Patents

Literature

34 results about "Procedure site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

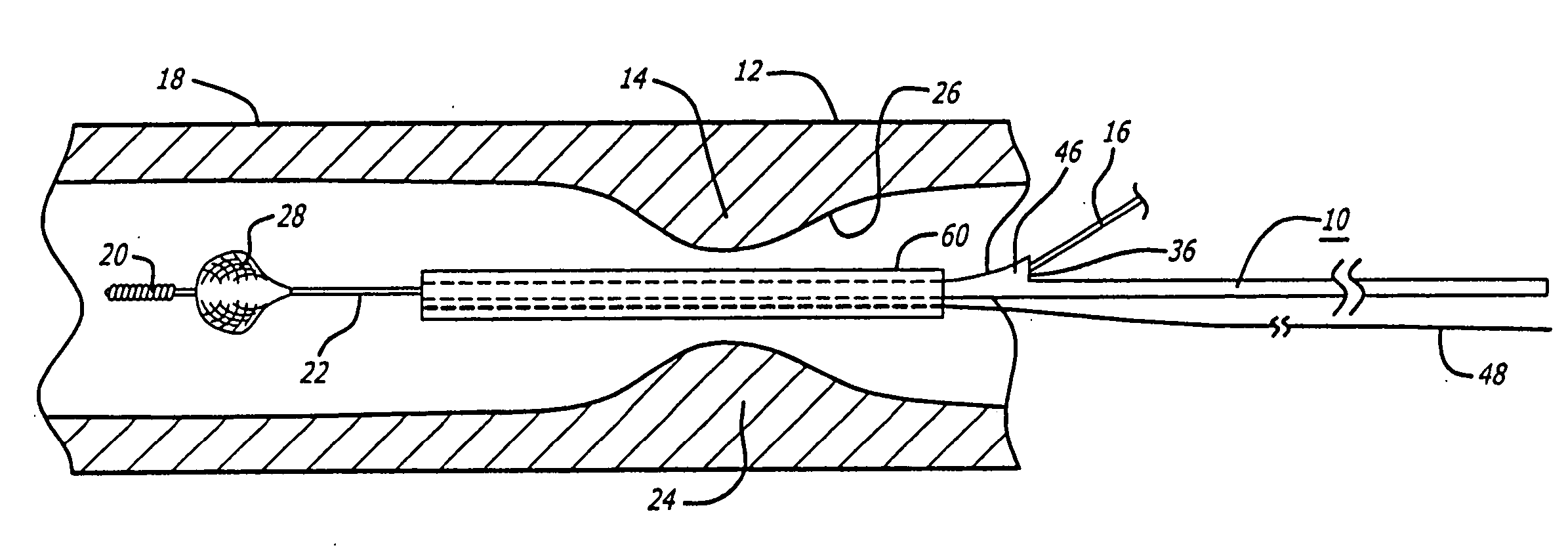

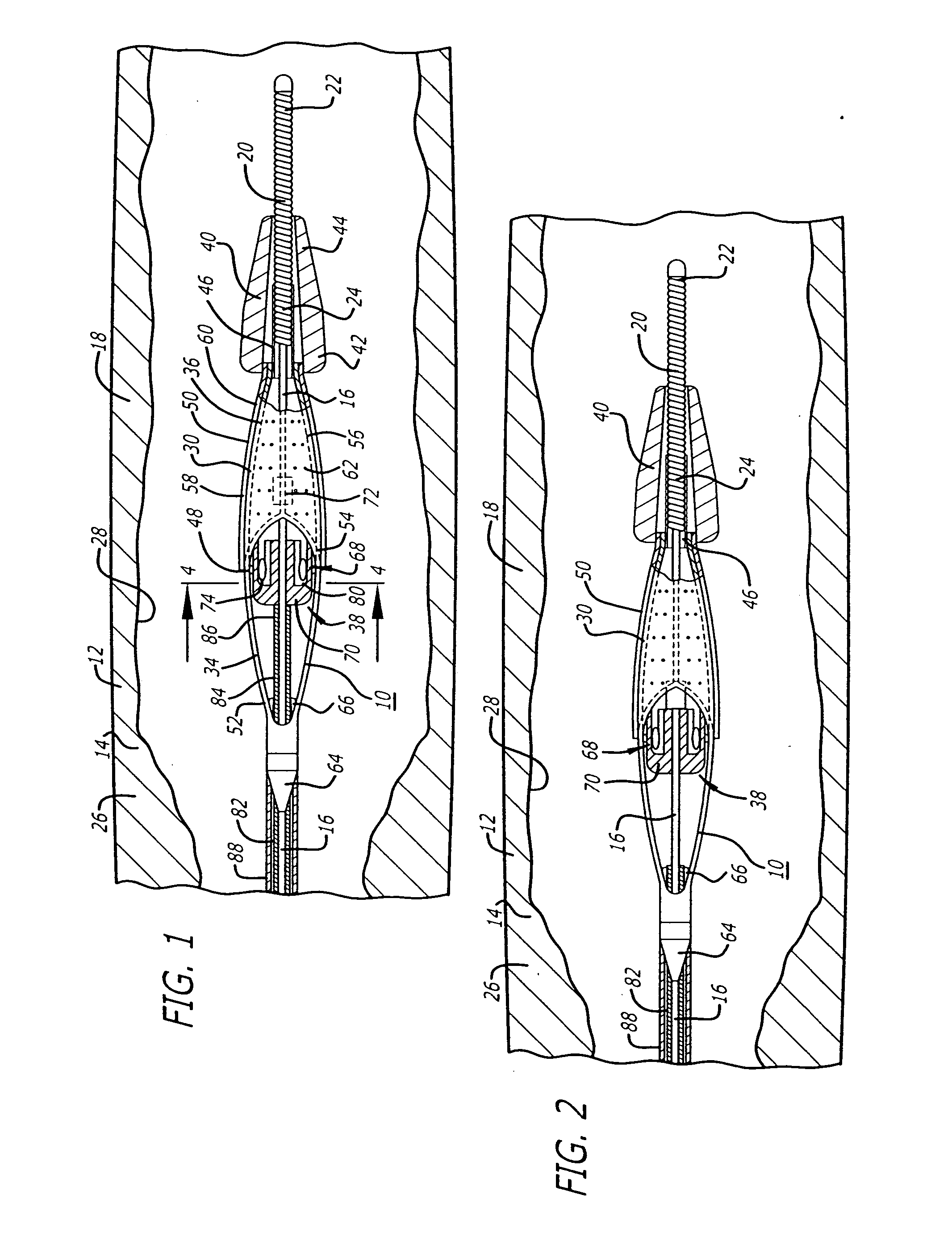

Vessel occlusion device for embolic protection system

A system used in a blood vessel when an interventional procedure is being performed in a stenosed or occluded region, which is capable of capturing embolic material which may be released into a blood vessel during a therapeutic interventional procedure at the site of a lesion in the blood vessel. The system is adapted to be utilized in a collateral blood supply system adapted to enable the flow of blood to bypass the blood vessel upon blocking thereof and to enable the reverse flow of blood through the blood vessel upon unblocking thereof. The system includes a guide wire, including a distal end, adapted to be positioned in a blood vessel relative to an interventional procedure site. A guide catheter, including a distal end, is adapted to enable the interventional procedure to be performed, and to be inserted over the guide wire and through a patient's vasculature to a position in the blood vessel relative to the interventional procedure site. An occluding device for occluding and blocking a blood vessel at a location relative to the interventional procedure site is adapted to be positionable at a location relative to he interventional procedure site, to be expandable so as to prevent and block the flow of blood past the occlusion, and to enable the capture of embolic material which may be released into the blood in the blood vessel during the therapeutic interventional procedure, and to be contracted to unblock the blood vessel and enable the recovery of captured embolic material.

Owner:ABBOTT CARDIOVASCULAR

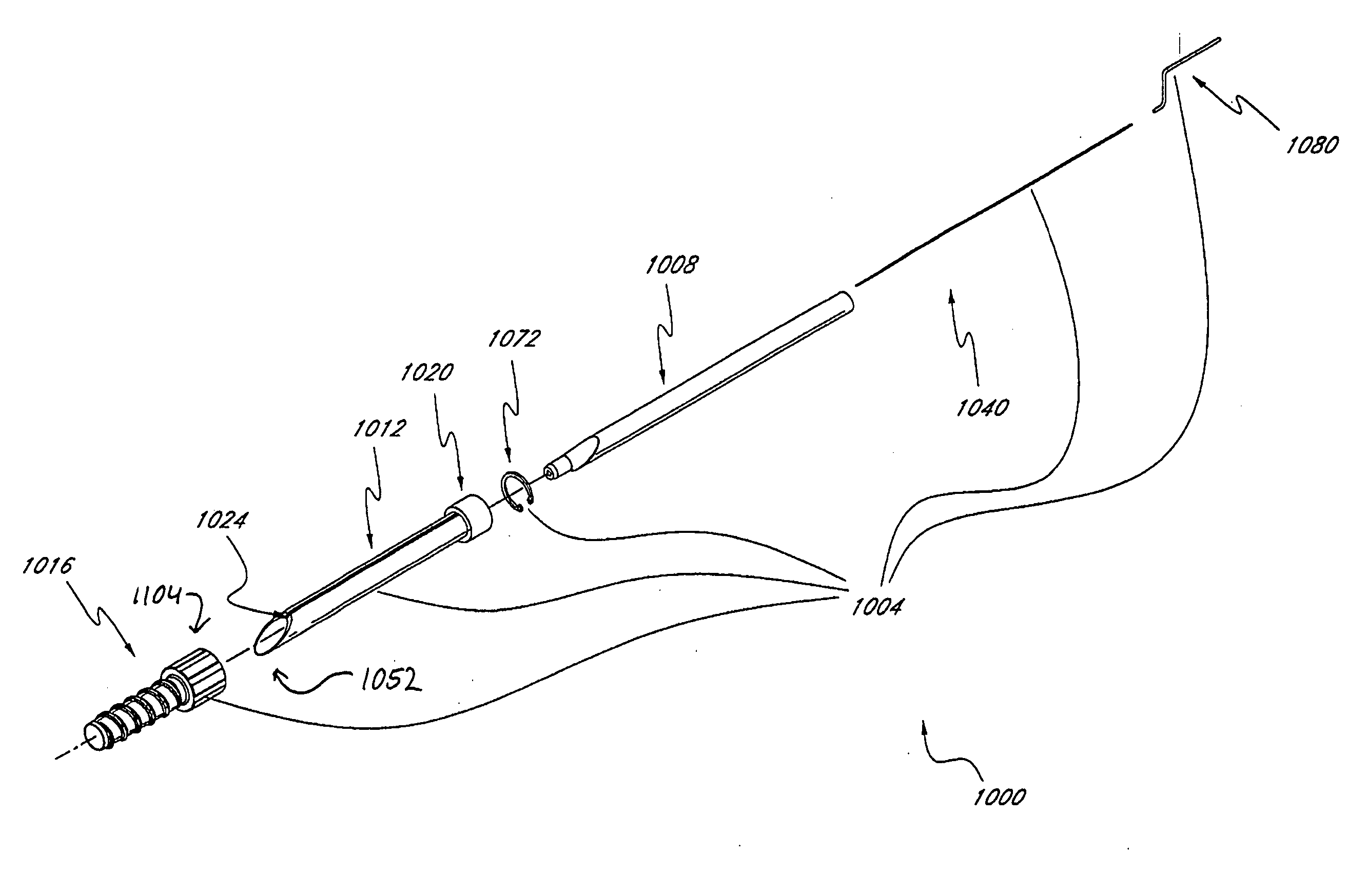

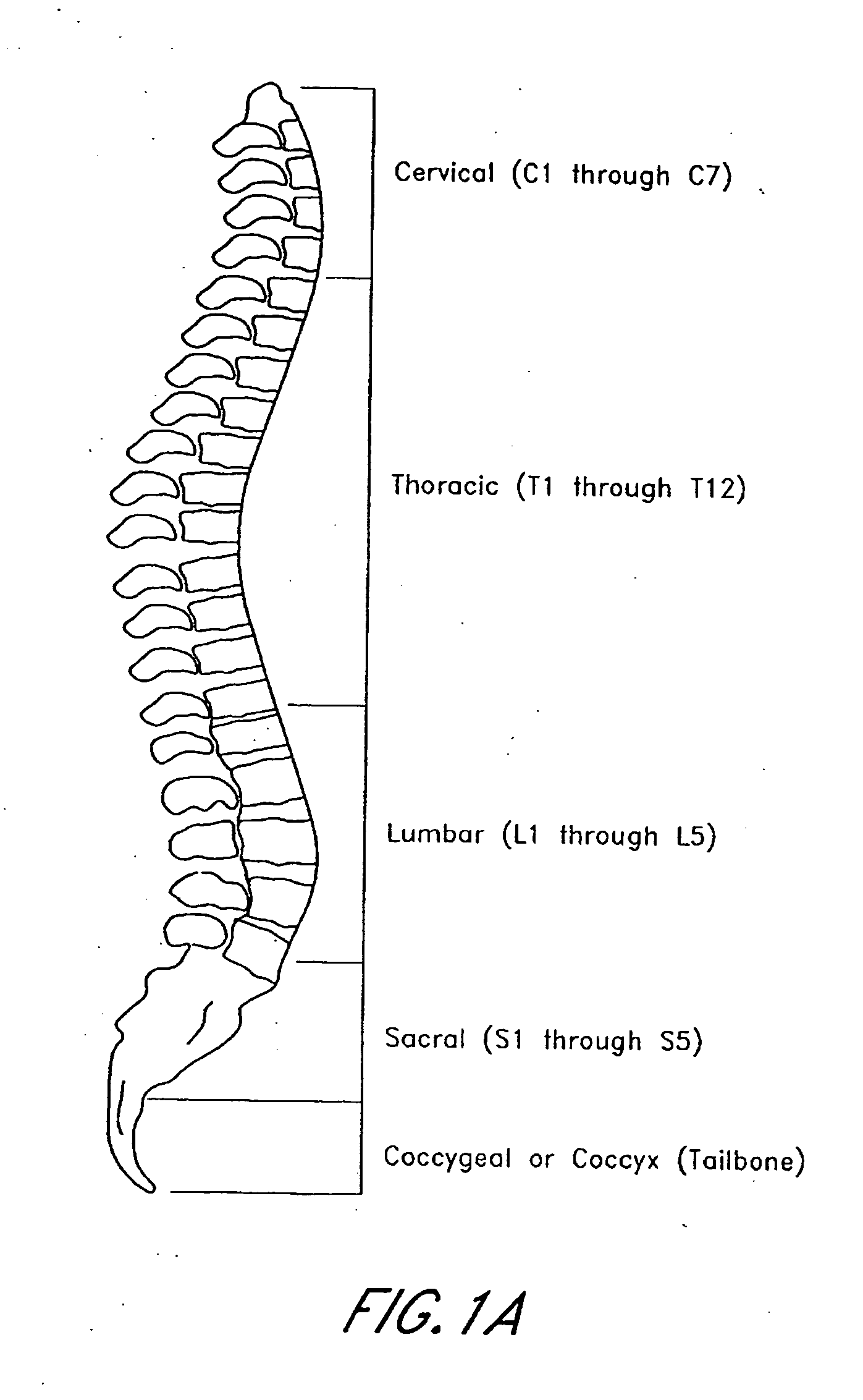

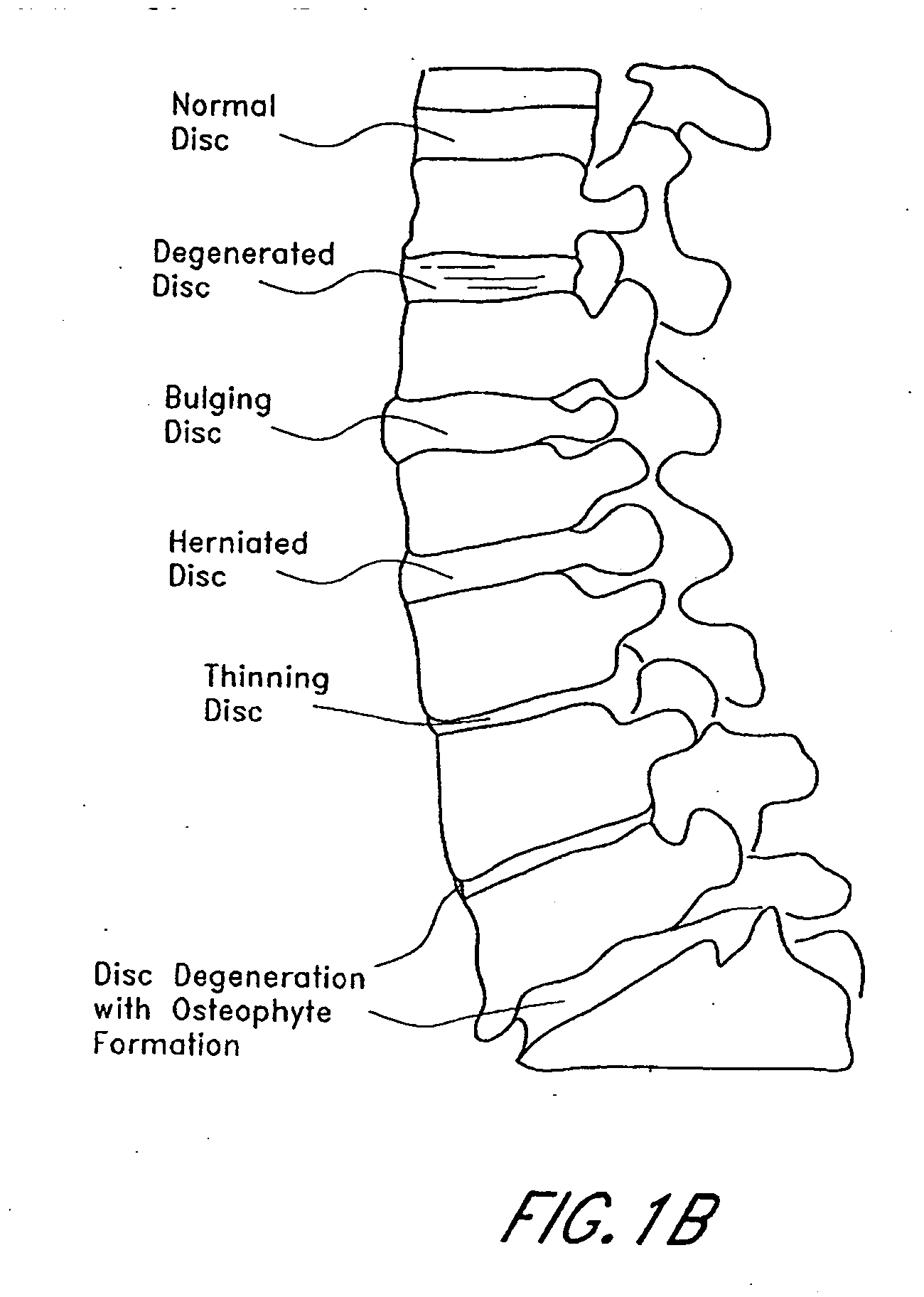

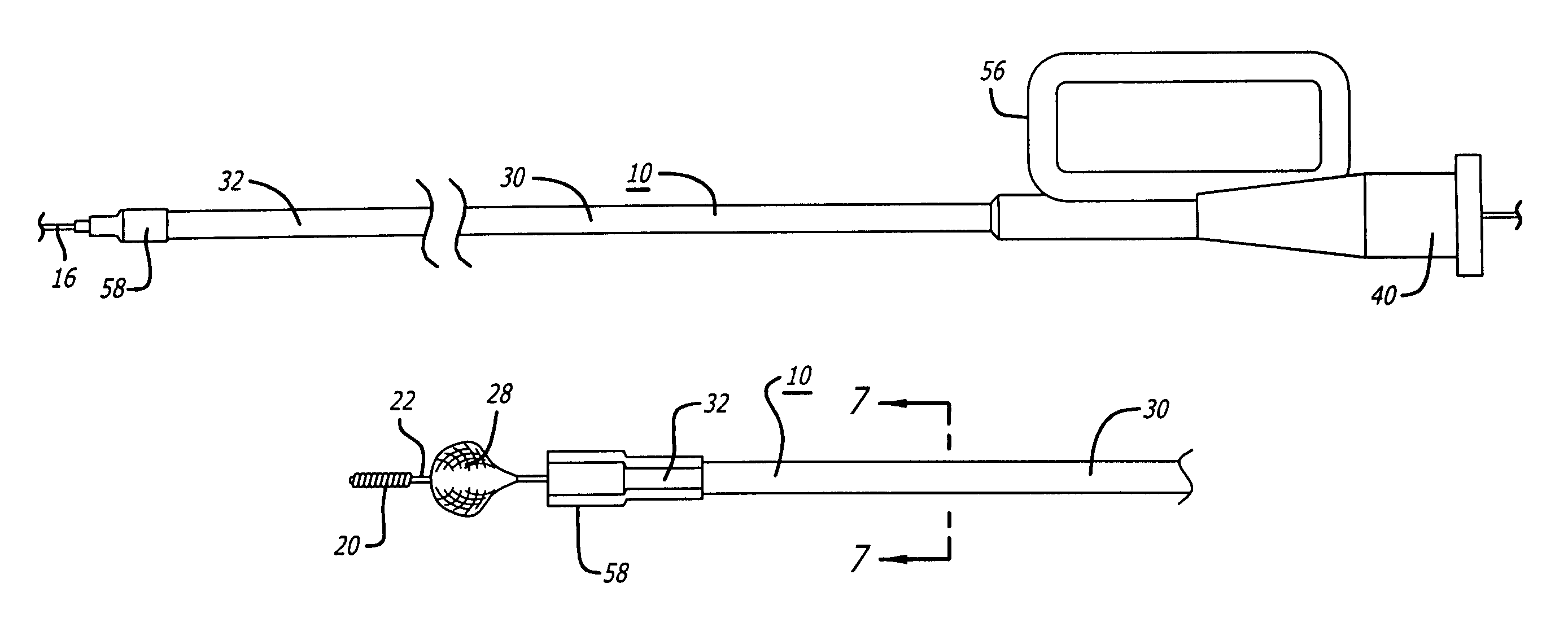

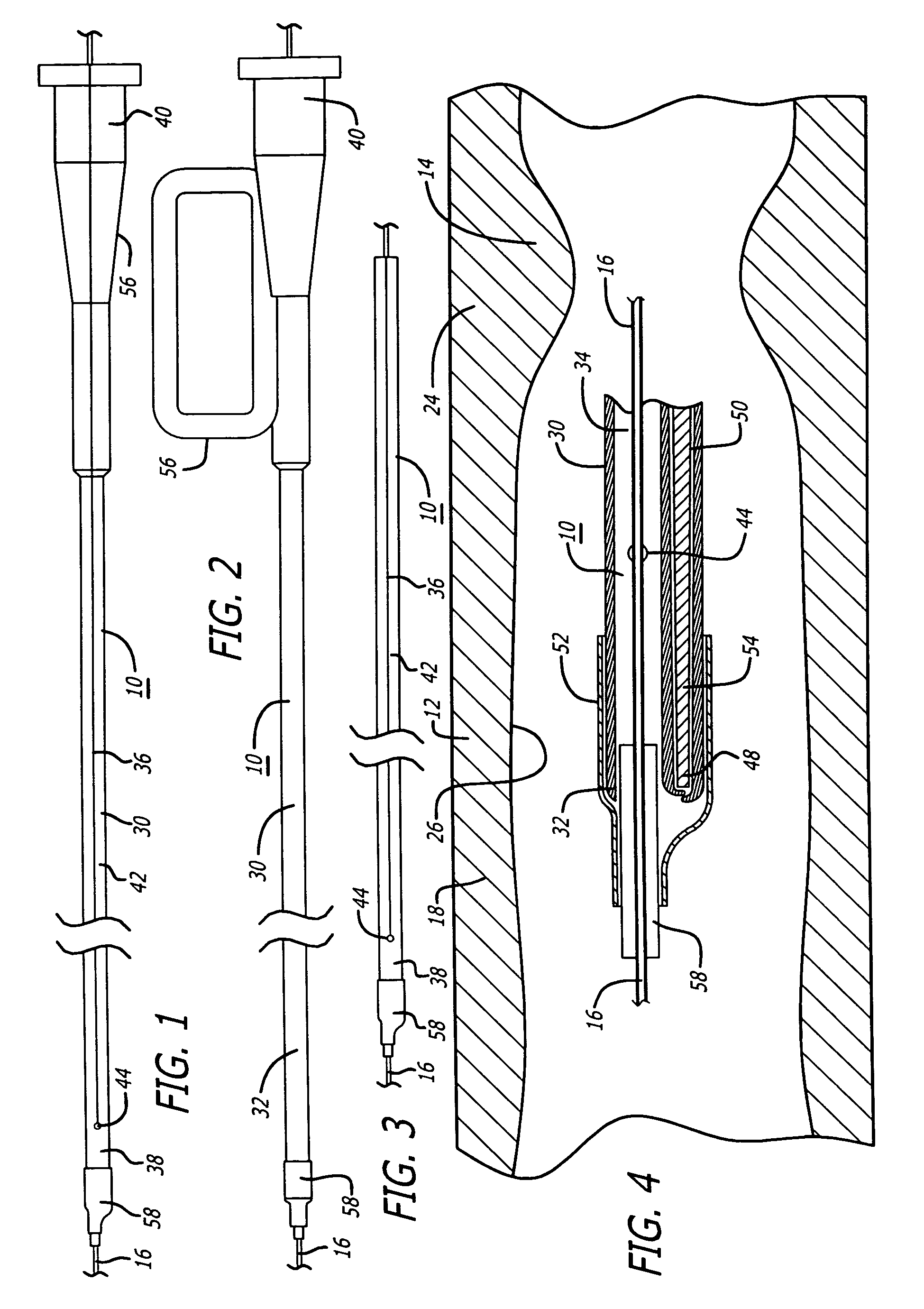

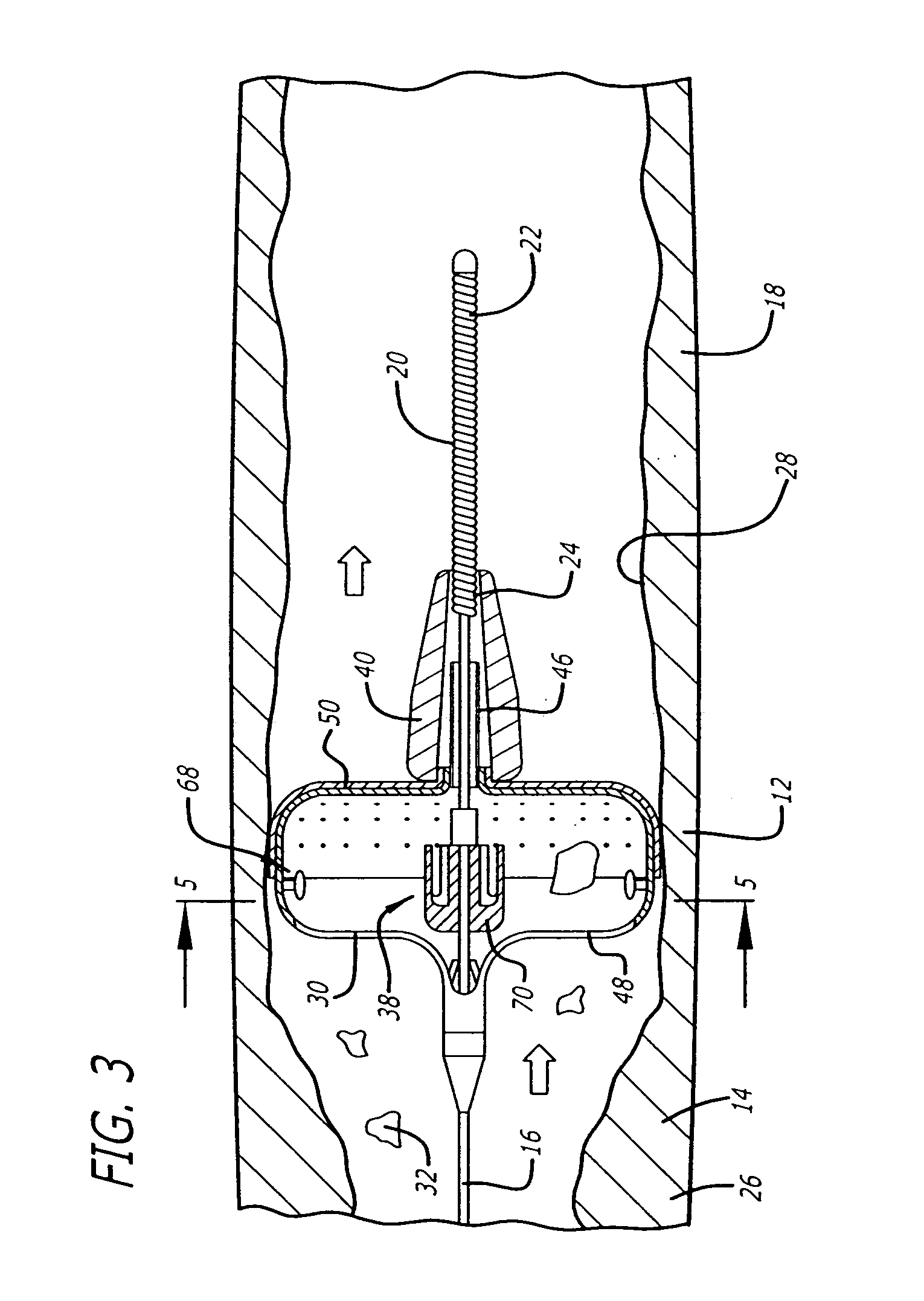

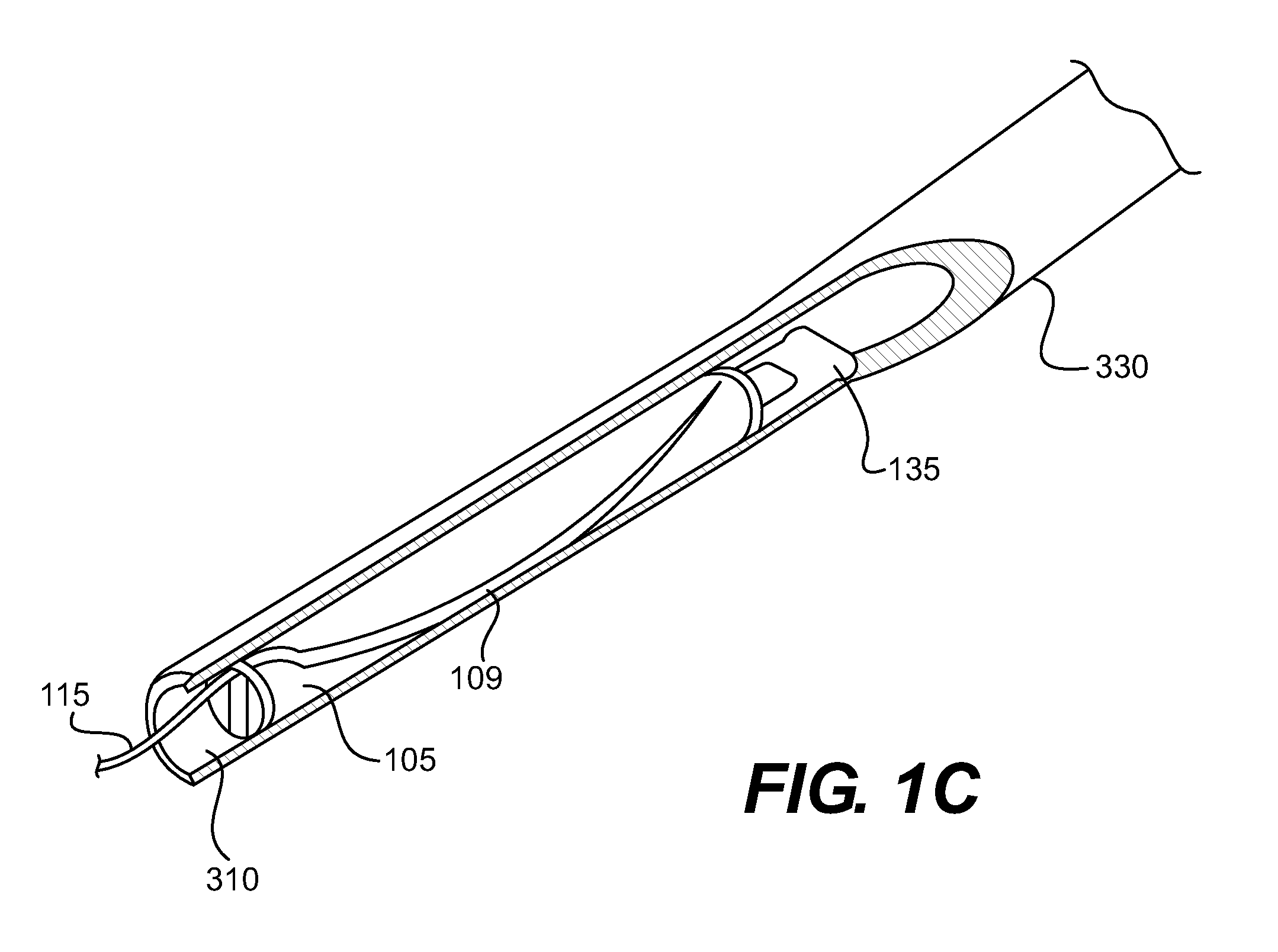

Exchange system for axial spinal procedures

InactiveUS20070066977A1Increase the cross-sectional areaInternal osteosythesisCannulasSpinal columnDrill

An exchange system is disclosed, for providing a protected path to a subcutaneous procedure site. An exchange cannula is provided with a central lumen, and a drill wire lumen that serves as a portal for a drill wire for coupling the assembly to bone. The wall thickness of the exchange cannula may be eccentric, to accommodate the drill wire lumen within the exchange cannula wall. A tensioning handle may be carried over the exchange cannula, for engaging adjacent tissue. The exchange cannula may have a proximal “T” handle. An exchange rod is movably positionable within the central lumen of the exchange cannula.

