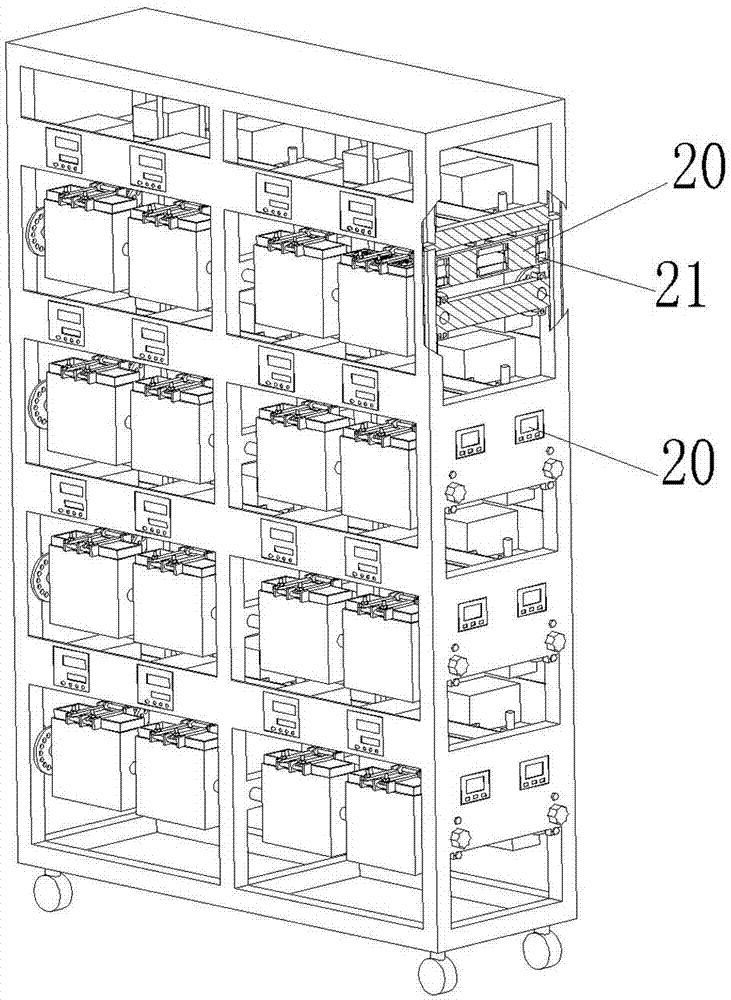

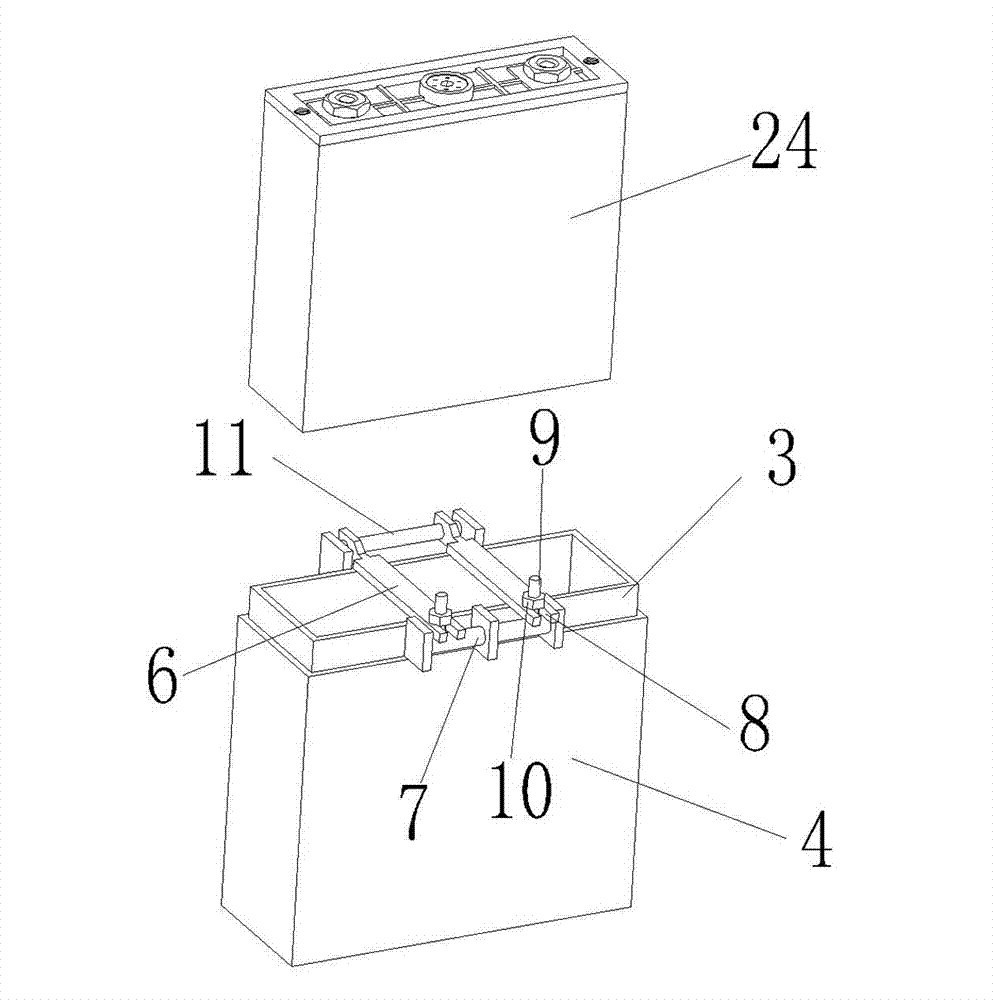

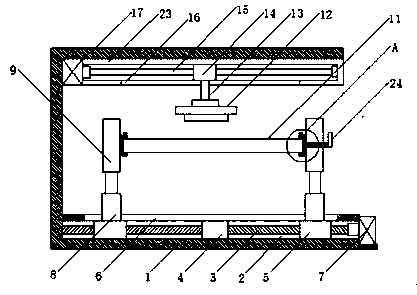

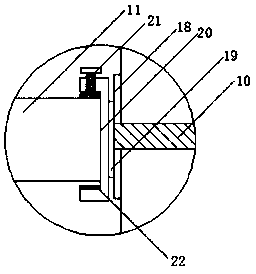

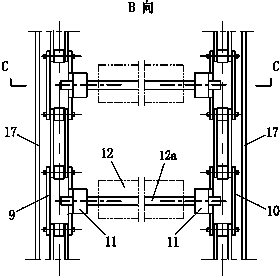

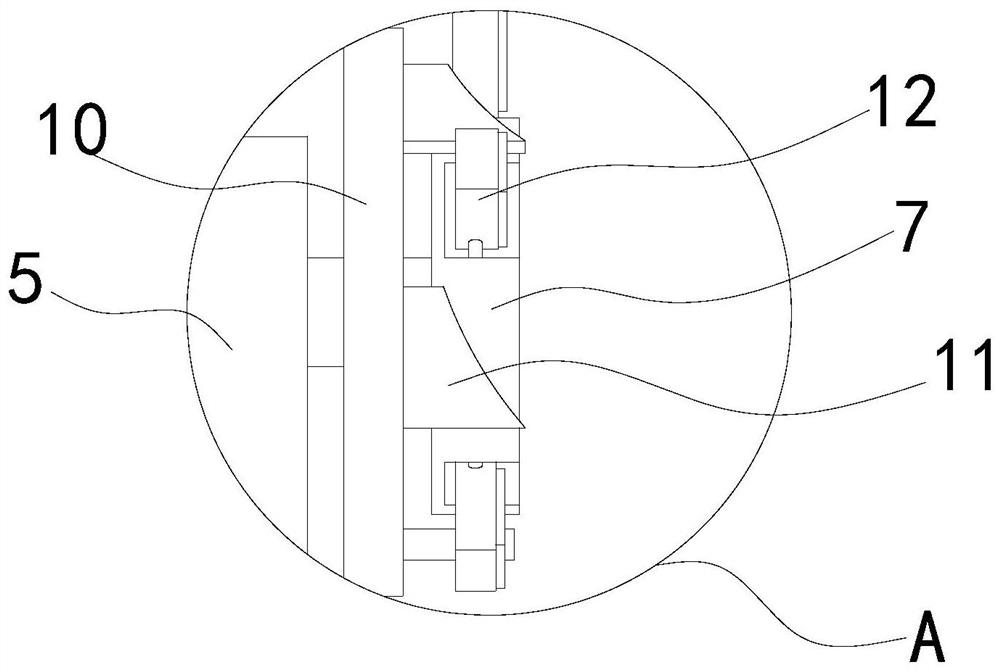

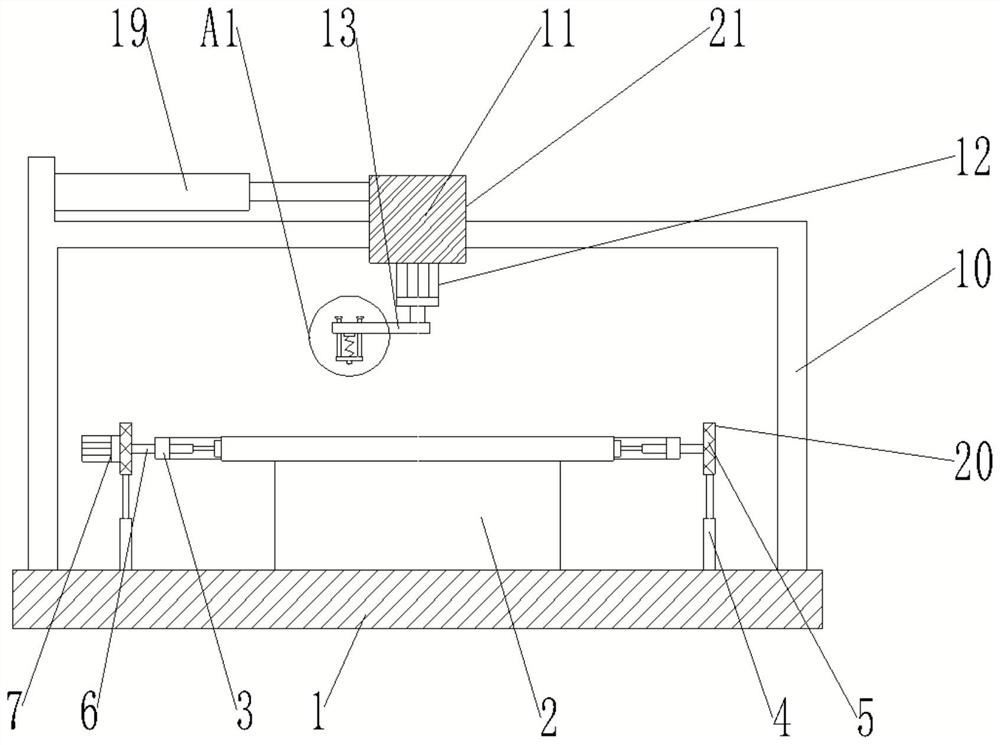

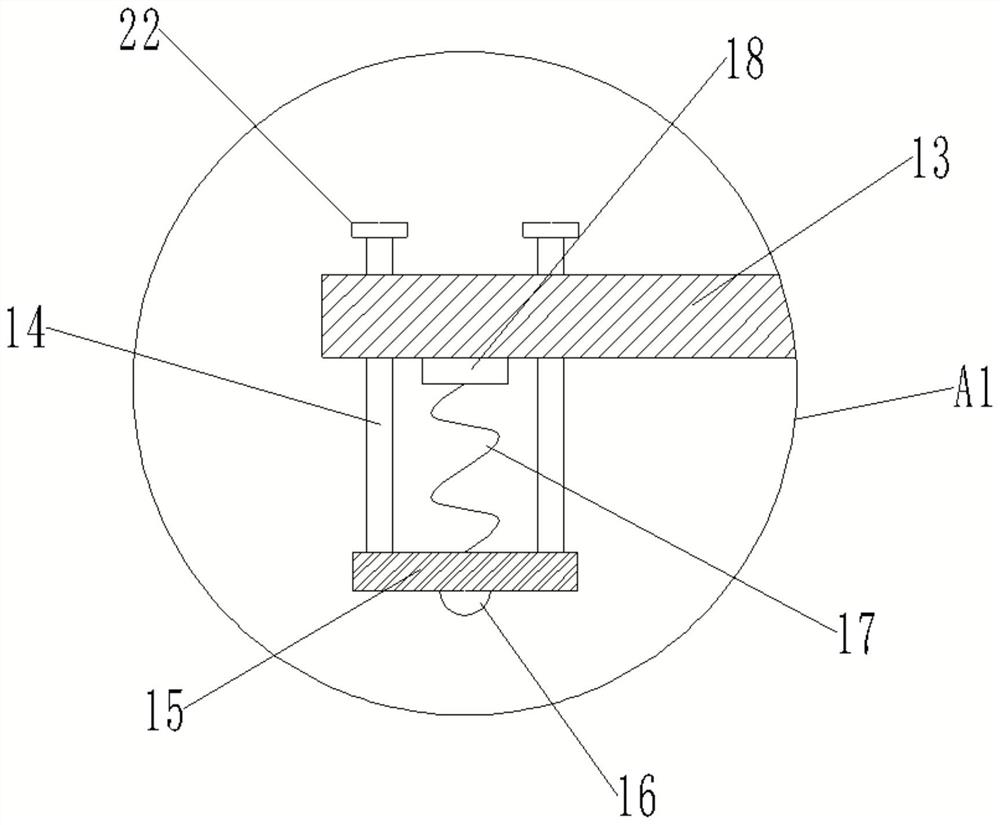

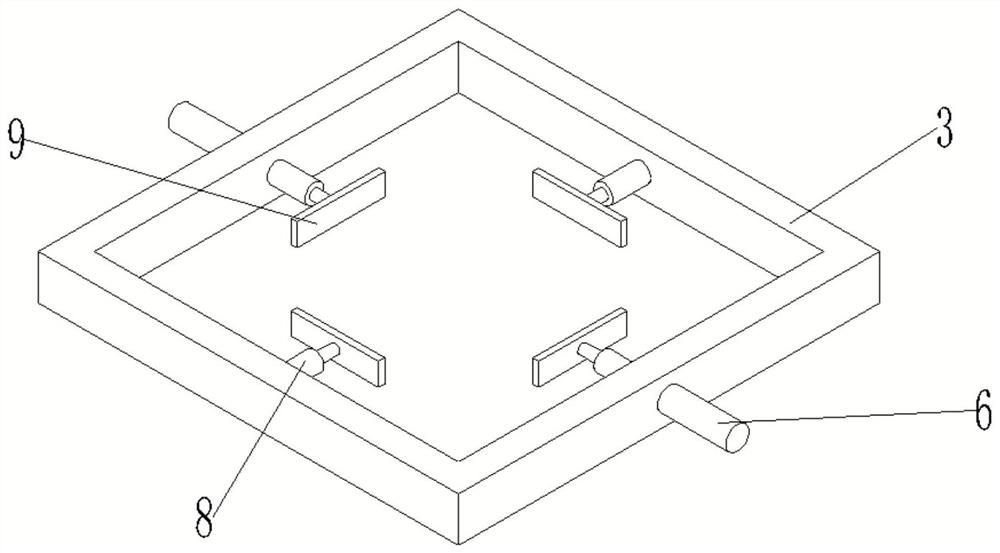

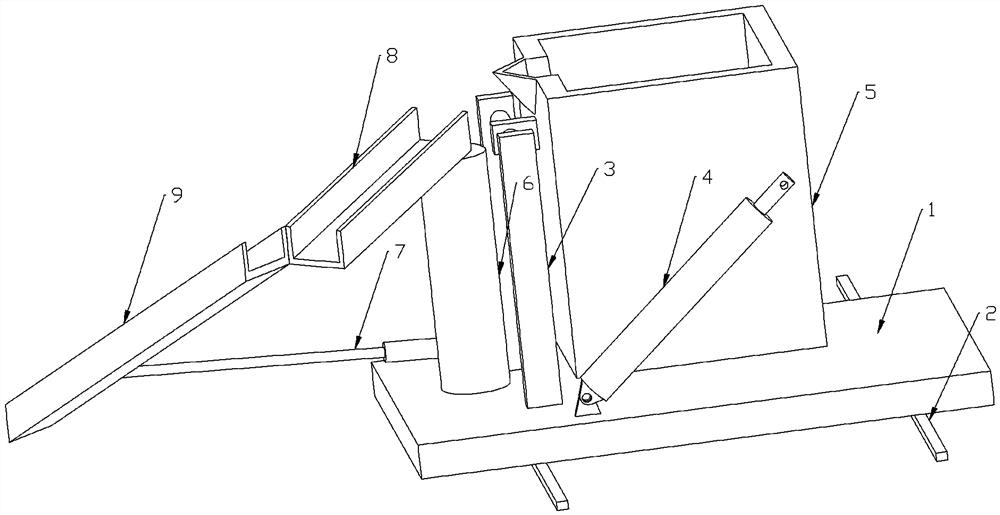

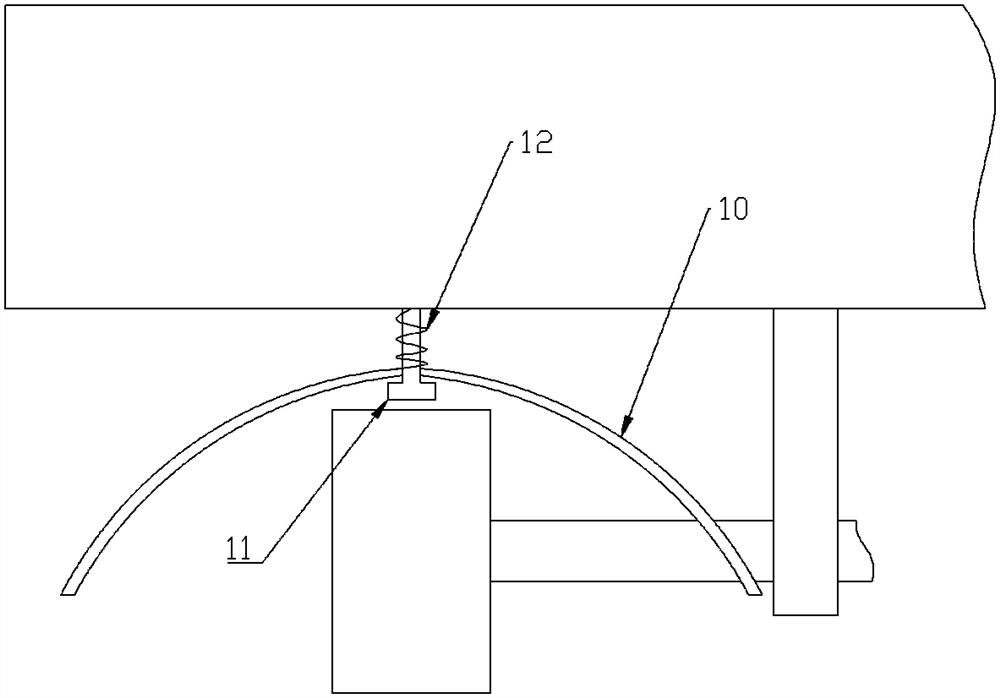

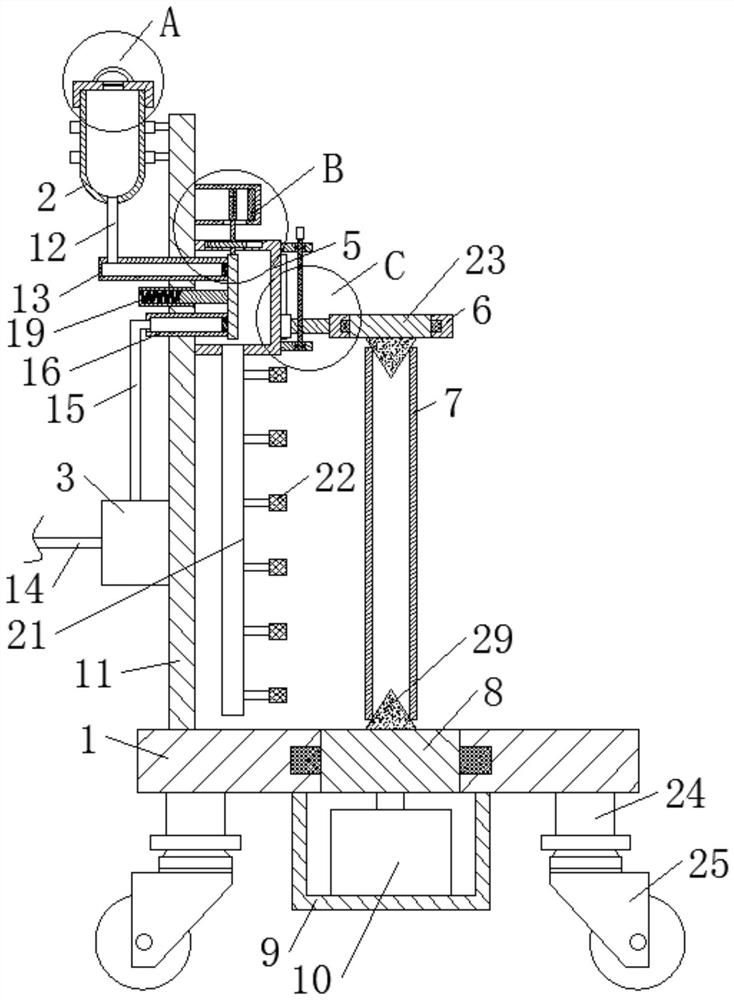

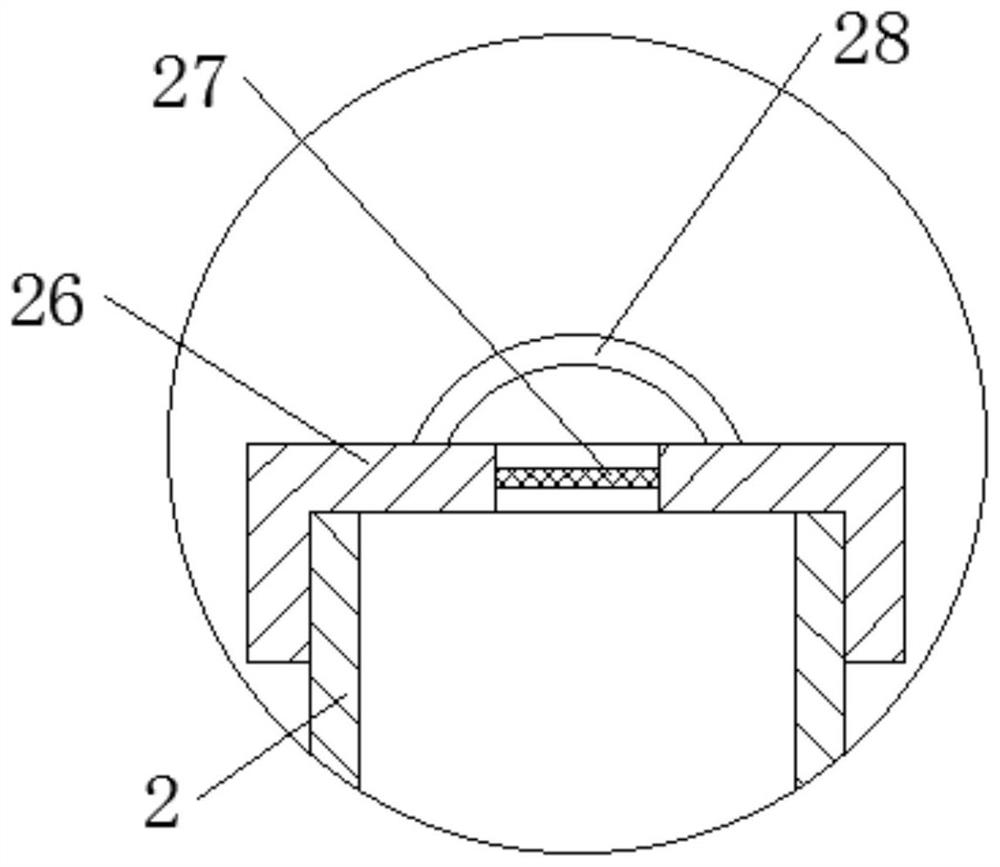

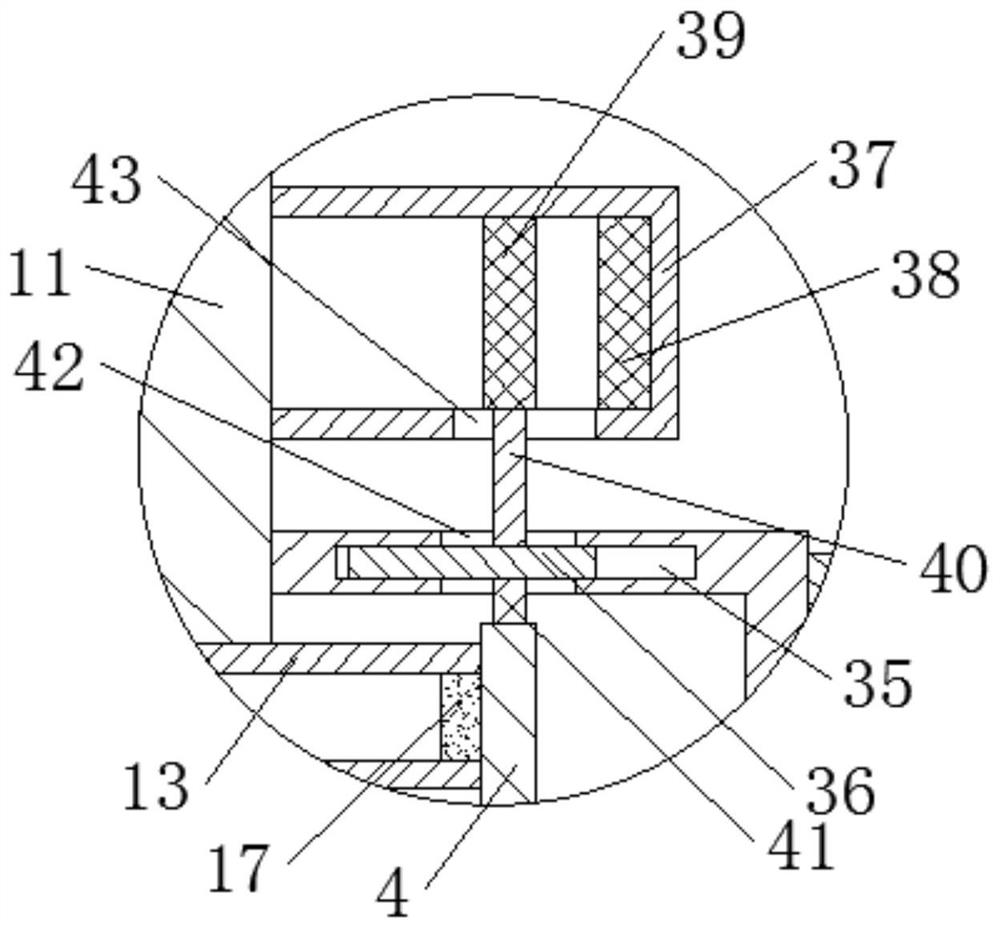

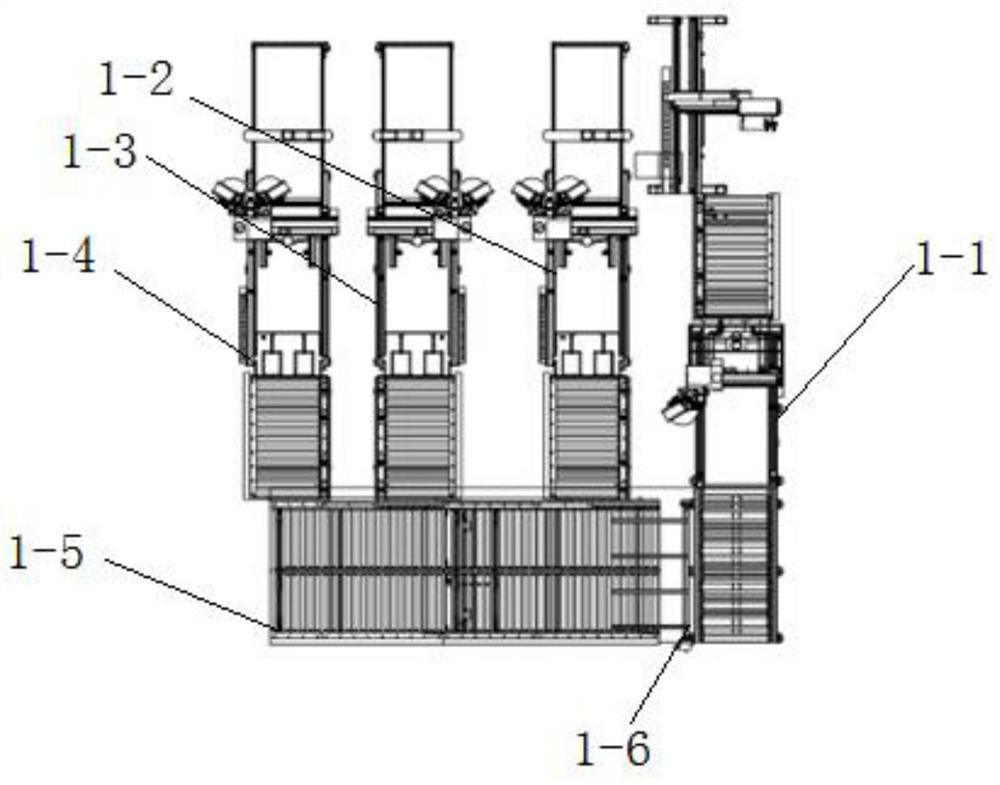

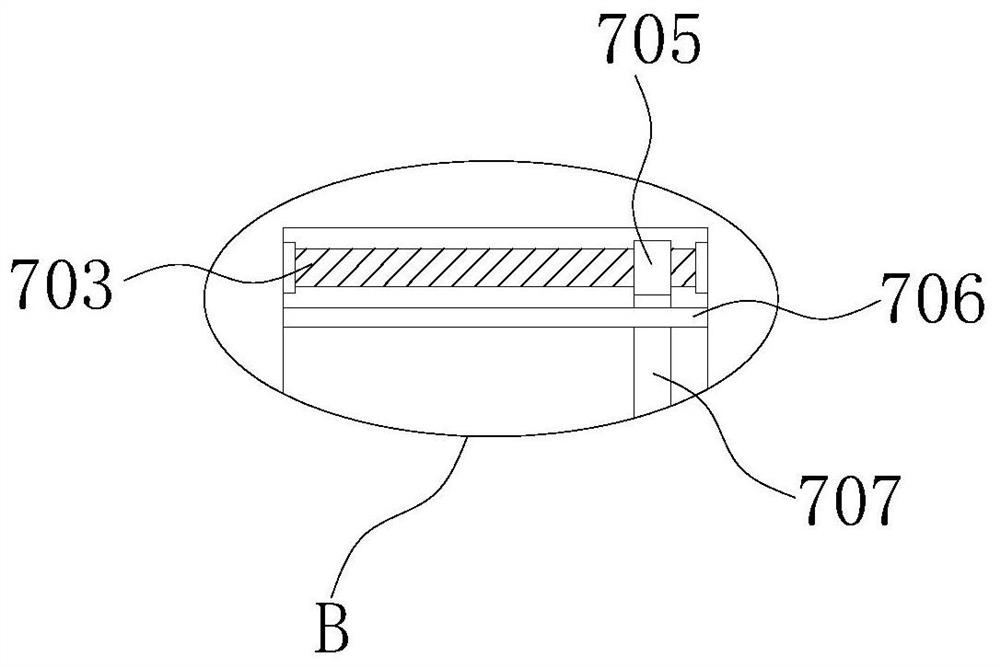

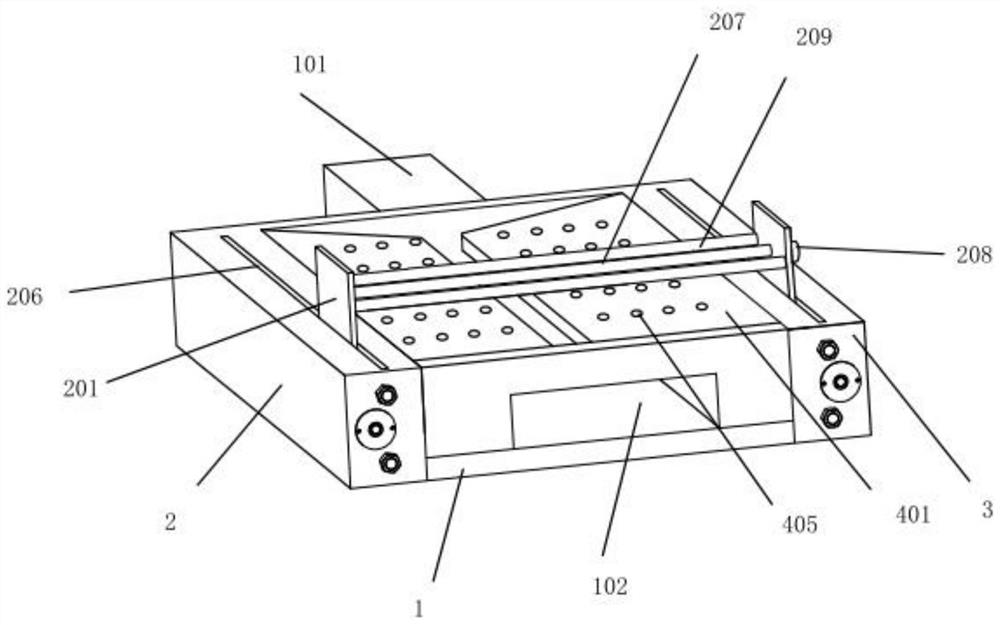

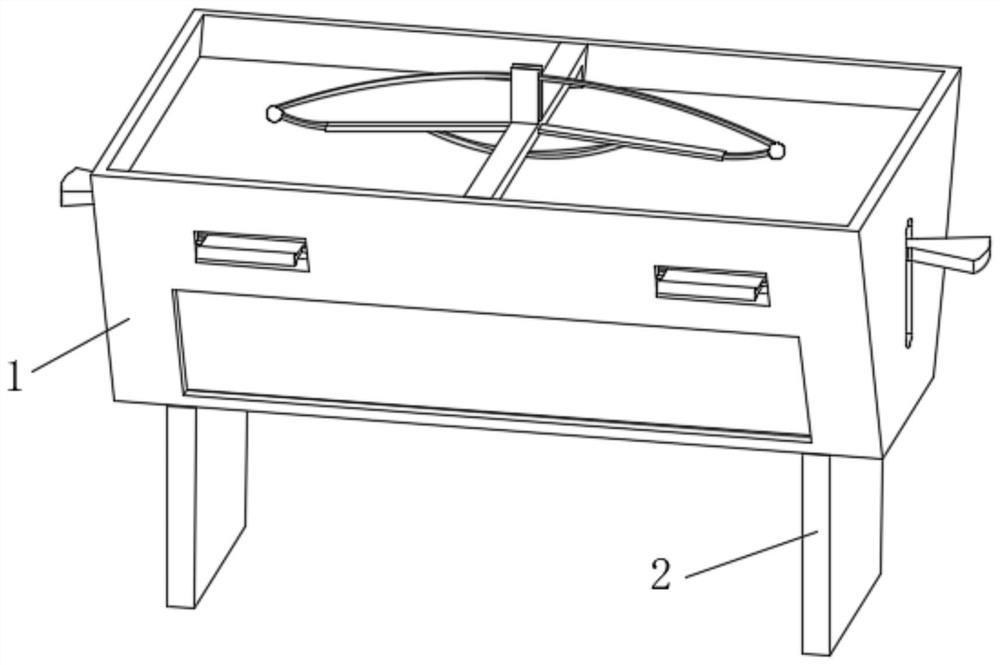

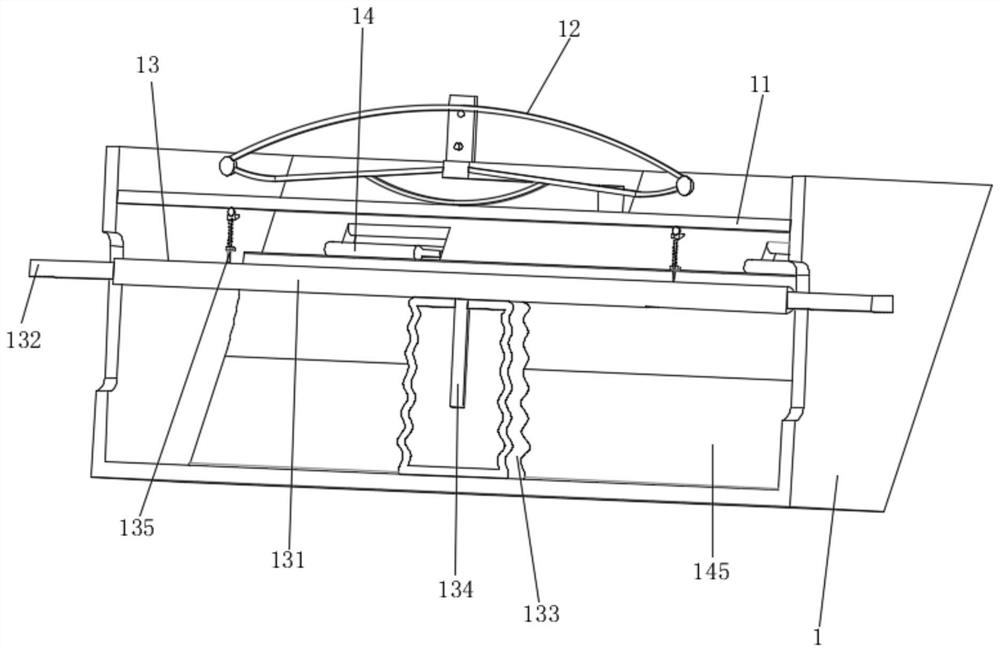

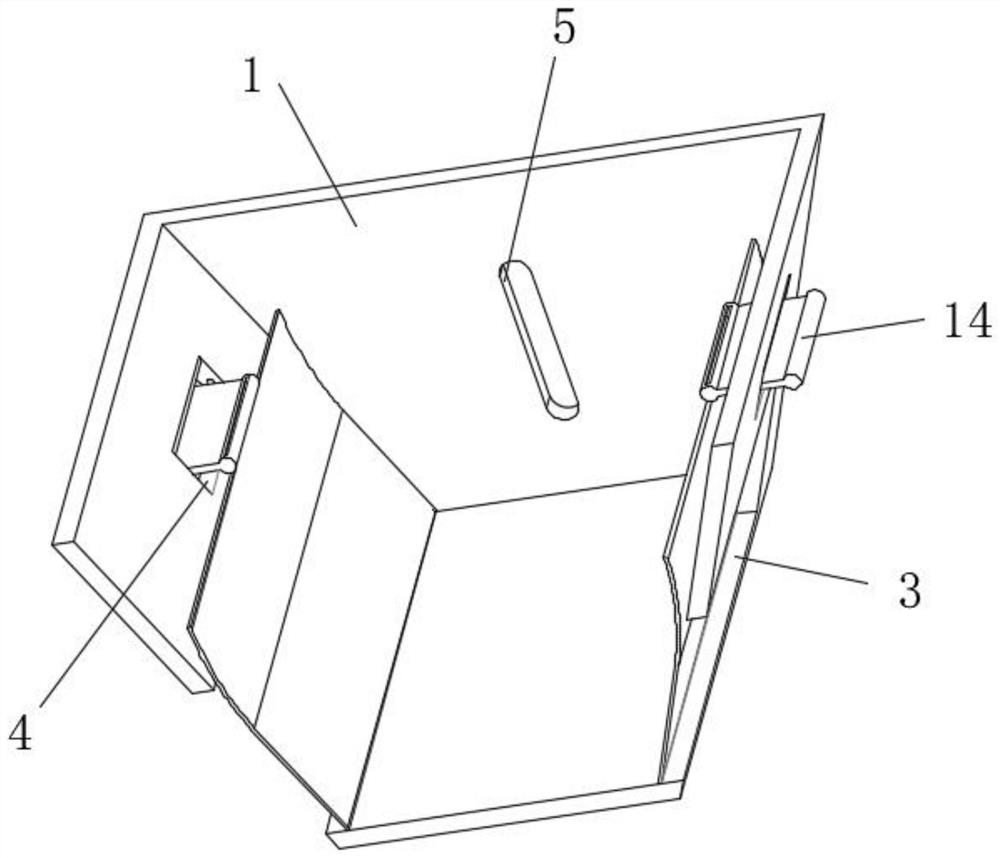

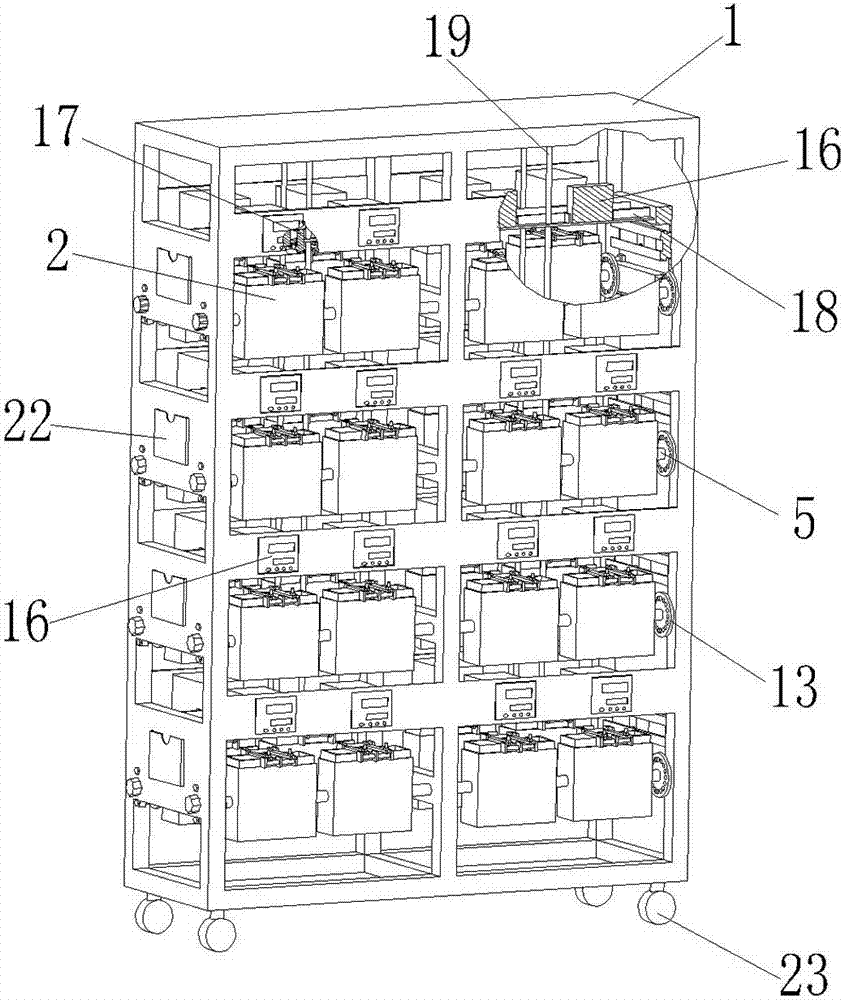

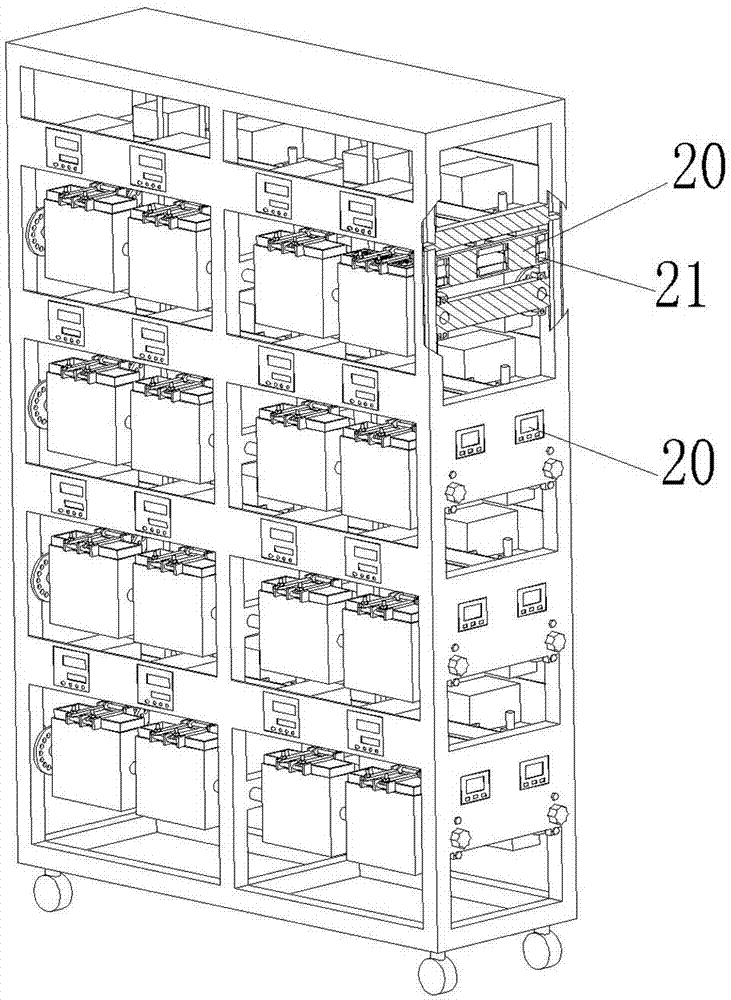

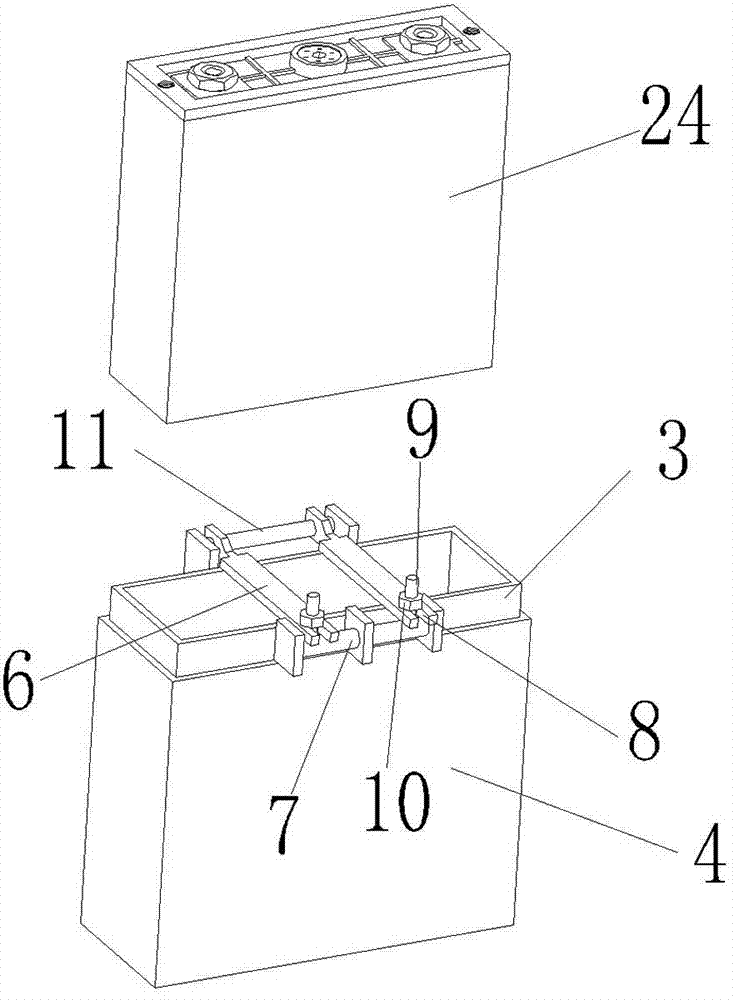

The invention discloses a safety device for formation and sub-capacity of a lithium ion battery. The safety device comprises a cabinet, wherein at least a row of battery compartments are arranged in the cabinet; an opening is formed at the upper end of each battery compartment; each battery compartment consists of an internal insulation fireproof layer and an external stainless steel layer; the battery compartments are connected in series by shafts so as to form a battery compartment row; rotating shafts are arranged at two ends of the battery compartment row; the two ends of each rotating shaft penetrate through the side wall of the cabinet; and a battery locating mechanism for locating the battery is arranged at the upper end of each battery compartment. Due to the adoption of the battery compartments of a two-layer structure, the battery has good insulation effect on the outside; and the short circuit of the battery caused by inappropriate operation of an operator or other accidents is avoided. The battery compartments of the two-layer structure further have high anti-explosion capability; and due to the adoption of the rotating shafts of the battery compartments, the battery can rotate in multiple angles in a standing stage (which can improve the infiltration effect of electrolyte); and the battery does not need to be manually rotated one by one. Therefore, the production efficiency of a workshop is greatly improved.

