Safety device for formation and sub-capacity of lithium ion battery

A lithium-ion battery and safety device technology, which is applied in the manufacture of battery pack components, non-aqueous electrolyte batteries, and electrolyte batteries, can solve unfavorable lithium-ion battery safety production and management issues, and achieve simple and efficient production processes and high explosion-proof ability, the effect of good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

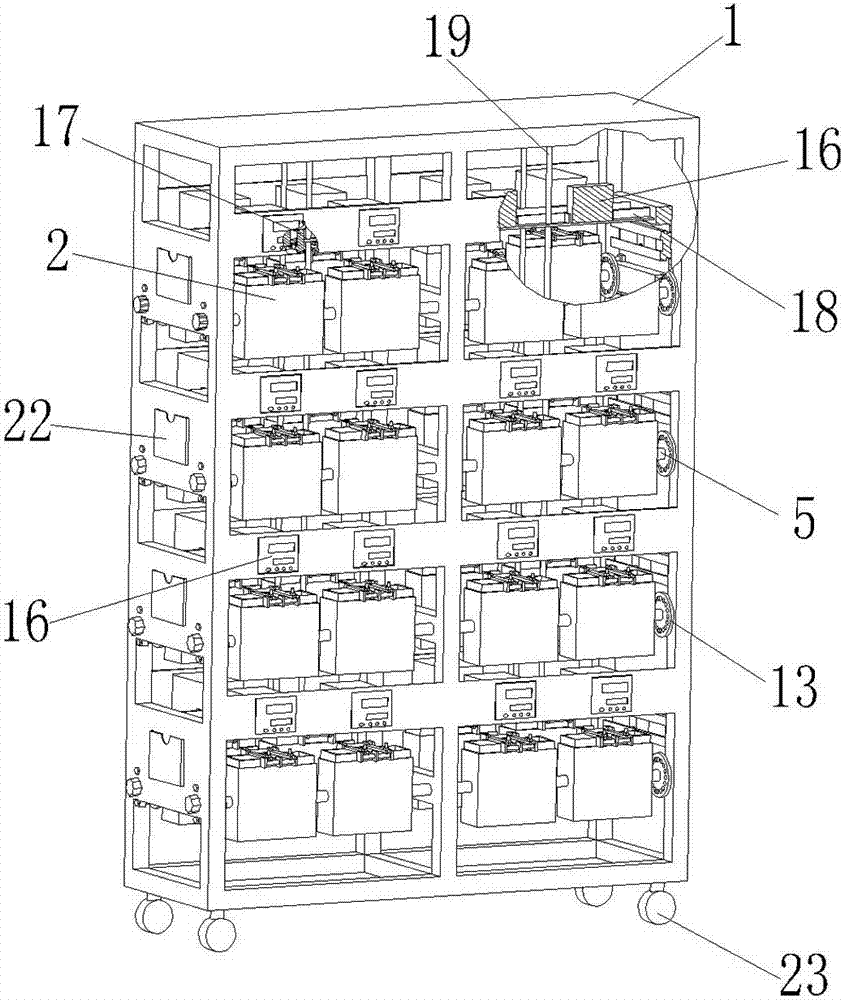

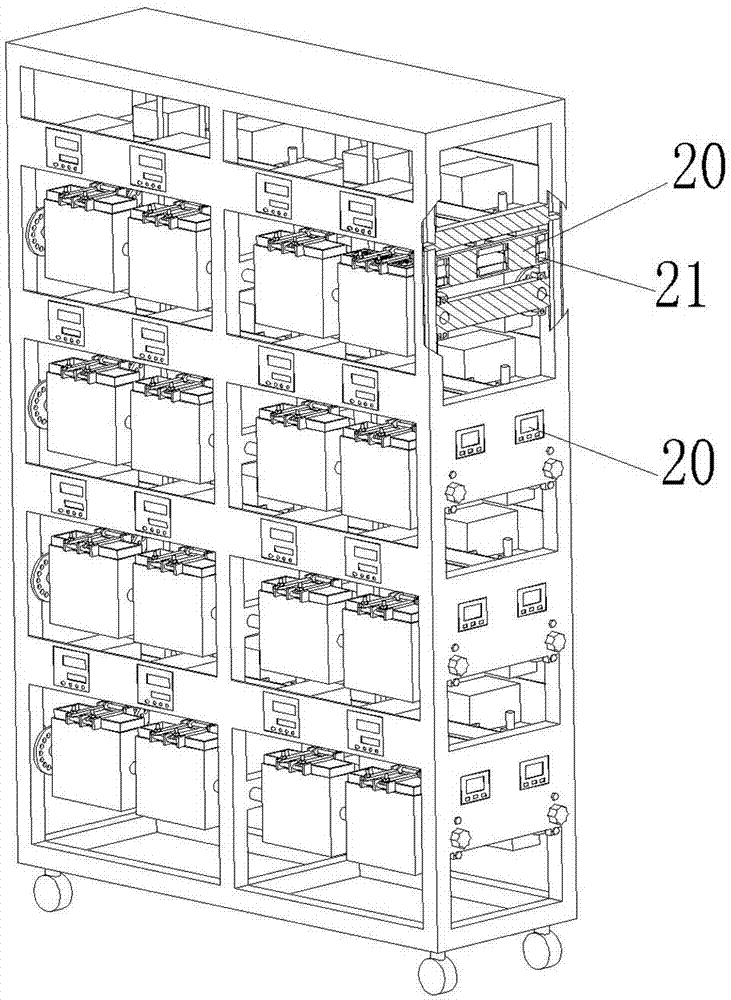

[0027] refer to Figure 1~Figure 5 , a safety device for lithium-ion battery formation and capacity, including a cabinet 1;

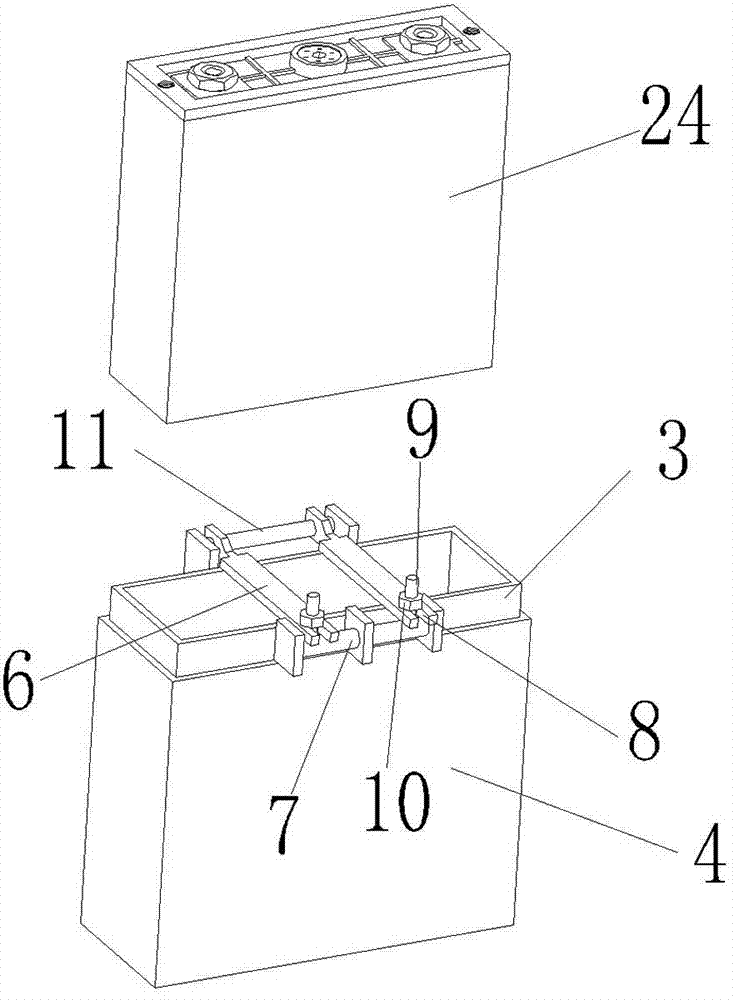

[0028] The cabinet body 1 is provided with four rows of battery compartments, the upper end of the battery compartment 2 is open, and the battery compartment 2 is composed of an inner insulating fireproof layer 3 and an outer stainless steel layer 4; between the battery compartments A battery compartment row is formed by connecting shafts in series, and the two ends of the battery compartment row are respectively provided with a rotating shaft 5, and both ends of the rotating shaft 5 pass through the side wall of the cabinet body 1;

[0029] The upper end of the battery compartment is provided with a battery positioning mechanism for positioning the battery. In this embodiment, the specific structure of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com