Owner:TRANS1

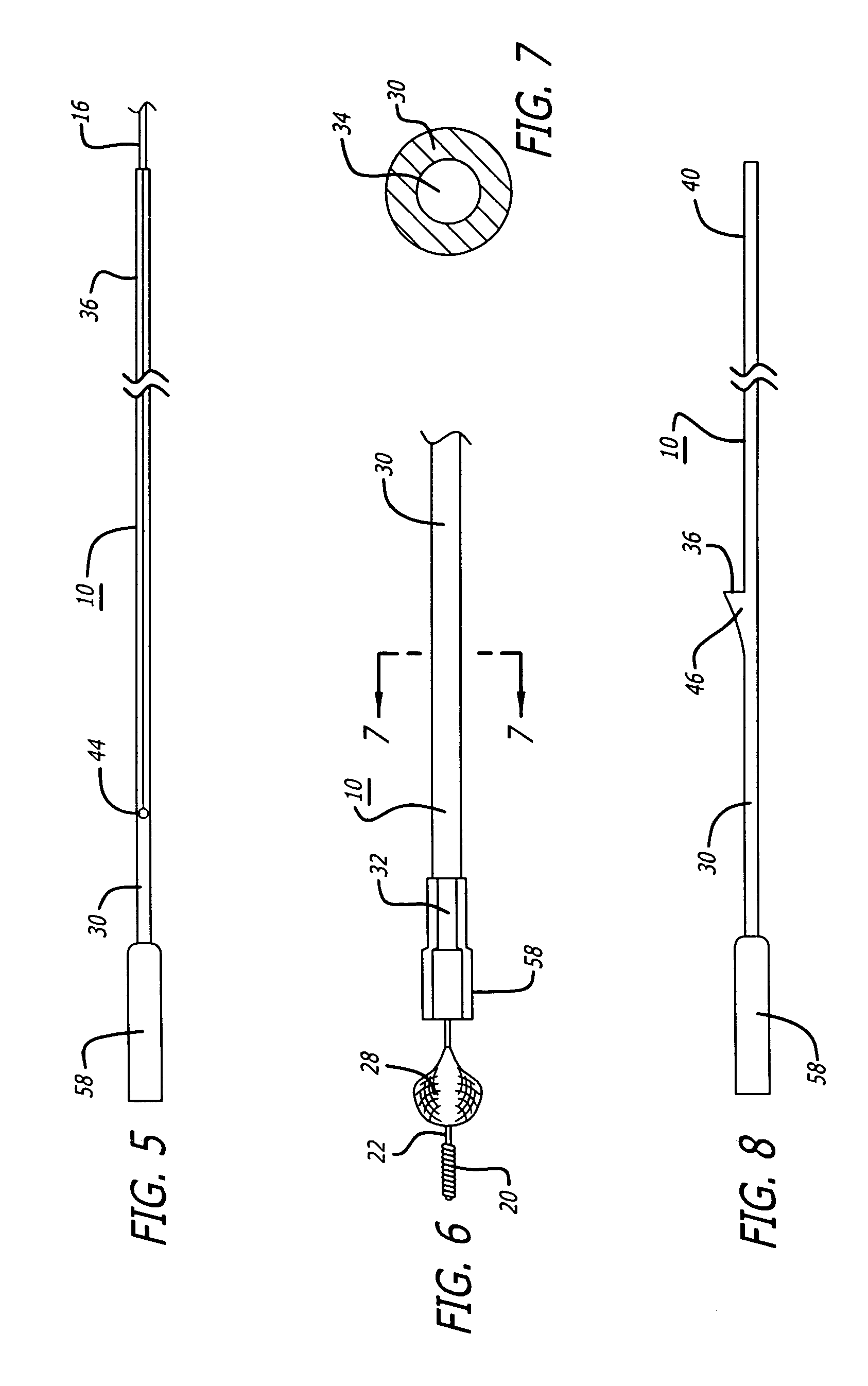

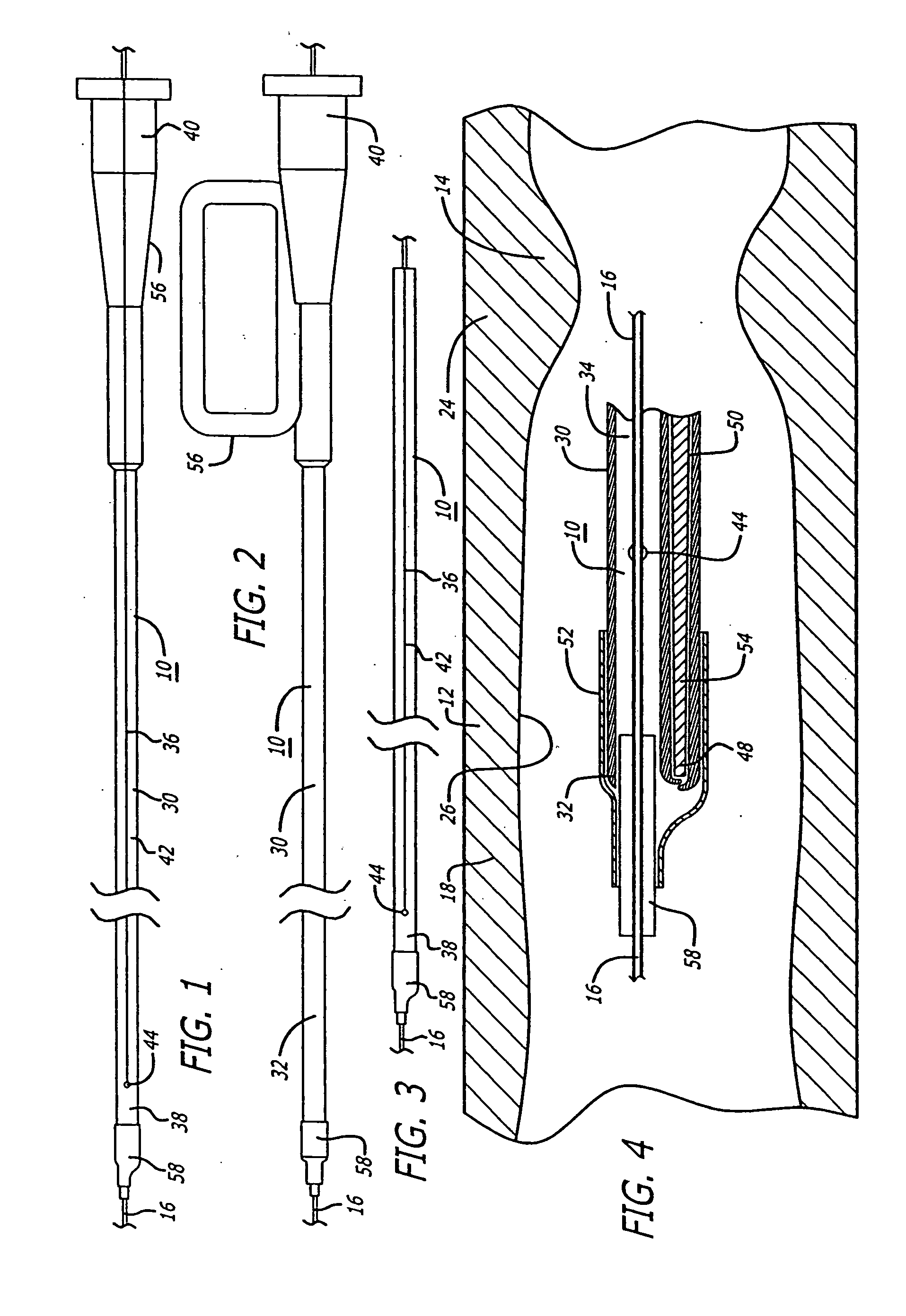

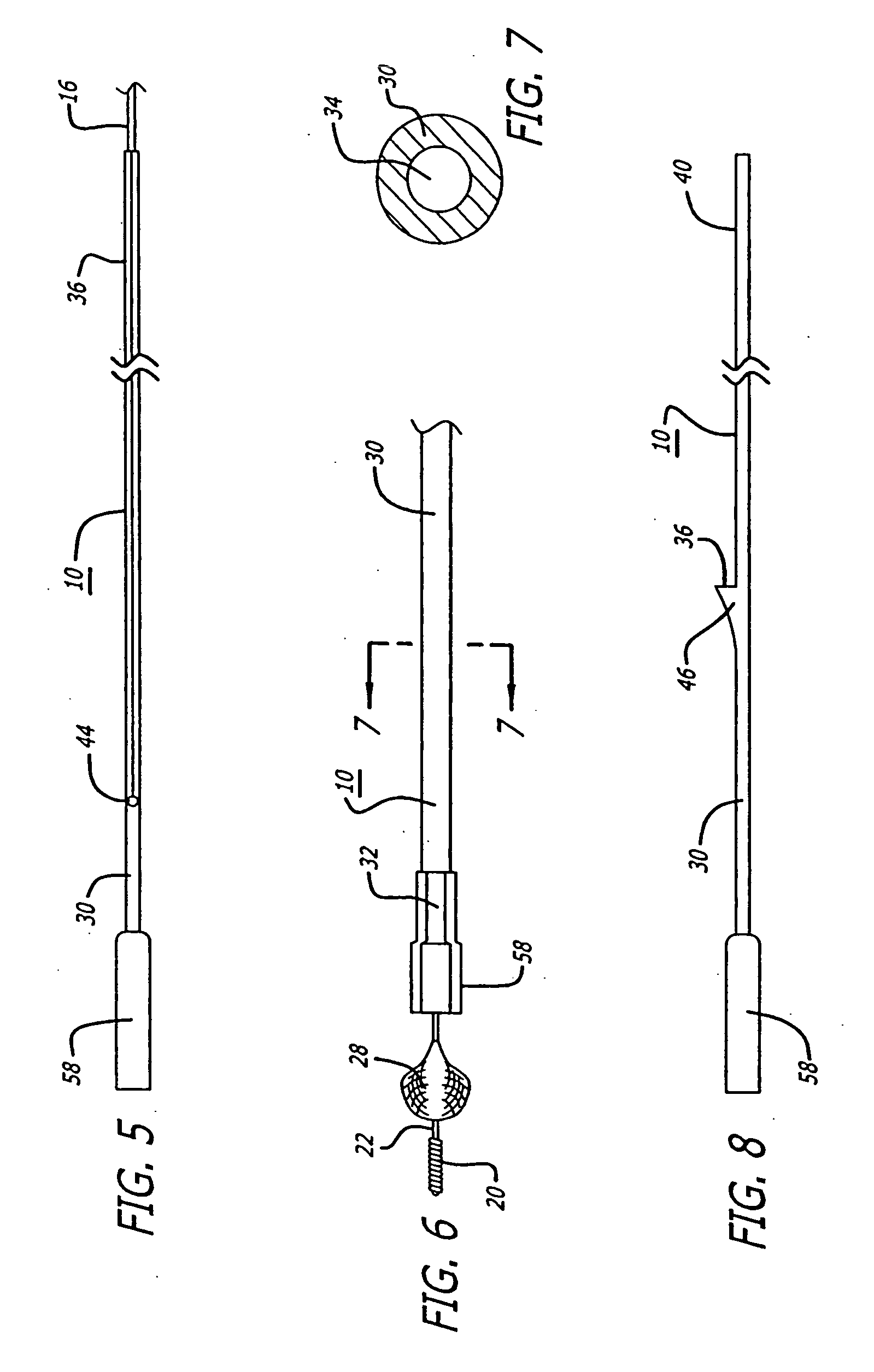

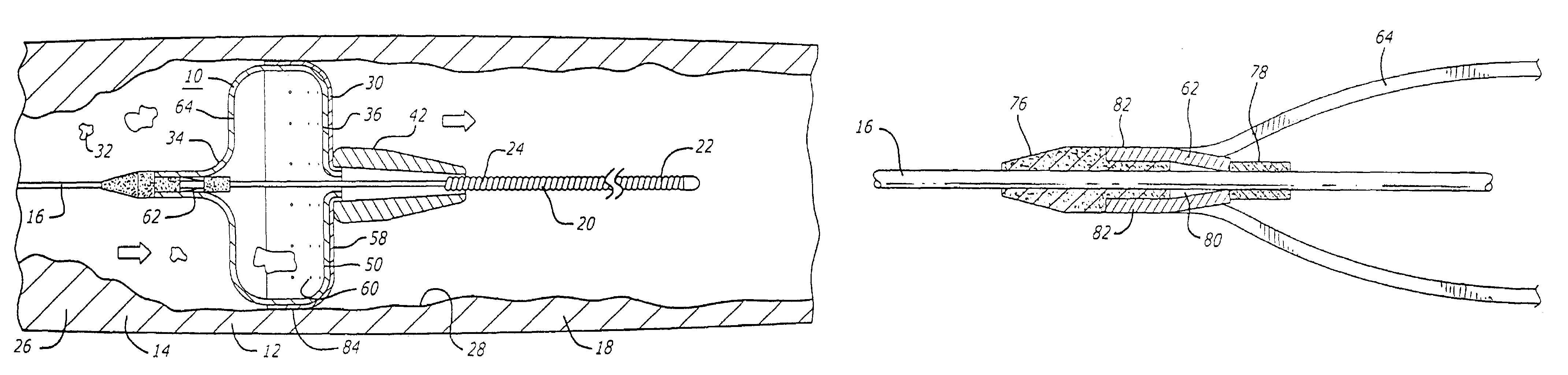

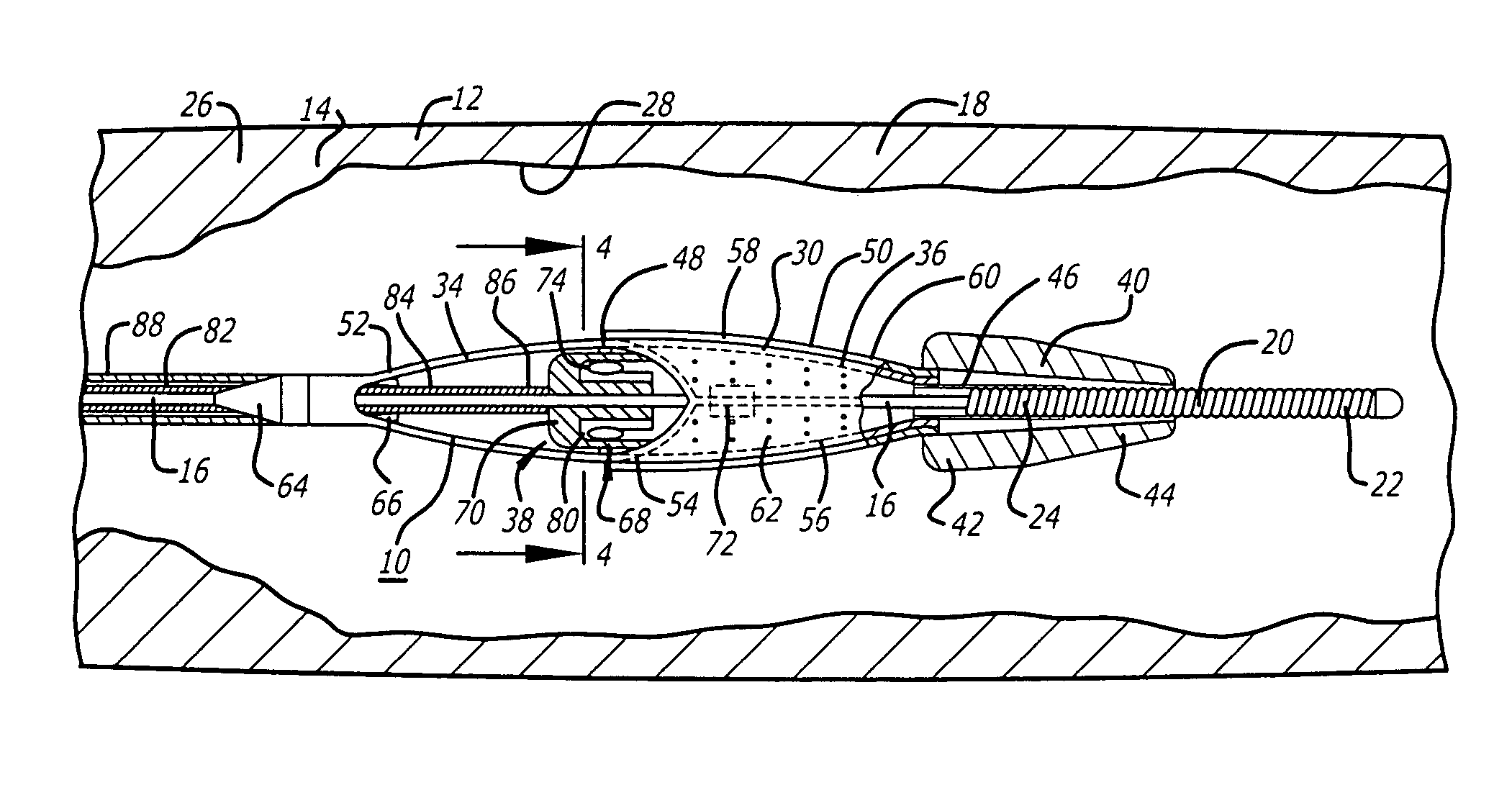

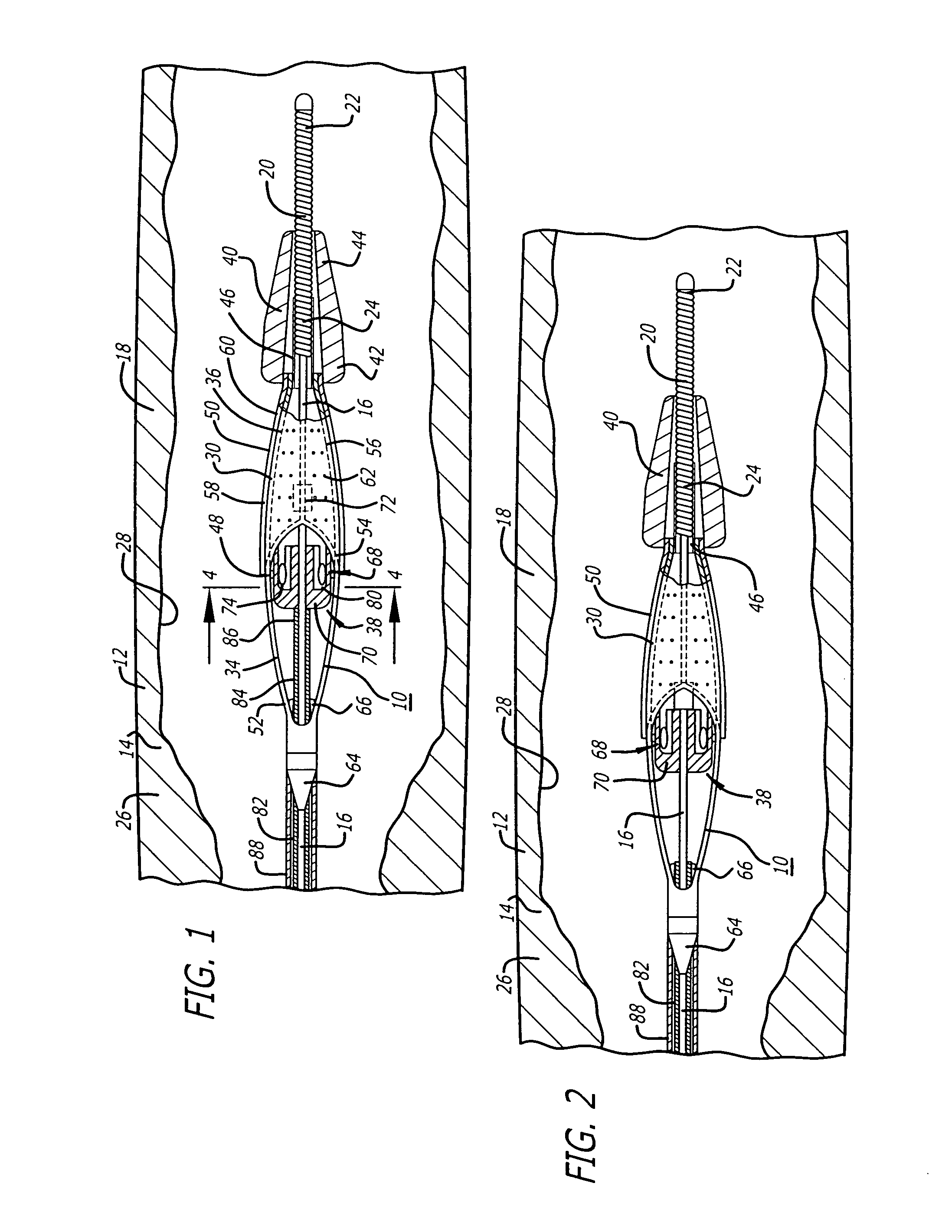

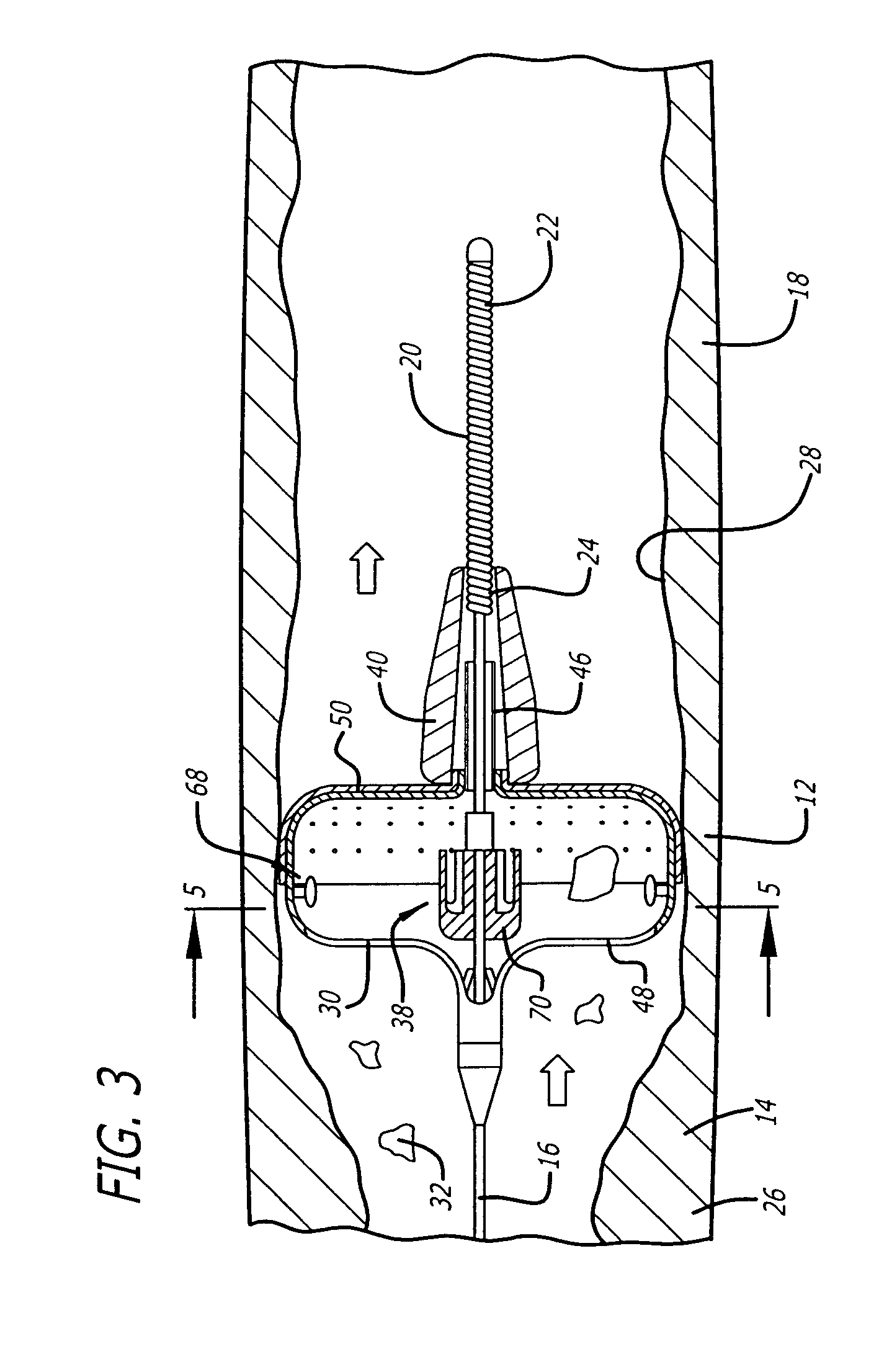

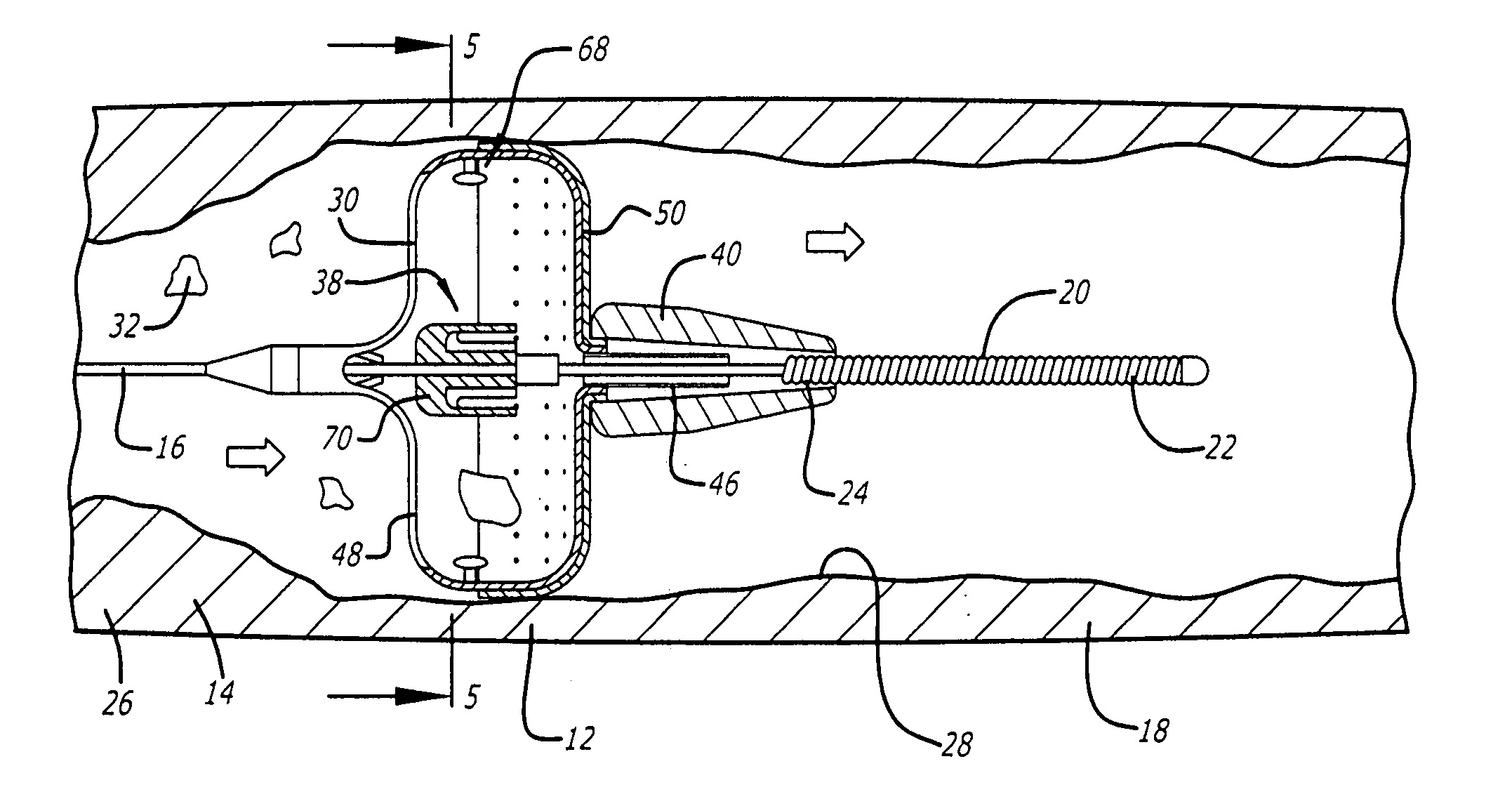

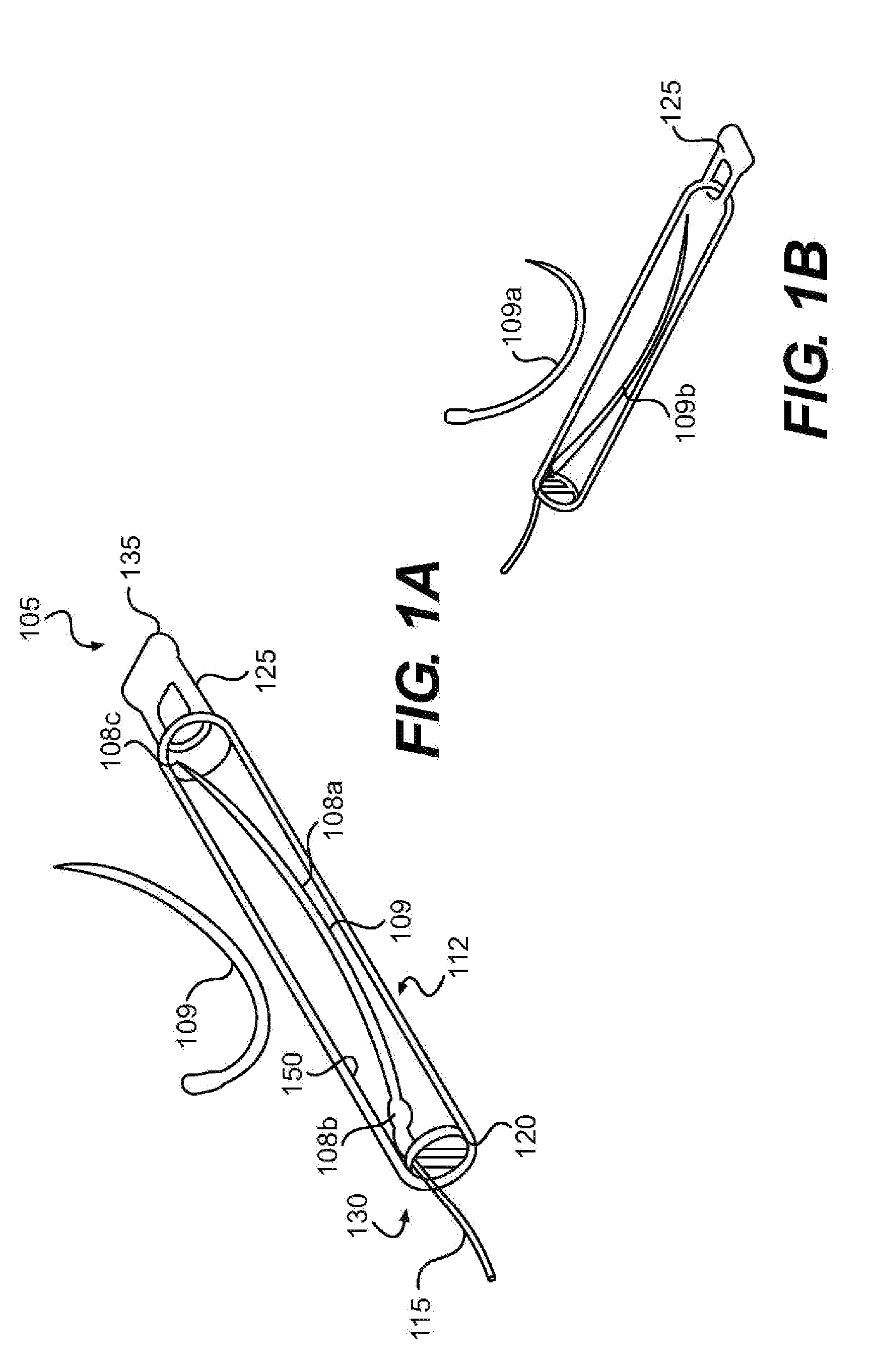

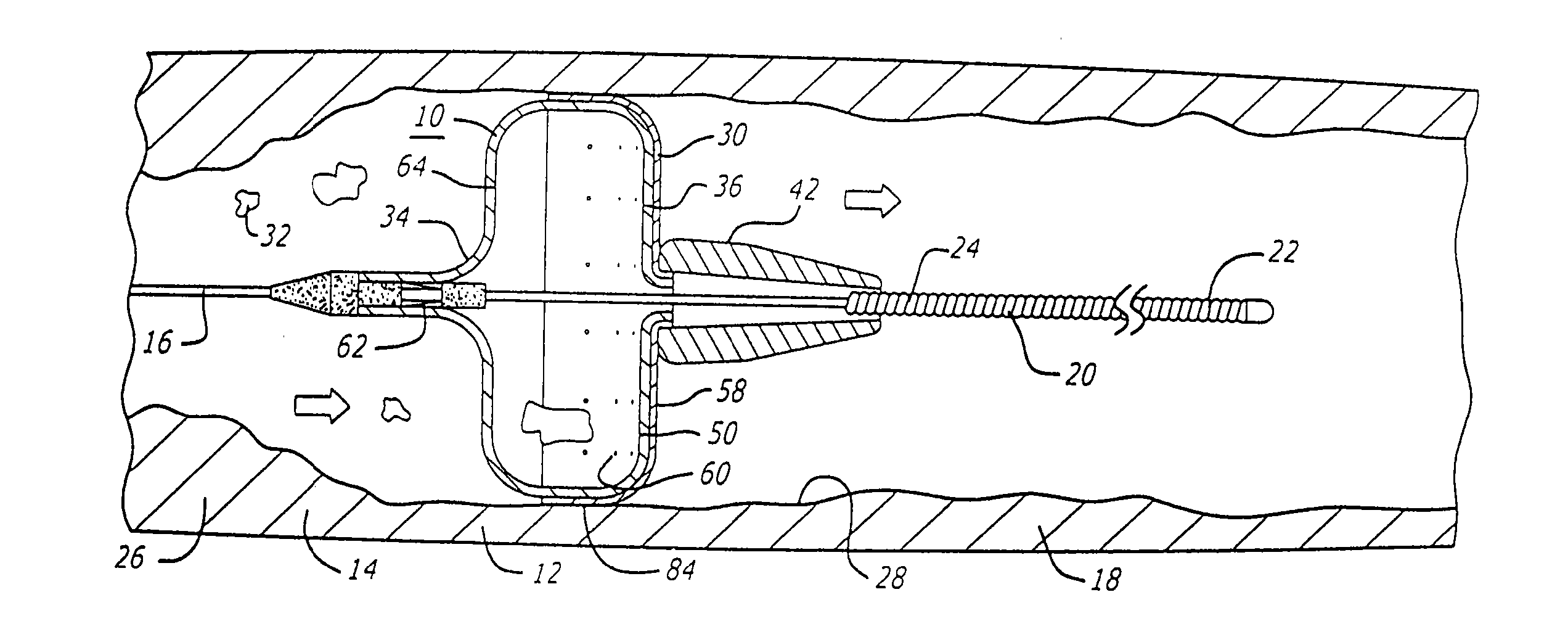

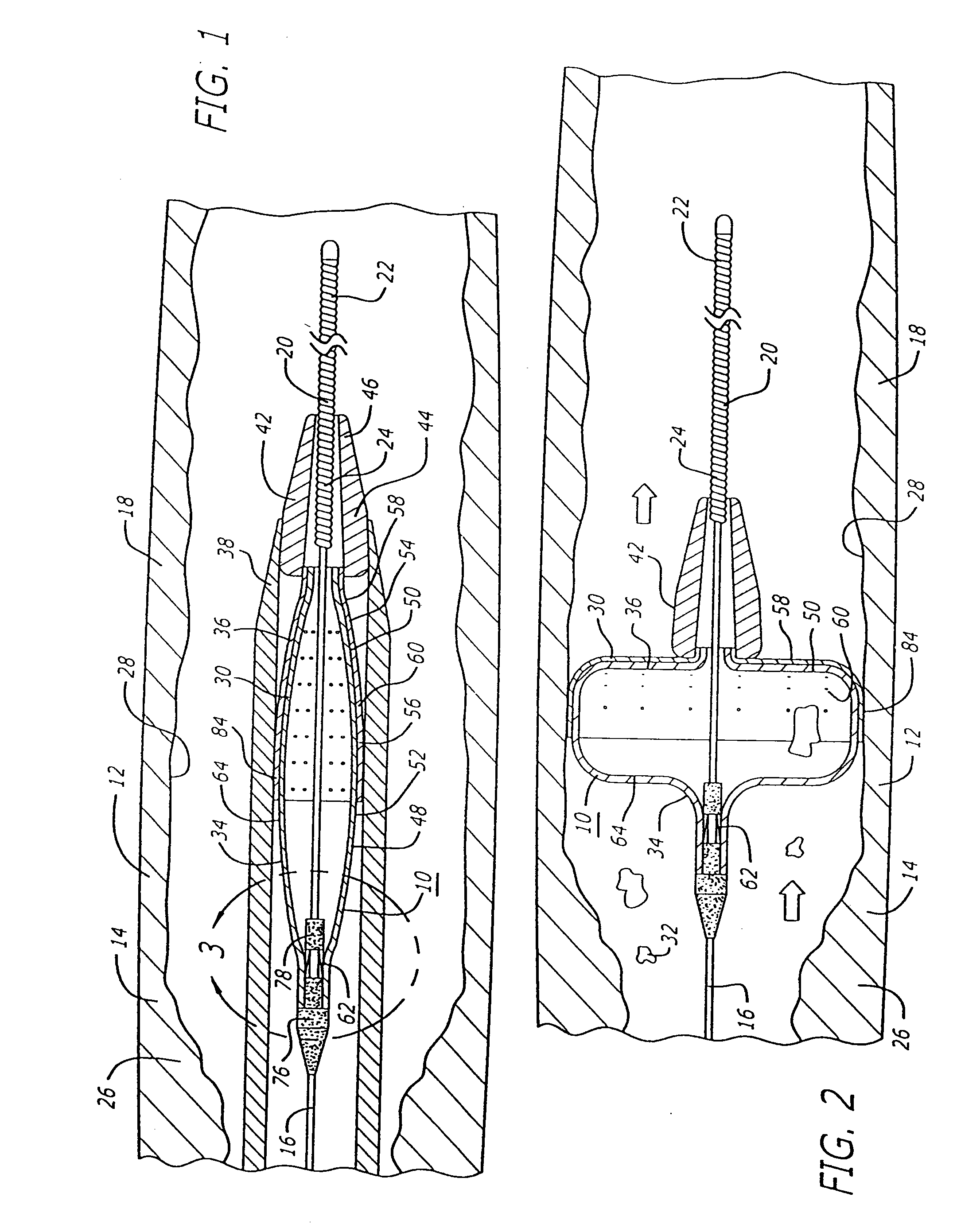

Delivery and recovery systems having steerability and rapid exchange operating modes for embolic protection systems

InactiveUS6929652B1ConfidenceImprove performanceEar treatmentSurgeryEmbolic Protection DevicesSurgical site

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which may be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, is capable of enabling at least one operator to control the delivery and removal of an embolic protection device to a position in a patient's vasculature distal to an interventional procedure site, to enable the exchange of the delivery and recovery system. The system, in another embodiment thereof, includes a delivery system and a recovery system which are capable of enabling the delivery and recovery of an embolic protection device so as to maintain a clinically acceptable profile and flexibility through the patient's vasculature.