Owner:NINGBO SHIJIE NEW ENERGY TECH

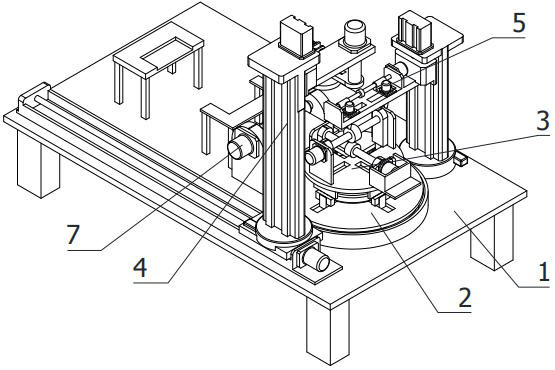

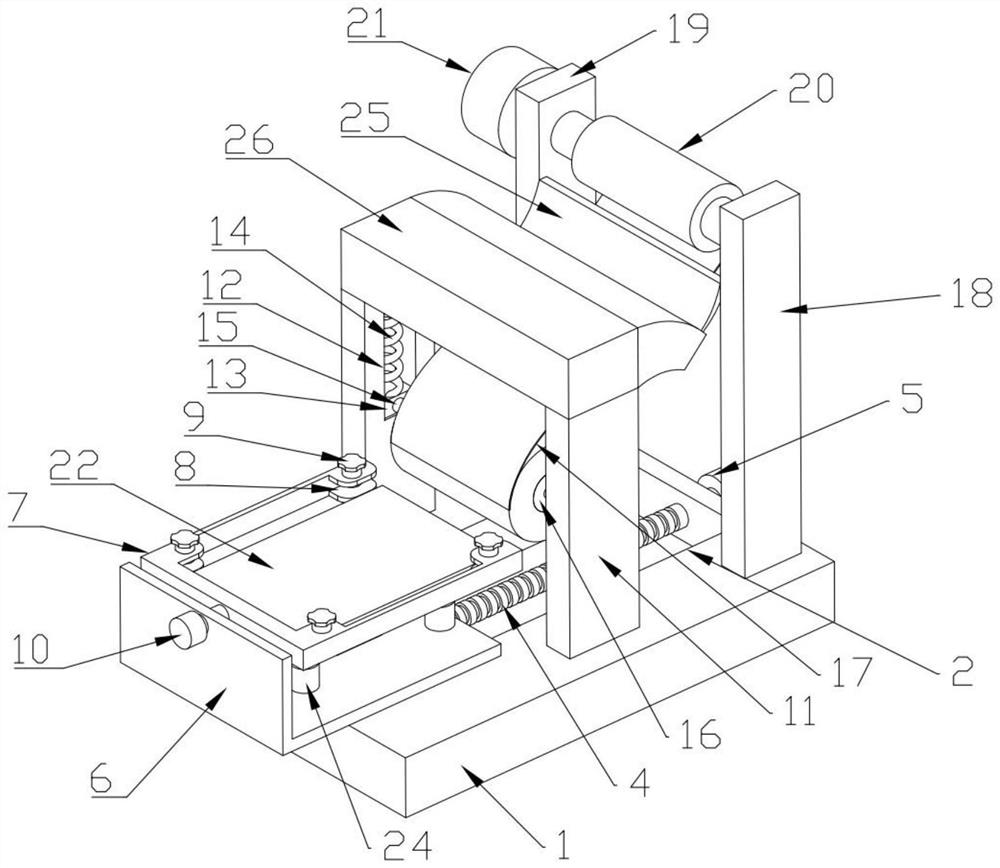

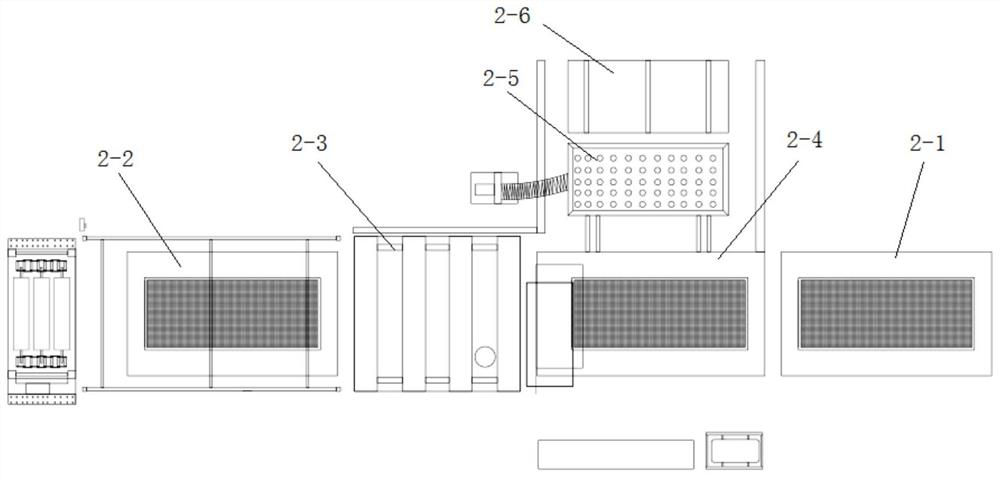

Refrigerator U shell metal plate forming line

InactiveCN109822415AAvoid offsetAvoid accidental damageEdge grinding machinesGrinding carriagesArchitectural engineeringDrive motor

The invention discloses a refrigerator U shell metal plate forming line comprising a workbench. The workbench is of a U-type structure; a mounting groove is formed in the bottom of the workbench; a horizontal threaded rod is arranged inside the mounting groove; one end of the threaded rod is fixed to the output end of a drive motor; the drive motor is vertically arranged at the bottom of the workbench; vertical hydraulic rods are installed at two ends of the threaded rod; vertical supporting boards are fixed to the tops of the two hydraulic rods; vertical concave limiting blocks are installedon one sides of the supporting boards; a horizontal refrigerator U shell plate is fixed in the middle of the two concave limiting blocks; a rotary shaft is installed on the side, close to the drive motor, of the concave limiting blocks; the rotary shaft extends out of the supporting boards and is fixedly provided with a handle; and a horizontal driver is installed on the inner top of the workbench. The refrigerator U shell metal plate forming line is ingenious in design, reasonable in structure, wide in polishing range, capable of fixing and polishing plates, high in practicability and suitable for being popularized,

Owner:滁州精峰机电科技有限公司

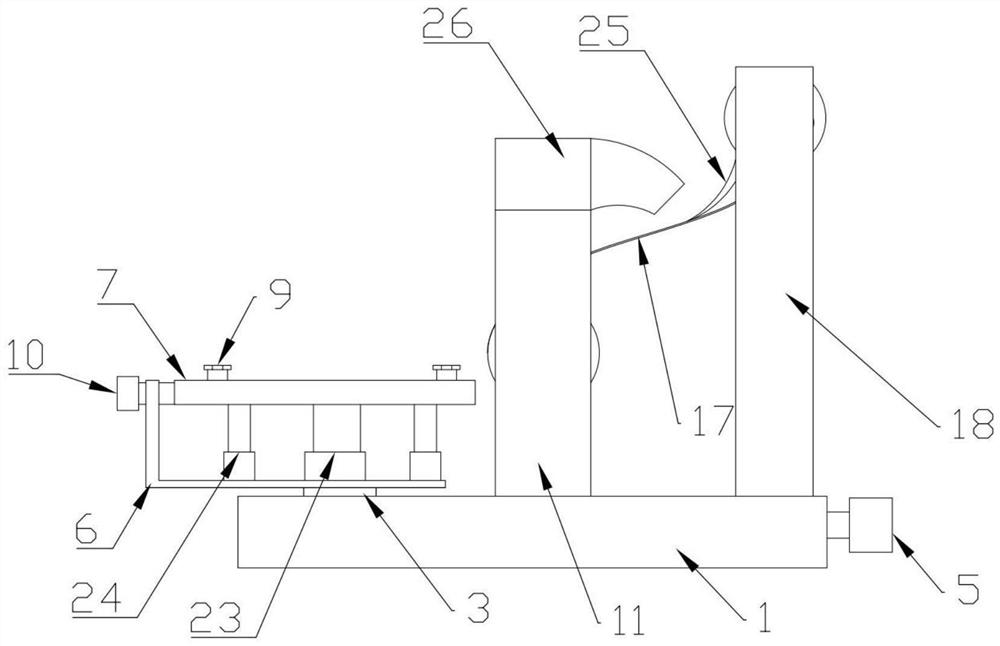

Polishing device facilitating overturning and used for bamboo floor processing and polishing method of polishing device

ActiveCN111993165AImprove polishing efficiencyReduce labor intensityEdge grinding machinesPolishing machinesPolishingBamboo floor

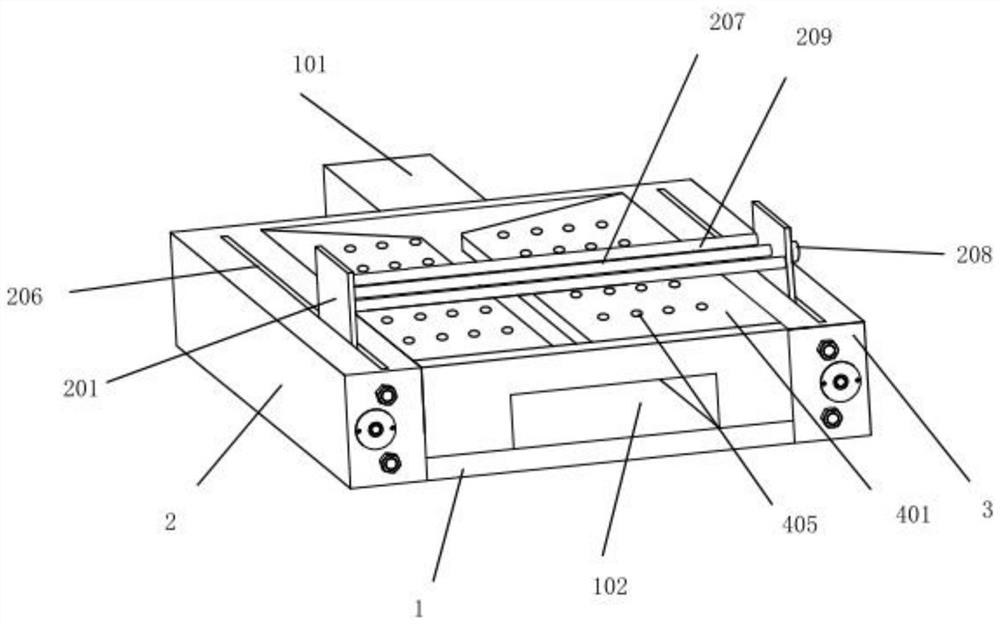

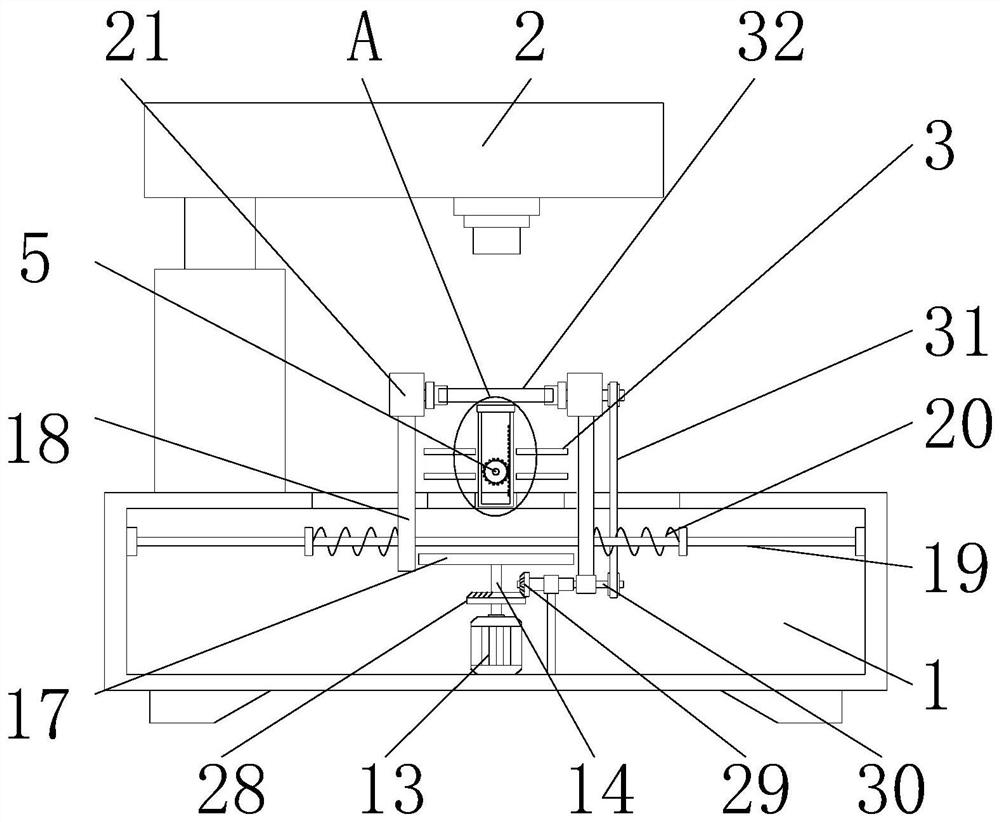

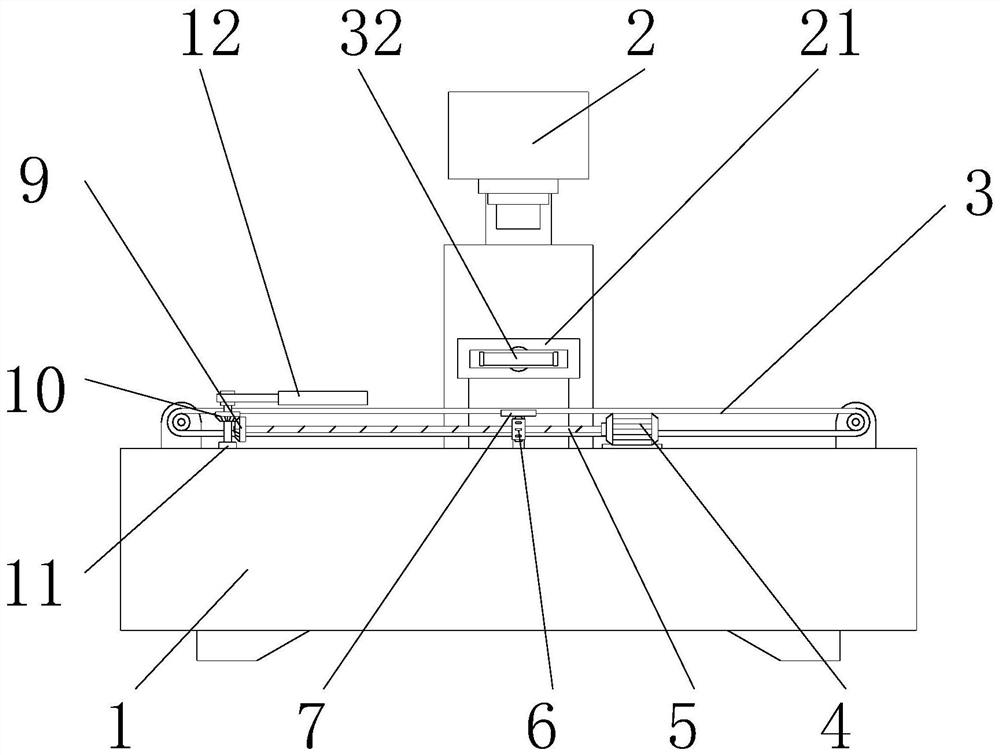

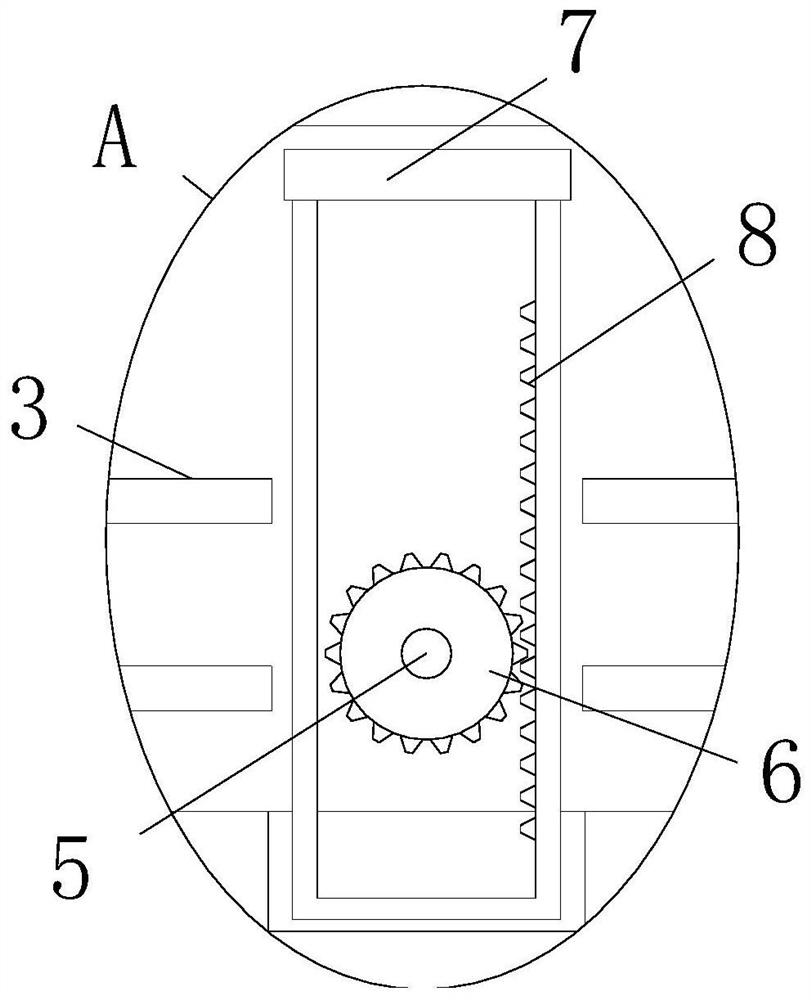

The invention discloses a polishing device facilitating overturning and used for bamboo floor processing and a polishing method of the polishing device. The polishing device comprises a base, whereinthe base is of a cuboid cavity structure with the top face being uncovered; a left guide cavity and a right guide cavity which are completely consistent in structure are formed in the two sides of thebase correspondingly; a waste scrap collecting cavity is formed in a cavity of the base; a supporting block is fixedly arranged at the center line position of the back face of the base; a vertical rack is fixedly arranged on the supporting block; and an overturning frame used for clamping and fixing a bamboo floor is fixedly arranged on the vertical rack. The polishing device achieves automatic overturning in the bamboo floor polishing process, traditional manual overturning is avoided, and the labor intensity of workers is lowered; and meanwhile, the polishing efficiency of the bamboo flooris improved, and large-scale production of enterprises is facilitated.

Owner:阜南县欣园柳编工艺品有限公司

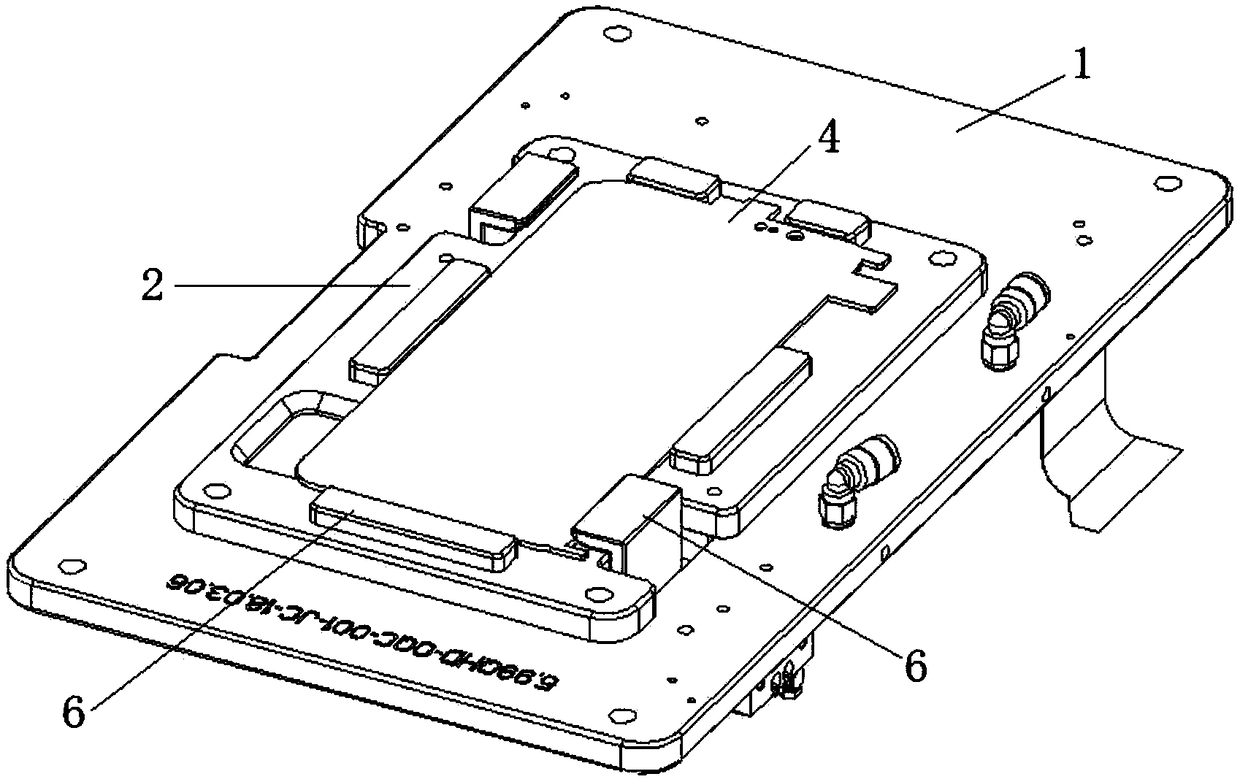

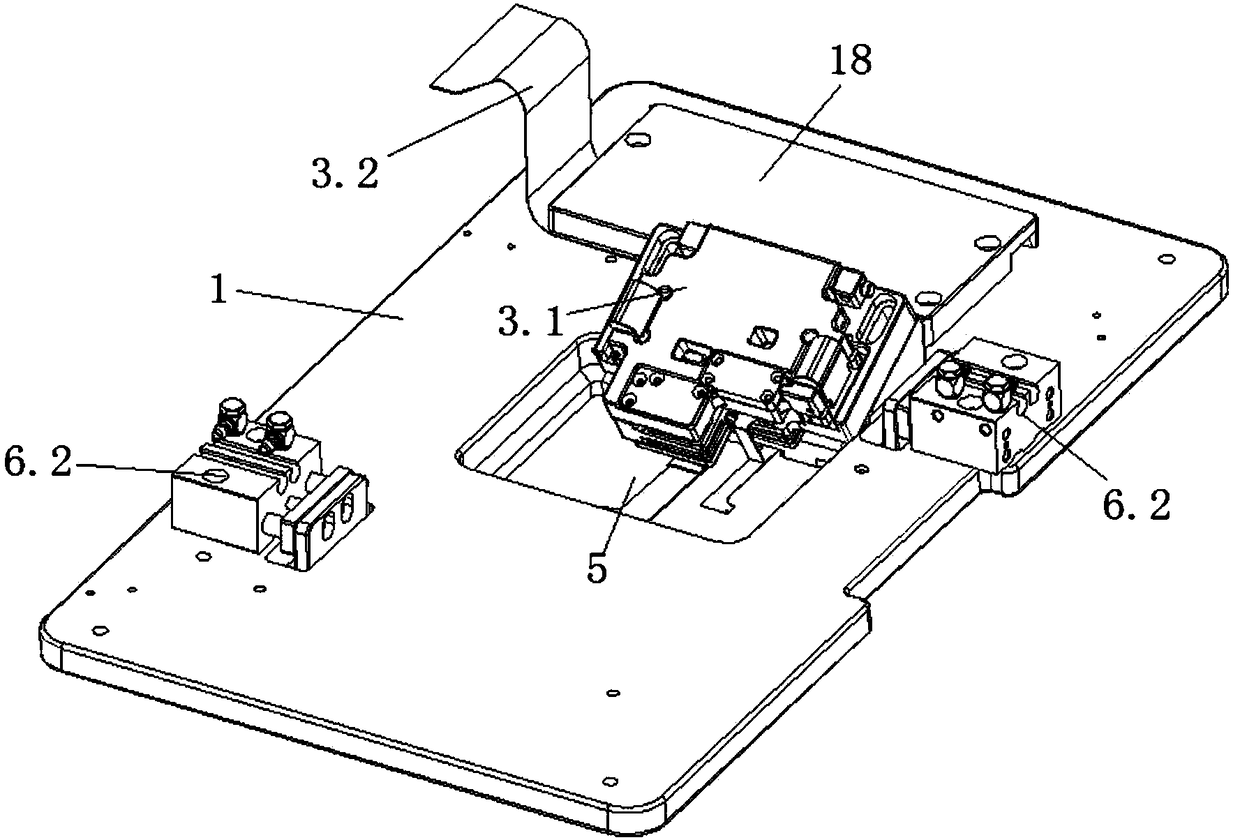

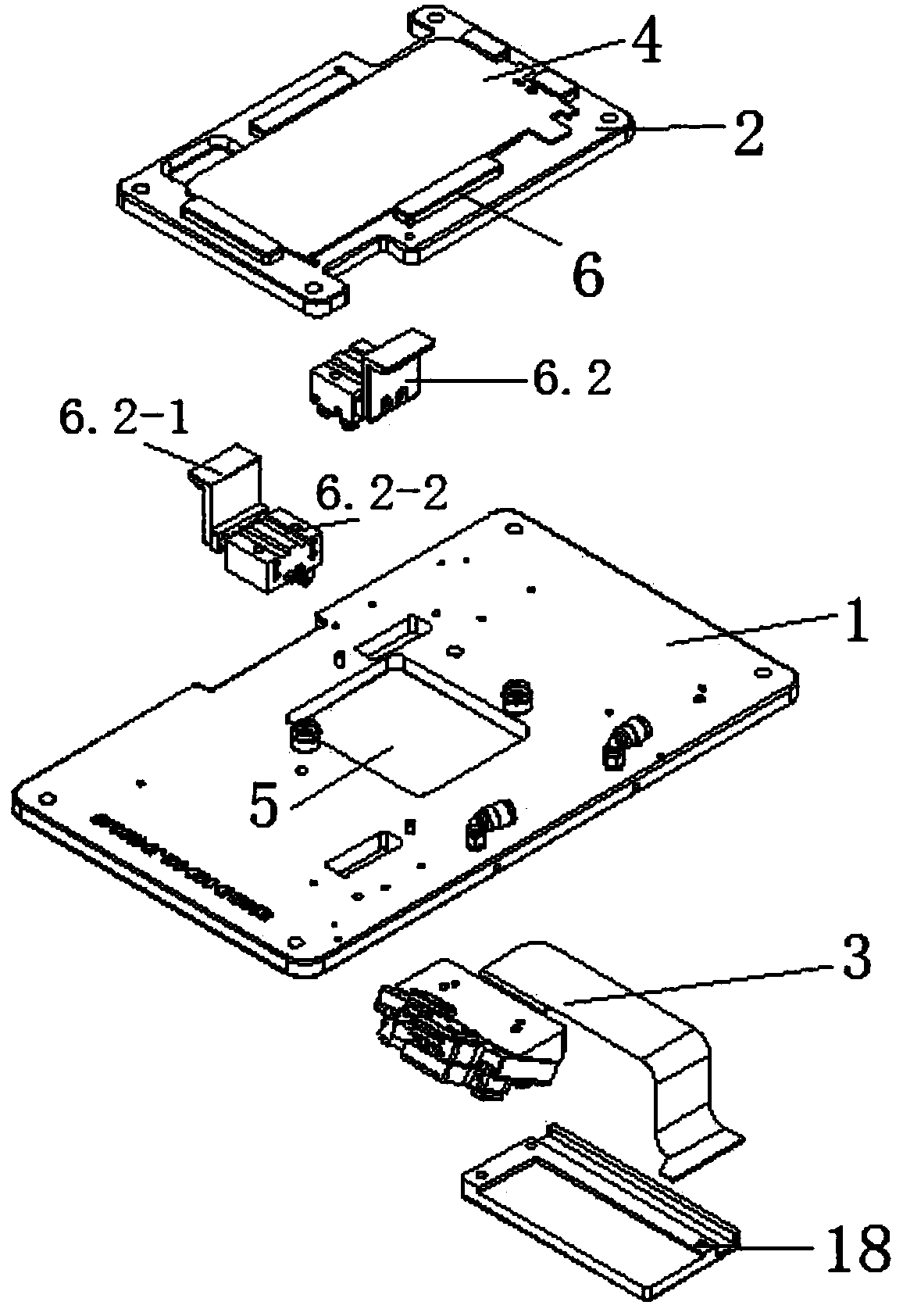

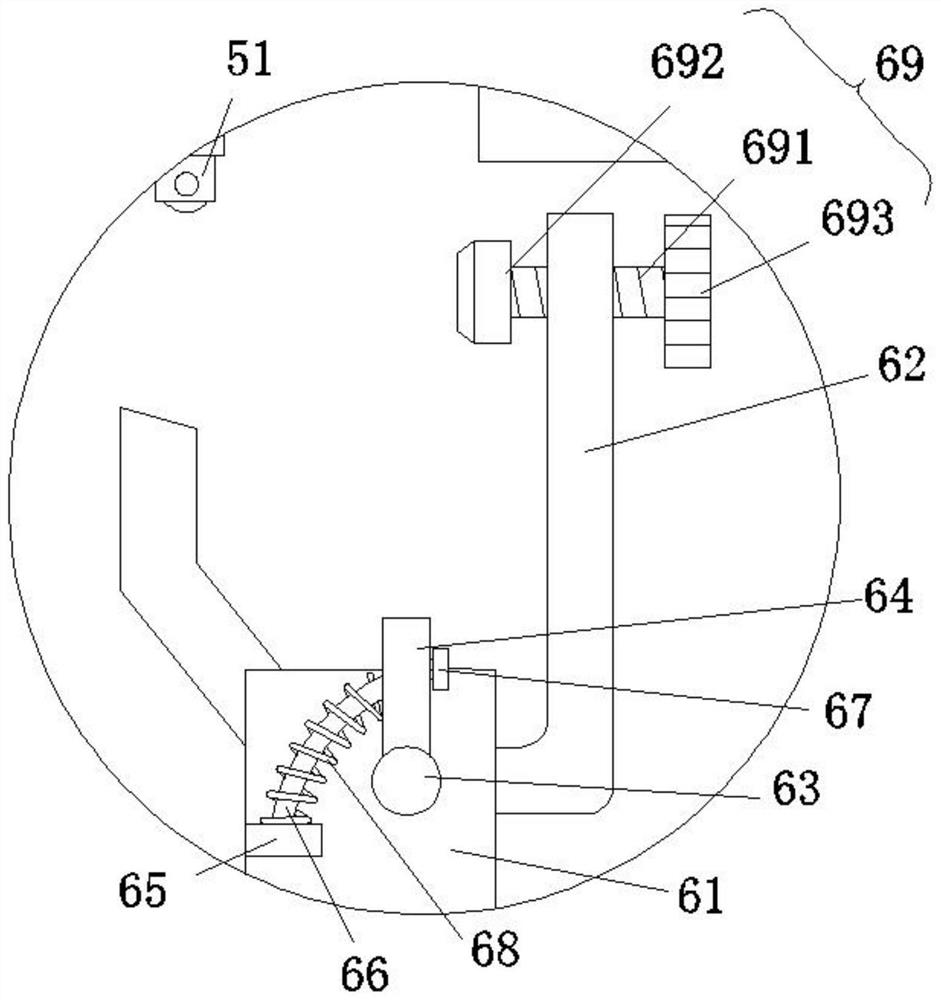

Press-connecting carrier for automatically turning testing jig

The invention discloses a press-connecting carrier for automatically turning a testing jig. The press-connecting carrier comprises a bottom plate, a carrier body and a conduction device. A limiting and fixing structure for containing and limiting a to-be-tested liquid crystal screen is arranged on the carrier body. The carrier body is fixedly connected to the surface of one side of the bottom plate. The conduction device is fixedly connected to the surface of the other side of the bottom plate. The bottom plate and the carrier are each provided with a through hole for a FPC of the back side ofthe to-be-tested electronic screen to penetrate through. A movable stop piece for preventing the to-be-tested electronic screen from being disengaged from the carrier body is arranged beside the carrier body. The press-connecting carrier is simple in structure and convenient to use; by forming the through holes for the FPC of the back side of the to-be-tested electronic screen to penetrate through in the bottom plate and the carrier body respectively, the to-be-tested electronic screen is prevented from being manually turned.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

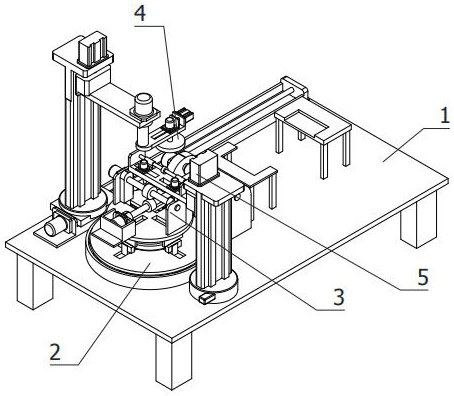

Efficient double-face polishing equipment for multi-model nodular cast iron well lids

InactiveCN112171473AEfficient and accurate multi-faceted grindingEfficient and precise operabilityGrinding carriagesGrinding machinesPolishingEngineering

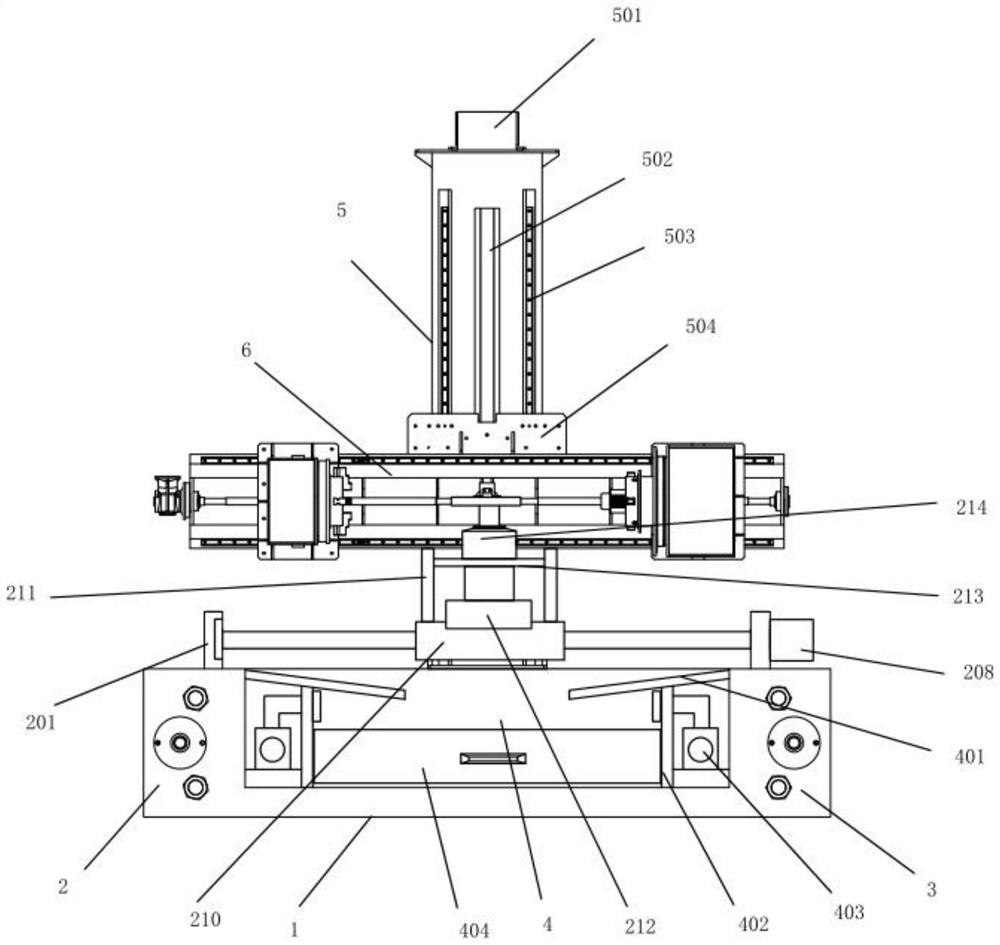

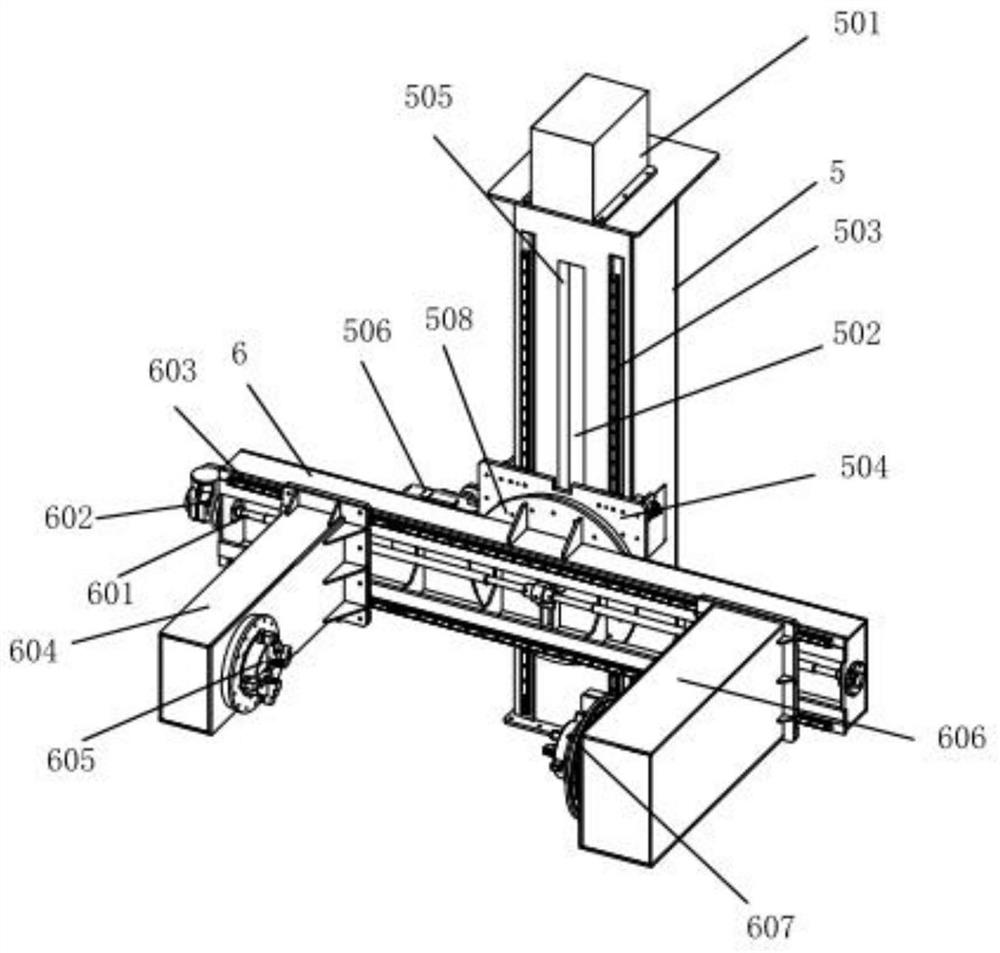

The invention relates to the technical field of nodular cast iron well lid polishing, in particular to efficient double-face polishing equipment for multi-model nodular cast iron well lids. The efficient double-face polishing equipment comprises a rack, a positioning and clamping assembly, an overturning and clamping assembly, a surface polishing assembly and a hole polishing assembly. The overturning and clamping assembly comprises two sets of side wall clamping mechanisms which are arranged to be perpendicular to each other, and an overturning mechanism. The side wall clamping mechanisms arearranged at the output end of the overturning mechanism. The overturning mechanism comprises a first support frame, a second servo motor, a first rotating shaft, an overturning plate and a clamping disc, the two ends of the first rotating shaft are in shaft connection with the side walls of the two sides of the first supporting frame correspondingly, and the output end of the second servo motor is fixedly connected with one end of the first rotating shaft. According to the efficient double-face polishing equipment for the multi-model nodular cast iron well lids, multi-face polishing and positioning hole polishing operation can be efficiently and accurately conducted on the nodular cast iron well lids, the labor intensity of workers is relieved, the working efficiency is improved, and thepracticability of the equipment is improved.

Owner:傅迪生

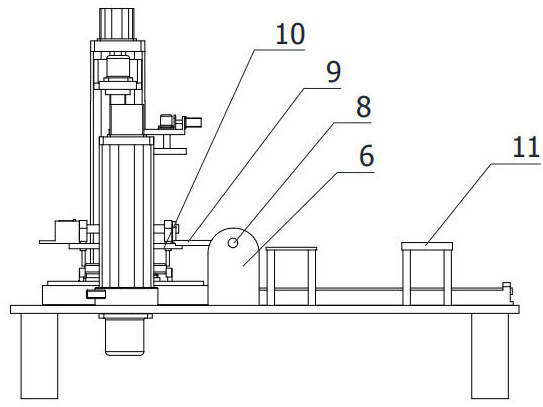

Storage rack device capable of storing and transmitting rolled materials

The invention discloses a storage rack device capable of storing and transmitting rolled materials. A support (1) comprises a first side frame (1a) and a second side frame (1b) which are respectively positioned on two sides; two ends of a drive shaft (2) are respectively connected to the first side frame and the second side frame, and a driving wheel (3), a first driving chain wheel (4) and a second driving chain wheel (5) are arranged on the drive shaft (2); a first driven chain wheel (7) and a second driven chain wheel (8) are arranged on the driven shaft (6); a first chain (9) is arranged on the first driving chain wheel and the first driven chain wheel, and a second chain (10) is arranged on the second driving chain wheel and the second driven chain wheel; a plurality of clamping seats, which are symmetrical and are used for installing and supporting the rolled materials, are arranged on the first chain and the second chain; elastic pressing pieces acting on the outer surfaces of the rolled materials are arranged on the first chain and the second chain. According to the storage rack device, a plurality of rolled materials can be stored, and the stored rolled materials can be transmitted to a cutting workbench or a corresponding outwards shown part through operation of the driving wheel.

Owner:HUNAN PALETTE GARMENT

Integrated circuit resistance detection device

InactiveCN113359004AHigh precisionEasy to detectConveyorsResistance/reactance/impedenceIntegrated circuitRotational axis

An integrated circuit resistance detection device disclosed by the invention comprises a detection device base, a connecting rod, a main shaft and a cam, wherein the top part of the detection device base is provided with a detection device main body, a conveyor belt is arranged right below the detection device main body, the middle part of the bottom part of the conveyor belt is provided with a first servo motor, the top part of the first servo motor is connected with a power gear through a connecting rod, and one side of the power gear is connected with a top plate through a rack. According to the integrated circuit resistance detection device, a supporting block is arranged on the detection device base, and an integrated board main body can be centrally positioned through a positioning block arranged on the supporting block, so that the position deviation of the integrated board main body is avoided, and the accuracy of the device is improved; and through the rotation of a belt pulley group, the belt pulley group drives the supporting block to rotate through a rotating shaft, so that a double-sided integrated board can be conveniently detected, manual turnover is avoided, and the working efficiency is improved.