Owner:ABBOTT CARDIOVASCULAR

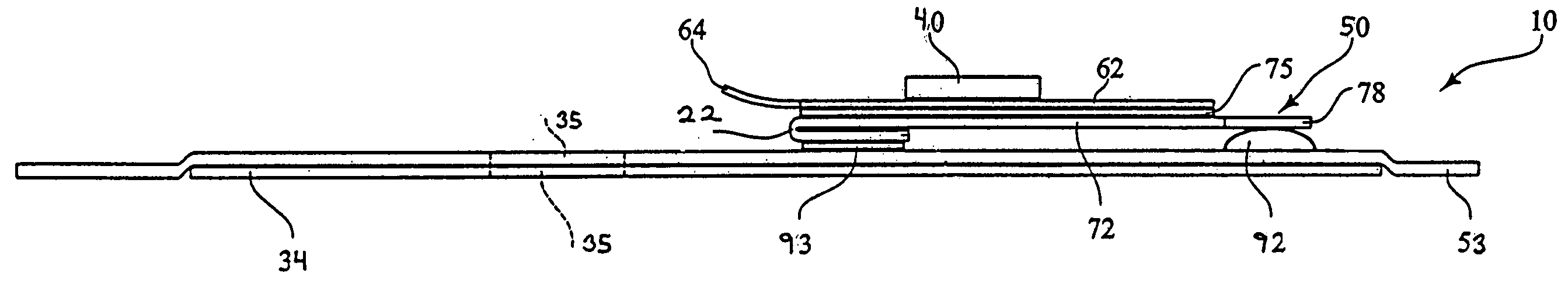

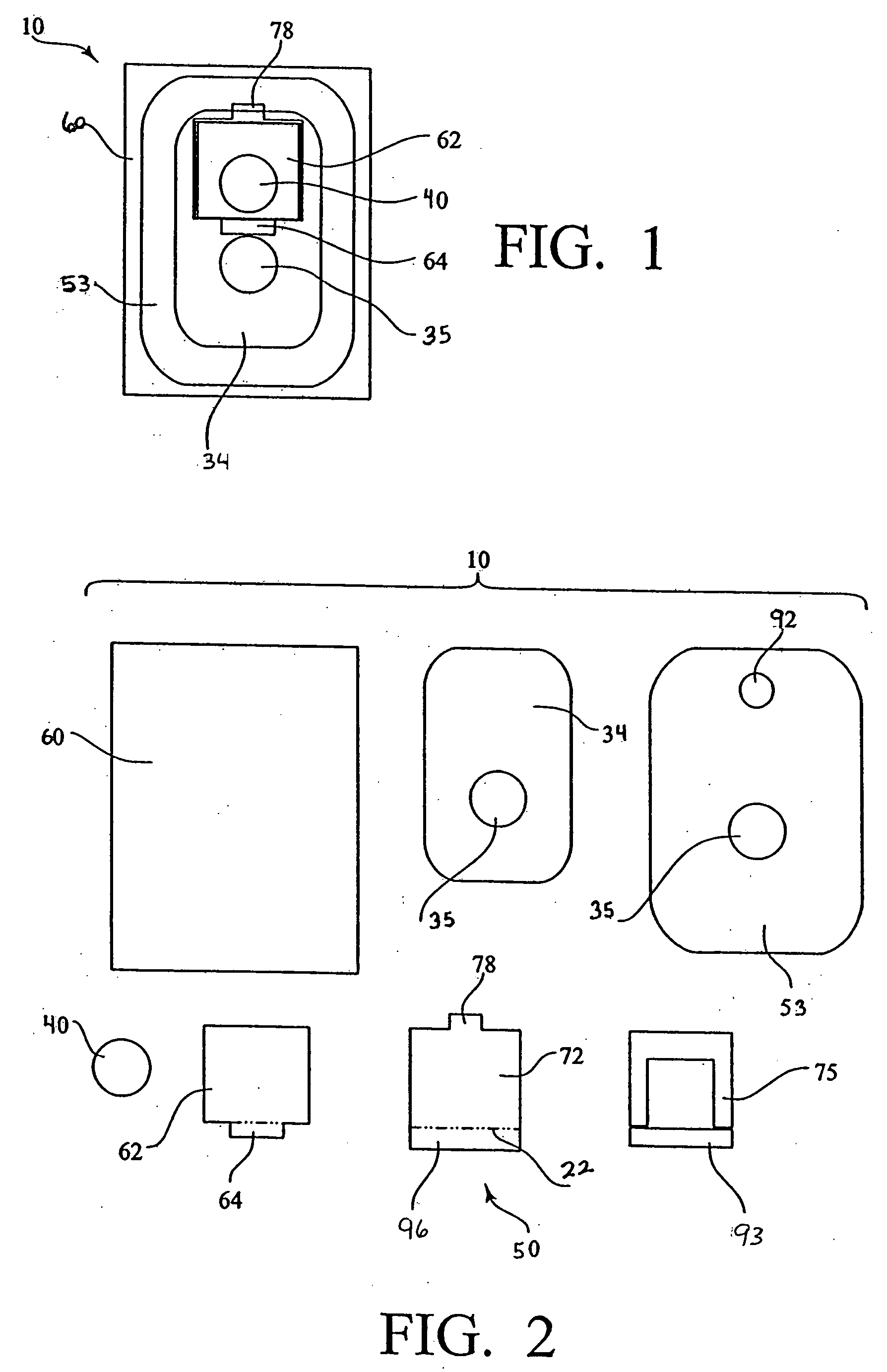

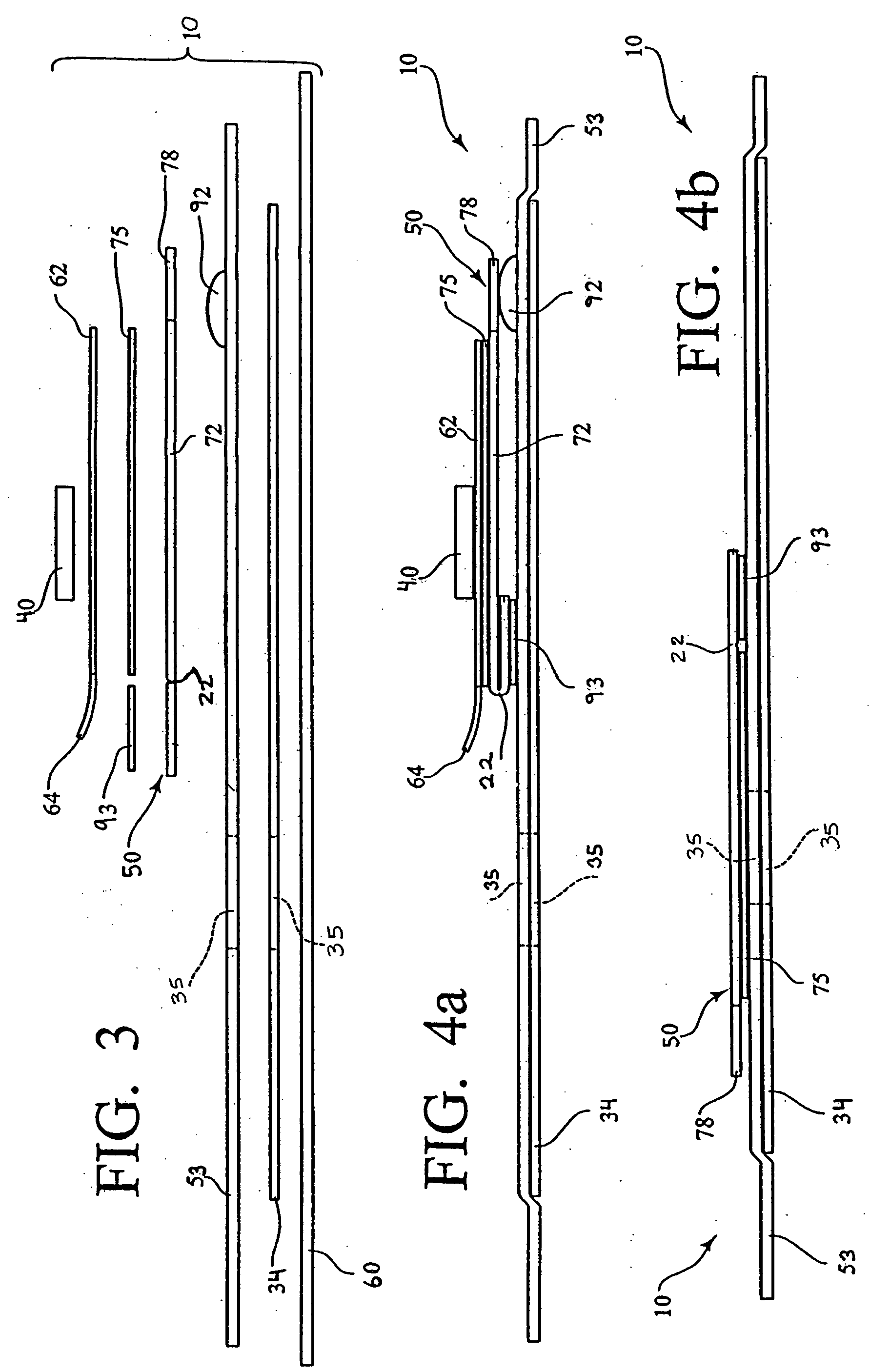

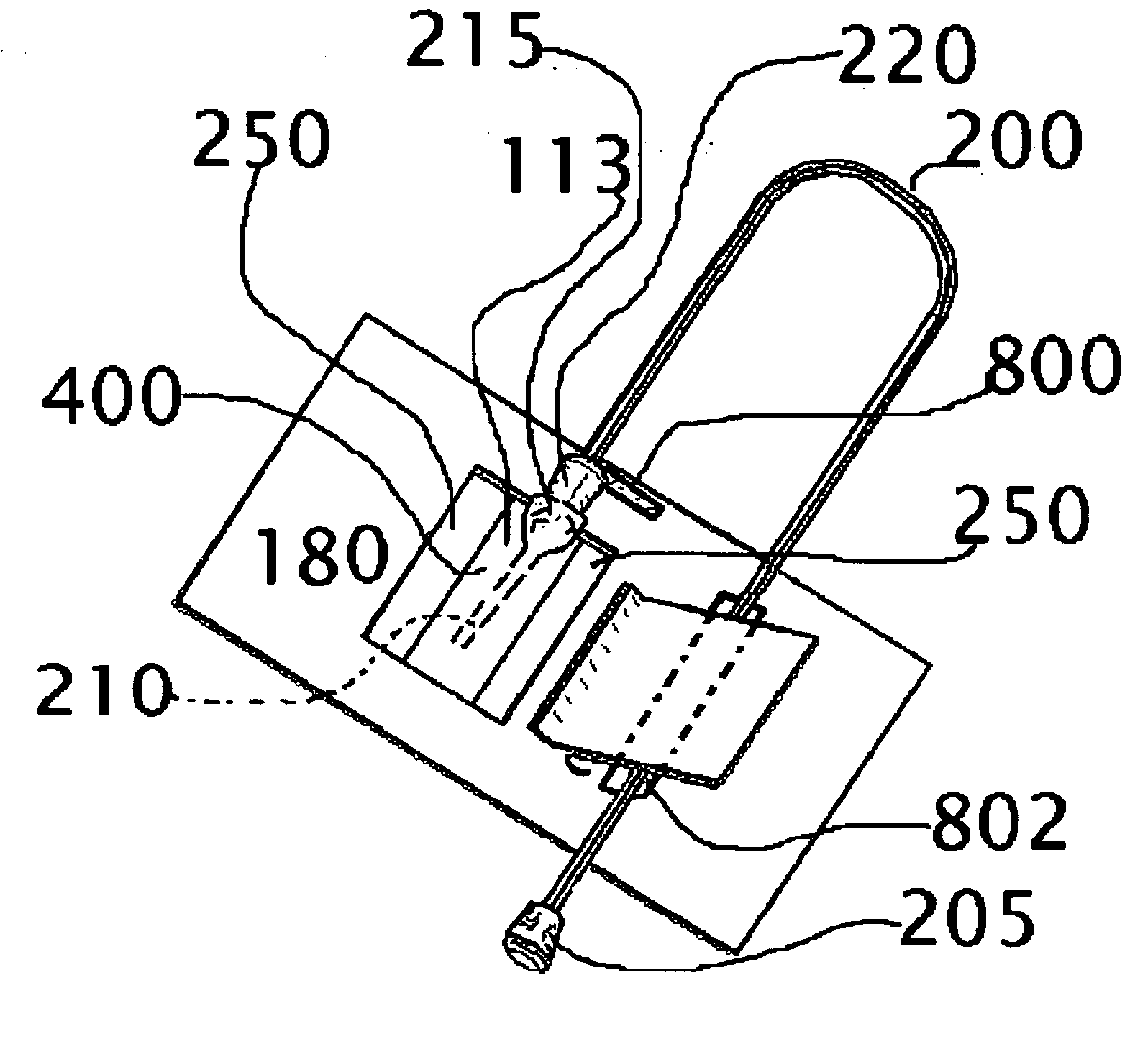

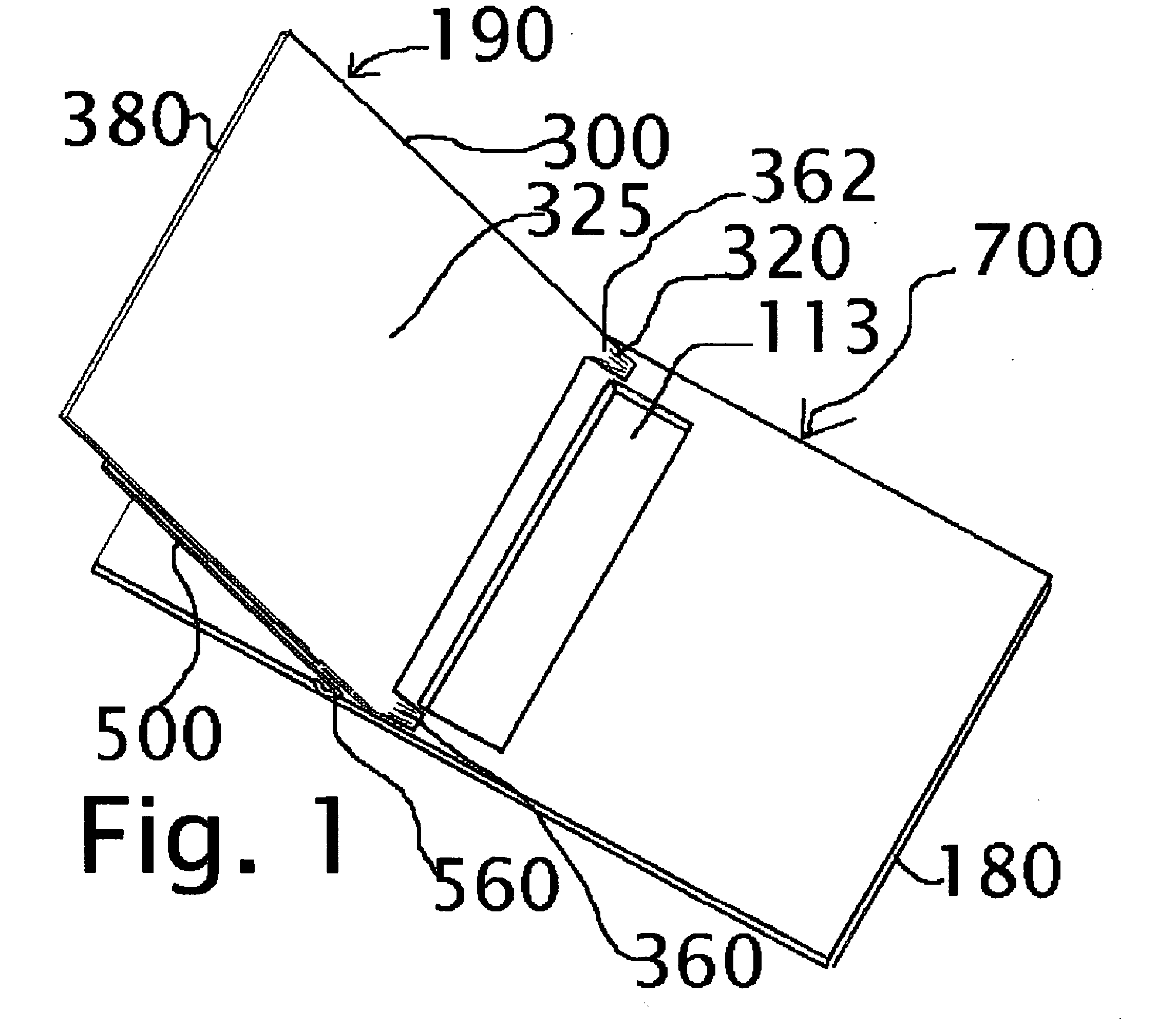

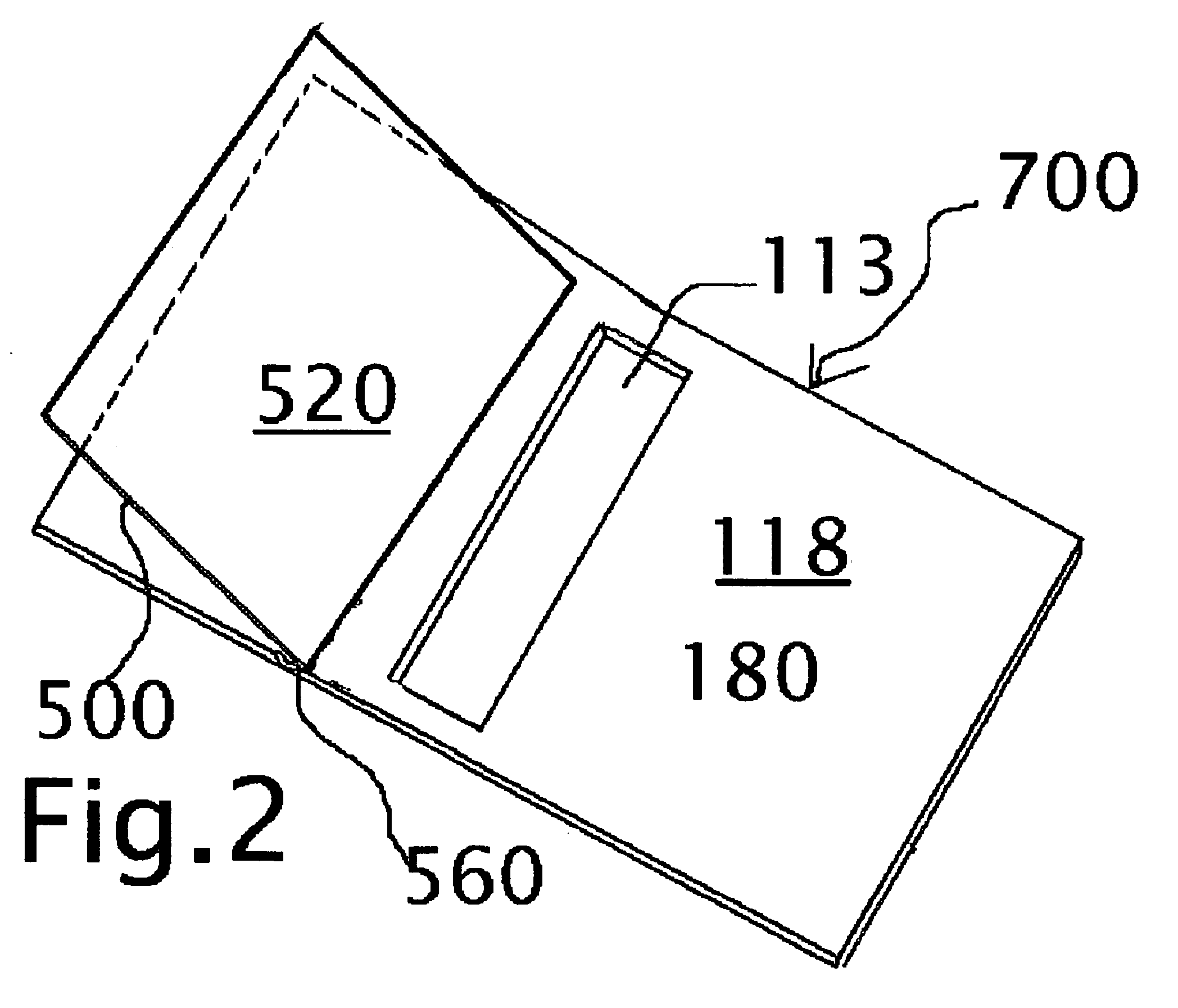

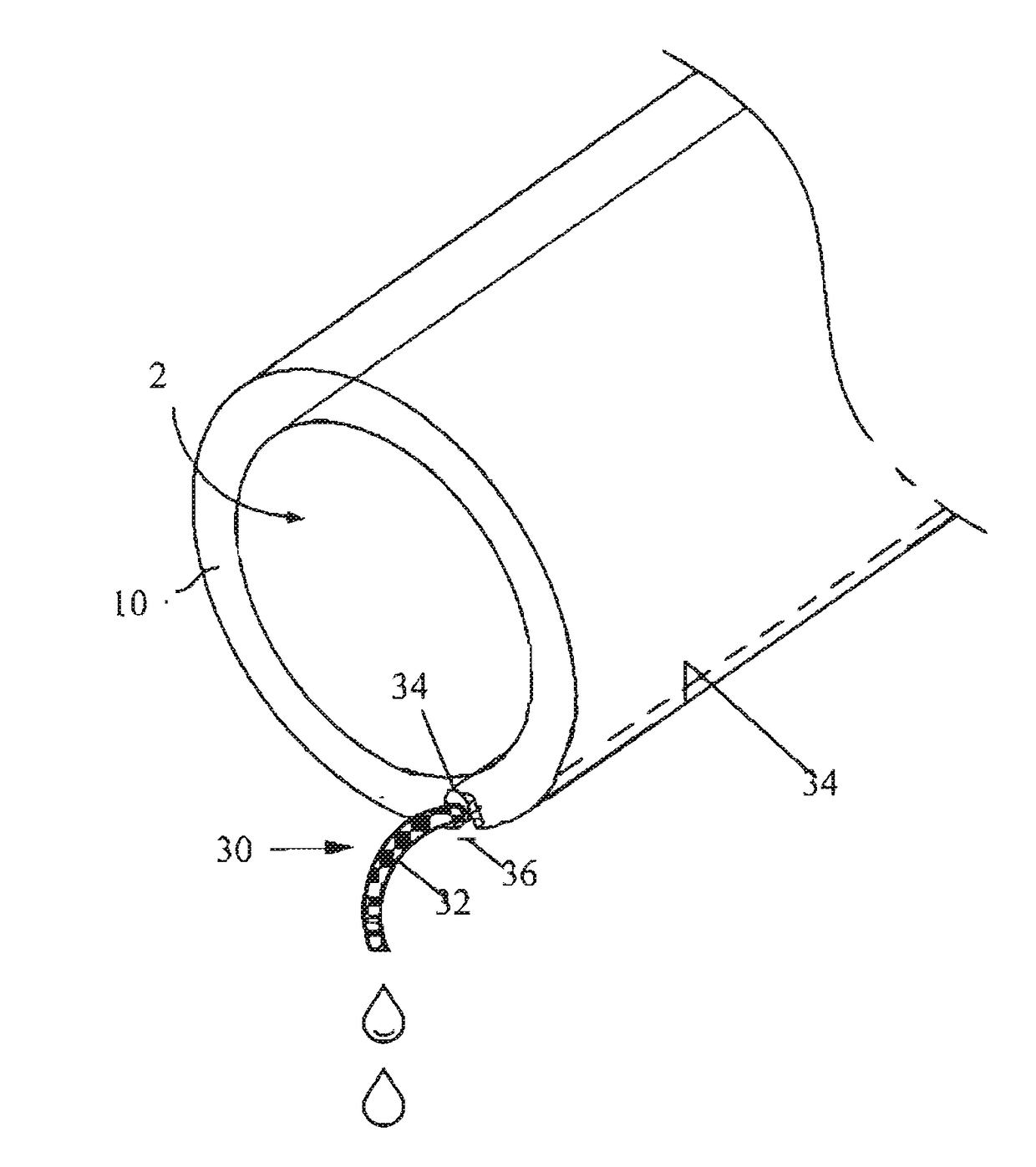

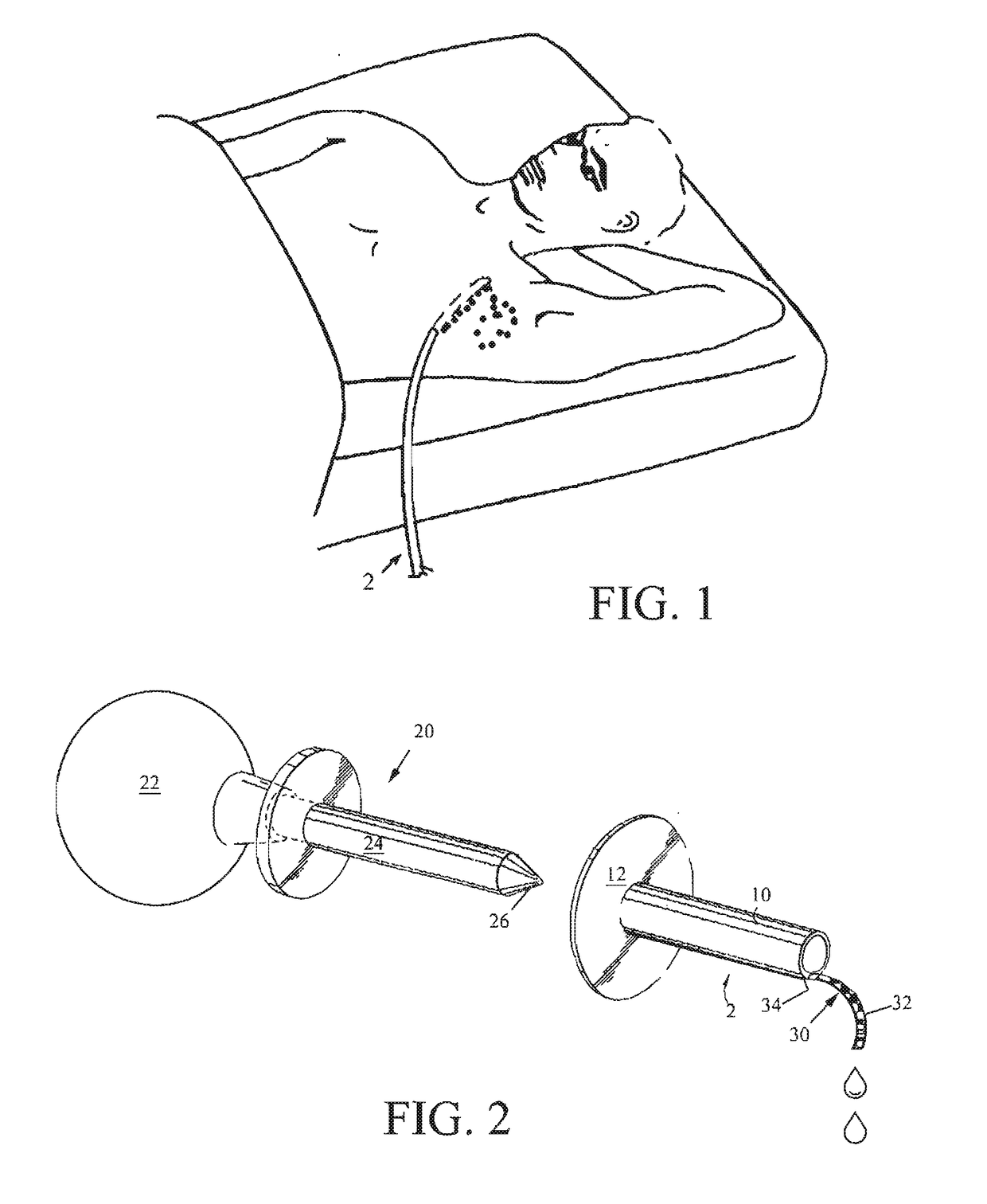

Simplified one-handed preemptive medical procedure site dressing to prevent sharps injuries and exposure to bloodborne pathogens

InactiveUS20040138602A1High protection levelShorten the timeAdhesive dressingsProcedure LocationAbsorbent Pads

A dressing for use with medical procedures is provided that permits application of the dressing prior to the commencement of a medical procedure and wherein the dressing remains on the site after the procedure has been completed. The dressing comprises an absorbent pad, a hinged door and an aperture through which the procedure site can be accessed or it comprises an adhesive bandage part, which is bent and secured in such a way that the bandage forms a door and a hinge, and an adhesive flap component which anchors the bandage to the skin. The bandage is positioned in such a way as to infer or define the location where the procedure is to be performed. In either embodiment, when it is deployed, the door or bandage is rotated around the hinge and can be set in place at a procedure location prior to the procedure. Importantly, the device can be deployed with one hand, to complete the bandaging of a procedure site simultaneous with or within a moment after the completion of the medical procedure. The device is not size-limited by the disclosure. The invention may be small enough to use to perform an injection or it may be large enough that a major surgical procedure can be performed through the aperture. Methods of using the dressing of the present invention are also provided.

Owner:ROSSEN JOEL S

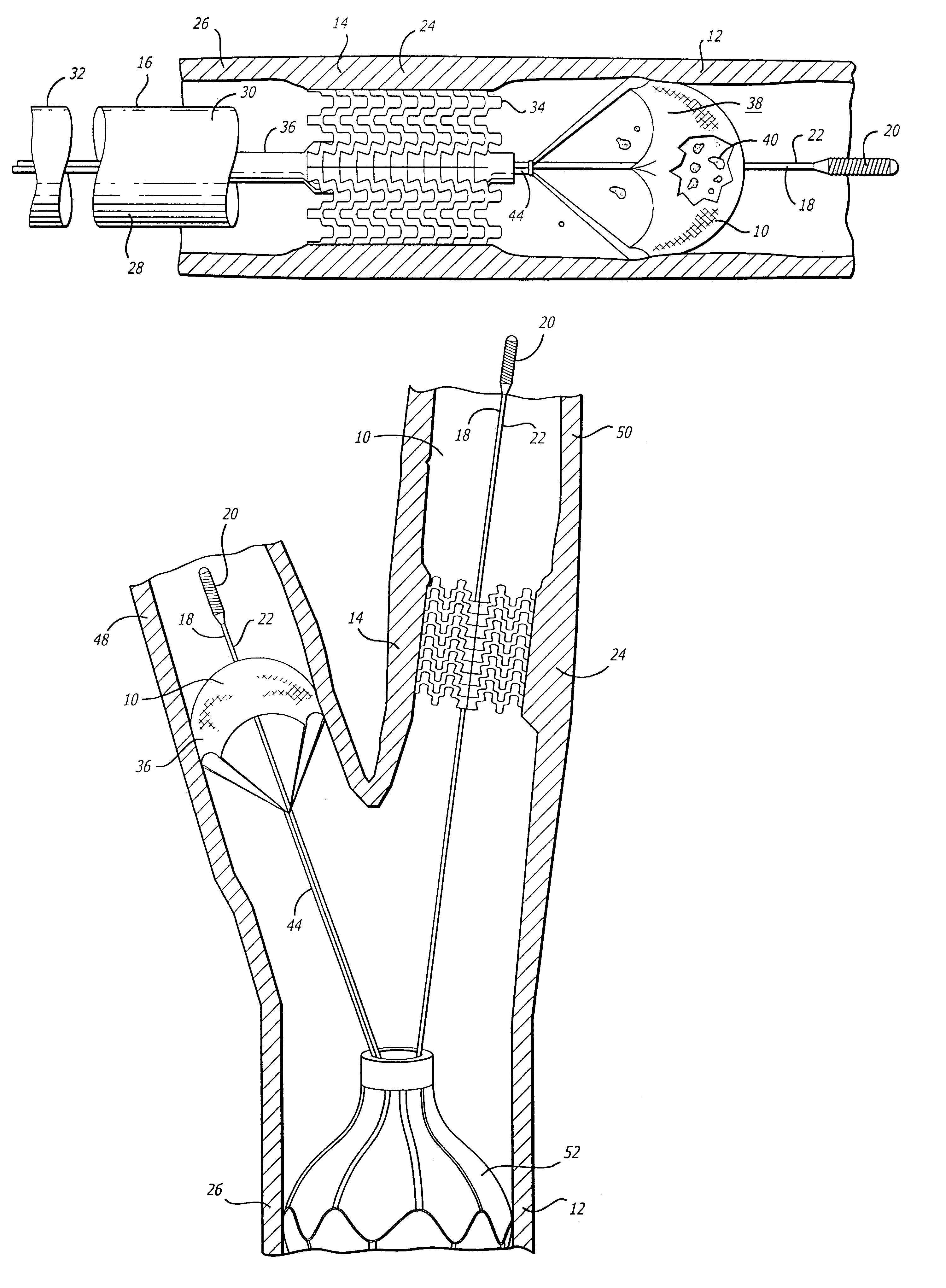

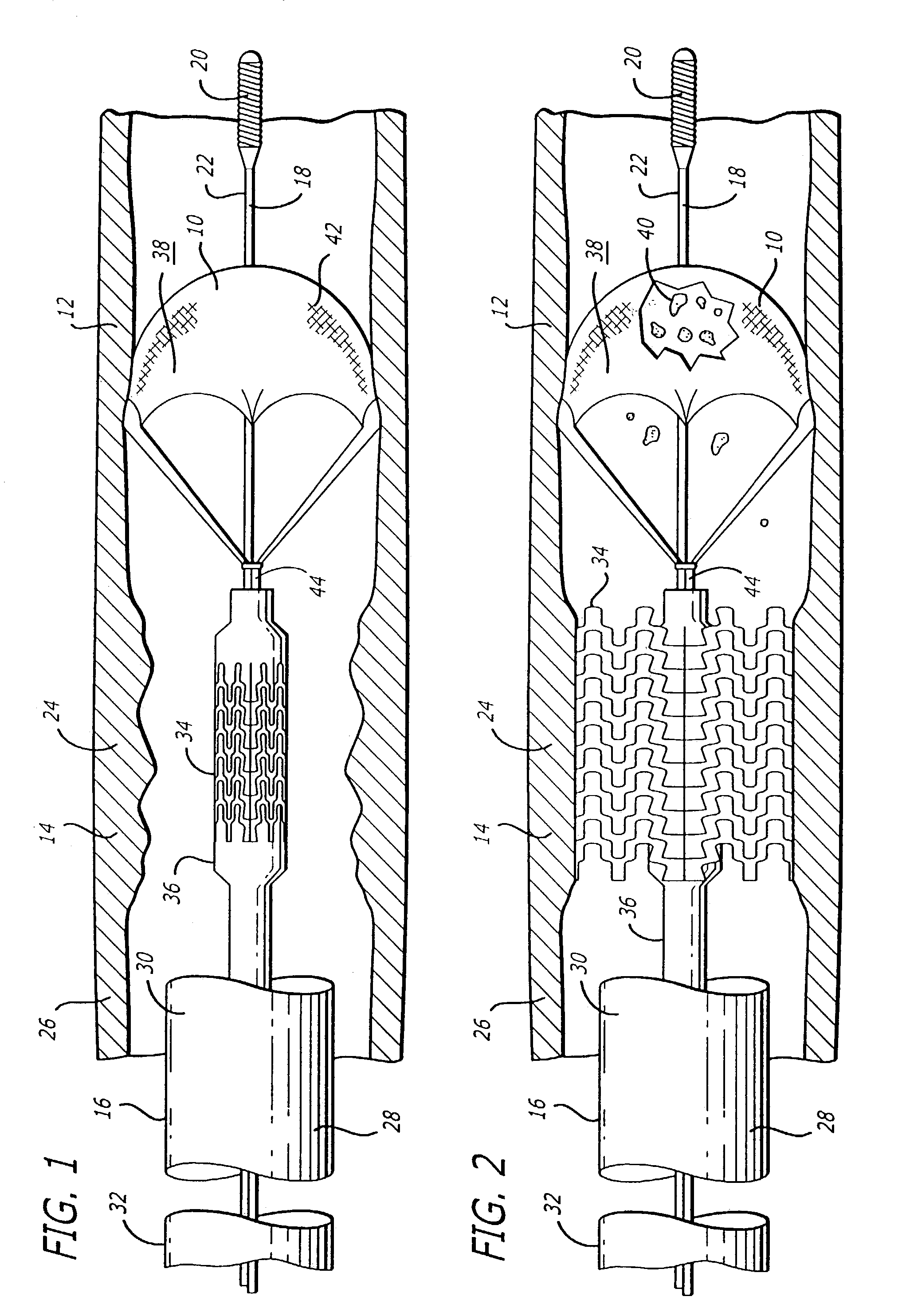

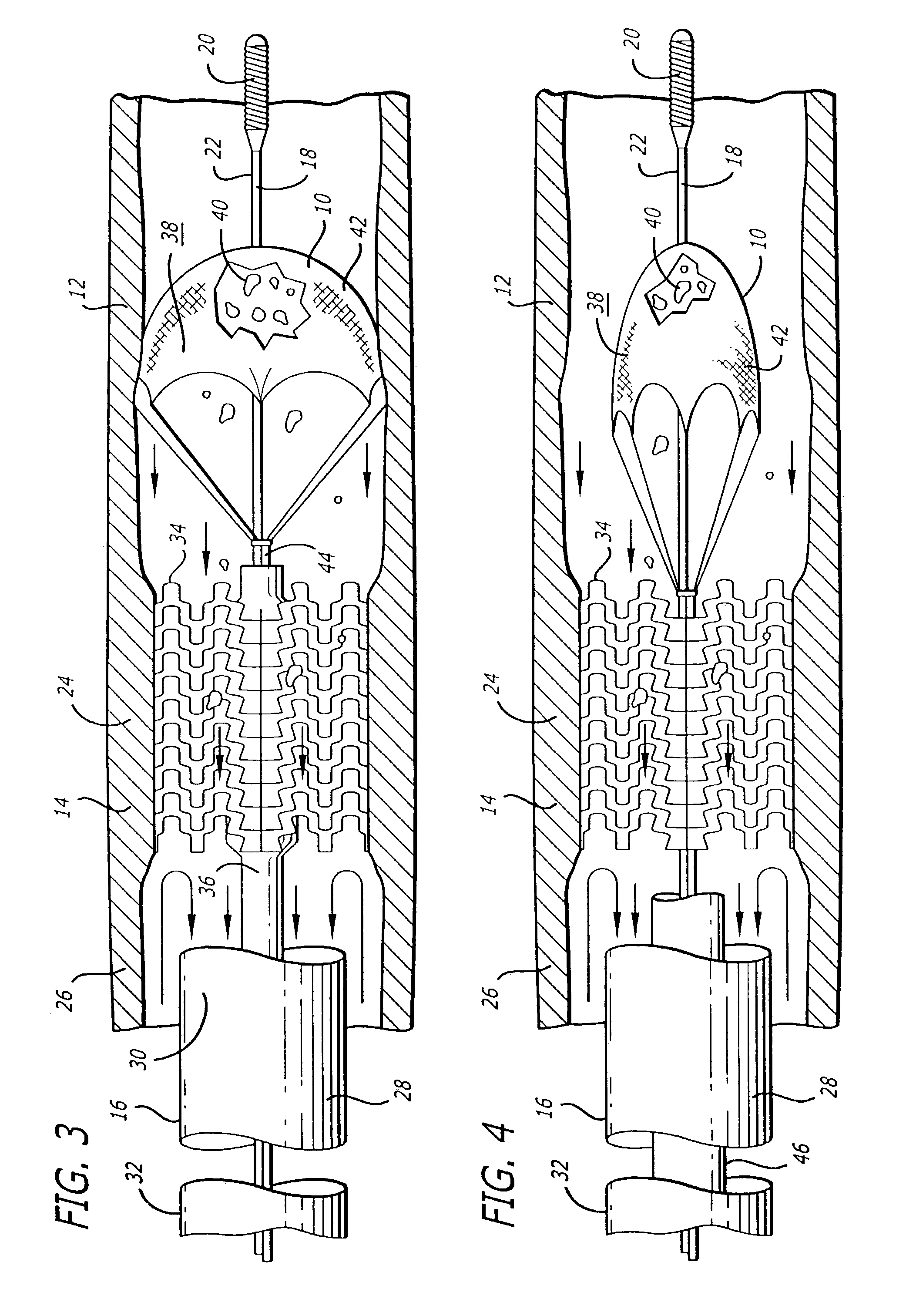

Delivery and recovery system for embolic protection system

InactiveUS20050228439A1ConfidenceImprove performanceSurgeryDilatorsEmbolic Protection DevicesSurgical site

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which can be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, is capable of enabling at least one operator to control the delivery and removal of an embolic protection device to a position in a patient's vasculature distal to an interventional procedure site, to enable the exchange of the delivery and recovery system. The system, in another embodiment thereof, includes a delivery system and a recovery system which are capable of enabling the delivery and recovery of an embolic protection device so as to maintain a clinically acceptable profile and flexibility through the patient's vasculature.

Owner:ANDREWS CHRISTOPHER C +10

Intravenous catheter and I.V. medical line securement dressing and stabilizer for human and veterinary medicine

InactiveUS20050215953A1Eliminates tape handlingMore materialCatheterInfusion needlesVeinIntravenous catheter

A preemptive bandaging device is presented for the facilitation of intravenous catheter placement and anchoring. The bandage of the present invention includes a frame of bandage base material and a hingedly attached door of a thin bandaging film, a layer of carrier paper to serve as a deployer, and an optional bandage base flap or island for integrating the present invention with certain tube and catheter stabilization devices. The dressing is anchored to the skin so as to frame the I.V. site. The bandage features anchors for I.V. tubing and is placed so as to frame the I.V. procedure site. Once the catheter is placed, deploying the door covers and secures the tubes and the catheter with a thin film of clear bandaging material.