Owner:潘希全

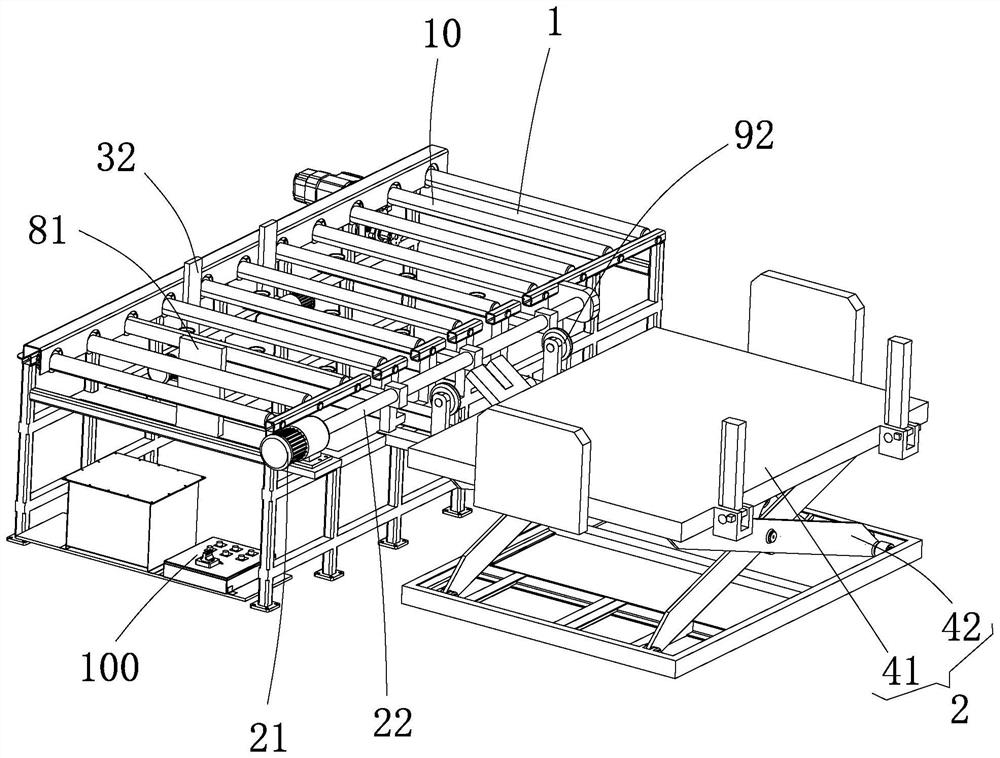

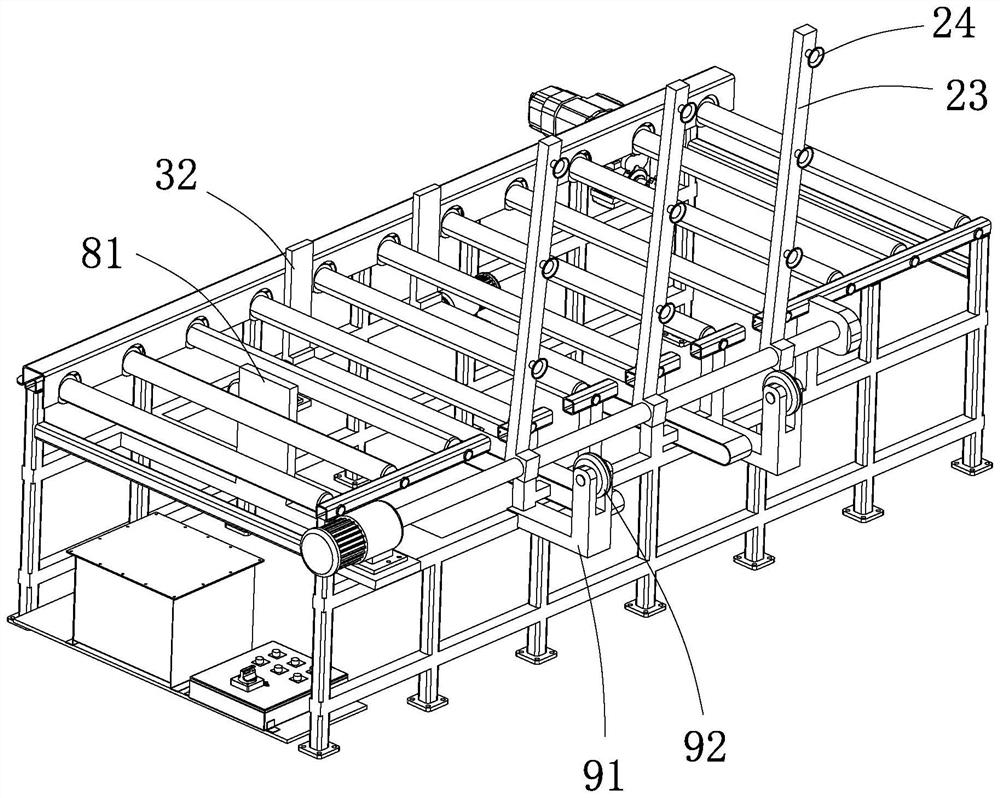

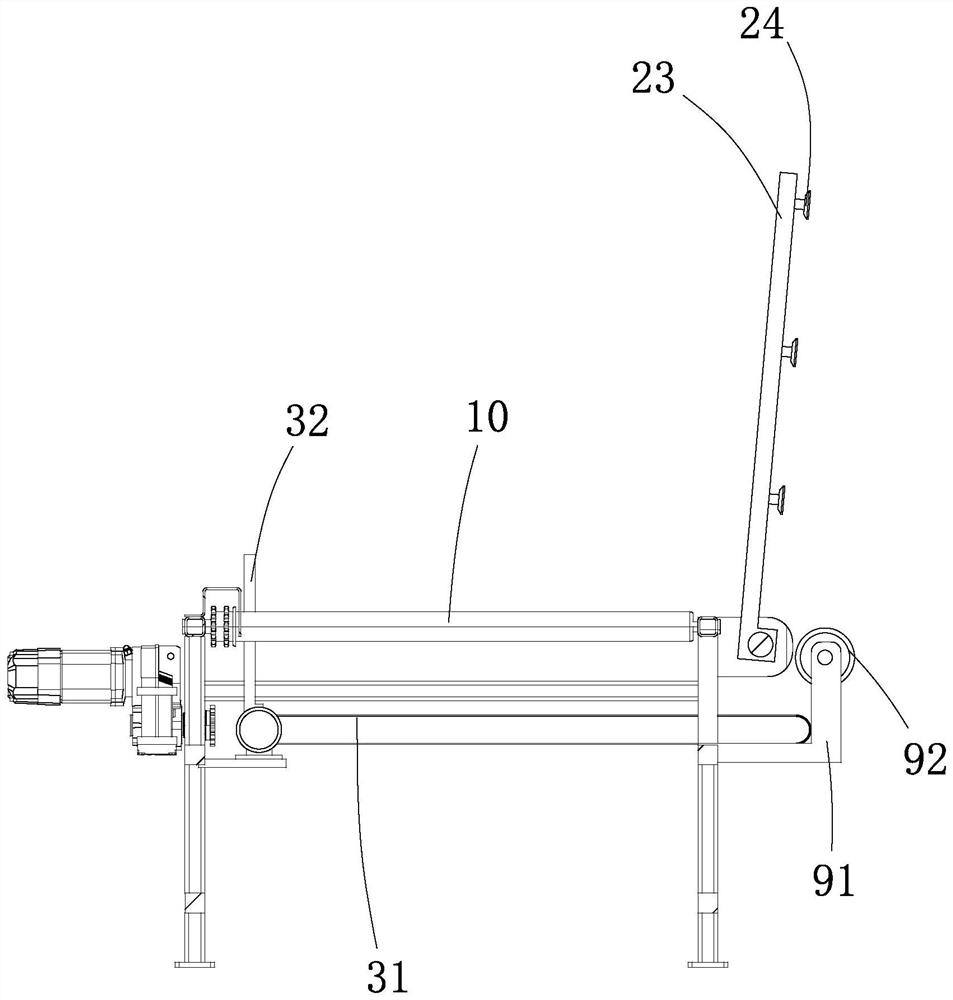

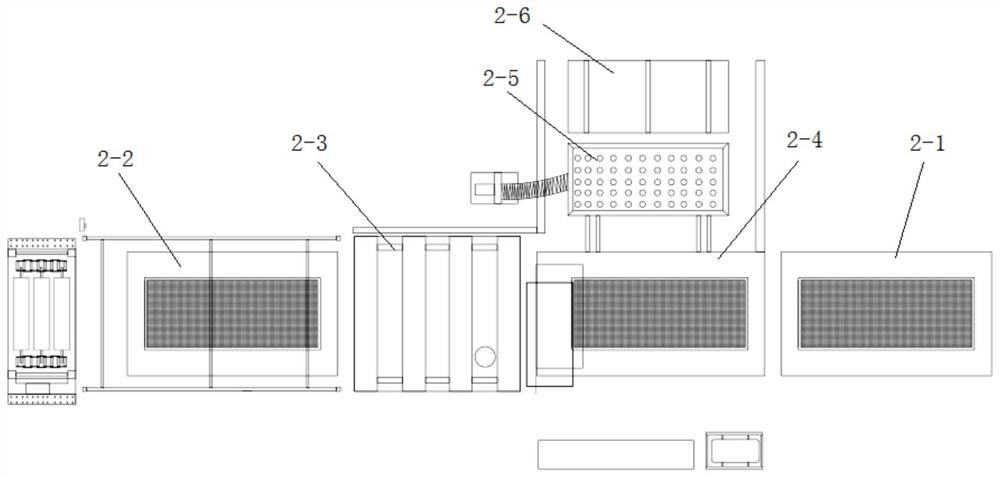

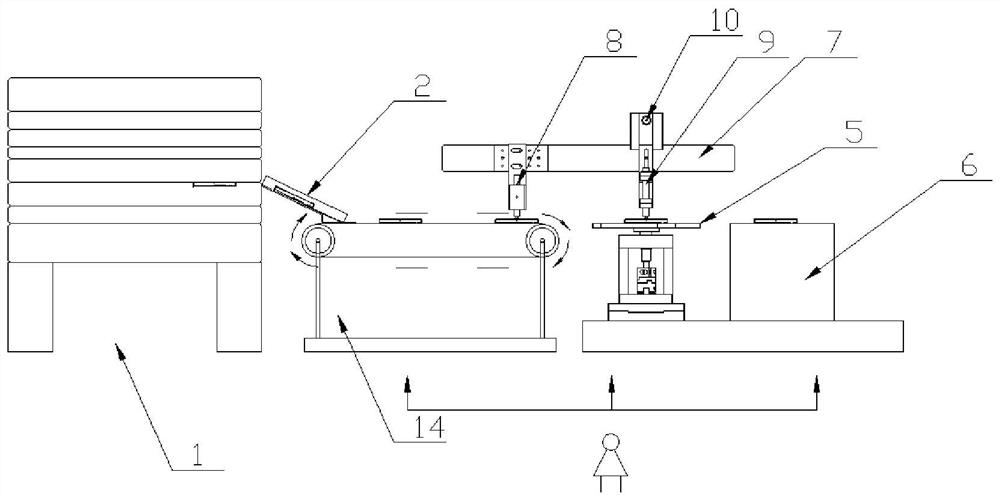

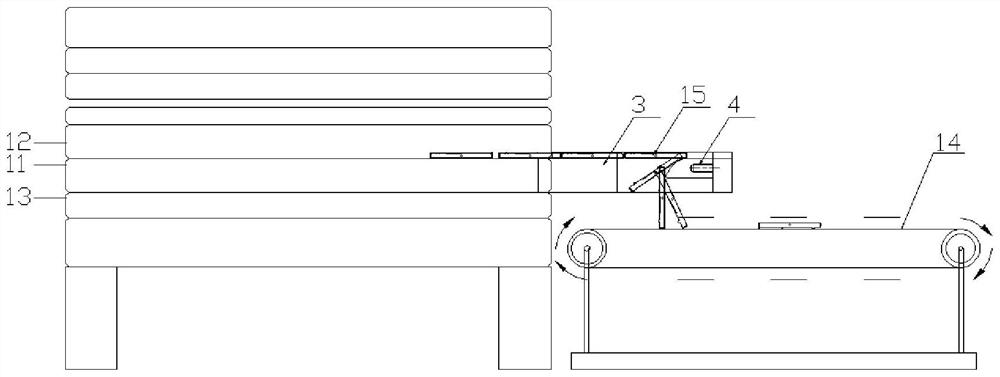

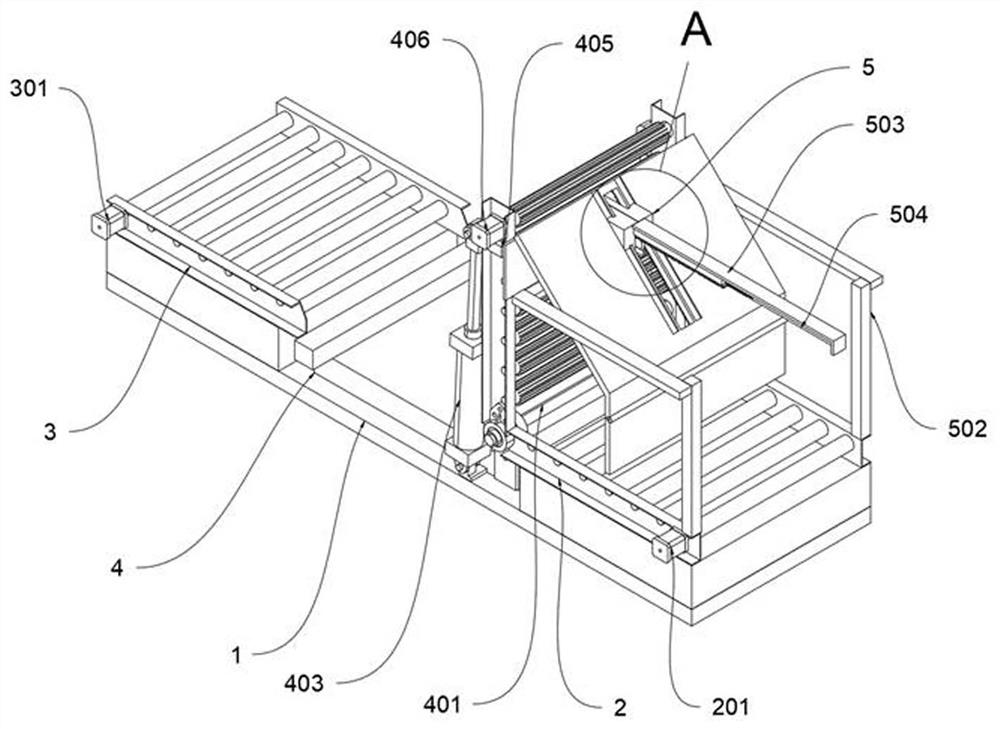

Automatic plate collecting and turning system for aluminum-plastic plate production line

InactiveCN114506650AAvoid manual flippingReduce labor intensityStacking articlesConveyor partsStructural engineeringManufacturing line

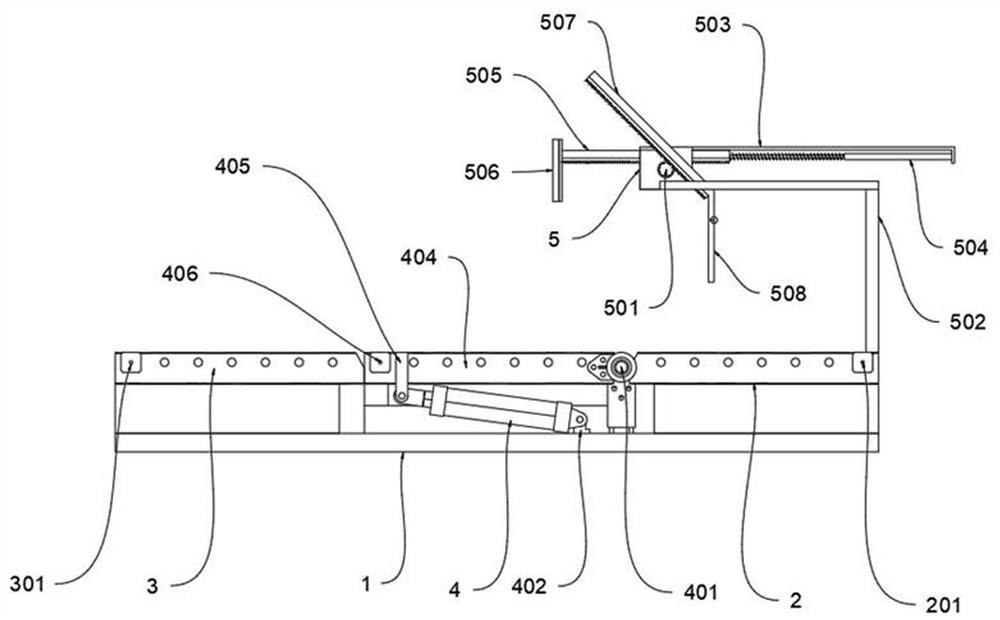

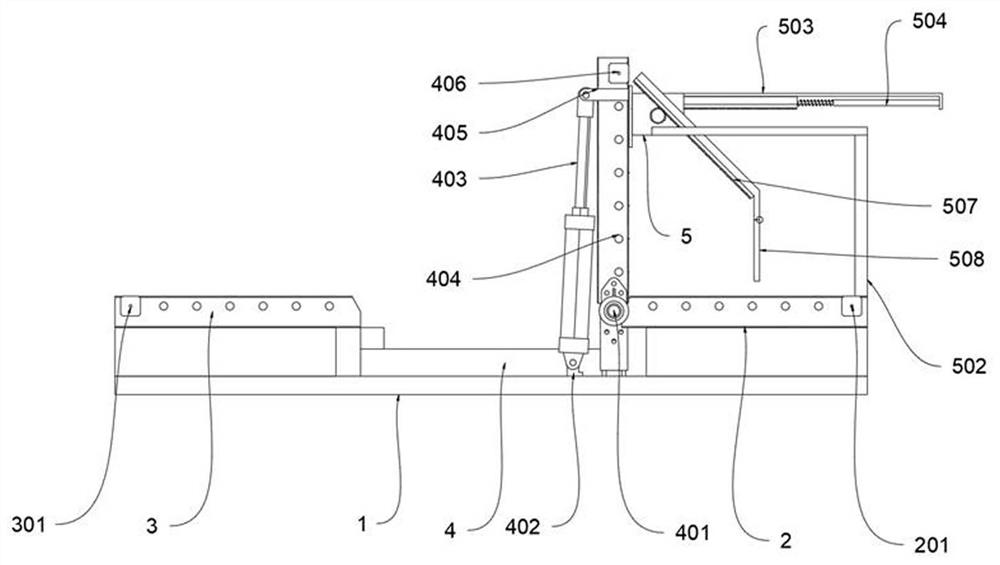

The invention discloses an aluminum-plastic panel production line automatic panel collecting and turning system which comprises a roller conveyor used for conveying aluminum-plastic panels and a collecting table arranged on one side of the roller conveyor and used for collecting and storing the aluminum-plastic panels, and a panel turning mechanism and a panel pushing mechanism which can sequentially and circularly work are arranged on the roller conveyor. The plate turning mechanism can convey the aluminum-plastic plates on the roller conveyor to the collecting table in a turning mode, the plate pushing mechanism can push the aluminum-plastic plates on the roller conveyor to the collecting table, and the collecting table is provided with an aligning mechanism capable of sequentially placing the aluminum-plastic plates stacked on the collecting table in order. The protective layers of the two aluminum-plastic panels are attached, manual overturning of the aluminum-plastic panels is avoided, the labor intensity of workers is reduced, time and labor are saved, and the working efficiency is improved. In addition, the aluminum-plastic plates on the collecting table are arranged and aligned through the aligning mechanism, collection is facilitated, meanwhile, follow-up transportation and carrying operation is facilitated, and the production efficiency is improved.

Owner:何学锋

Manufacturing method of wood carving film-pressing door plank

PendingCN112025902AReduce idle wait timeShorten the timeProfiling/shaping machinesWood veneer joiningSanderNumerical control

The invention discloses a manufacturing method of a wood carving film-pressing door plank.The manufacturing method comprises the following steps that step one. a numerical control carving machine comprising a reverse side carving machine position and at least two front side carving machine positions is used for carving a door plank base material, the reverse side carving machine position is used for carving reverse side patterns and hinge holes in the door plank base materials continuously entering in sequence, the door plank base material with the reverse side being carved is turned to the front side by a turning part and is sent to the idle front side carving machine positions by a conveying belt for front side pattern caving, and the time for carving the reverse side of the door plank base material is less than the time for carving the front side of the door plank base material; step two. the door plank base material with the front side and the reverse side being carved is put intoa special-shaped sanding machine to be subjected to surface burr polishing, and surface burrs are removed; step three. surface glue spraying operation is performed on the polished door plank base material, and the polished door plank base material is placed and aired; and step four. the aired door plank base material is fed into a plastic vacuum forming machine to be subjected to PVC (polyvinyl chloride) high-temperature film coating. The manufacturing method can reduce labor cost and improve manufacturing efficiency.

Owner:上海速居科技集团有限公司

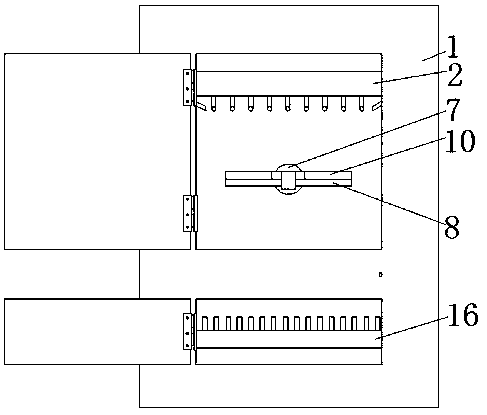

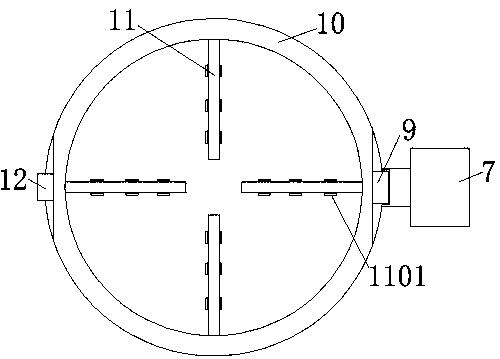

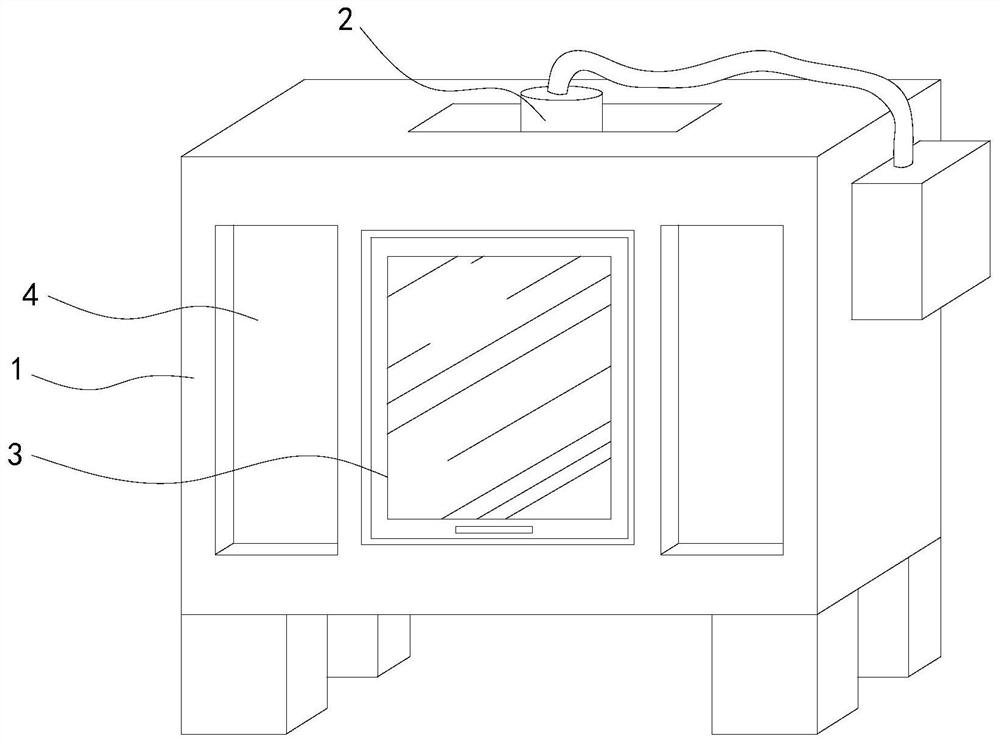

Surface dust removing equipment for optics lens

PendingCN109848161AAvoid manual flippingImprove dust removal efficiencyFlexible article cleaningCleaning using gasesArchitectural engineeringOptic lens

The invention discloses surface dust removing equipment for an optics lens. The surface dust removing equipment for the optics lens comprises a box body, a blowing part is fixed to the portion, closeto the top, of the inner wall of the box body, and a first air pump is connected to a blowing device and fixed to the outer wall of one side of the box body through a bracket; and a circular hole is formed in the center of the inner wall of one side of the box body, a bearing is sleeved with the inner wall of the circular hole, a bearing part is sleeved with the bearing and comprises a transmission rod sleeved with the inner wall of the bearing, the end, located in the box body, of the transmission rod is sleeved with a connecting part, a circular-ring-shaped bottom bracket is welded to the bottom of the end, far away from the transmission rod, of the connecting rod, a hinge block is hinged to the top of the end, far away from the transmission rod, of the connecting part, and a circular-ring-shaped top bracket is welded to the end, far away from the transmission rod, of the hinge block. According to the surface dust removing equipment for the optics lens, the purpose of removing dust on the two faces of the lens at a time is achieved, manual face turning is avoided, the dust removing working efficiency is improved, the surface dust removing equipment can adapt to the lens with moredifferent sizes, and the practicability is high.

Owner:江苏欧达光学有限公司

Flock cleaning equipment for medical protective clothing production

ActiveCN113914087AEasy to cleanIncrease the support areaMechanical cleaningPressure cleaningElectric machineryStructural engineering

The invention discloses flock cleaning equipment for medical protective clothing production. The equipment comprises a base; a first sliding groove is formed in the base; a first sliding block in sliding connection with the first sliding groove is arranged in the first sliding groove; a lead screw in threaded connection with the first sliding block is arranged in the first sliding groove; one end of the lead screw is movably connected with the inner wall of the first sliding groove, and the other end of the lead screw penetrates out of the base and is connected with the output end of a first motor arranged on the outer wall of the base; an L-shaped supporting plate is arranged on the first sliding block; a U-shaped fixing frame used for fixing protective clothing is arranged close to the upper portion of the L-shaped supporting plate; a containing groove is formed in the inner side wall of the U-shaped fixing frame; a handle bolt penetrating into the containing groove is arranged on the U-shaped fixing frame; and a second motor is arranged on the outer side face of the L-shaped supporting plate. Compared with the prior art, the equipment has the advantages of being high in flock adhesion efficiency, lasting in adhesion, good in flock adhesion effect and thorough in cleaning.

Owner:沛县盛玛特新材料研究院有限公司

Metal craft welding protection workbench

PendingCN112496510AIncrease productivityEasy flipWelding protection meansEngineeringMechanical engineering

The invention relates to the field of metal welding workbench equipment, in particular to a metal craft welding protection workbench. The metal craft welding protection workbench comprises a device body and a welding device, a protection baffle is movably installed at the middle end of the front face of the device body, and a movable base is movably installed at the lower end in the device body. Aclamping device is movably installed on the right side of the movable base, a placing table is fixedly installed at the lower end of the welding device, clamping plates arranged at equal intervals are movably installed on the outer side of a clamping device, a rotating plate is movably installed on the left side of the clamping device, and a driving plate is fixedly installed at the position, opposite to the interval of the clamping plates, of the right side of the rotating plate. After the clamping device makes contact with a metal craft, by driving the rotating plate to rotate independently, the inclined arc right side of the driving plate makes contact with the clamping plates and applies acting force, so that the clamping plates overcome the acting force of an elastic rotating shaft to rotate rightwards to clamp the outer side of one end of the metal craft in an all-around mode, and the effect of preventing only two ends of the metal craft from being deformed and damaged by extrusion force is achieved.

Owner:浙江江山福鑫工艺品有限公司

Aviation aluminum product testing device

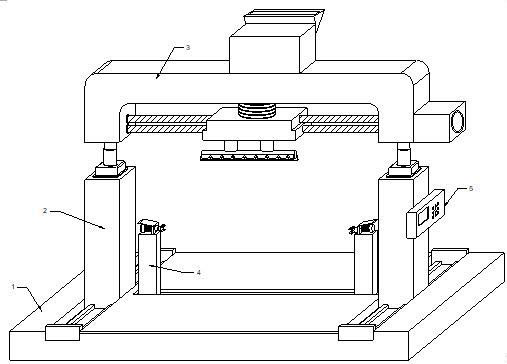

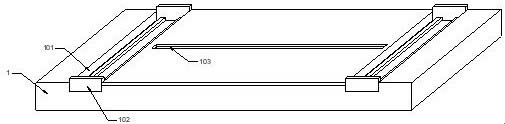

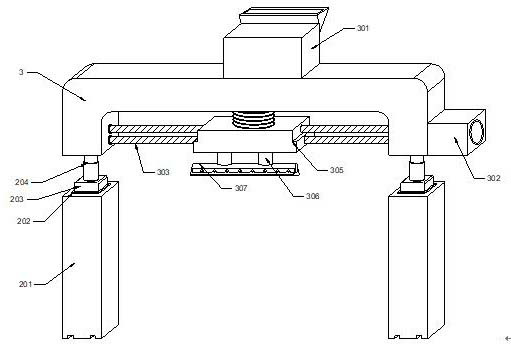

PendingCN114526667AAvoid manual flippingImprove accuracyMechanical roughness/irregularity measurementsAviationProduct testing

The invention relates to the technical field of aluminum product production devices, and discloses an aviation aluminum product testing device which comprises a base, a placement table is fixedly installed in the middle of the surface of one side of the base, clamping assemblies distributed around the placement table are arranged on the surface of one side of the base, and a support of a U-shaped structure with an opening pointing to the base is fixedly installed on the base. The support is provided with a moving assembly, the moving assembly comprises a rotating plate, and the rotating plate is provided with a testing assembly. Compared with the prior art, the aluminum product surface testing device has the beneficial effects that the surface of an aluminum product can be comprehensively tested, the testing area is increased, the aluminum product can be automatically turned over in the testing process, the aluminum product is prevented from being manually turned over, the testing speed and efficiency are improved, meanwhile, the influence of manual re-clamping on the testing result can be avoided, and the testing efficiency is improved. The accuracy of a test result is improved and the use is facilitated.