Owner:ROSSEN JOEL STEPHEN

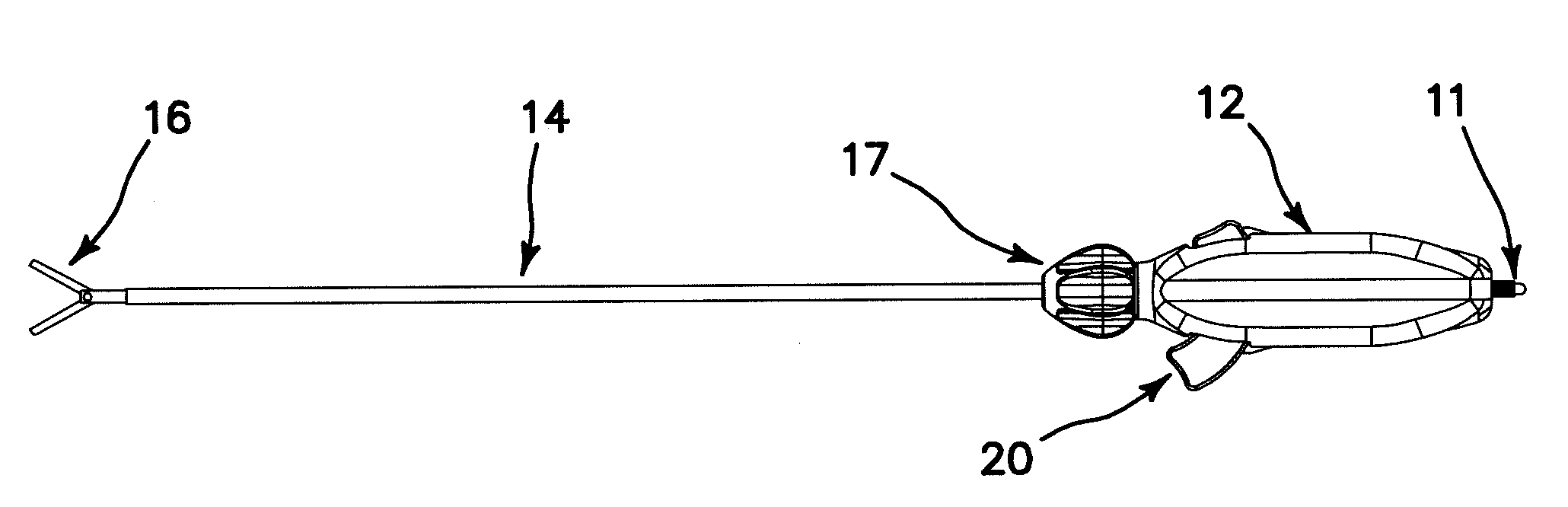

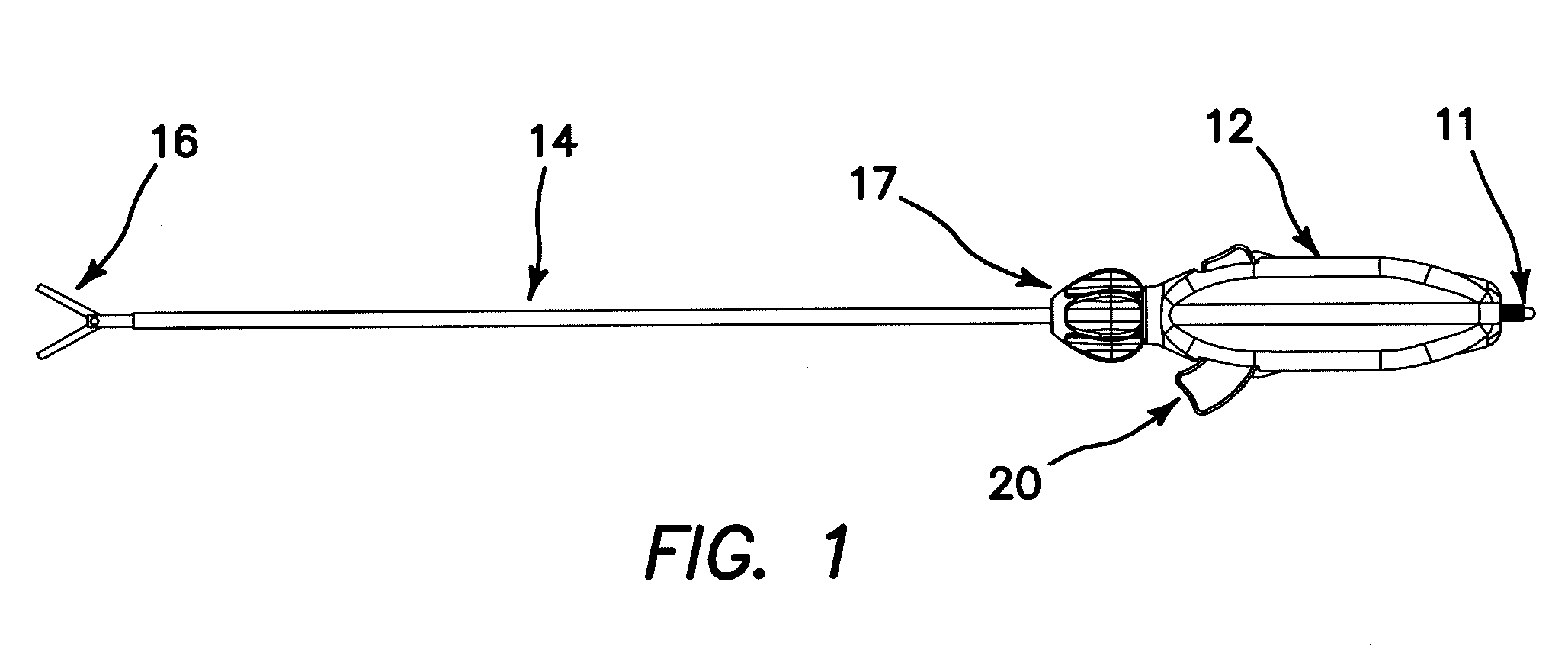

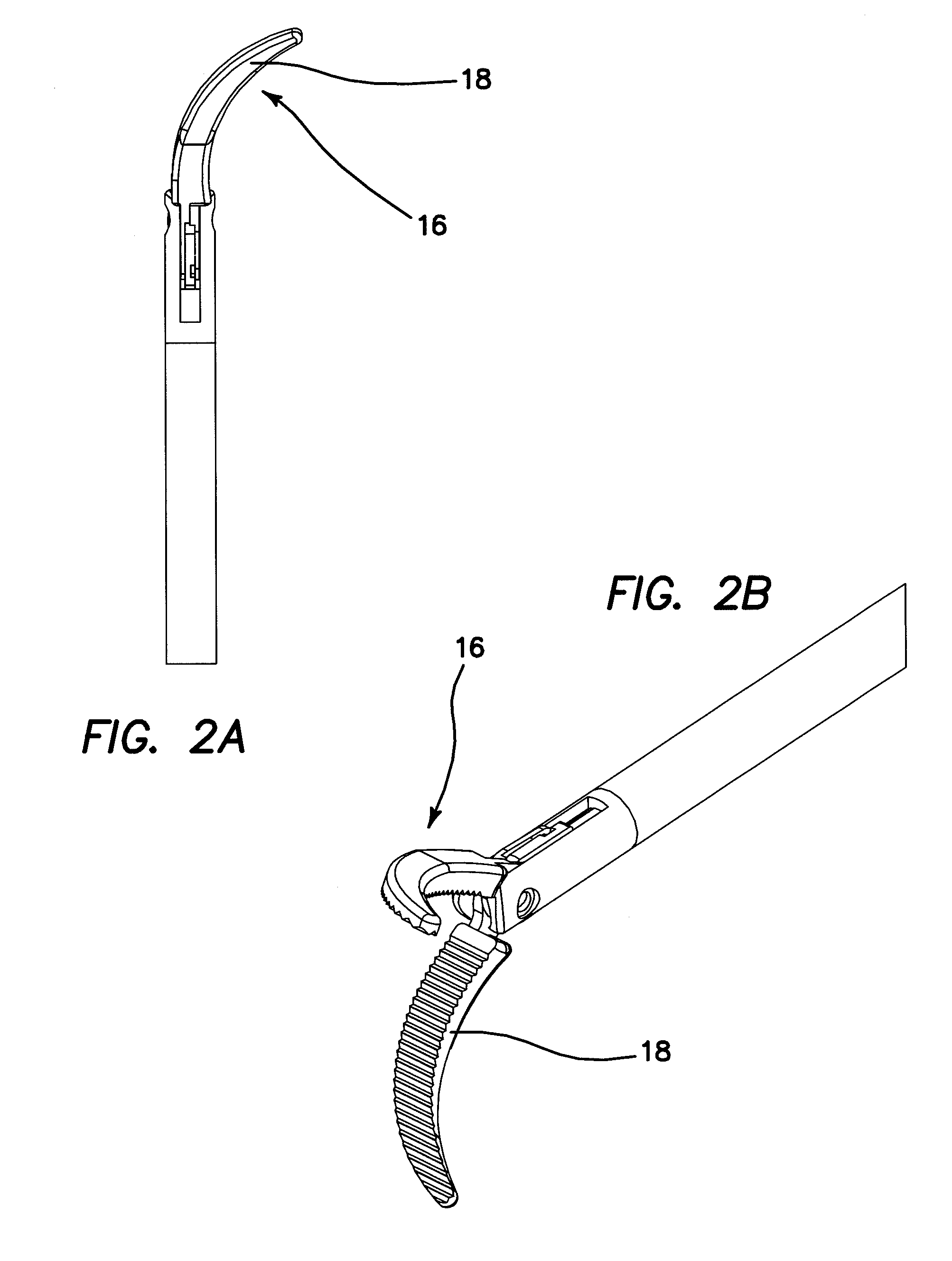

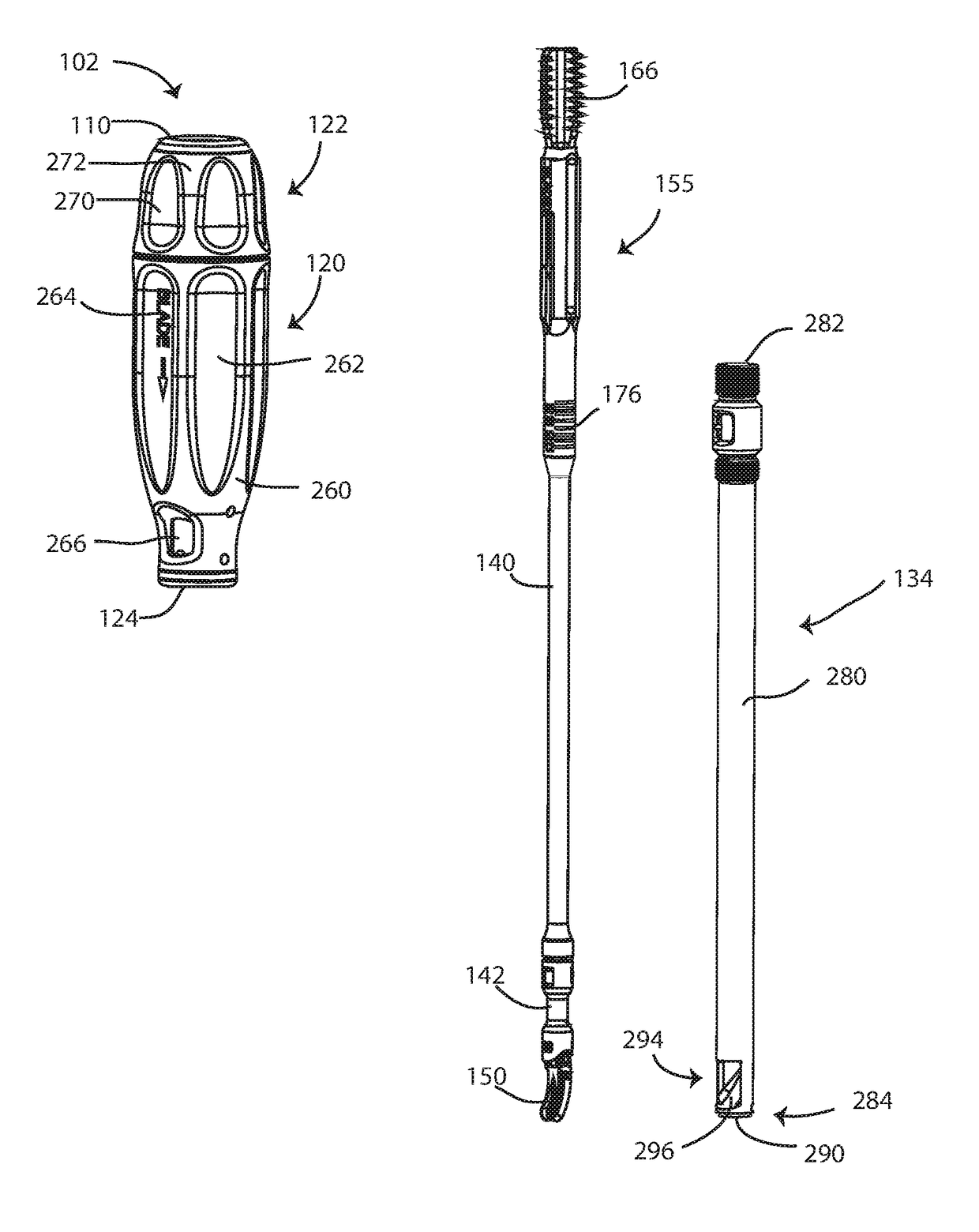

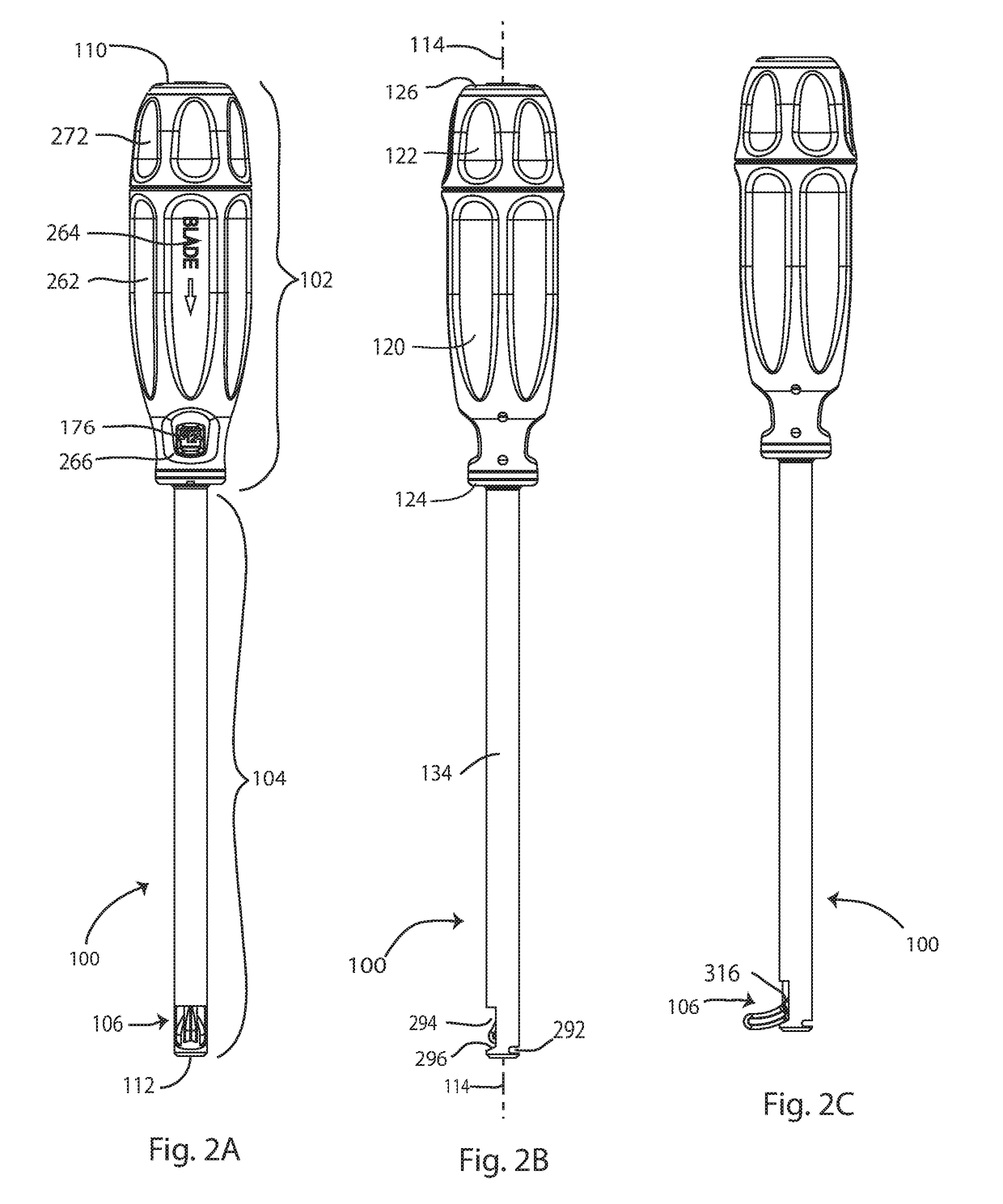

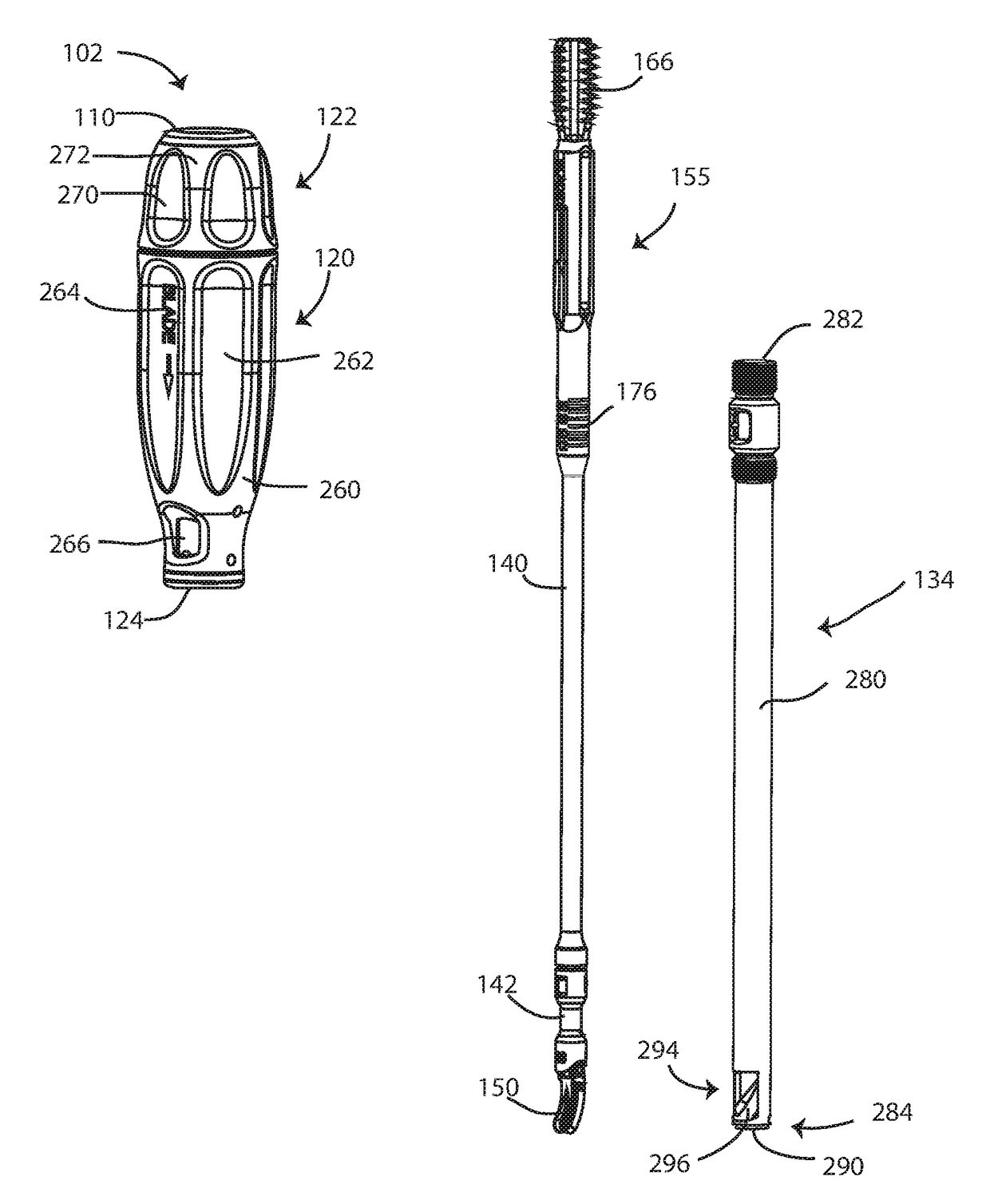

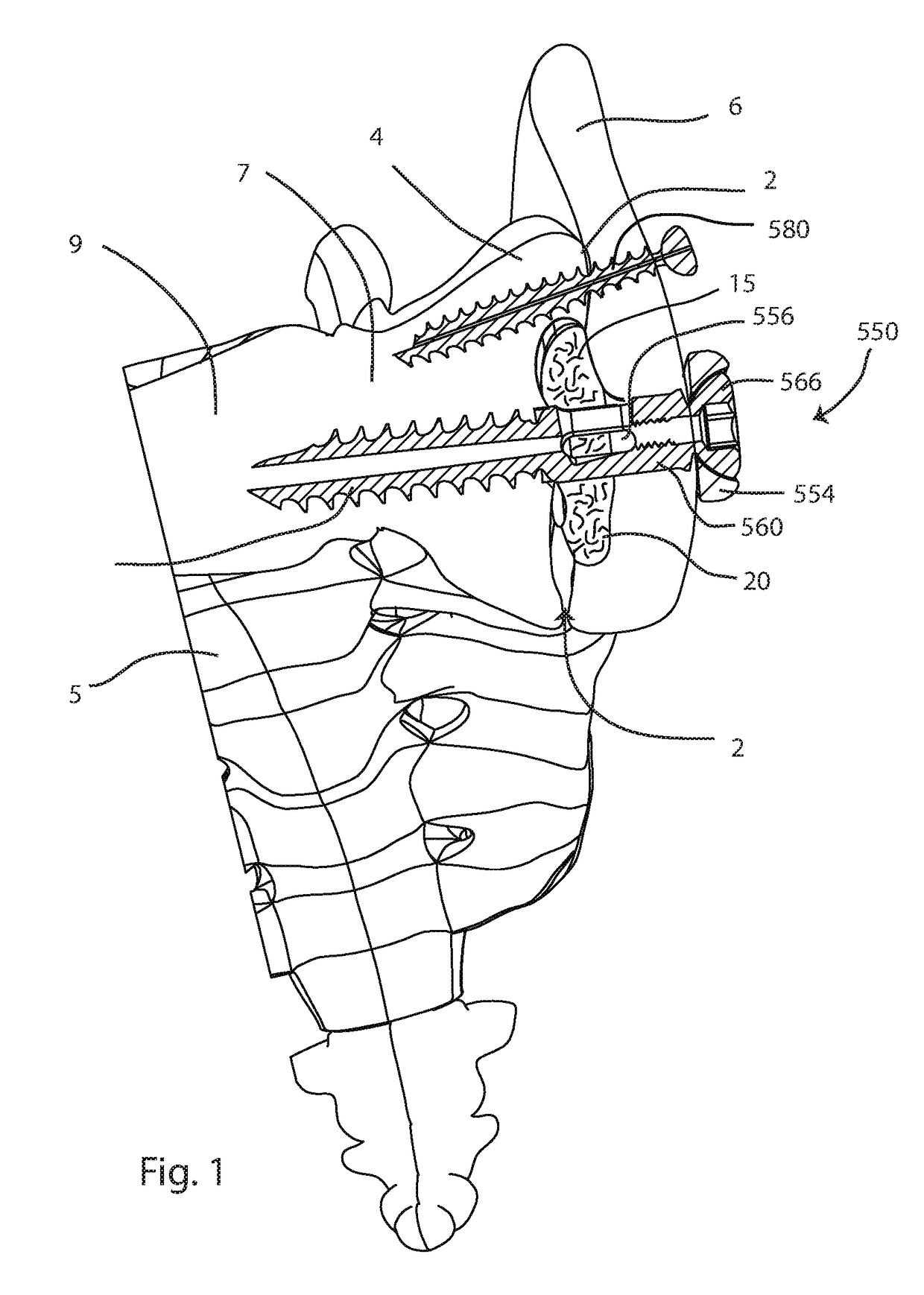

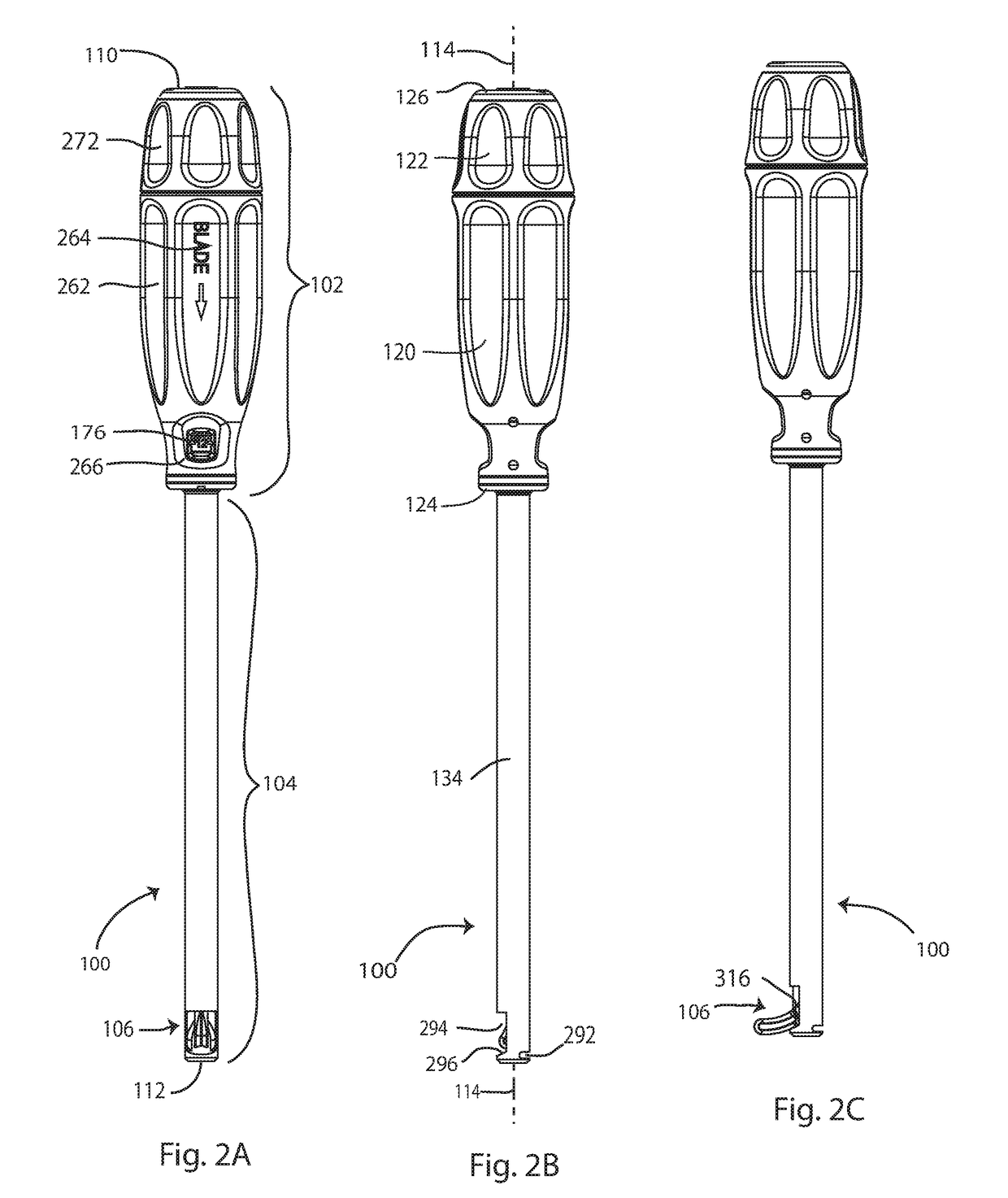

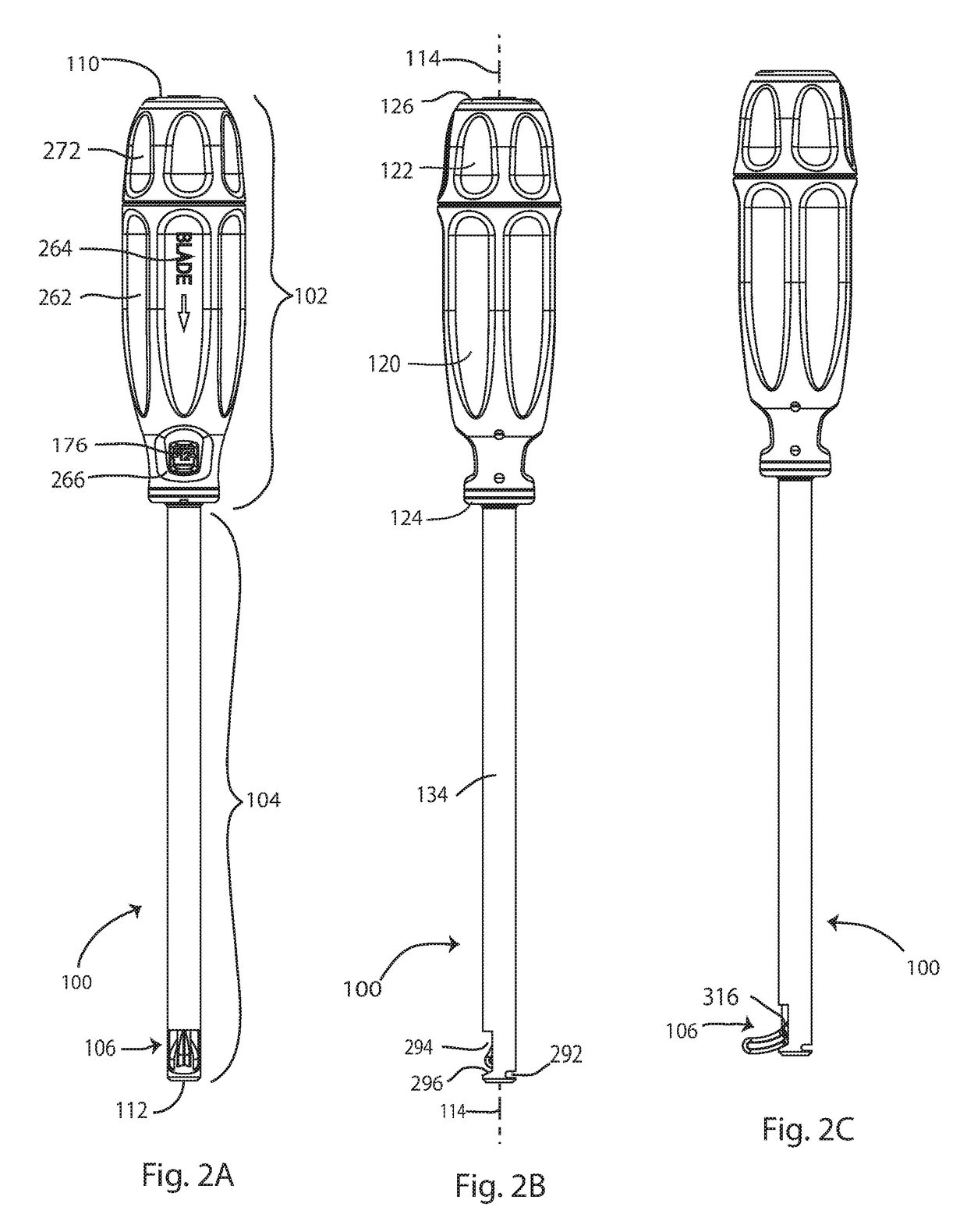

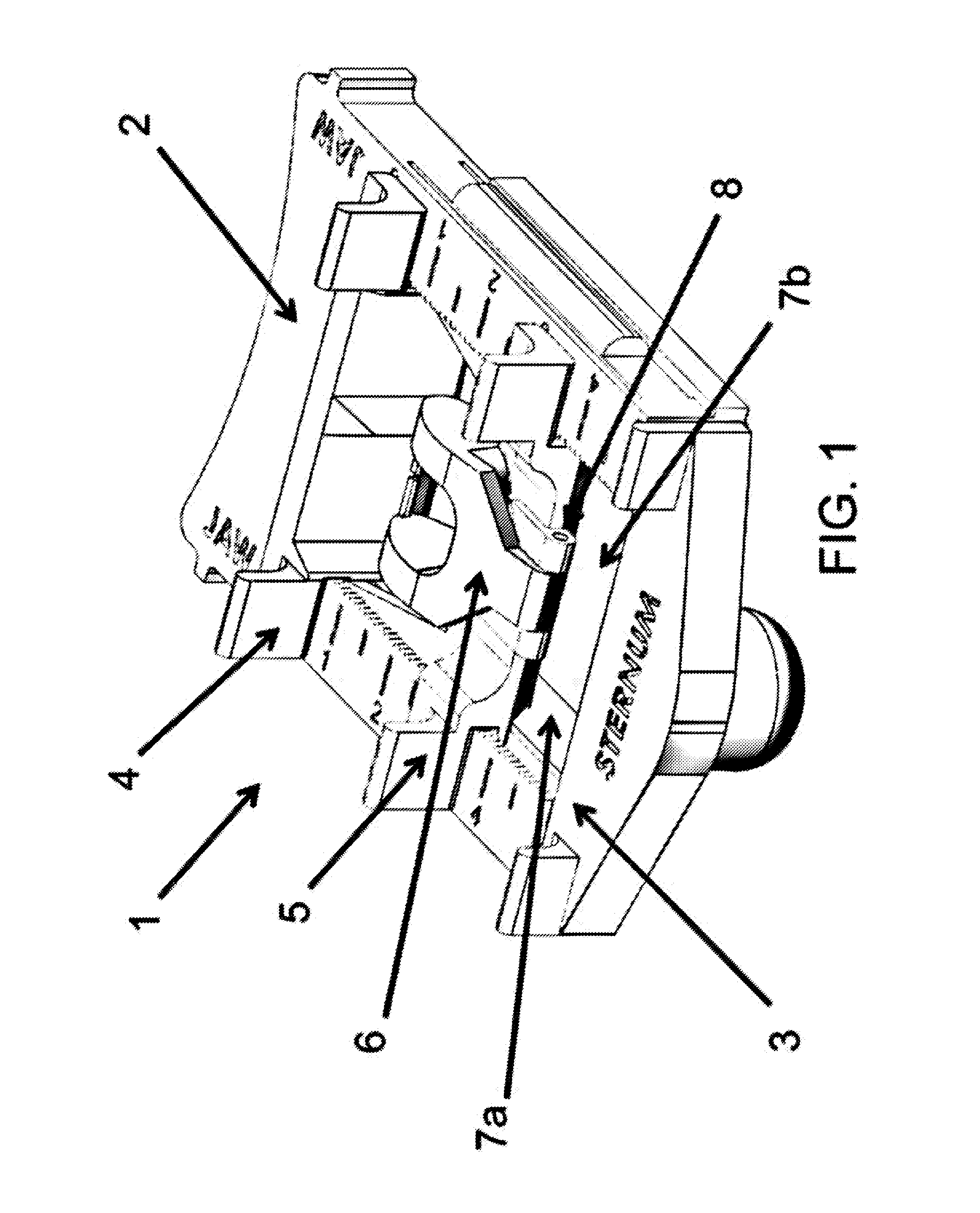

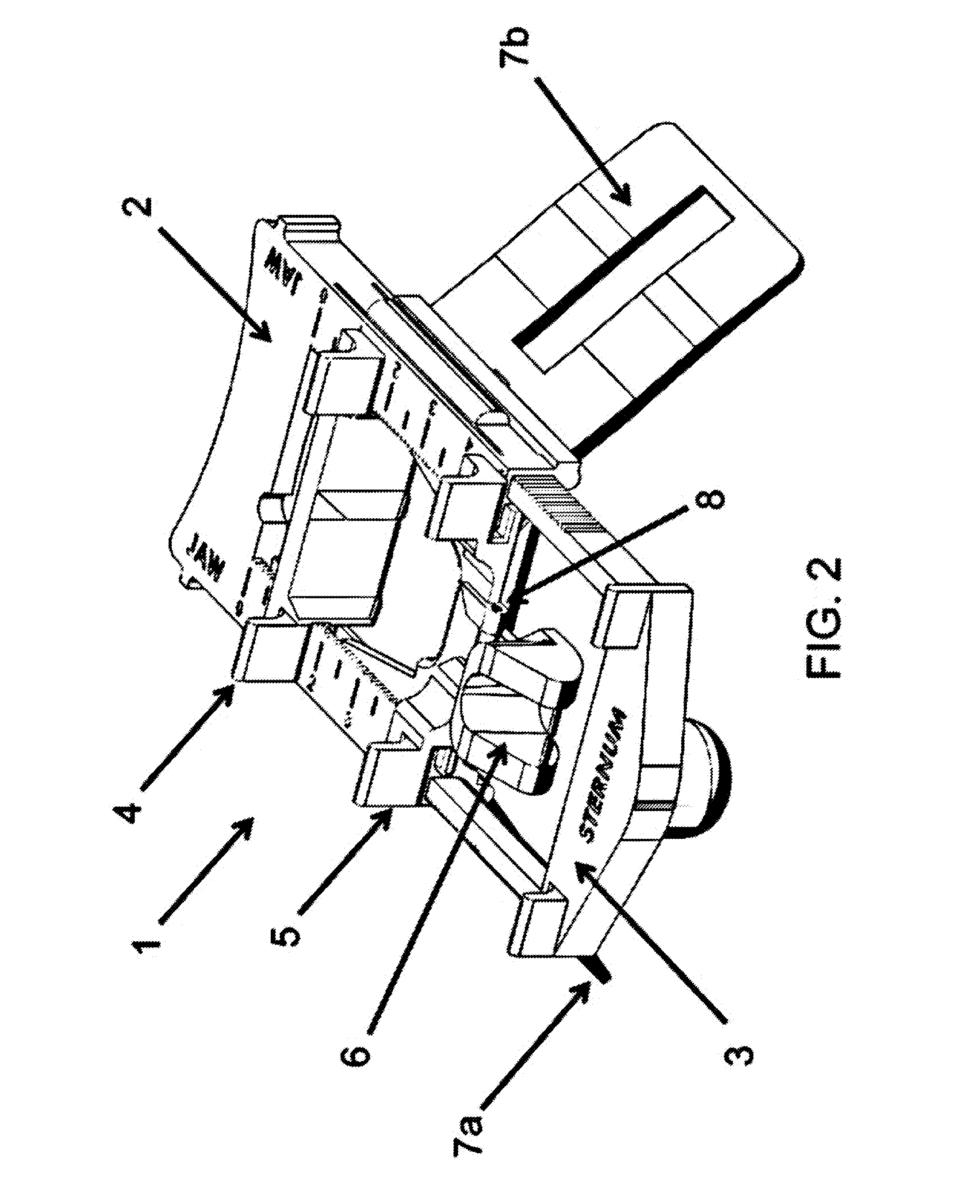

Single Port Instruments

Surgical tools that can be used in single port laparoscopic procedures can include a low-profile handle assembly to minimize tool interference adjacent the incision site. For example, a handle assembly for a surgical instrument can have a generally in-line configuration extending linearly along a central longitudinal axis of an elongate shaft of the instrument. A linkage mechanism including a trigger, an actuation link, and an actuation shaft can be positioned within the in-line handle. The linkage mechanism can be pivoted between an open position in which end effectors of the instrument are open and a toggle position in which the end effectors are locked closed. A locking mechanism such as a ratchet mechanism can also be used to lock the end effectors. A surgical dissector can include gripping jaws having a curved profile or an angled elongate shaft to minimize tool interference and maximize visibility within a procedure site.

Owner:APPL MEDICAL RESOURCES CORP

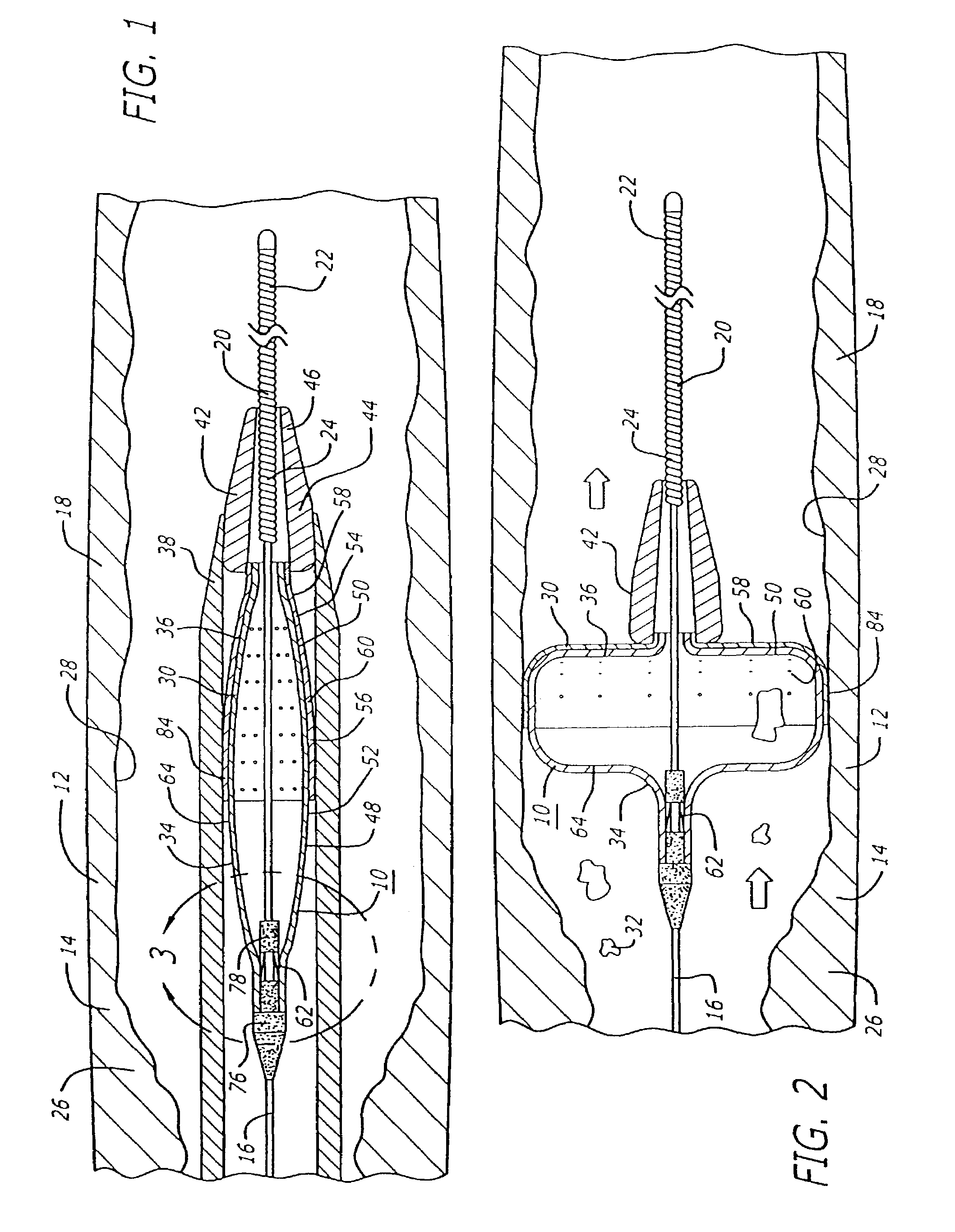

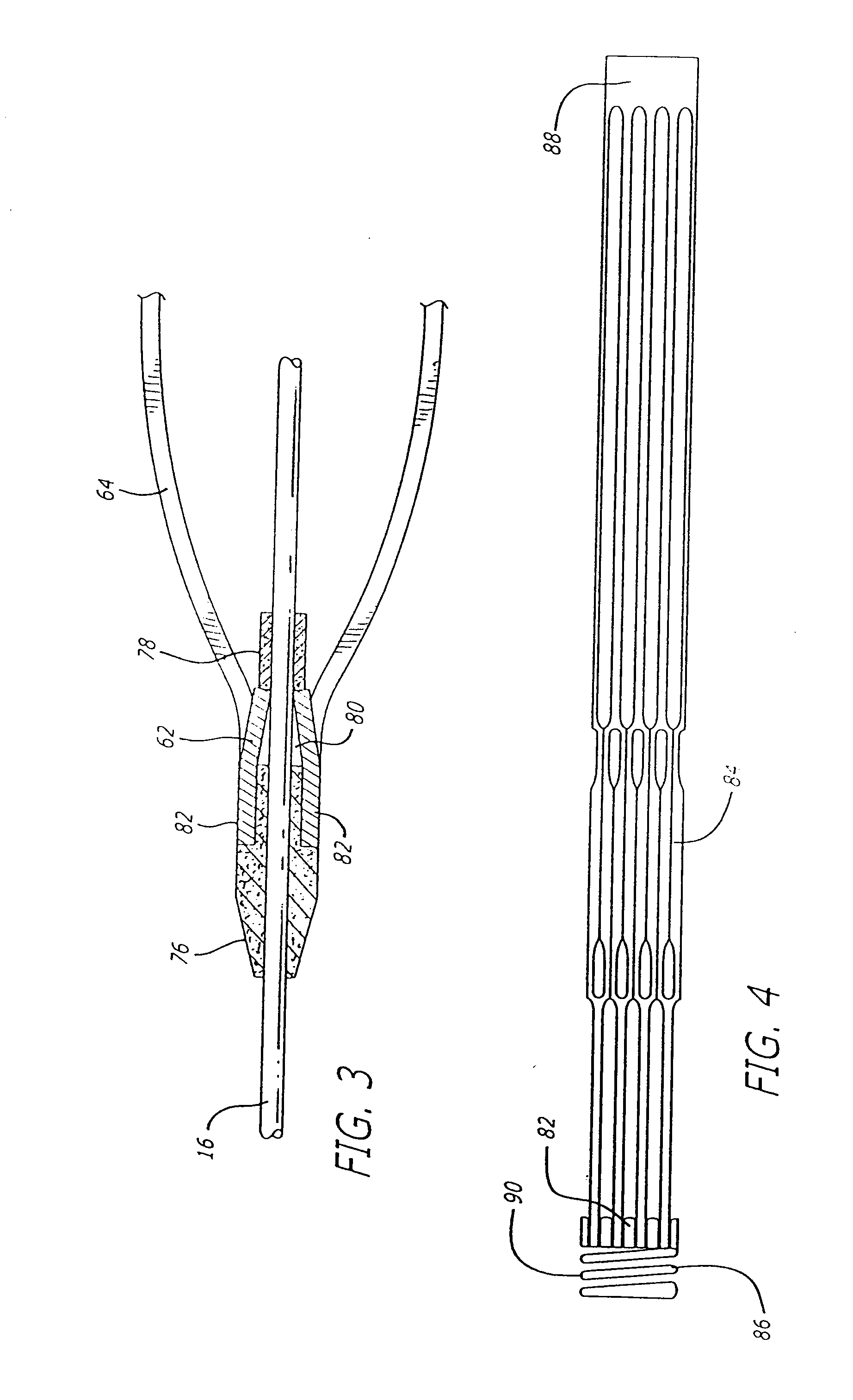

Filter device for embolic protection systems

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which may be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, enables the device to be snap-fitted so as to engage the distal end of a guide wire, to provide a reference for positioning the device at a location distal to the interventional procedure site, and to enable an end of the device to be in tension, enabling a portion of the device to be in tension and another portion to be in compression, so as to assist in bending thereof in tortuous vasculature.

Owner:ABBOTT CARDIOVASCULAR

Sheathless embolic protection system

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which may be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, enables the device to be compressed for insertion thereof through a patient's vasculature so as to cross the stenosis in a low profile, and to enable release of compression thereof for expansion and deployment of the device at a location distal to the interventional procedure site.

Owner:ABBOTT CARDIOVASCULAR

Sheathless embolic protection system

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which may be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, enables the device to be compressed for insertion thereof through a patient's vasculature so as to cross the stenosis in a low profile, and to enable release of compression thereof for expansion and deployment of the device at a location distal to the interventional procedure site.

Owner:ABBOTT CARDIOVASCULAR

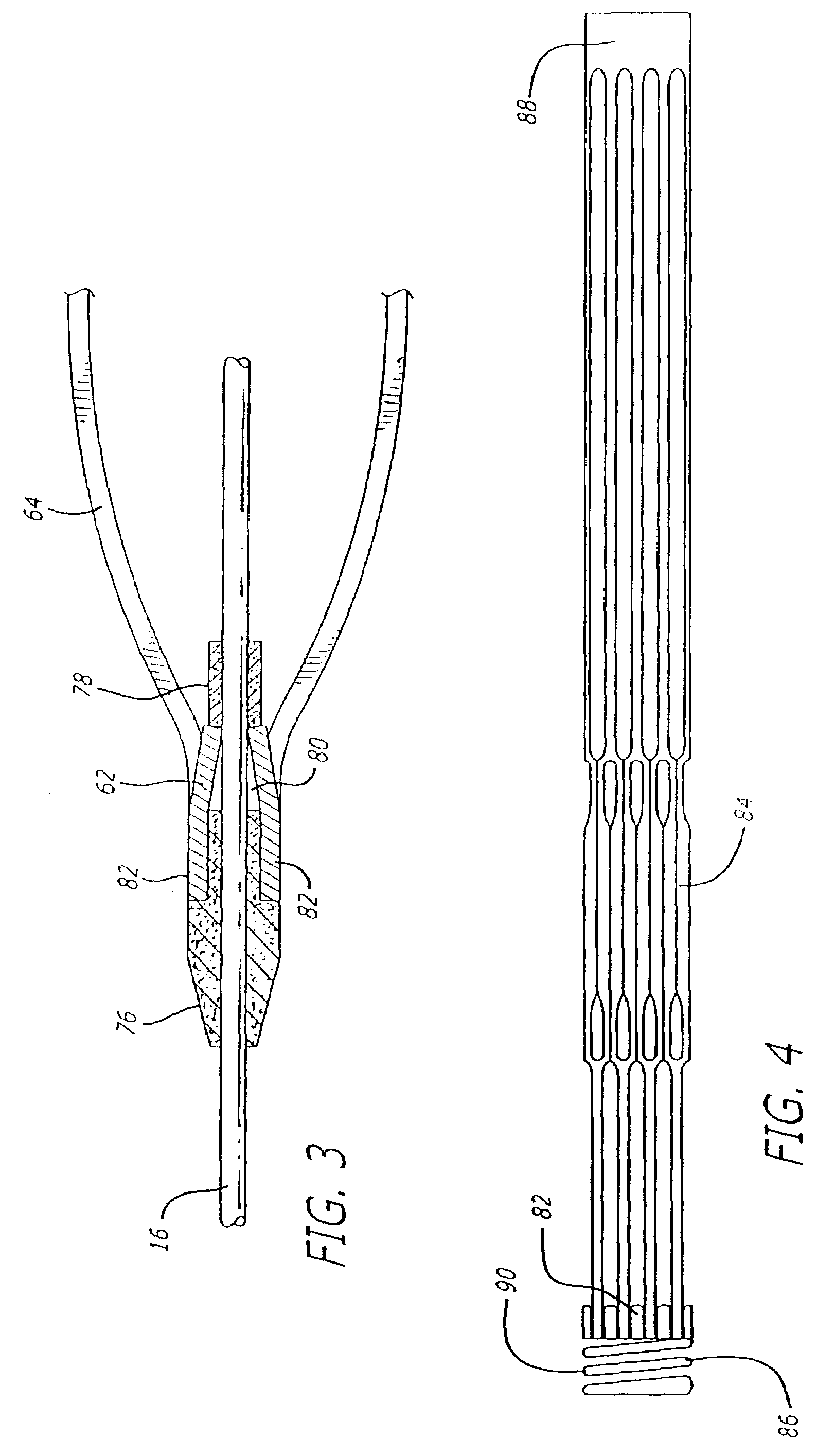

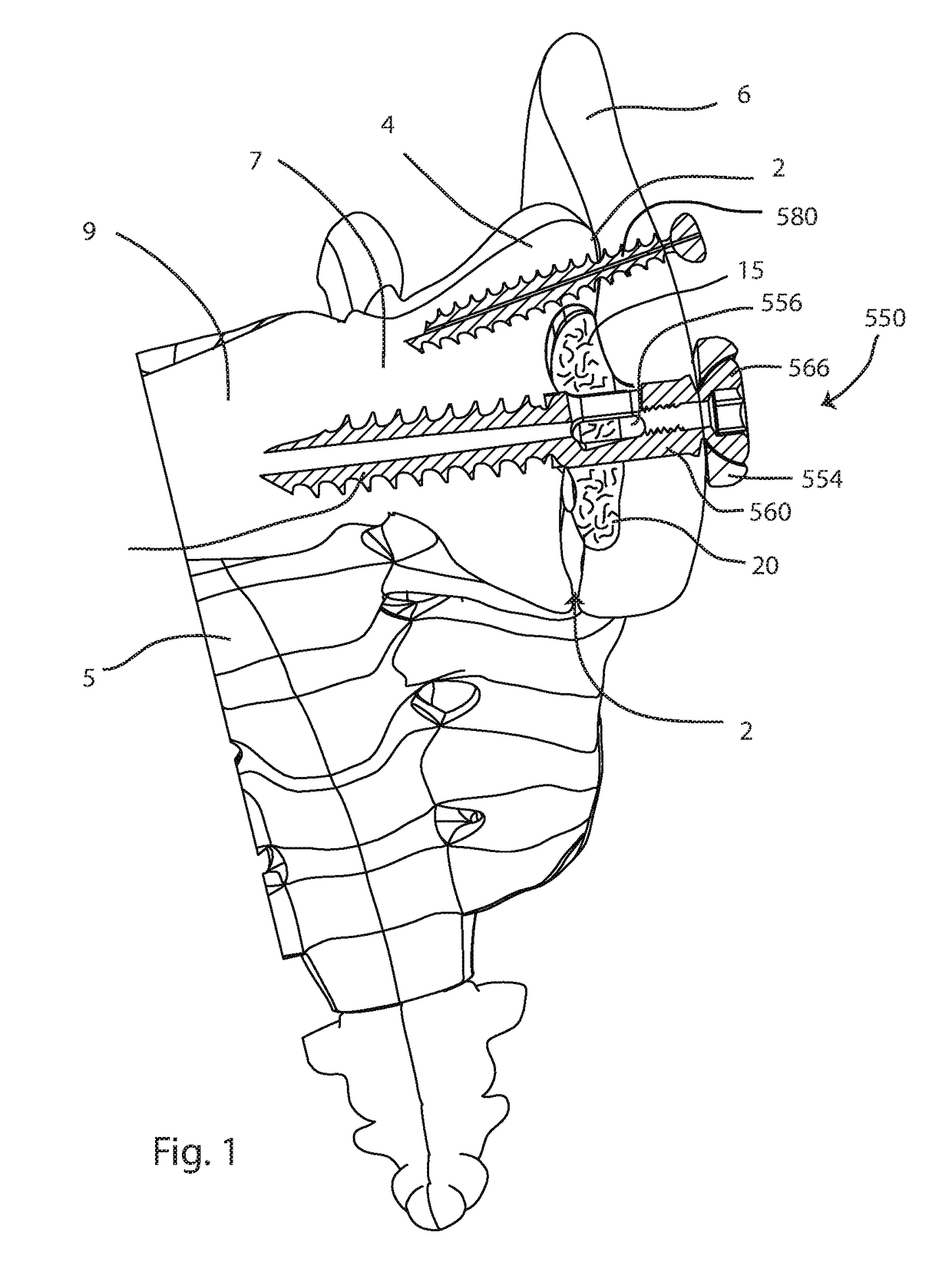

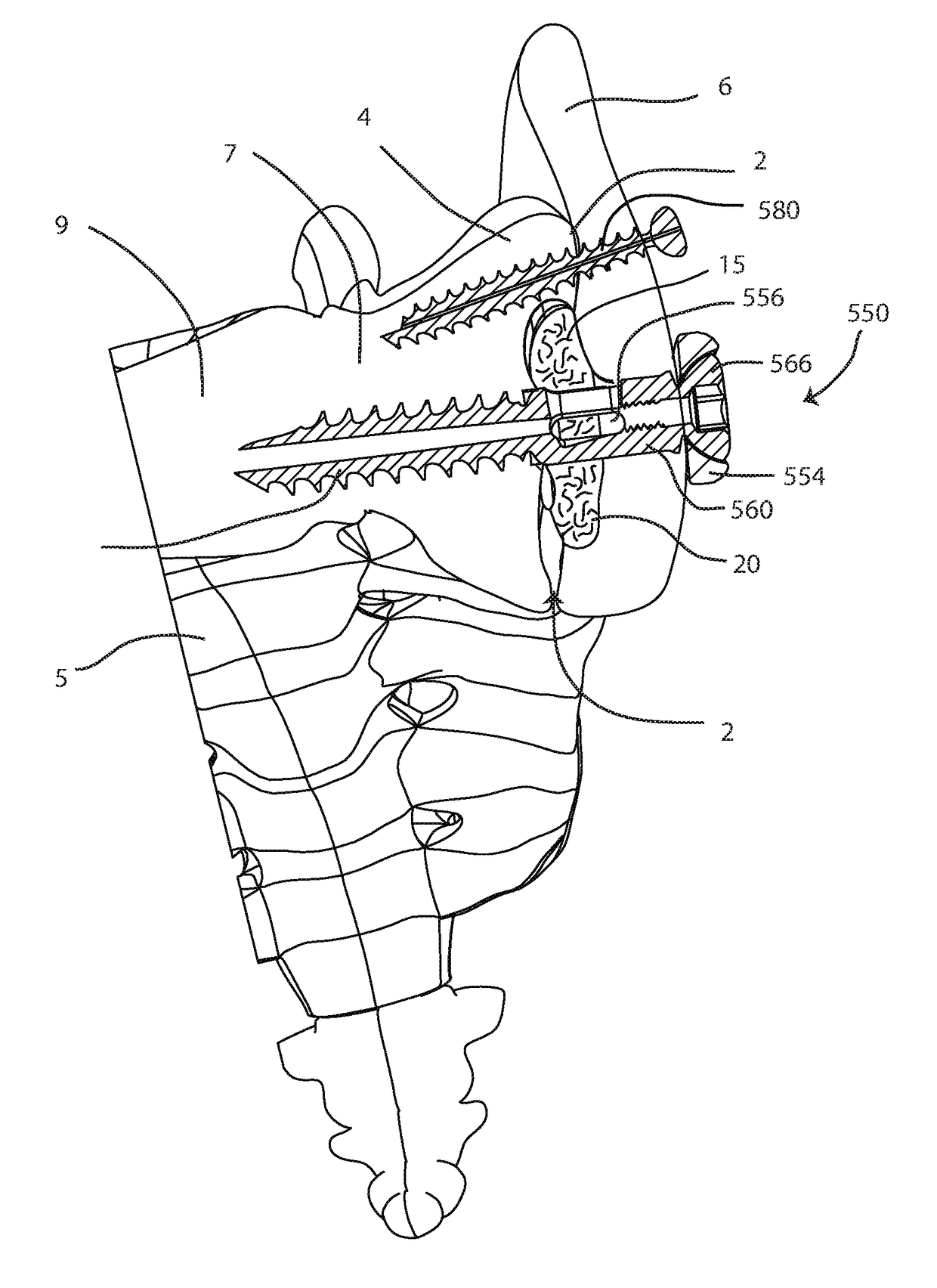

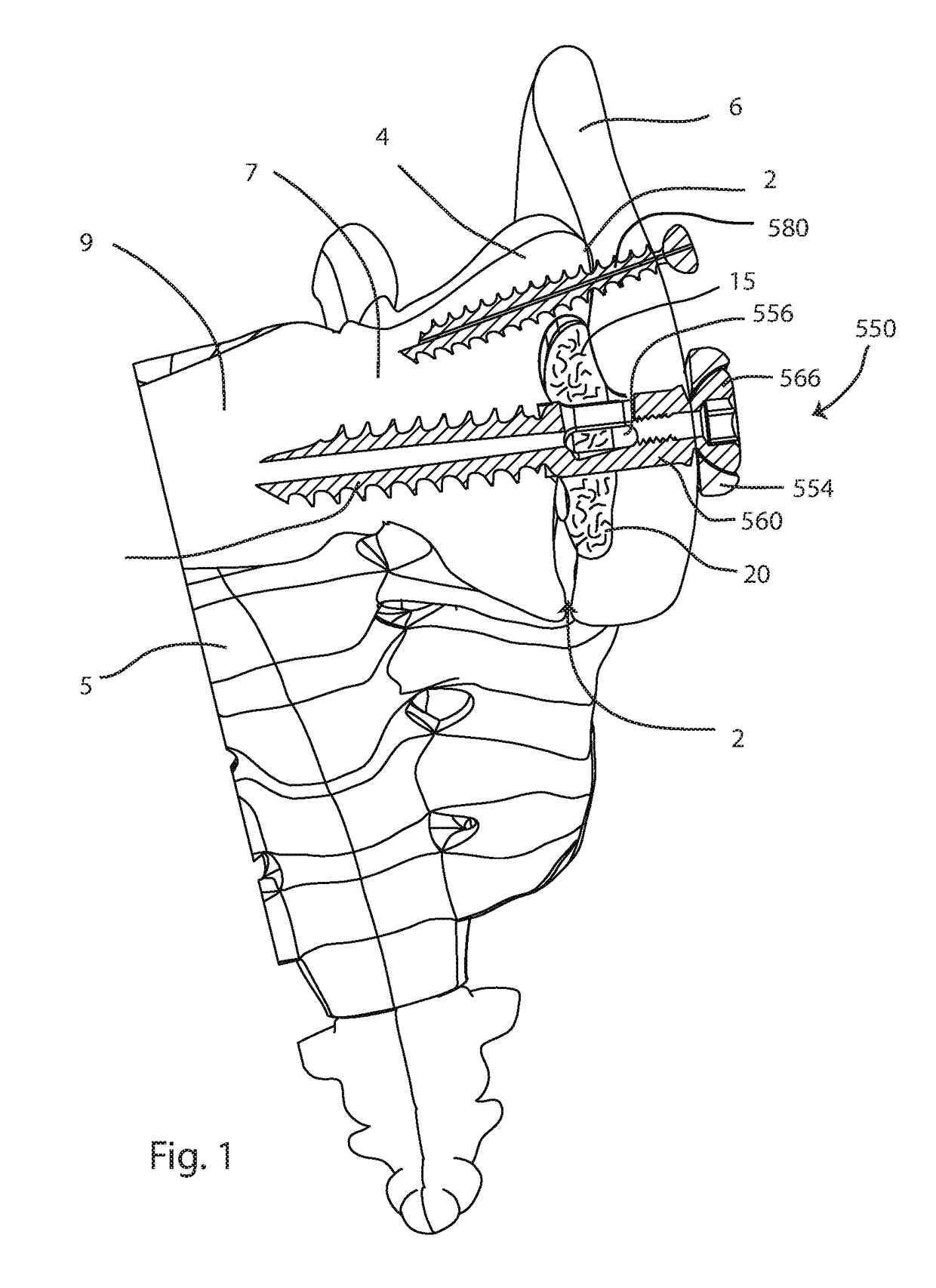

Joint fusion instrumentation and methods

ActiveUS20170303938A1Small incisionShort operating timeInternal osteosythesisDiagnosticsJoint fusionSacroiliac joint

Systems and methods for joint preparation and fusion are disclosed. The system includes a cutting device having a handle, and rigid blade member. The blade member may include cutting edges on first and second sides, and may be curved in one or more planes. The blade member may be deployed to project outside of an outer tube, and the cutting device may be rotated to create a circular cavity. In a method of use, a cannula provides access to a procedure site such as a joint. A pathway to the joint is created, and the cutting device is inserted and deployed to undercut a cavity in the joint. A fusion device may be implanted across the joint to provide compression and fuse the joint. The system may also include instrumentation for creating access to a joint, bone graft insertion and implant insertion.