Owner:苏州腾益达精密机械有限公司

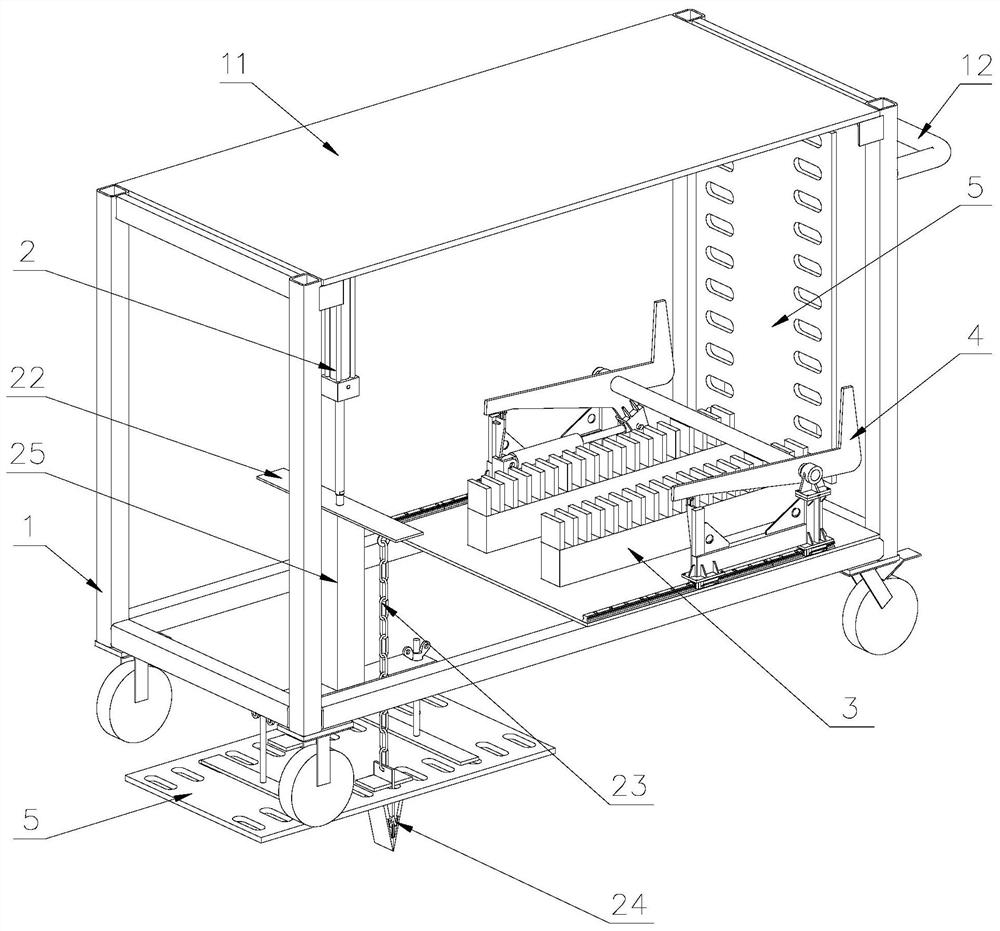

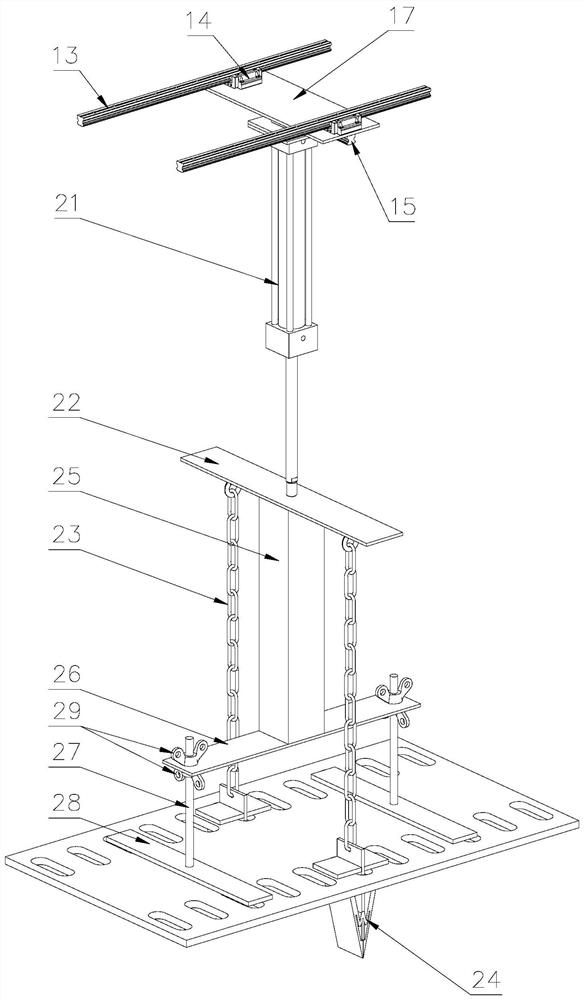

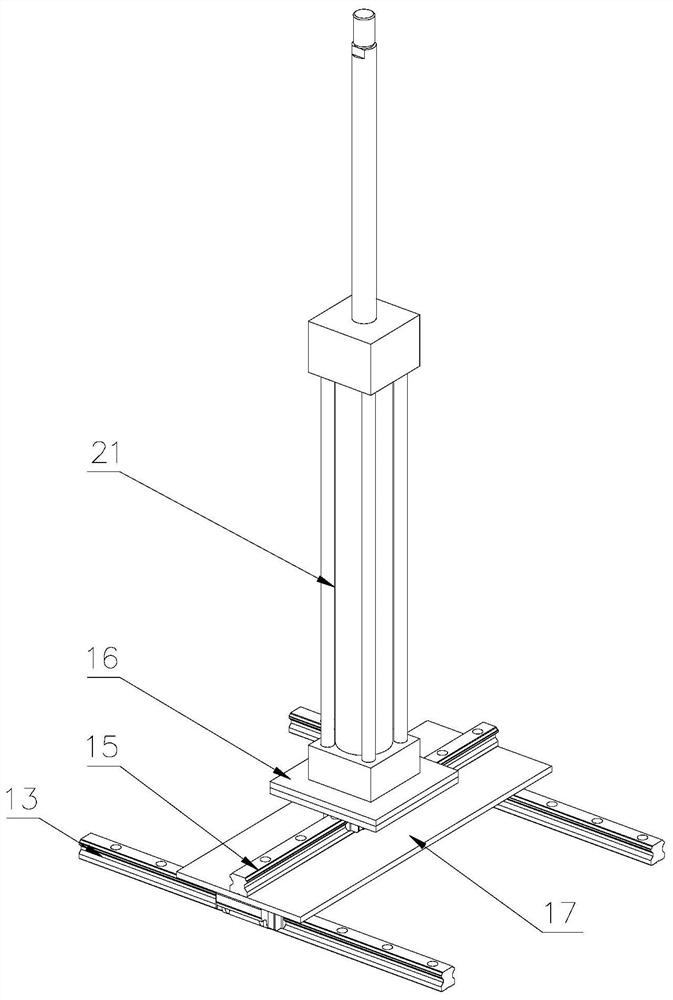

Feeding vehicle for laterite nickel ore sintering

PendingCN113175819AImprove labor efficiencyReduce labor intensityRotary drum furnacesCharge manipulationEngineeringStructural engineering

The invention relates to the technical field of metallurgical equipment, and discloses a feeding vehicle for laterite nickel ore sintering. The feeding vehicle comprises a RGV vehicle and a rail, wherein the RGV vehicle is mounted on the rail; a supporting rod, a first hydraulic cylinder and a charging barrel are arranged on the RGV vehicle; the charging basket is hinged at a position, away from the RGV vehicle, of the supporting rod; a shell of the first hydraulic cylinder is hinged on the RGV vehicle; a piston rod of the first hydraulic cylinder is hinged on the side wall of the charging barrel; the charging barrel is turned over by extending out and drawing back the first hydraulic cylinder; a guide assembly is further arranged on the RGV vehicle; and the feeding end of the guide assembly is positioned below a discharge hole of the charging barrel. The feeding device has the beneficial effects that: the charging barrel is arranged on the RGV vehicle and is turned over through the first hydraulic cylinder, so that the charging barrel is prevented from being manually turned over, labor efficiency is improved, and labor intensity of a worker is reduced.

Owner:河南省煜晟镍业有限责任公司

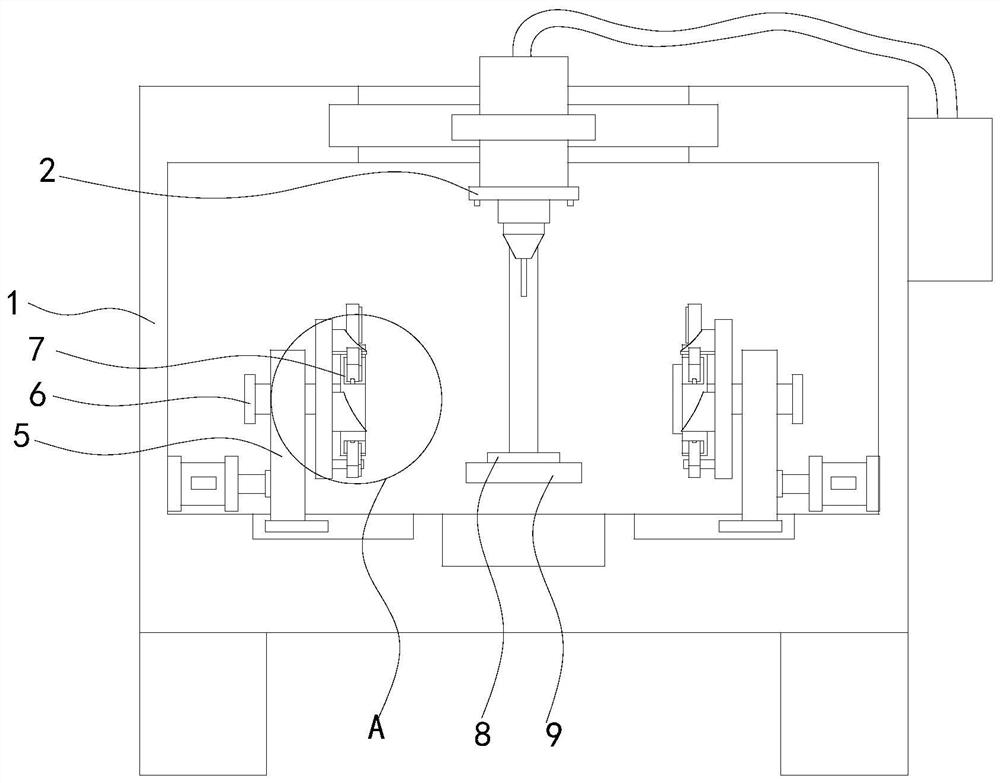

Machining equipment with turnover clamping mechanism

PendingCN112894733AReduce work intensityReduce operating efficiencyWork benchesElectric machineryBilateral symmetry

The invention discloses machining equipment with a turnover clamping mechanism. The machining equipment comprises a machining workbench, a containing tool is arranged at the center position of the upper surface of the machining workbench, two lifting mechanisms which are in bilateral symmetry are arranged on the upper surface of the machining workbench, a driving mechanism is arranged on the lower side of the machining workbench, the two lifting mechanisms are in transmission connection through the driving mechanism, each lifting mechanism comprises a moving block, first motors are installed on the inner sides of the two moving blocks correspondingly, installation plates are fixed to the inner sides of output shafts of the two first motors correspondingly, pressing oil cylinders are installed on the inner sides of the two installation plates correspondingly, and clamping long blocks are fixed on output shafts of the two pressing oil cylinders. According to the machining equipment with the turnover clamping mechanism, products can be automatically turned, clamped and fixed, so that manual operation is avoided, the operation intensity of operators is reduced, efficiency is improved, meanwhile, the clamping and fixing stability of the products is improved, and potential safety hazards are reduced.

Owner:安徽省旌德旌峰机械制造有限公司

Automatic equipment for spraying paint on aluminum plate

Owner:山东吉宇建材有限公司

Pipeline outer wall spraying device for automobile manufacturing

ActiveCN112058528AIncrease the degree of atomizationAvoid manual flippingLiquid spraying apparatusElectric machineryStructural engineering

The invention discloses a pipeline outer wall spraying device for automobile manufacturing. The pipeline outer wall spraying device comprises a base, a paint barrel, a draught fan, a sealing plate, amixing cover, a base plate and a pipeline body. A paint spraying pipe is fixedly connected to the bottom of the mixing cover, and spraying heads are vertically, evenly and fixedly connected to the right side of the paint spraying pipe. The pipeline outer wall spraying device for the automobile manufacturing has the beneficial effects that in the using process, the draught fan pumps outside air into the mixing cover, in the process, the anticorrosive paint enters the mixing cover at the same time, the air is mixed with the paint, the paint can be primarily atomized and then sprayed out after being secondarily atomized by the spraying heads, the atomization degree of the paint is higher, a formed coating is finer, in the spraying process, a motor drives the pipeline body to rotate, so that the outer wall of the pipeline body can be comprehensively sprayed , manual overturning is avoided, and therefore the labor intensity is reduced.

Owner:COOPER STANDARD JINGDA JINGZHOU AUTOMOBILE FITTINGS

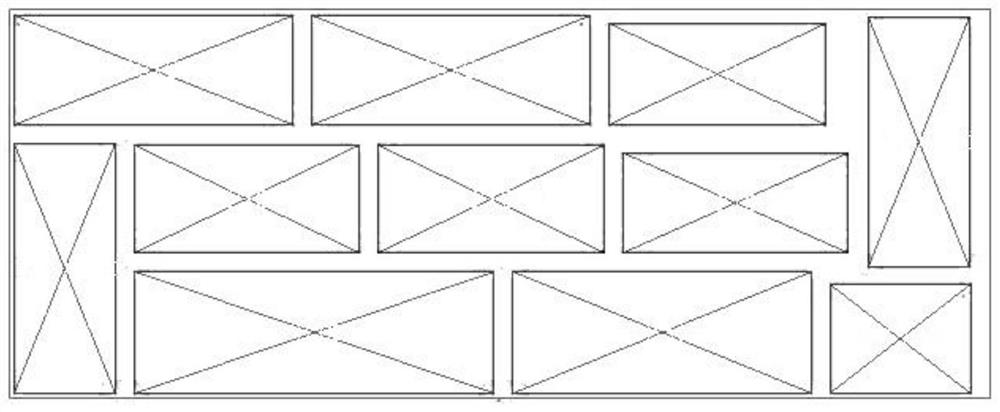

Efficient manufacturing method of wood carving film pressing door plate

PendingCN112008824AEfficient preparation methodReduce idle wait timeDecorative surface effectsLaminationNumerical controlFilm-coated tablet

The invention discloses an efficient manufacturing method of a wood carving film pressing door plate. The efficient manufacturing method comprises the following steps that a numerical control carvingmachine is used for carving the front face and the back face of a door plate base material; surface burr grinding is conducted on the door plate base material with the front face and the back face being carved, and surface burrs are removed; the surface glue spraying operation is conducted on the ground door plate base material, and the placing and airing are conducted; before a plurality of doorplate base materials to be subjected to high-temperature film coating are placed on a film coating workbench of a high-temperature film coating machine, the placing positions of the plurality of aireddoor plate base materials to be subjected to high-temperature film coating on a film coating station are reasonably planned and arranged in advance; according to a pre-planned layout, the door platebase materials to be subjected to high-temperature film coating are placed at designated positions of the film coating workbench; the surfaces of the plurality of door plate base materials are coveredwith a PVC film on the film coating workbench; and the film coating workbench drives the door plate base materials to enter the high-temperature film coating station for PVC high-temperature film coating. According to the efficient manufacturing method, the labor cost can be reduced, and the manufacturing efficiency can be improved.

Owner:上海速居科技集团有限公司

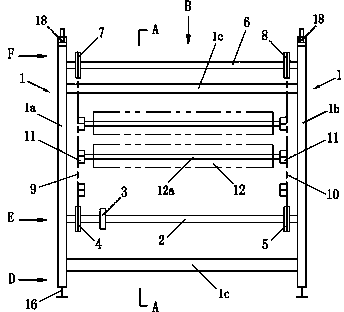

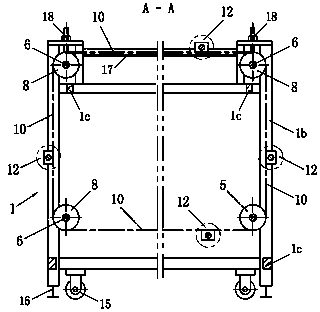

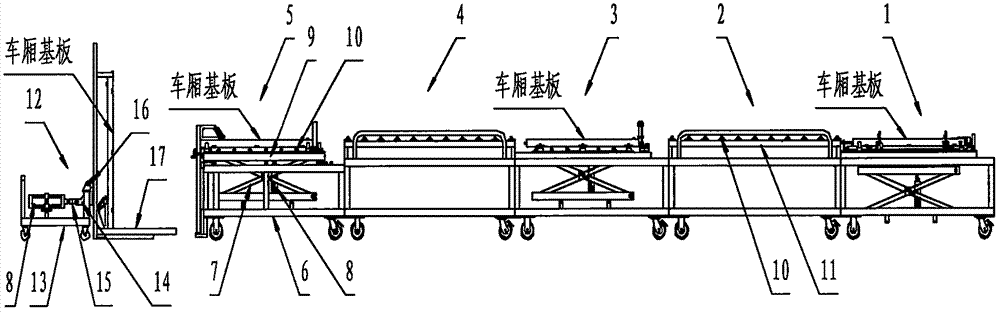

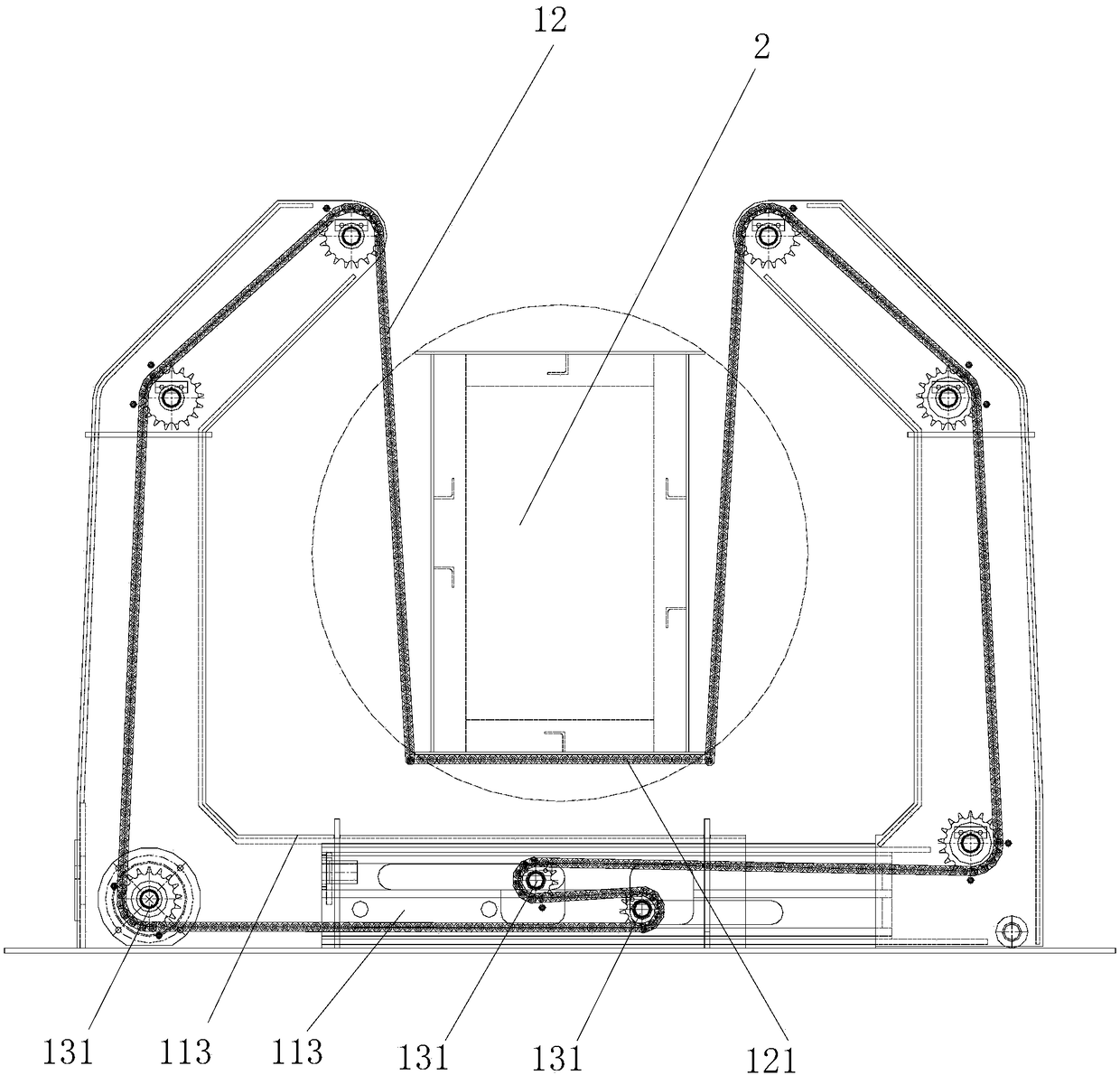

An operation method of electric vehicle compartment welding assembly line

ActiveCN105269166BDifficulties during resolutionResolving Time VariancesWelding/cutting auxillary devicesAuxillary welding devicesAssembly lineElectric vehicle