Owner:IMDS CORPORATION +1

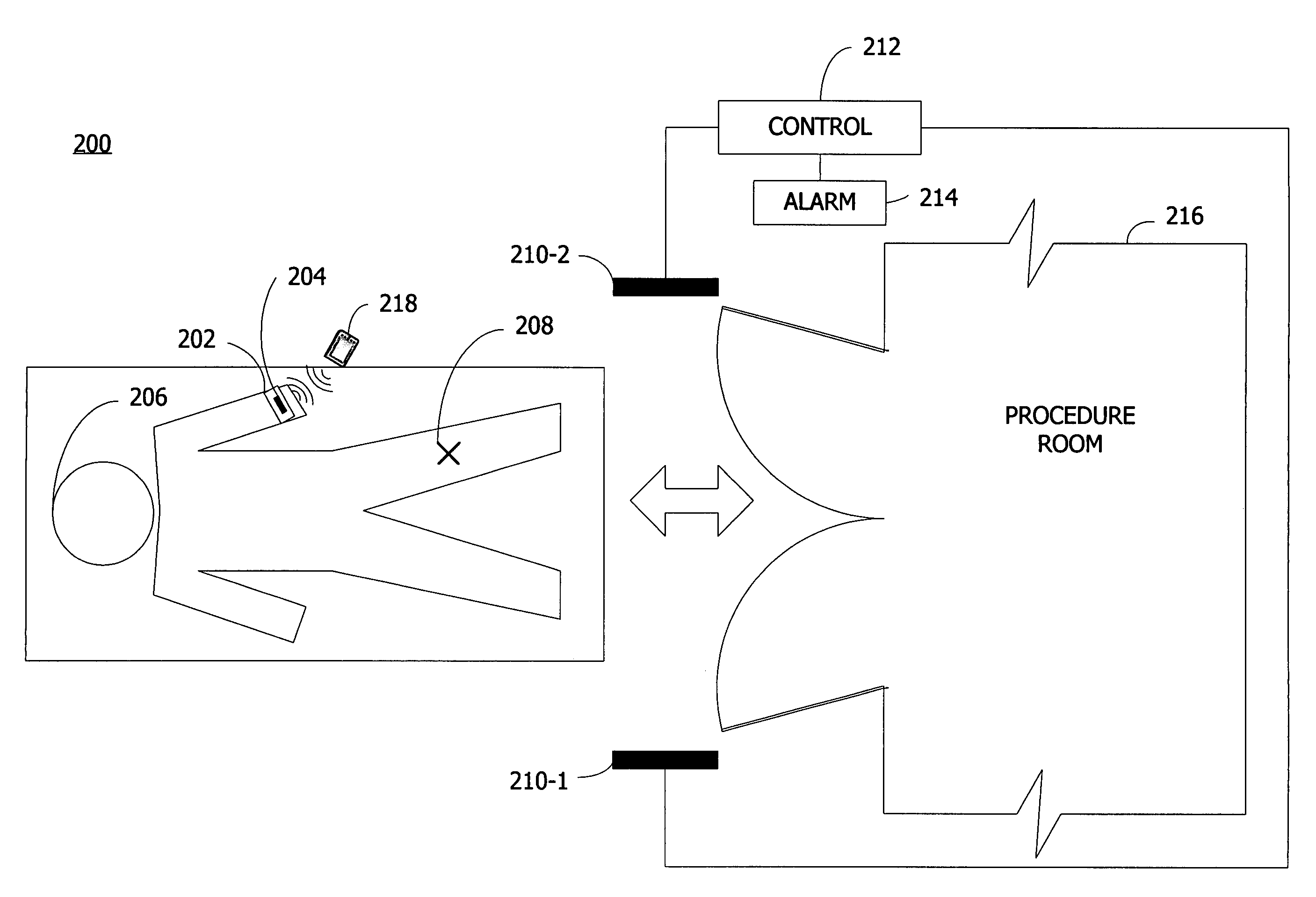

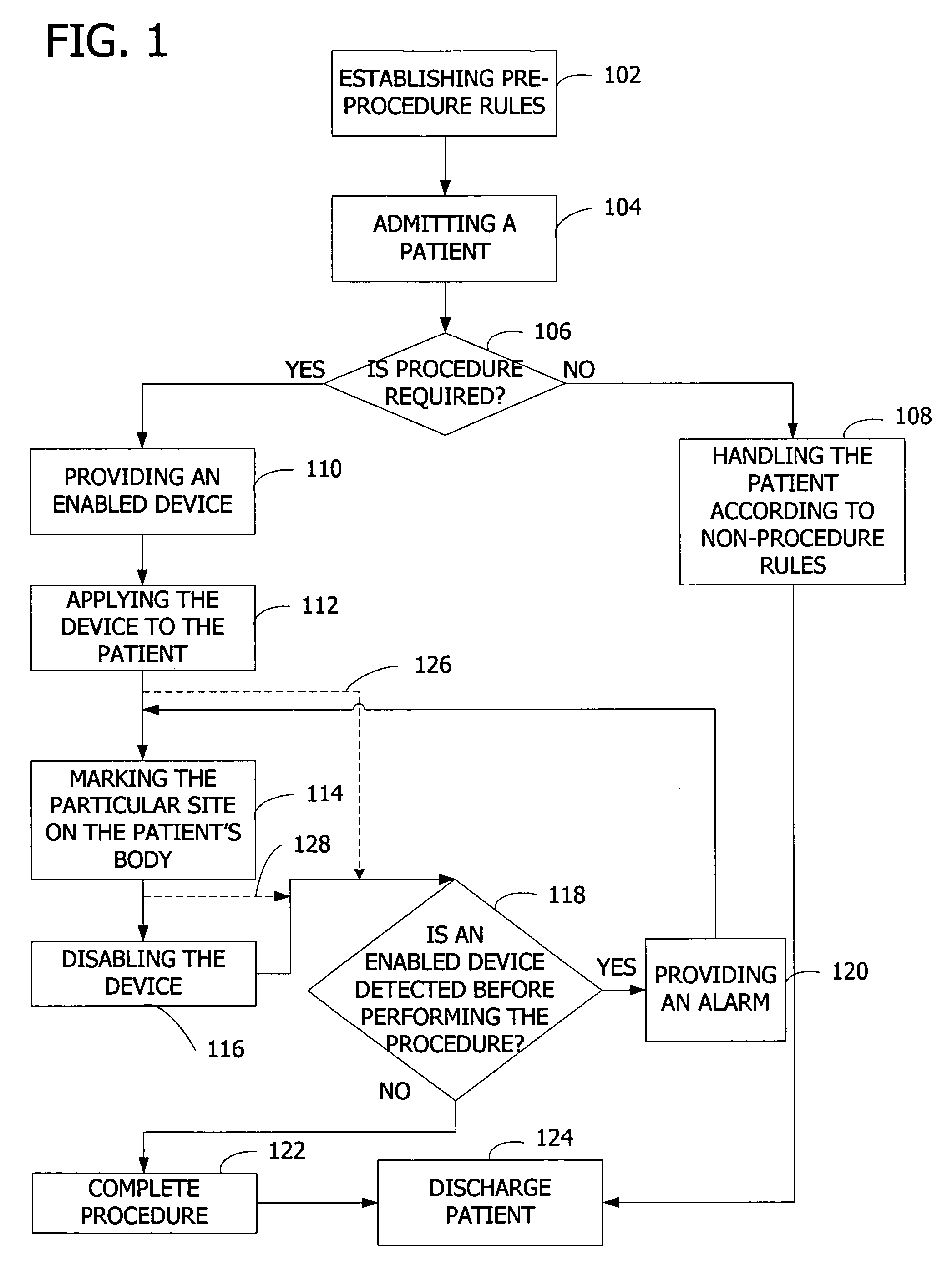

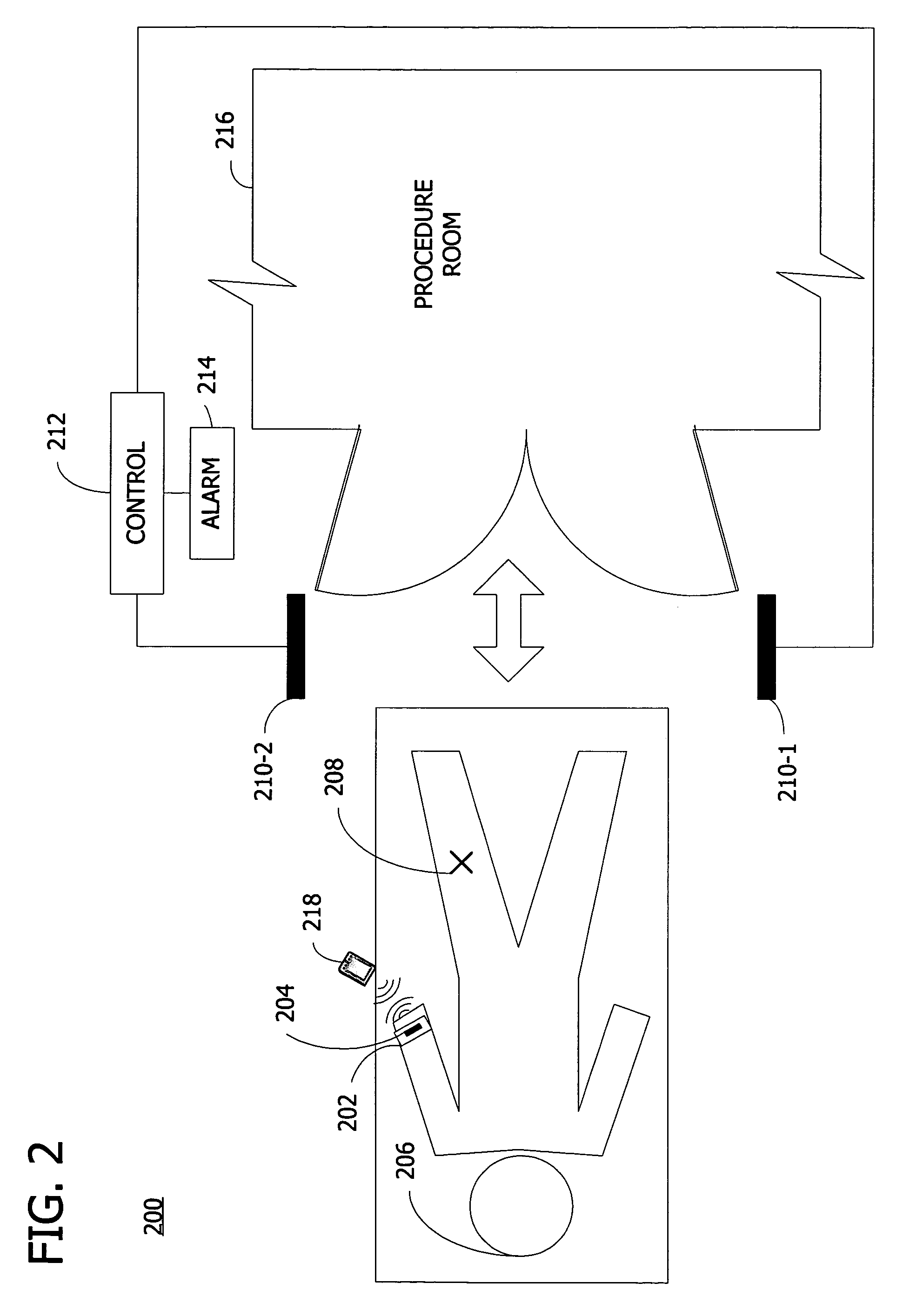

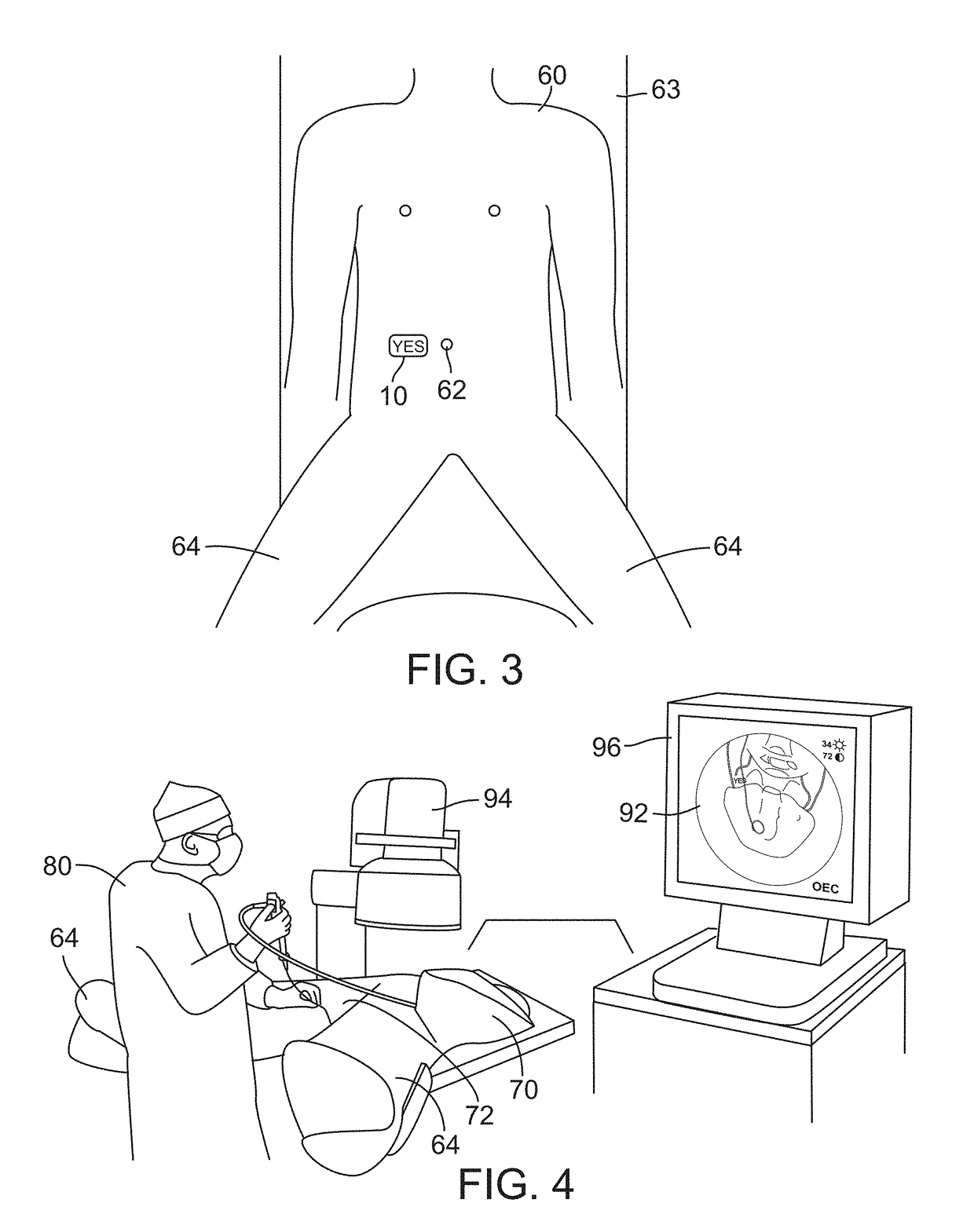

Patient identification system and method for preventing wrong site procedure

A patient equipped with a device in a first mode is scheduled for a procedure in a procedure room at a facility with pre-procedure rules (e.g., requiring procedure site marking). Only a surgeon or other authorized individual is permitted to change the first mode to a second mode after complying with the rules (e.g., marking a site on the patient's body). A detector is located at or near the entrance of the procedure room for detecting devices having the first mode. If the first mode is detected, an alarm is provided indicating that the rule may not have been followed.

Owner:WASHINGTON UNIV IN SAINT LOUIS

Joint fusion instrumentation and methods

ActiveUS9833321B2Small incisionShort operating timeInternal osteosythesisDiagnosticsJoint fusionSacroiliac joint

Systems and methods for joint preparation and fusion are disclosed. The system includes a cutting device having a handle, and rigid blade member. The blade member may include cutting edges on first and second sides, and may be curved in one or more planes. The blade member may be deployed to project outside of an outer tube, and the cutting device may be rotated to create a circular cavity. In a method of use, a cannula provides access to a procedure site such as a joint. A pathway to the joint is created, and the cutting device is inserted and deployed to undercut a cavity in the joint. A fusion device may be implanted across the joint to provide compression and fuse the joint. The system may also include instrumentation for creating access to a joint, bone graft insertion and implant insertion.

Owner:IMDS CORPORATION +1

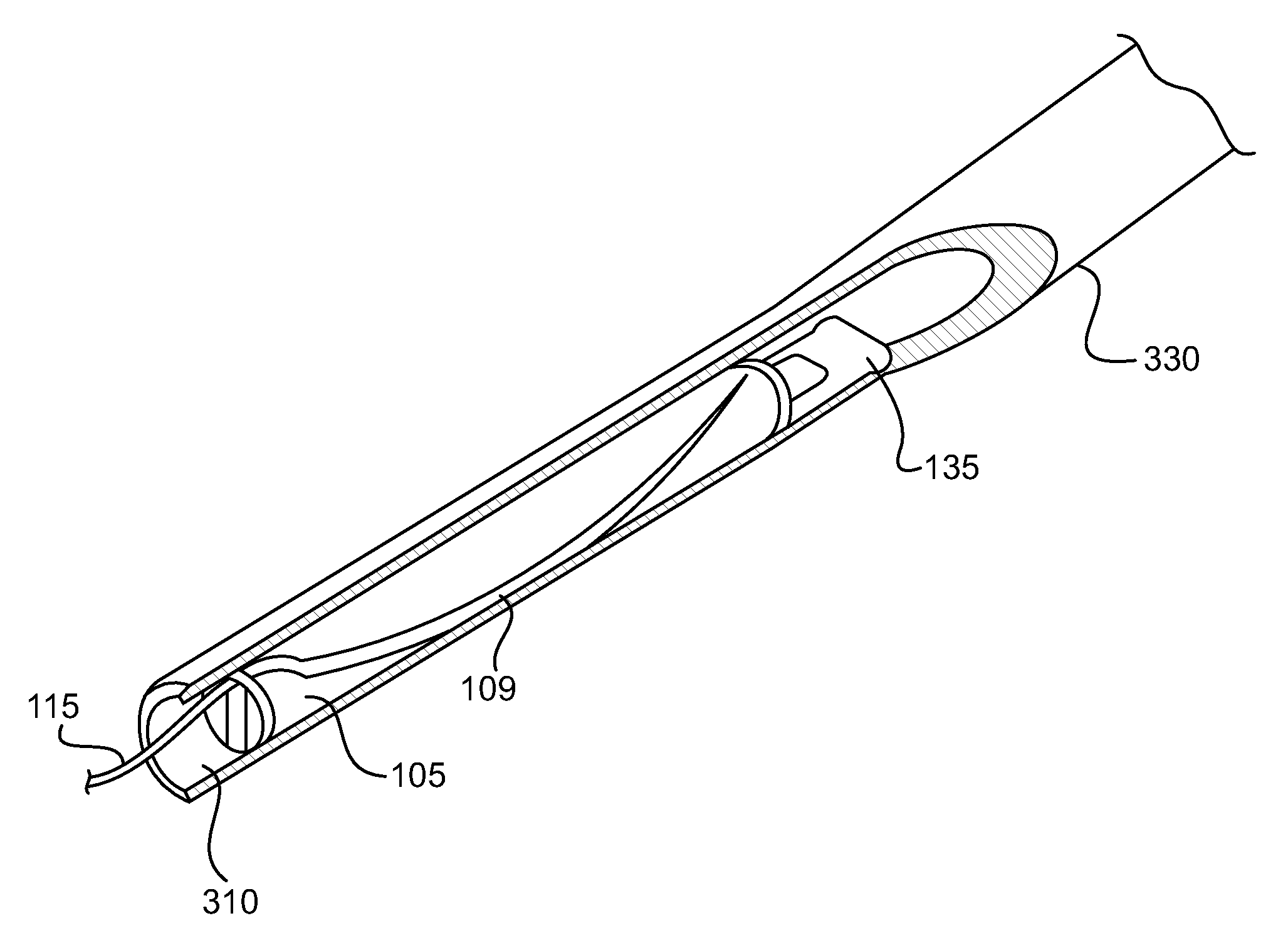

Tool delivery systems and methods of use

InactiveUS20110172706A1Reduce the possibilitySignificant to useSuture equipmentsDiagnosticsSurgical siteCatheter

Tool delivery systems and methods of use are disclosed herein. The delivery systems include a case for transporting a flexible tool to a procedure site and a guide tube. In one aspect, the flexible tool has a first size and shape greater than the diameter of a lumen within the guide tube. Placing the flexible tool into the case changes the flexible tool into a second, smaller size and shape and allows delivery of the needle through the guide tube.

Owner:BOSTON SCI SCIMED INC

Joint fusion instrumentation and methods

ActiveUS20170304060A1Small incisionShort operating timeInternal osteosythesisDiagnosticsJoint fusionSacroiliac joint

Systems and methods for joint preparation and fusion are disclosed. The system includes a cutting device having a handle, and rigid blade member. The blade member may include cutting edges on first and second sides, and may be curved in one or more planes. The blade member may be deployed to project outside of an outer tube, and the cutting device may be rotated to create a circular cavity. In a method of use, a cannula provides access to a procedure site such as a joint. A pathway to the joint is created, and the cutting device is inserted and deployed to undercut a cavity in the joint. A fusion device may be implanted across the joint to provide compression and fuse the joint. The system may also include instrumentation for creating access to a joint, bone graft insertion and implant insertion.

Owner:IMDS CORPORATION +1

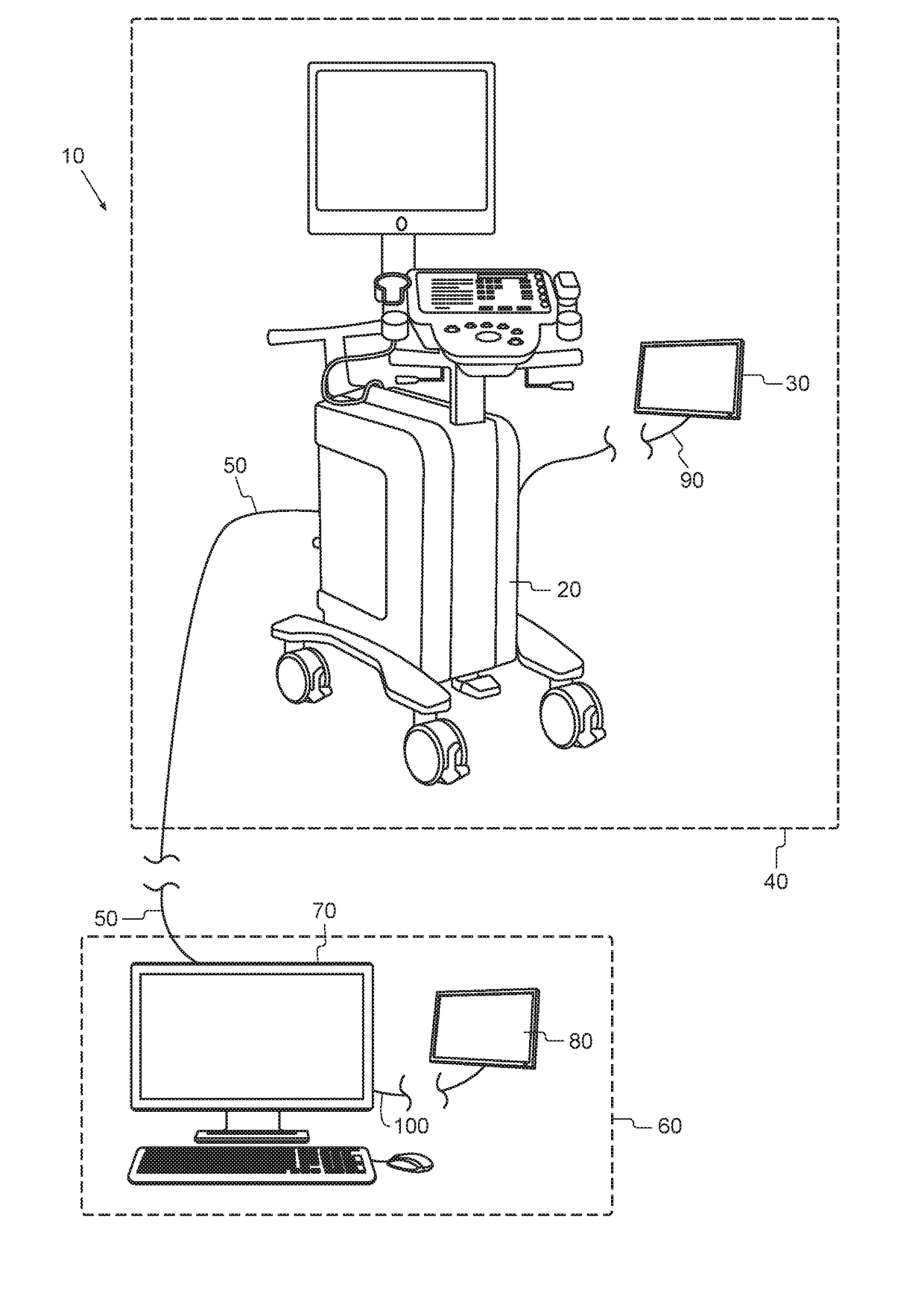

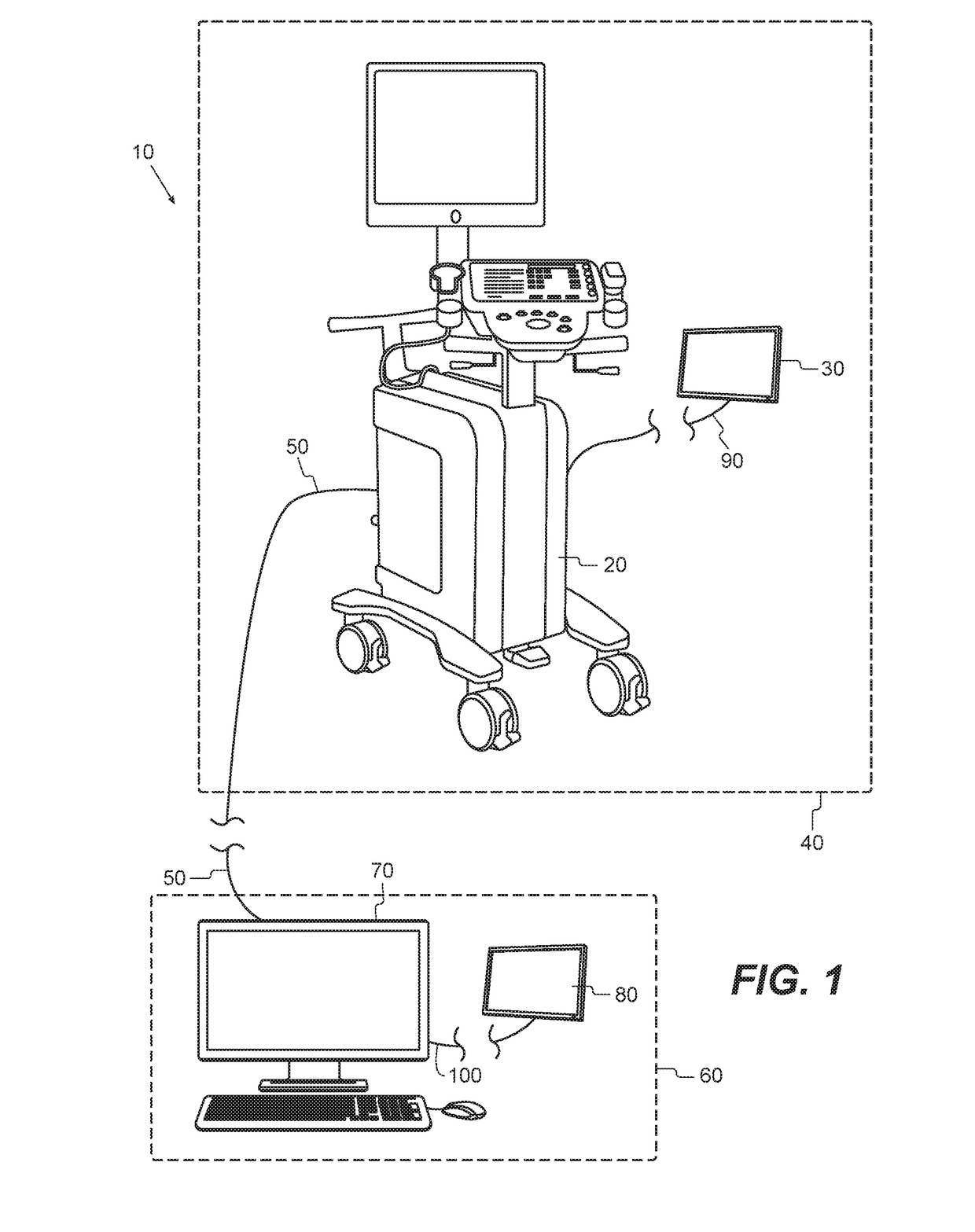

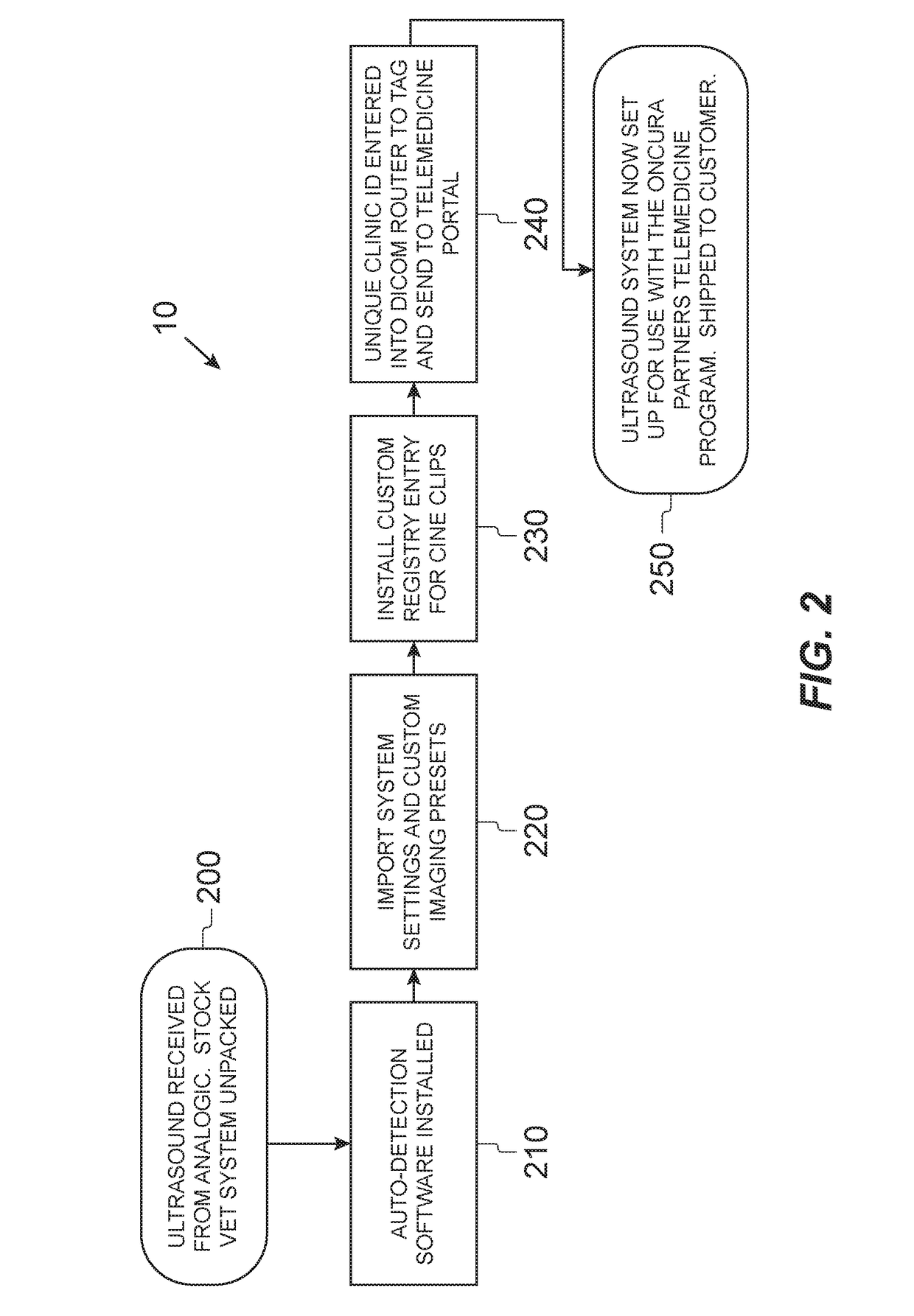

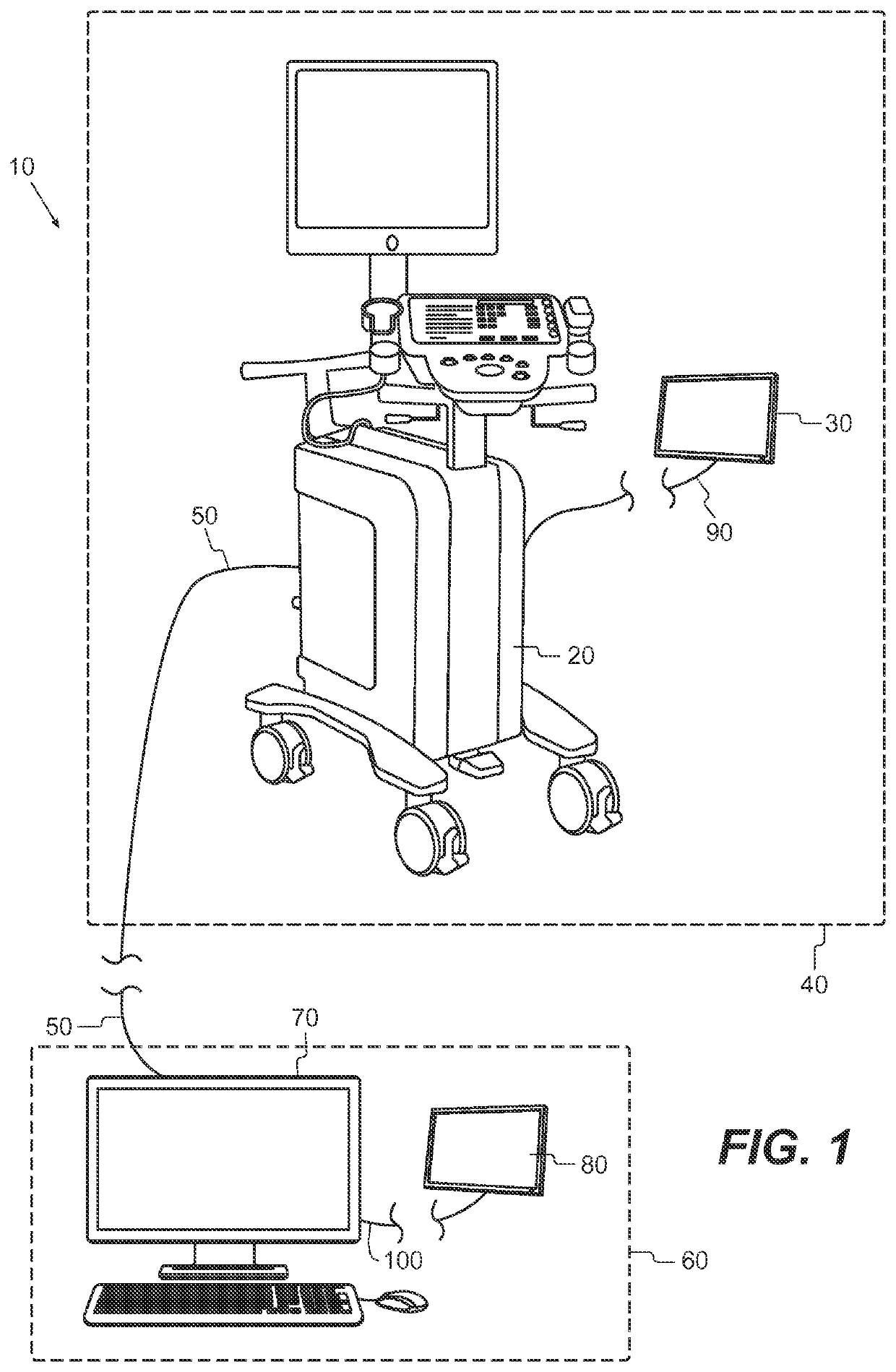

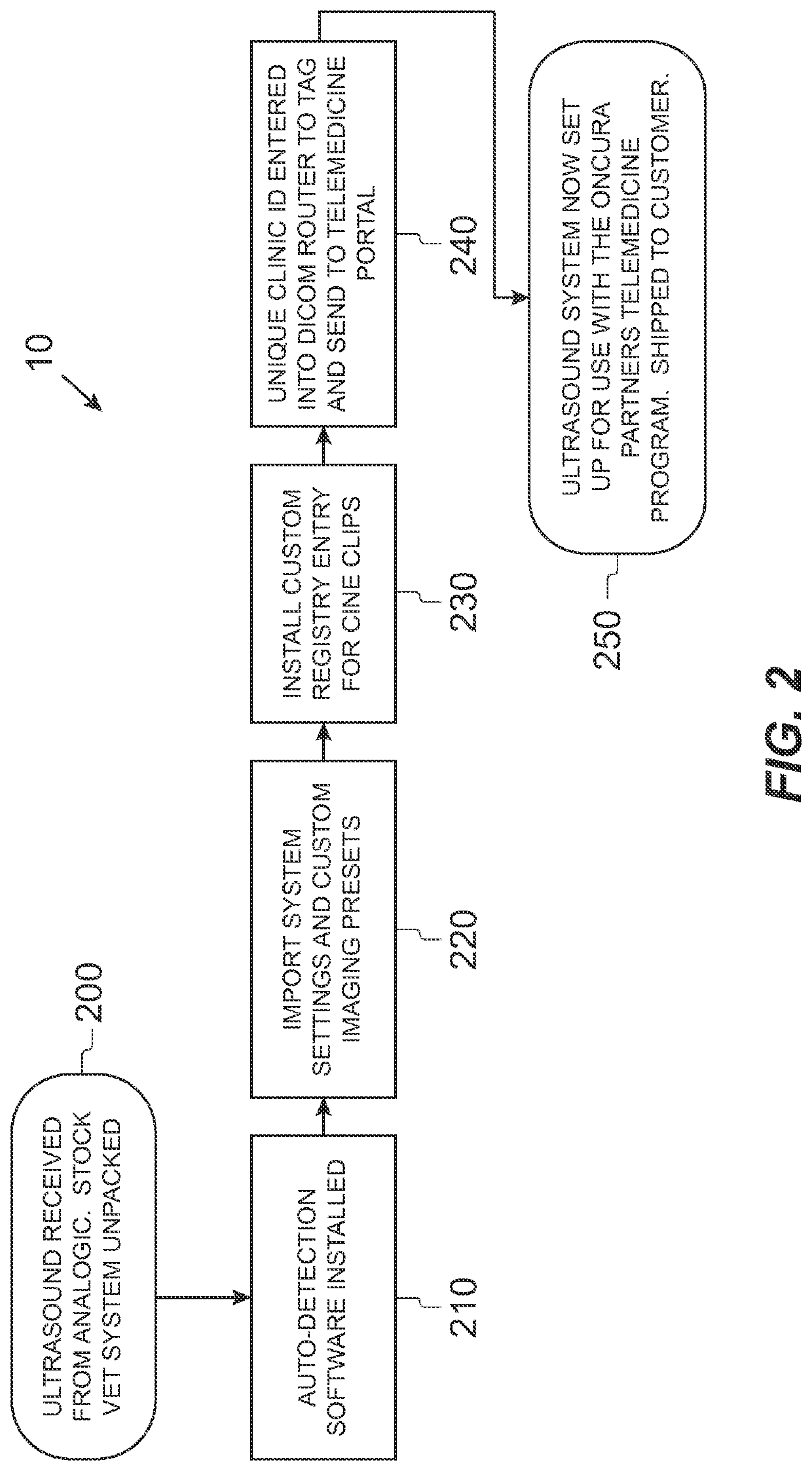

Ultrasound remote monitoring, operating and training system

InactiveUS20180303344A1Diagnostic recording/measuringInfrasonic diagnosticsULTRASOUND PROCEDURESSonification

The present invention is a method, system, and apparatus used to transmit information to an individual and or receiver who is not located at the actual ultrasound procedure that may monitor, communicate, and assist in the procedure in real time as well as provide protocols for specific procedures; wherein the ultrasound machine communicates to a receiver operational information such as but not limited to audio, visual, performance, and so forth; wherein the information may be received in real time to another party not located at the site of the procedure who may assist with the procedure, training, protocols, and so forth; and wherein the receiver may then transmit back to the ultrasound machine specific directions as well as communicate with the ultrasound operator.