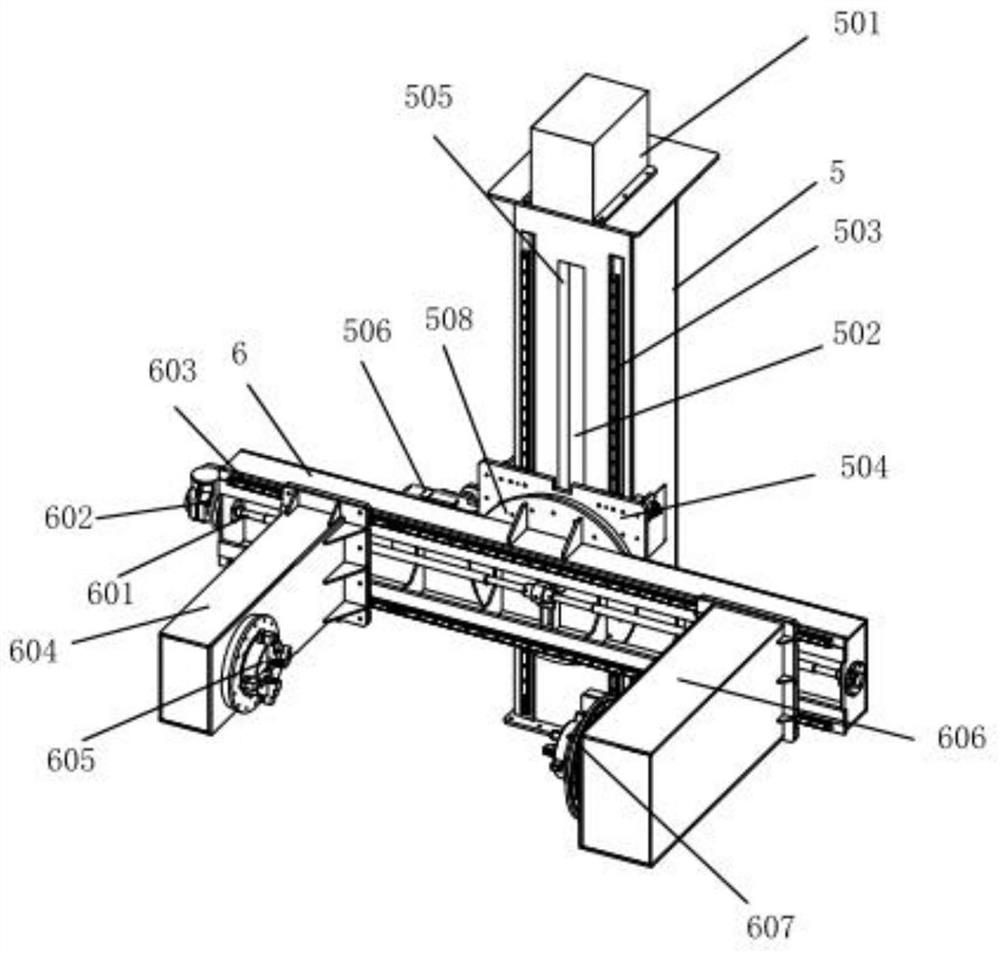

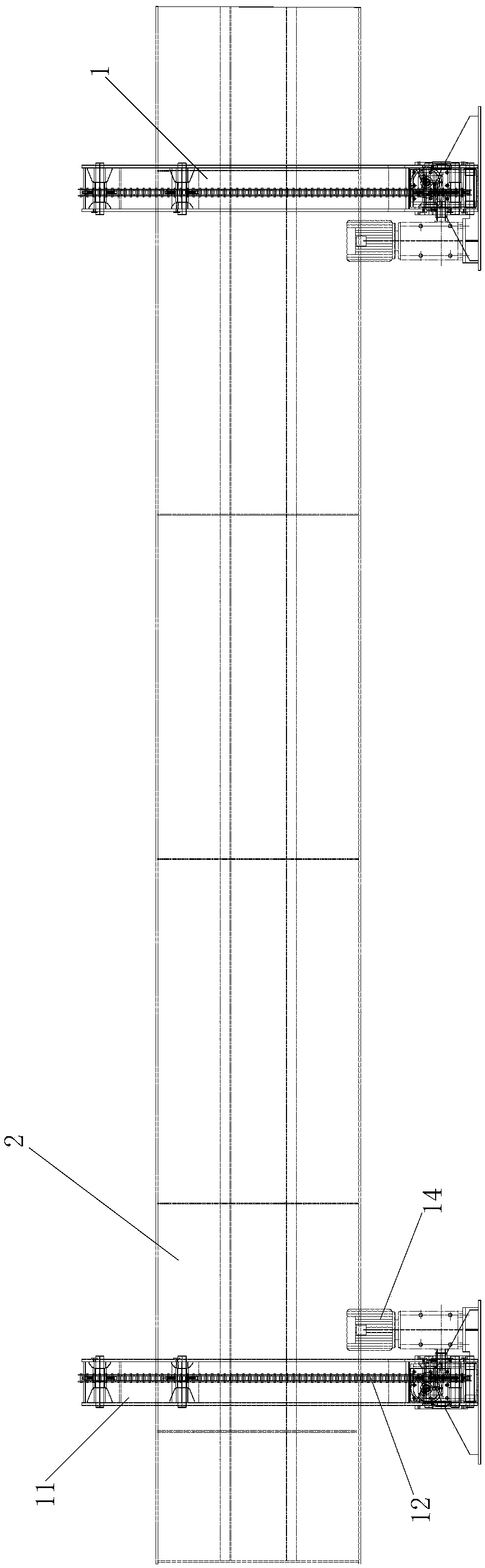

The invention discloses an operation method for an electric vehicle carriage welding assembly line. A first lifting frame, a first temporary storage frame, a second lifting frame, a second temporary storage frame and a third lifting frame are sequentially connected to form the whole welding assembly line. A self-overturning frame moves to the back of the third lifting frame, a carriage base plate is placed on an ox horn bearing of a supporting table of the first lifting frame, all parts are welded to the carriage base plate, and the carriage base plate slides to an ox horn bearing of the second lifting frame through the first temporary storage frame along the ox horn bearing; a carriage front plate is welded to the front portion of the carriage base plate and then slides to an ox horn bearing of the third lifting frame through the second temporary storage frame; and a carriage back plate is welded to the tail portion of the carriage base plate, and a movable cart carries the welded carriage base plate to move to a next manufacturing procedure site, so that fast demolding of a welded piece is achieved, the labor operation intensity of workers is reduced, fast transferring and omnibearing welding are achieved, welding deformation can not be caused in the welding process, the welding efficiency is improved, and the welding quality is guaranteed.

Owner:HENAN JINPENG VEHICLE IND CO LTD

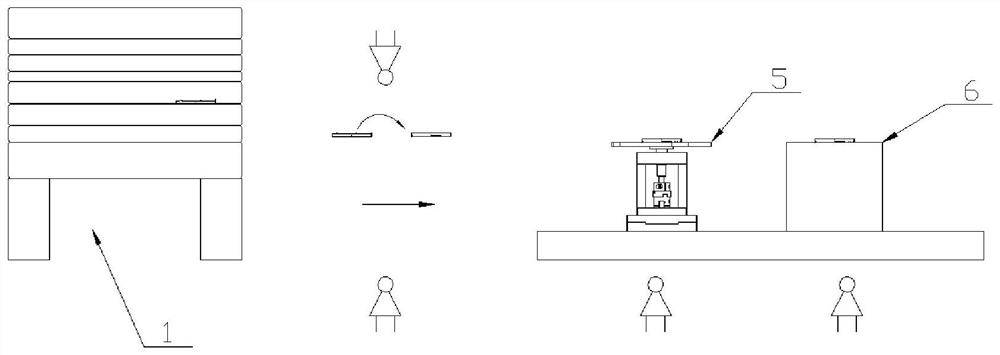

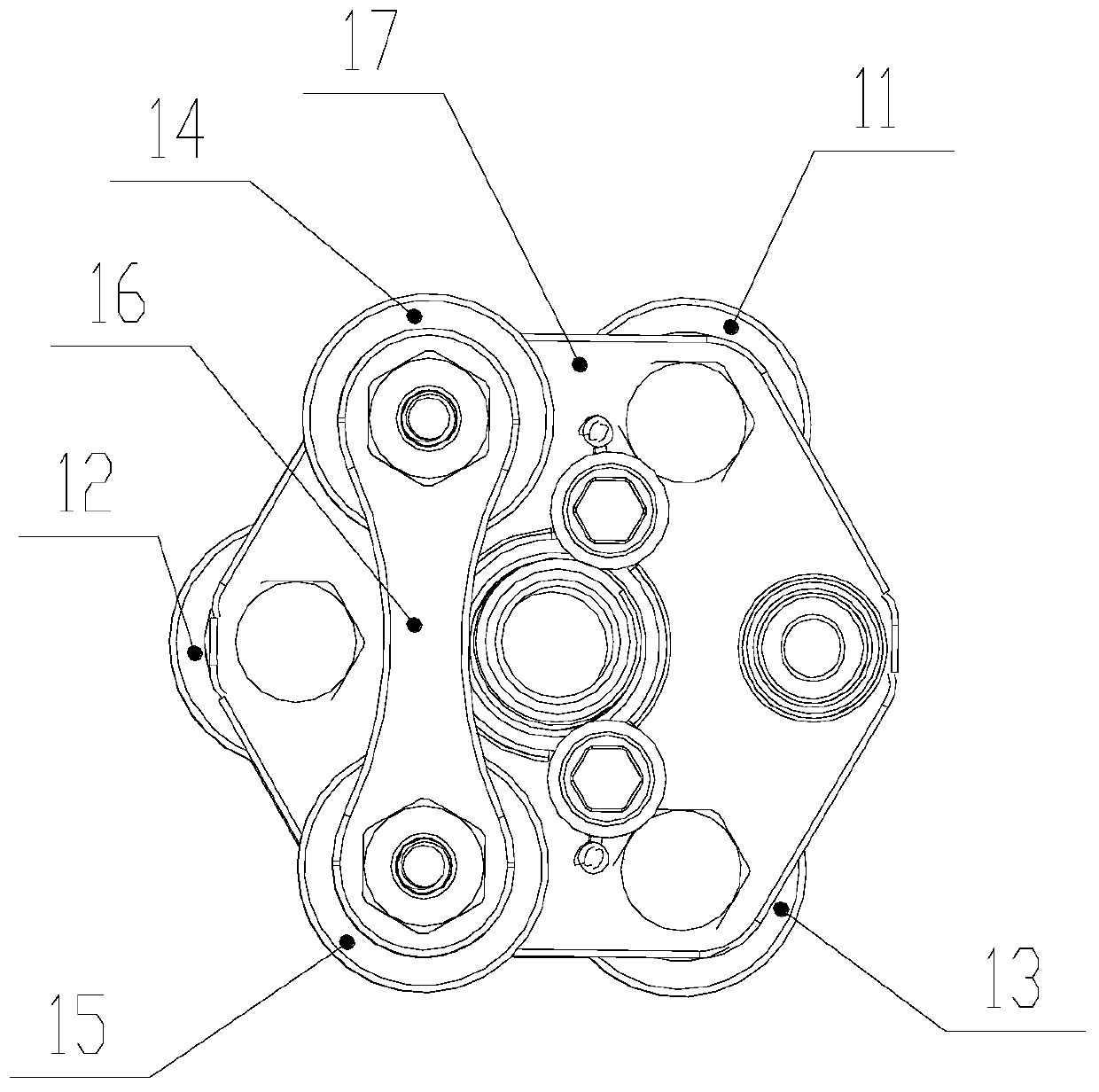

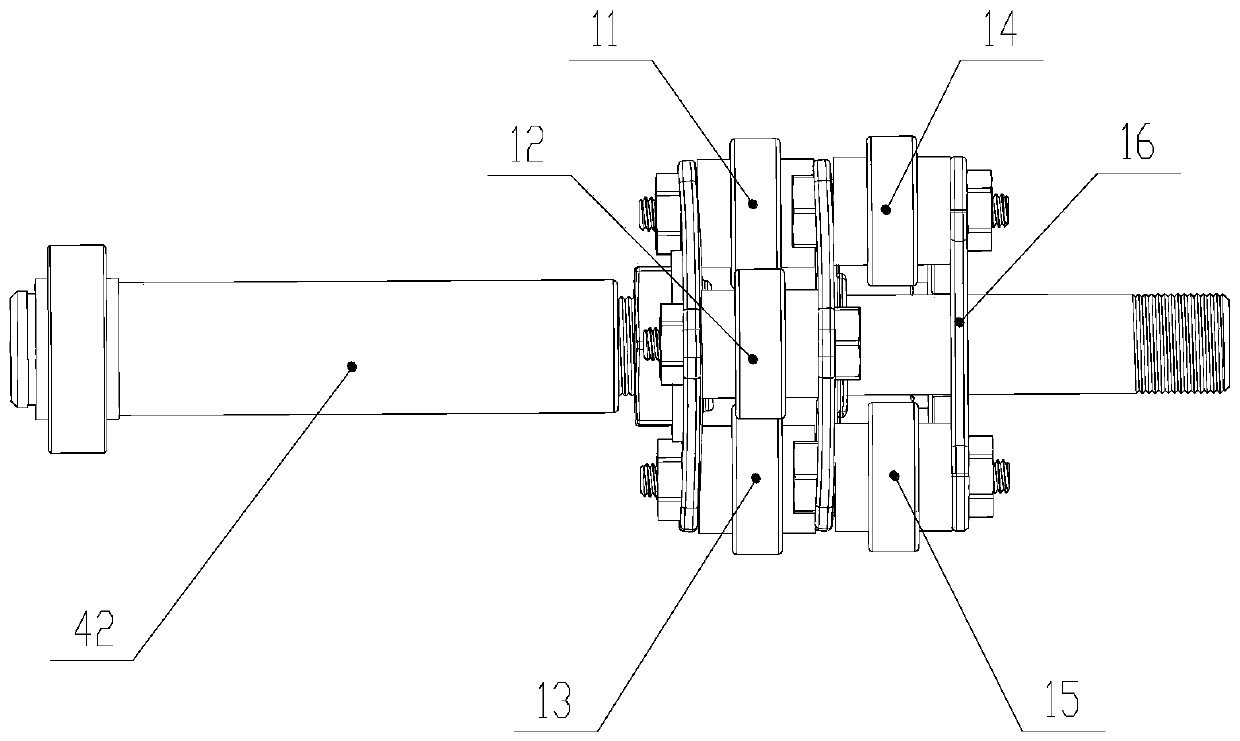

Intelligent connection mechanism for mold and automatic equipment

PendingCN114769453ADock stableRealize automatic handlingMetal-working feeding devicesStripping-off devicesControl engineeringProcess engineering

The intelligent connection mechanism comprises a forming die and a follow-up work station, a discharging port is formed in one side of the forming die, a discharging channel, a conveying belt mechanism and the automatic equipment are further arranged, one end of the discharging channel is directly communicated with the discharging port of the forming die, and the other end of the discharging channel is communicated with the follow-up work station. The other end of the discharging channel is connected with the surface of the upper side of the starting end of a conveying belt of the conveying belt mechanism in a right-facing mode, and the automatic equipment can grab products on the surface of the conveying tail end of the conveying belt of the conveying belt mechanism and convey the products into a follow-up work station for follow-up treatment. Automatic carrying, detecting and packaging of the products are achieved, manual carrying and back turning are not needed, the post-processing efficiency of the products is greatly improved, the labor cost is reduced, the products are detected through automatic equipment, the detection precision is improved, detection errors and damage to the products in the manual carrying process are avoided, and the enterprise competitiveness is greatly improved.

Owner:CHERRY CHIEF PRECISION IND KUNSHAN

Batched bottle unscrambling equipment with automatic draining function

The invention discloses batched bottle unscrambling equipment with an automatic draining function, and relates to the technical field of bottle unscrambling. The batched bottle unscrambling equipmentwith the automatic draining function comprises a fixed base, wherein a box body is fixedly mounted at the top of the fixed base; a first rotating column is rotatably mounted on the inner wall of one side of the box body; and a second rotating column is rotatably mounted on the inner wall of the other side of the box body. According to the batched bottle unscrambling equipment with the automatic draining function, through the cooperative use of a rotating mechanism and a clamping mechanism, rubber pads are fixedly mounted on the inner walls of right clamp holders and left clamp holders, so thatdamage to bottle bodies by the right clamp holders and the left clamp holders is avoided; and through arranging the rotating mechanism, the left clamping devices in first clamping bases and second clamping bases can be moved at the same time, so that the right clamping devices and the left clamping devices can clamp bottles with different sizes, multiple sets of bottles can be clamped at the sametime so as to be drained, and the working efficiency is effectively improved.

Owner:浙江御品源饮品有限公司

A cable trench cover opening device

ActiveCN112607613BImprove securityReduce labor intensityBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderChain link

The invention discloses a cable trench cover opening device. A hoisting device is installed at the lower part of the top plate. The hoisting device comprises a first hydraulic cylinder, a first suspending plate arranged at the lower part of a piston rod of the first hydraulic cylinder, and two suspending plates arranged on the lower part of the first suspending plate. The chain on the lower part of the side, the lower part of the chain is provided with a grab hook, the grab hook includes a symmetrical and inclined splint, and a W-shaped plate arranged in the middle of the splint on both sides. Separation; when the splints on both sides are parallel, the spacing is smaller than the width of the cable trench perforation. In the initial state, the spacing between the upper parts of the two plywood is greater than the cable trench perforation width. In the invention, two chains are connected at both ends of the lower part of the first hanging plate of the hoisting device, hooks are arranged at the lower part of the chains, the hooks are used to extend into the perforated lower part of the cover plate of the cable trench, and the first hydraulic cylinder is used to lift the cover plate of the cable trench , Complete the opening of the cable trench cover, reduce the labor intensity of workers, and enhance the safety of the cable trench cover opening.

Owner:国网山东省电力公司曹县供电公司

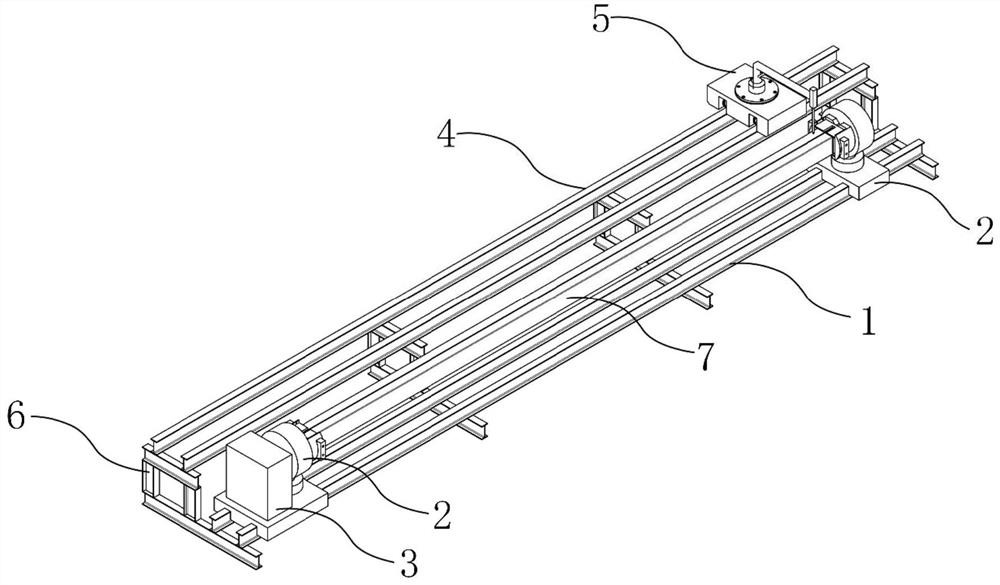

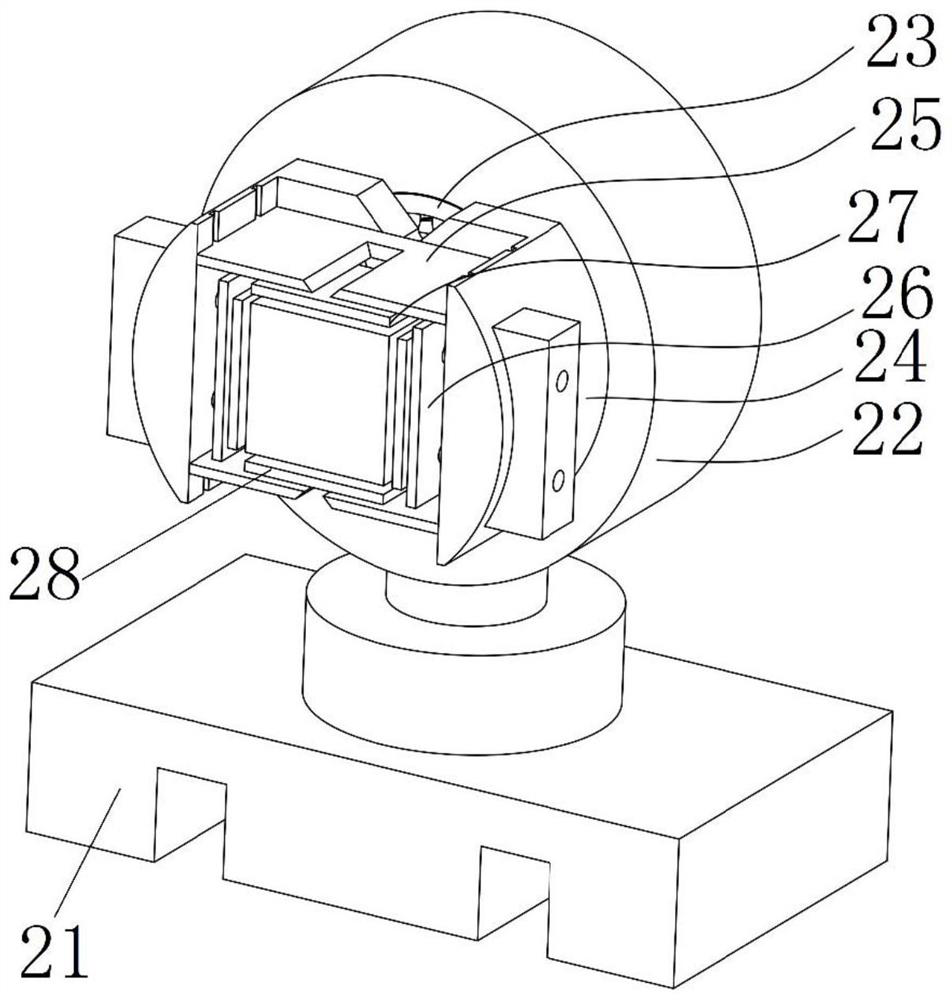

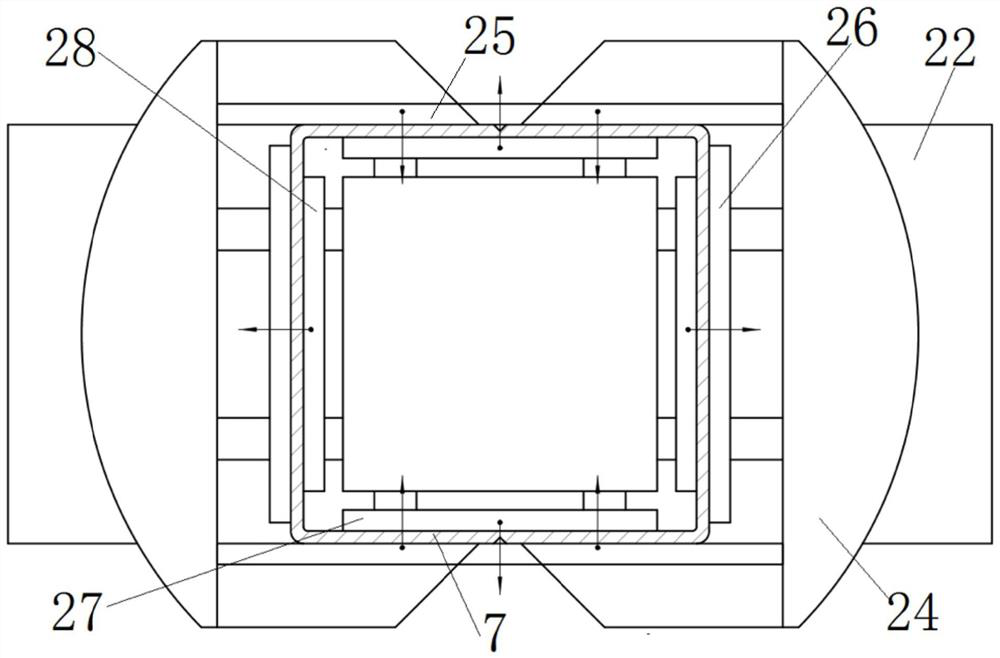

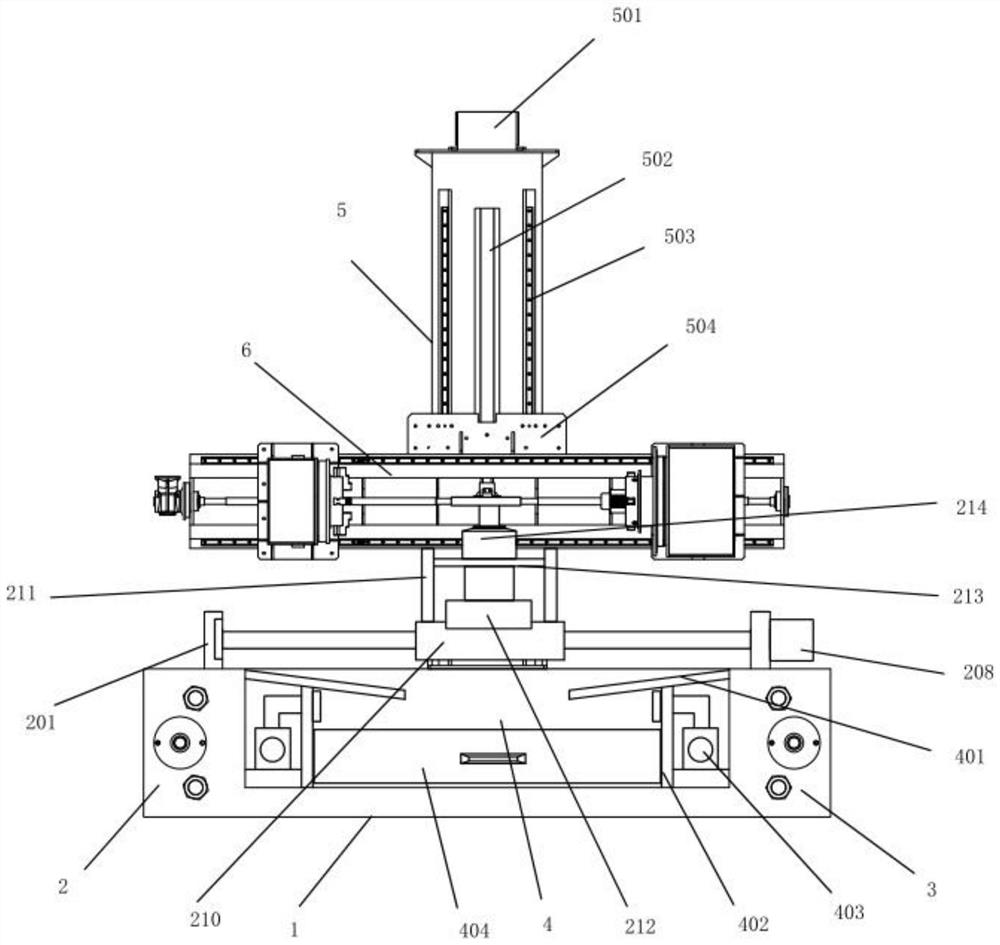

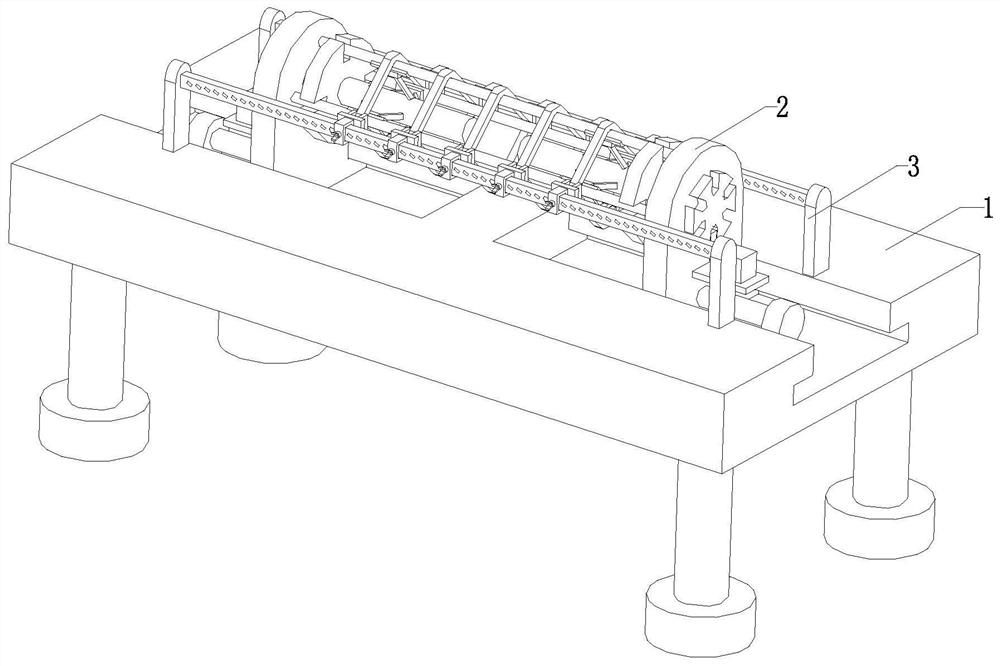

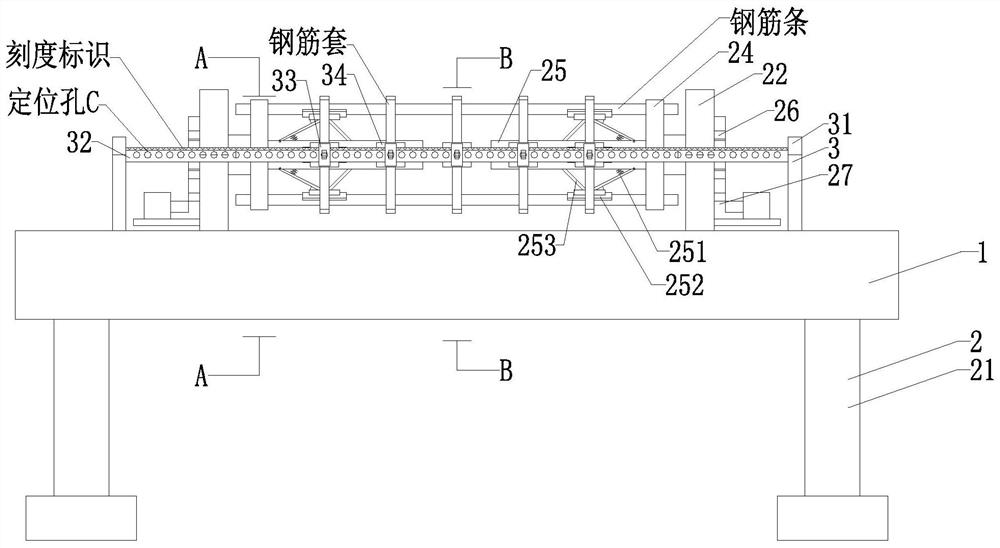

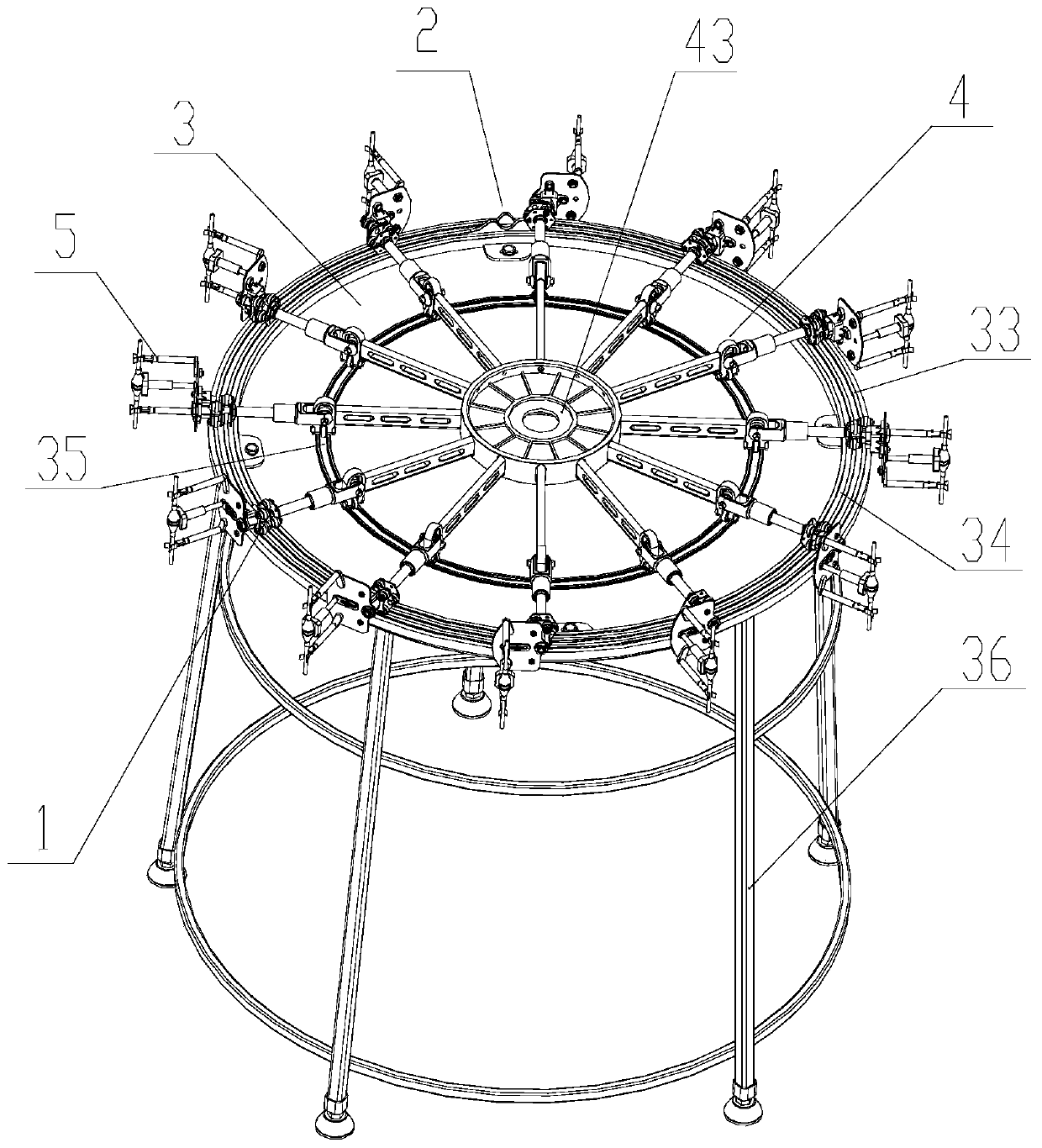

Assembling and welding mould for thin-wall rectangular beam and using method thereof

InactiveCN111940975AFast solderingPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesWeldingThin wall

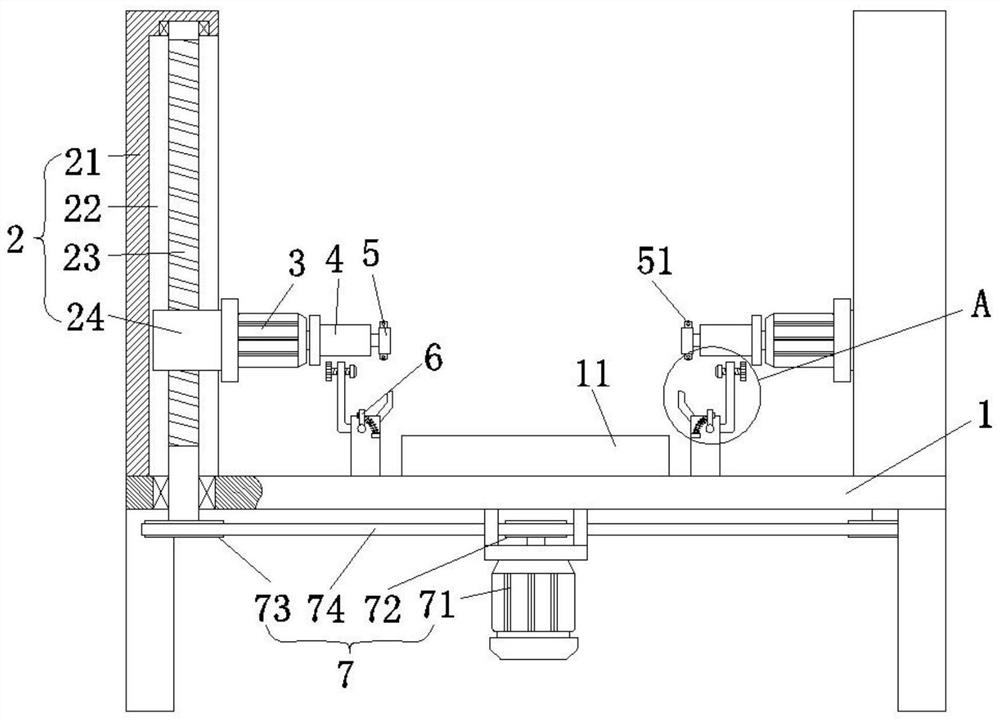

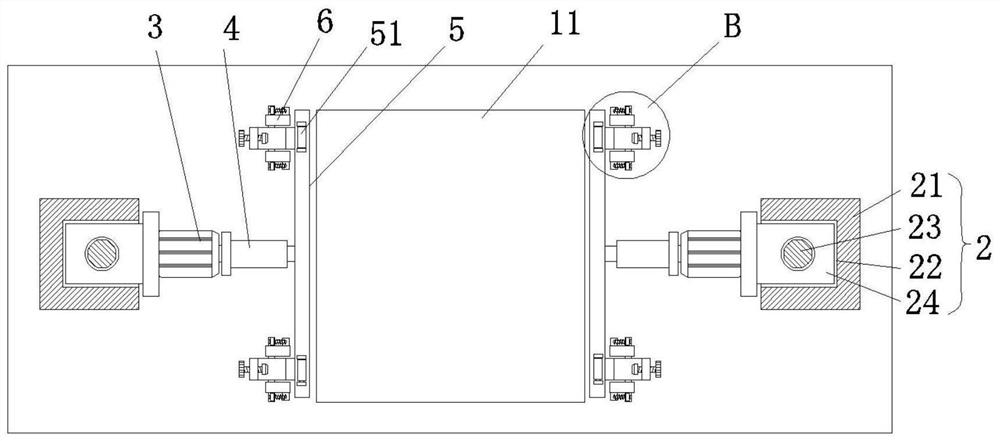

The invention discloses an assembling and welding mould for a thin-wall rectangular beam and a using method thereof. The assembling and welding mould comprises chuck guide rails, the chuck guide railsare horizontally arranged in parallel with a welding machine guide rail, and two chucks are symmetrically arranged on the chuck guide rails; a to-be-welded workpiece is horizontally arranged betweenthe two chucks, and the chucks are used for clamping the end of the to-be-welded workpiece and can drive the to-be-welded workpiece to rotate around the axes of the chucks; and a welding machine is arranged on the welding machine guide rail in a sliding manner and used for welding the to-be-welded workpiece. According to the assembling and welding mould, the two chucks are used for clamping the to-be-welded workpiece, so that transverse positioning of the to-be-welded workpiece is achieved, and the positioning process is simple, rapid and accurate; the chucks drive the to-be-welded workpiece to rotate, so that the whole workpiece is stably overturned, and cracking, deformation or positioning failures of the workpiece in the overturning process is avoided; and the welding machine is arranged on the welding machine guide rail in the sliding manner, so that rapid welding of the to-be-welded workpiece is achieved through movement of the welding machine, the welding efficiency is high, andthe assembling and welding yield is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of polishing device and polishing method for bamboo floor processing that is easy to turn over

ActiveCN111993165BImprove polishing efficiencyReduce labor intensityEdge grinding machinesPolishing machinesPolishingWaste collection

The invention discloses a polishing device and a polishing method for processing bamboo floors which are easy to turn over. Consistent left guide cavity and right guide cavity, a waste collection cavity is provided inside the cavity of the base, a support block is fixedly installed at the midline position on the back of the base, and a vertical frame is fixedly installed on the support block , the vertical frame is fixedly provided with an overturning frame for clamping and fixing the bamboo floor, and the polishing device realizes independent overturning during the polishing process of the bamboo floor, avoiding the traditional manual overturning and reducing the labor intensity of the staff , It also improves the polishing efficiency of bamboo flooring, which is conducive to the large-scale production of enterprises.

Owner:阜南县欣园柳编工艺品有限公司

Beam body overturning device

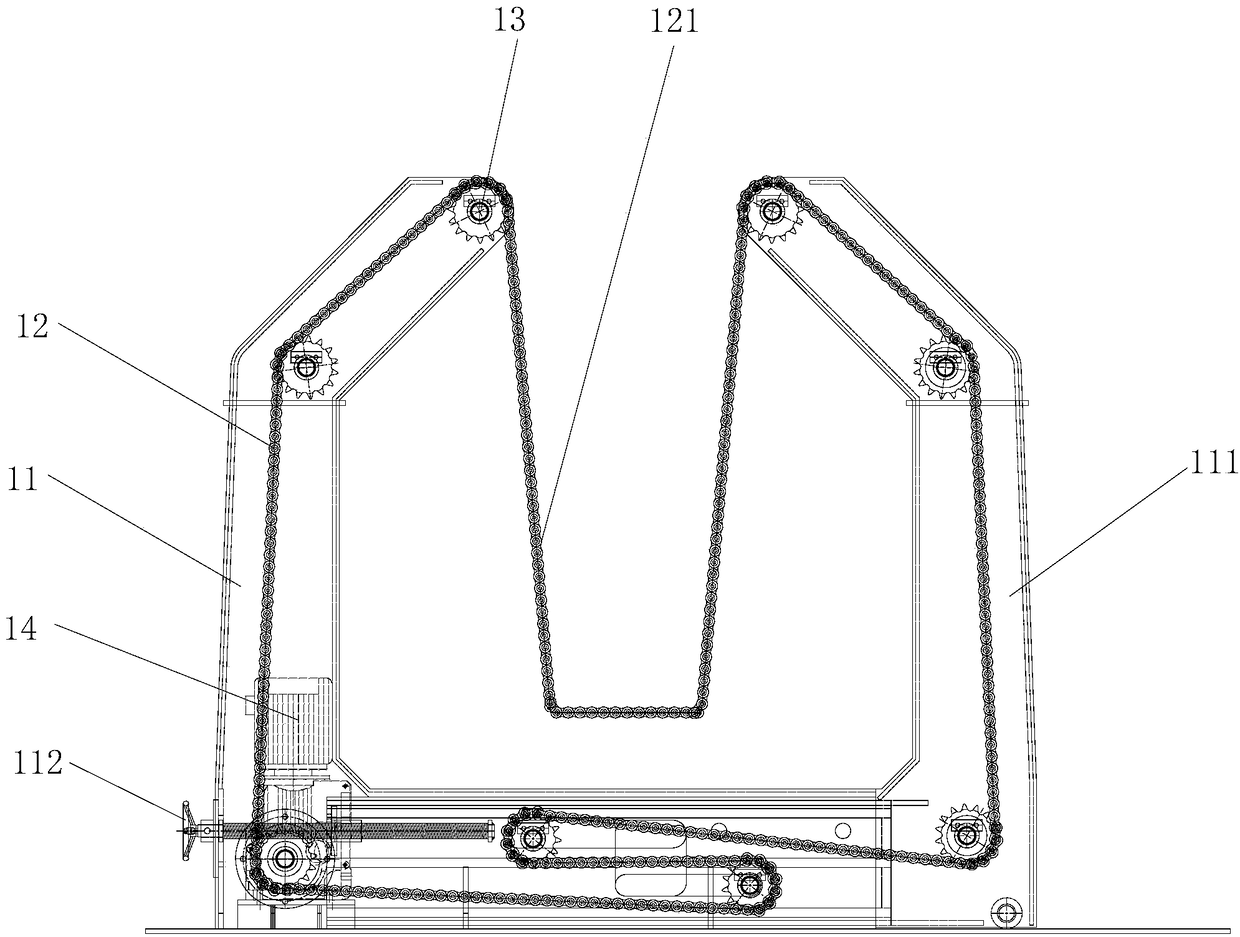

PendingCN109368567AAvoid Manual FlippingSimple structureLifting devicesHoisting equipmentsEngineeringMechanical engineering

Owner:HUNAN WUXIN MACHINERY

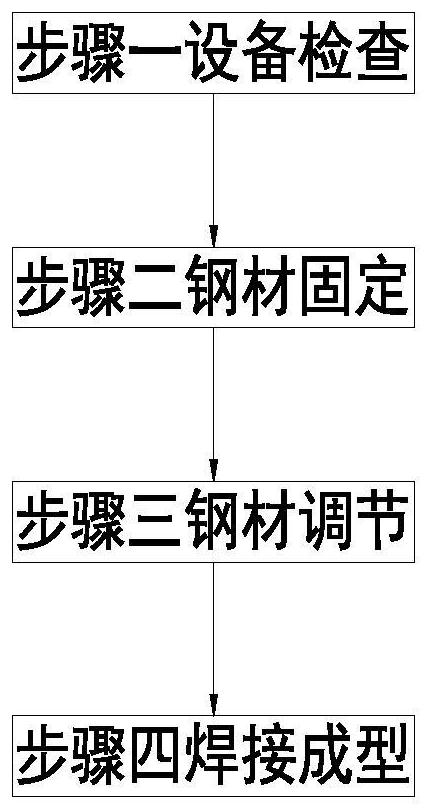

Building construction steel structure assembly machining method

InactiveCN112846561AIncrease workloadEvenly distributedWelding/cutting auxillary devicesAuxillary welding devicesConstruction engineeringRebar

The invention relates to a building construction steel structure assembly machining method which mainly comprises the following steps of equipment inspection, steel fixing, steel adjusting and welding forming. Building construction steel structure assembly manufacturing equipment comprises a mounting base plate, a fixing suite and an adjusting suite, wherein the fixing suite is mounted on the mounting base plate, and the adjusting suite is arranged on the outer side of the fixing suite. The method can solve the following problems during production of existing steel structure buried parts: a, existing buried parts are often aligned manually during splicing, so that reinforcing steel bars are often not uniformly distributed and are prone to inclination, and great potential safety hazards exist; and b, an existing buried part is usually welded in a manual welding mode, then the buried part needs to be turned over to be welded after one side of the buried part is welded, the situation that the angle of a reinforcing steel bar deflects frequently occurs, manual rotation is needed, the workload of workers is greatly increased, and manpower is wasted.

Owner:南京嘉奋棠建筑科技有限公司

Grain airing device based on solar energy

ActiveCN113606875AGuaranteed drying effectImprove Flip EffectDrying solid materials with heatFood processingThermodynamicsHeat conducting

The invention relates to the technical field of solar energy, and discloses a grain airing device based on solar energy. The grain airing device comprises an airing table, supporting legs are arranged at the two ends of the bottom of the airing table, sliding grooves are formed in the left end and the right end of the airing table, a first rectangular groove and two second rectangular grooves are formed in each of the front end and the back end of the airing table, and the four second rectangular grooves are formed above the two first rectangular grooves correspondingly. According to the grain airing device, heat conducting pieces are arranged, external sunlight irradiates the heat conducting pieces, heat is transmitted along a transverse rod and a heat conducting rod, after air in an air bag is heated, the size is increased, the air bag is supported, thus a magnetic bead can be moved upwards and jacked through the air bag, a rubber supporting film is deformed, and the grain airing effect can be guaranteed; and when the magnetic bead slowly moves upwards, the magnetic bead can attract knocking balls, the knocking balls drive the middle of a pull rope to move downwards, accordingly, the rubber supporting film can be driven to shake, and the overturning effect of grains on the rubber supporting film is better.

Owner:南京尚科得科技发展有限公司

Safety device for formation and sub-capacity of lithium ion battery

ActiveCN102881942BAvoid short circuitAvoid manual flippingFinal product manufactureCell component detailsElectrical batteryLithium-ion battery

A safety device for lithium-ion batteries, including a cabinet body; at least one row of battery compartments are arranged in the cabinet body, the upper end of the battery compartment is open, and the battery compartment is composed of an insulating fireproof layer on the inner layer and a stainless steel layer on the outer layer ; The battery compartments are connected in series through shafts to form a battery compartment row. The two ends of the battery compartment row are respectively provided with rotating shafts, and both ends of the rotating shaft pass through the side wall of the cabinet body; Battery positioning mechanism. The present invention uses a battery compartment with a two-layer structure so that the battery has a good insulation effect from the outside world, and avoids short-circuiting of the battery due to careless operation by personnel or other accidents. The battery compartment with a two-layer structure also has a high explosion-proof capability; by using the structure of the battery compartment's rotating shaft, the battery can be turned over at multiple angles during the static stage (to improve the effect of electrolyte infiltration), avoiding the need for manual handling of the batteries one by one. Flip, the workshop production efficiency is greatly improved.

Owner:NINGBO SHIJIE NEW ENERGY TECH

Small conveying device for plastic product packaging

The invention provides a small conveying device for plastic product packaging, and relates to the technical field of material packaging, supplying and conveying. A conveying belt A is arranged at the front end of the top of the assembly base, the rear end of the conveying belt A is designed to be of an oblique angle, the middle of the top of the assembly base is fixedly connected with the bottom of the placement base, and the front lower portions of the two sides of the placement base are each fixedly connected with a supporting base. After the plastic products are turned over by 90 degrees through the cooperation of the guide conveying belt, the plastic products at the front end of the conveying belt A are conveyed to the top position of the guide conveying belt after the guide conveying belt is reset through the two guide air cylinders; and then the turned plastic products are conveyed to the top position of the conveying belt B through the guide conveying belt. The problem that in the plastic product conveying step, materials are prone to shifting and turning over, and consequently the plastic products need to be turned over manually when being conveyed to the packaging link in an inverted state is solved.

Owner:南通博宸精密制造有限公司

Turnover device

PendingCN111267053AAvoid manual turning of workpiecesReduce manual laborWork benchesPhysicsMoving parts

The invention provides a turnover device. The turnover device comprises turnover parts, a shifting part and a supporting platform. The shifting part is arranged on the supporting platform. The turnover parts can move on the supporting platform. Each turnover part comprises a first moving part, a second moving part, a third moving part, a first auxiliary part and a second auxiliary part, and a motion path of the first moving part, the second moving part and the third moving part on the supporting platform serves as a first path. A workpiece to be turned over is connected to the turnover parts.The shifting part comprises a first protrusion and a second protrusion which are located on the first path. When the turnover parts are in a first state, the shifting part is located on the advancingpath of the turnover parts and at the junctions where the first moving parts and the first auxiliary parts are connected with the supporting platform, the second moving parts are located on the sides,close to the shifting part, of the second moving parts, and the second moving parts are separated from the supporting platform. When the turnover parts is in a second state, the workpiece to be turned over is turned over by 90-270 degrees. Through the turnover device, manual turnover of workpieces can be avoided, manual labor of staff can be reduced, the production efficiency can be improved, andthe working procedures can be simplified.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com