Owner:ONCURA PARTNERS DIAGNOSTICS LLC

Single port instruments

Surgical tools that can be used in single port laparoscopic procedures can include a low-profile handle assembly to minimize tool interference adjacent the incision site. For example, a handle assembly for a surgical instrument can have a generally in-line configuration extending linearly along a central longitudinal axis of an elongate shaft of the instrument. A linkage mechanism including a trigger, an actuation link, and an actuation shaft can be positioned within the in-line handle. The linkage mechanism can be pivoted between an open position in which end effectors of the instrument are open and a toggle position in which the end effectors are locked closed. A locking mechanism such as a ratchet mechanism can also be used to lock the end effectors. A surgical dissector can include gripping jaws having a curved profile or an angled elongate shaft to minimize tool interference and maximize visibility within a procedure site.

Owner:APPL MEDICAL RESOURCES CORP

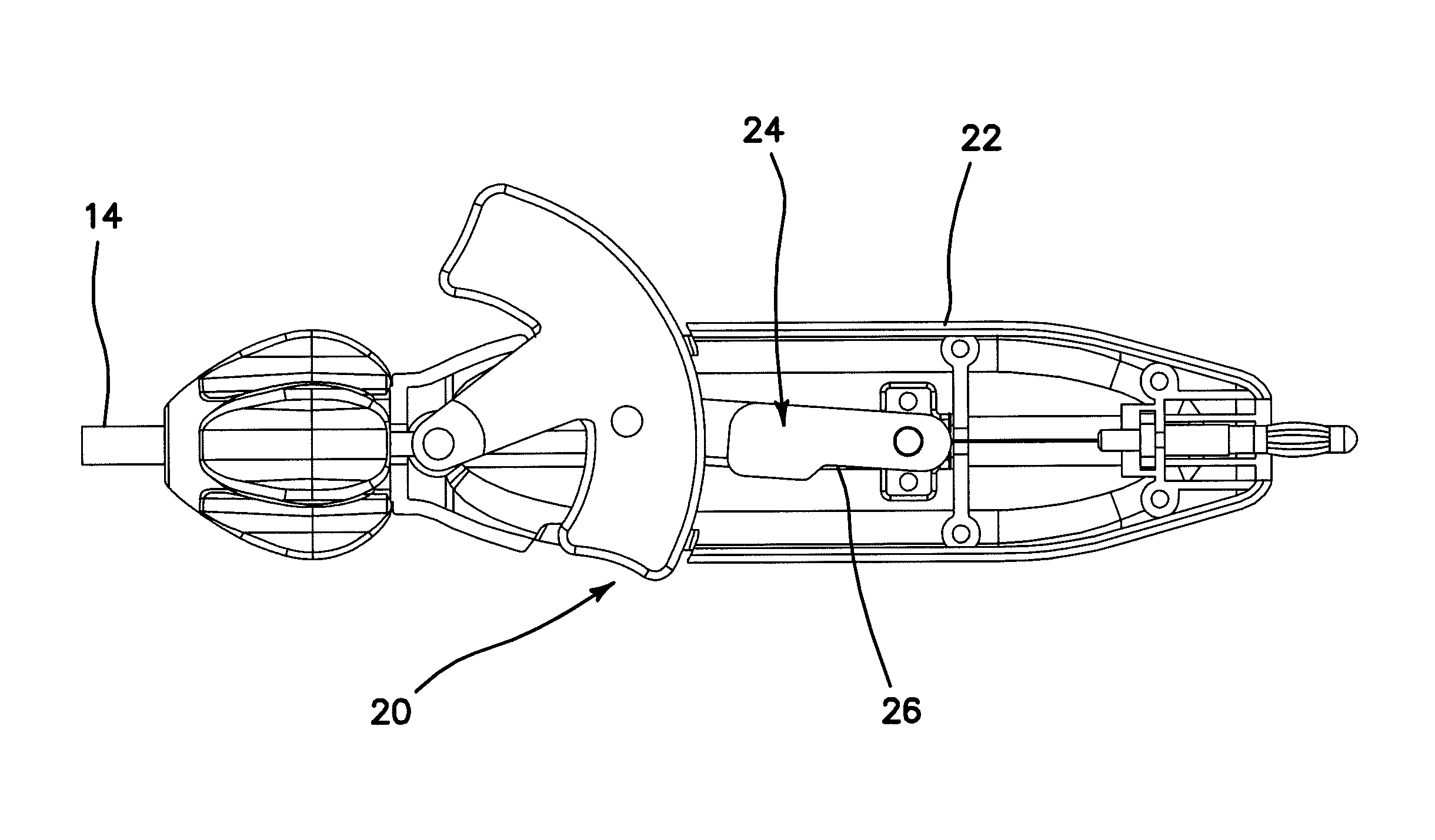

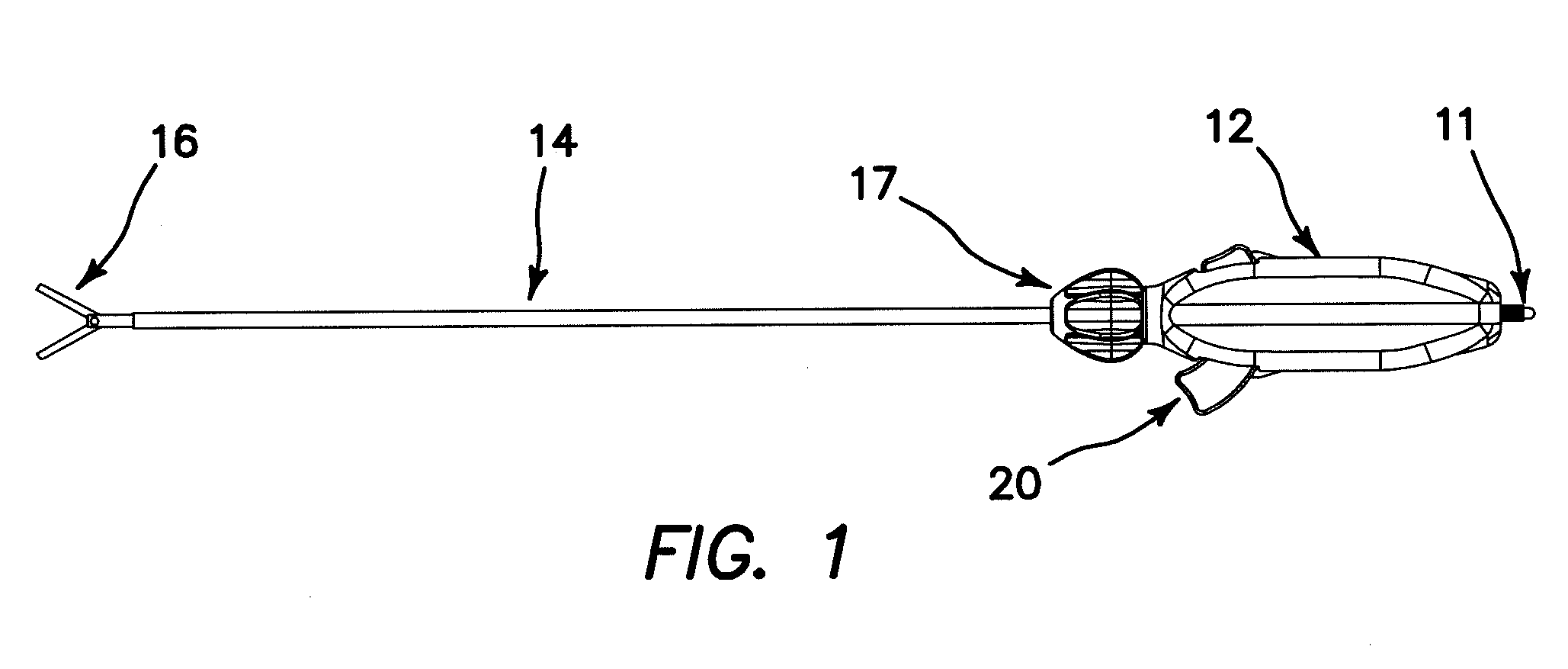

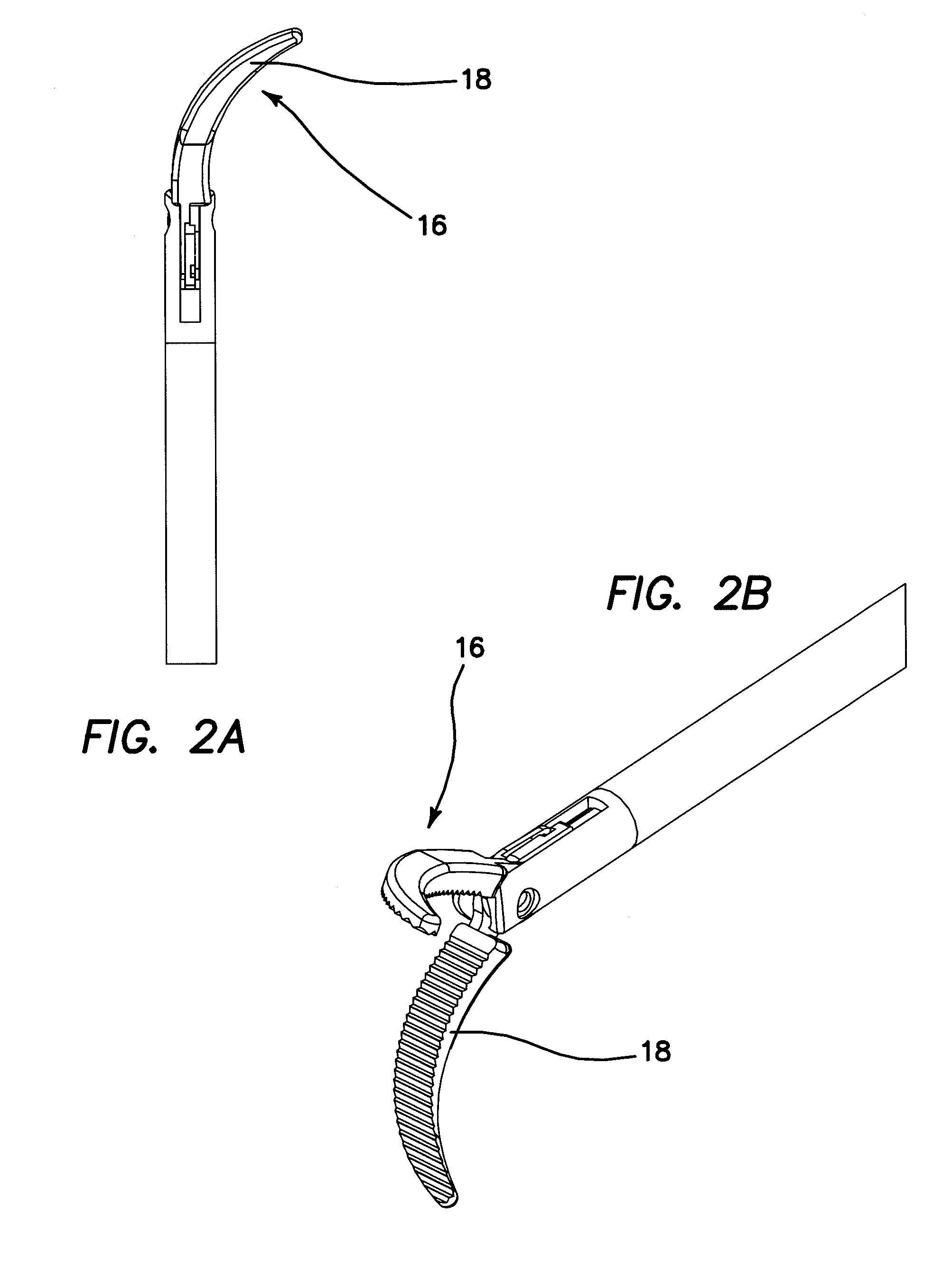

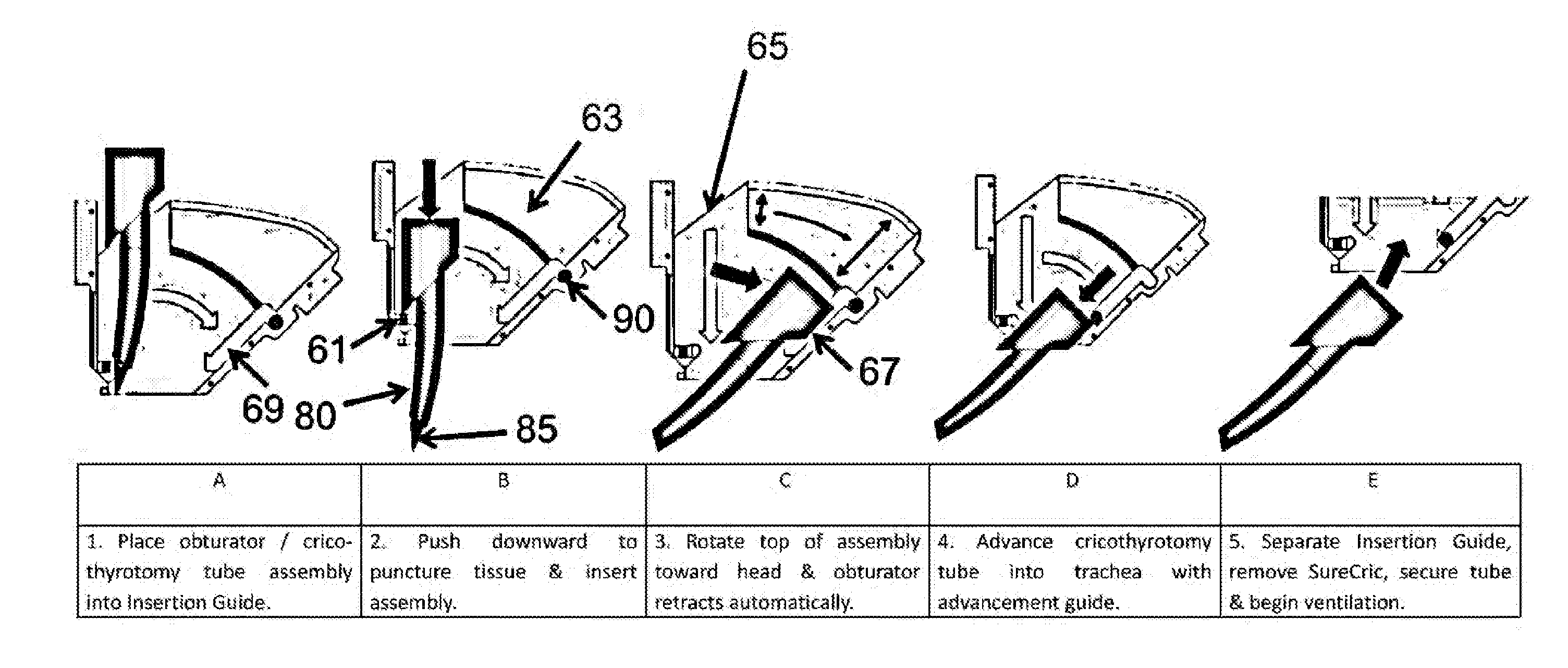

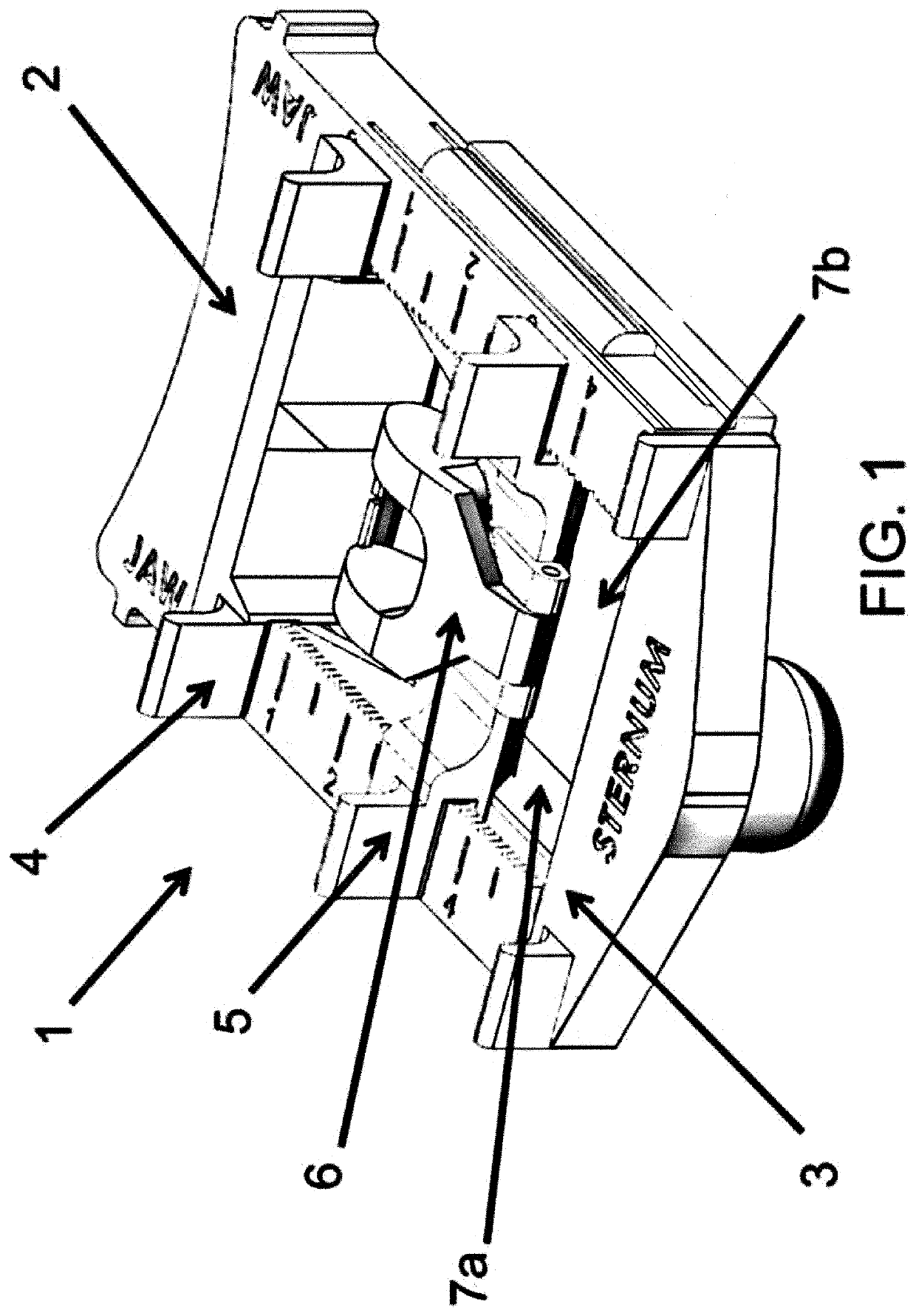

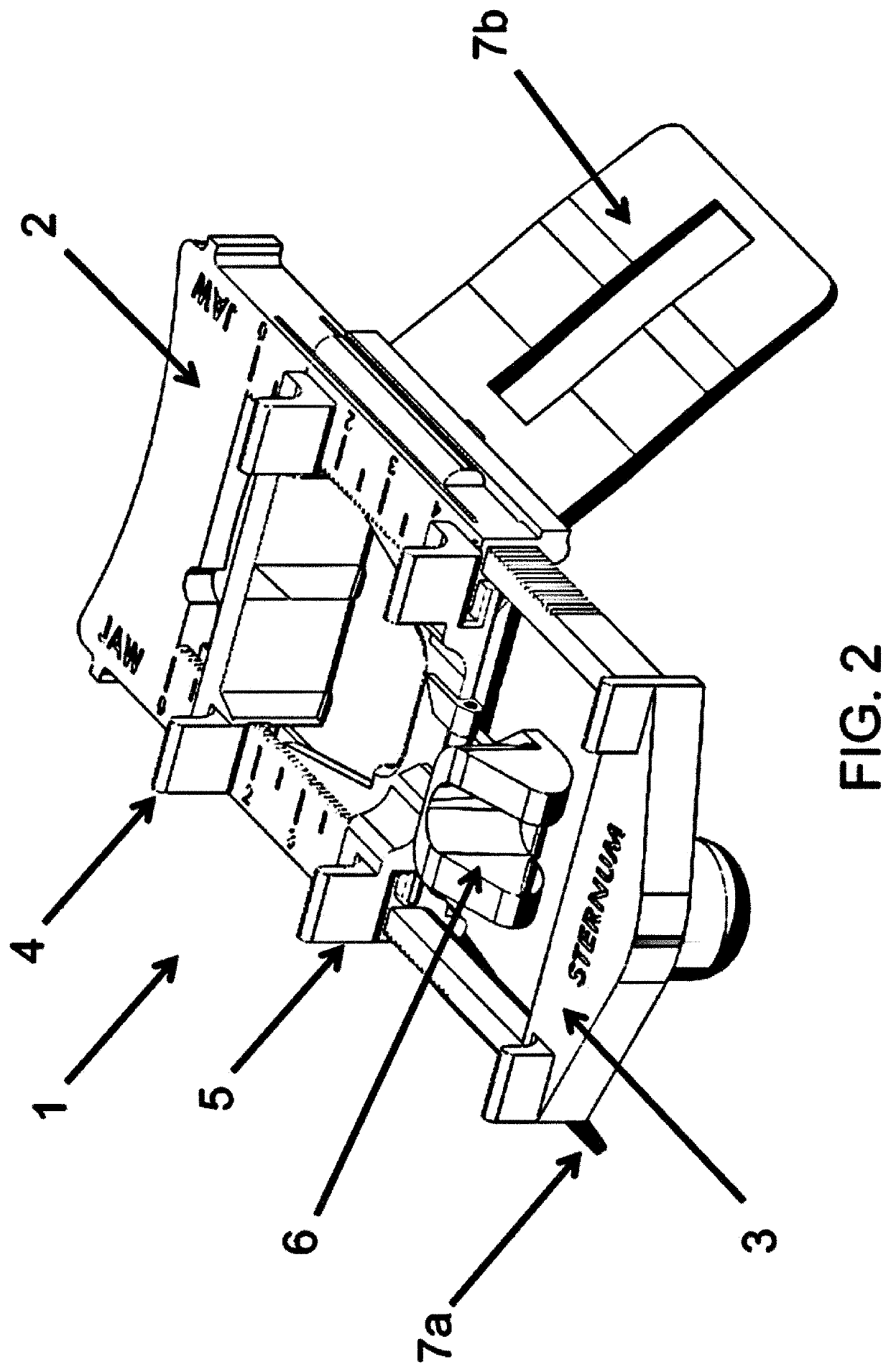

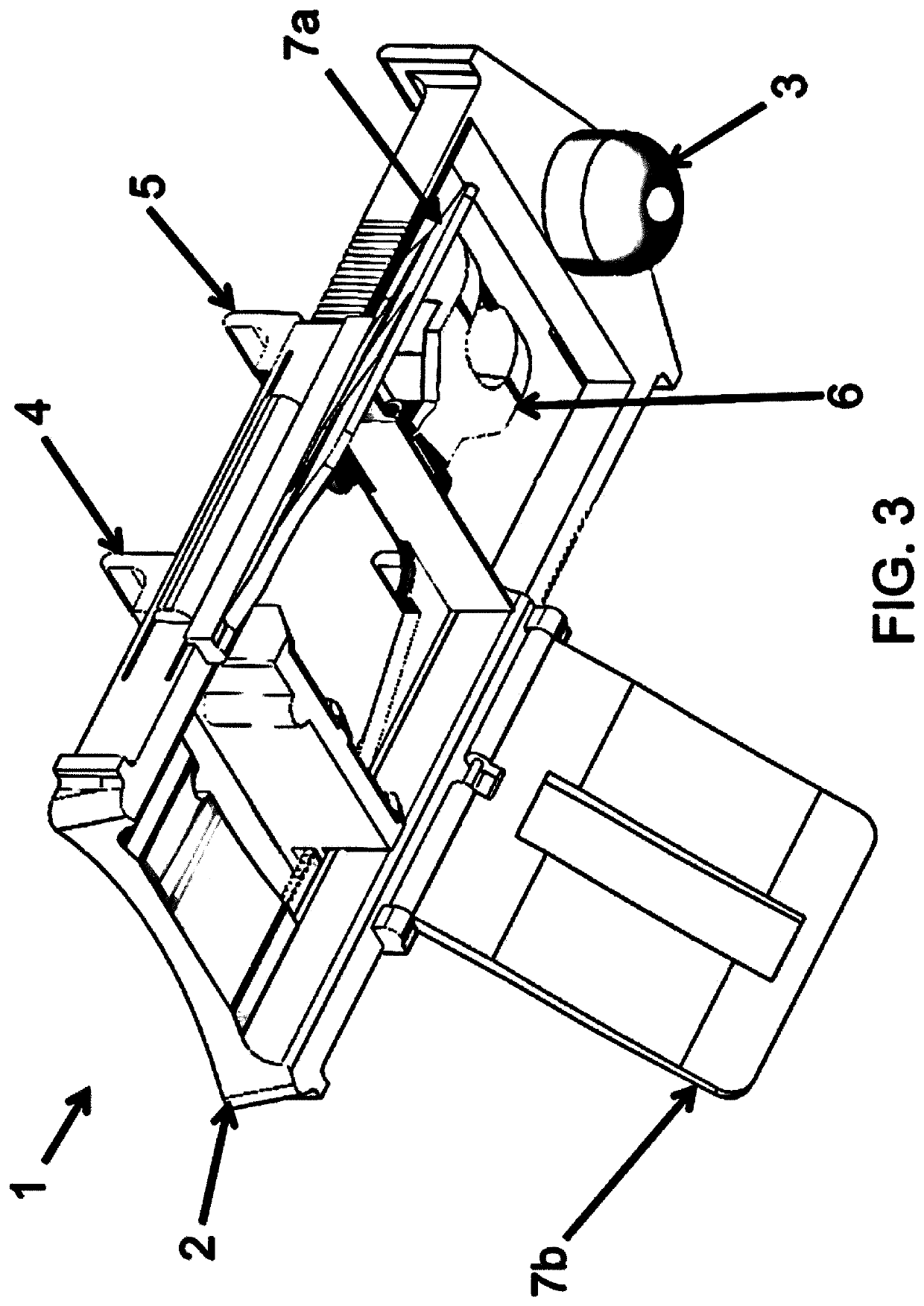

Assist device for medical procedures

ActiveUS20160220772A1Avoid damageEasily and safely removableTracheal tubesWound drainsAnatomical landmarkMedicine

A device to assist performing medical procedures that references anatomical landmarks through adjustable components to identify and stabilize a procedure site and provide guidance in performing the procedure. In one embodiment, an airway creation assist device (ACAD) can be dimensionally adjusted for different patient sizes and properly aligned using anatomical landmarks. The ACAD provides an adjustable template that enables accurate identification of the airway creation site, including but not limited to the cricothyroid membrane. The ACAD uses an insertion guide to guide the obturator and airway tube safely and consistently into the trachea, with a mechanical stop to prevent damaging the posterior trachea wall. The ACAD improves efficacy of the procedure, and makes perforating an incorrect airway creation procedure difficult. In another embodiment, a chest decompression assist device (DAD) Is disclosed for decompression treatment of air and / or fluid in the chest.

Owner:INNOVITAL LLC

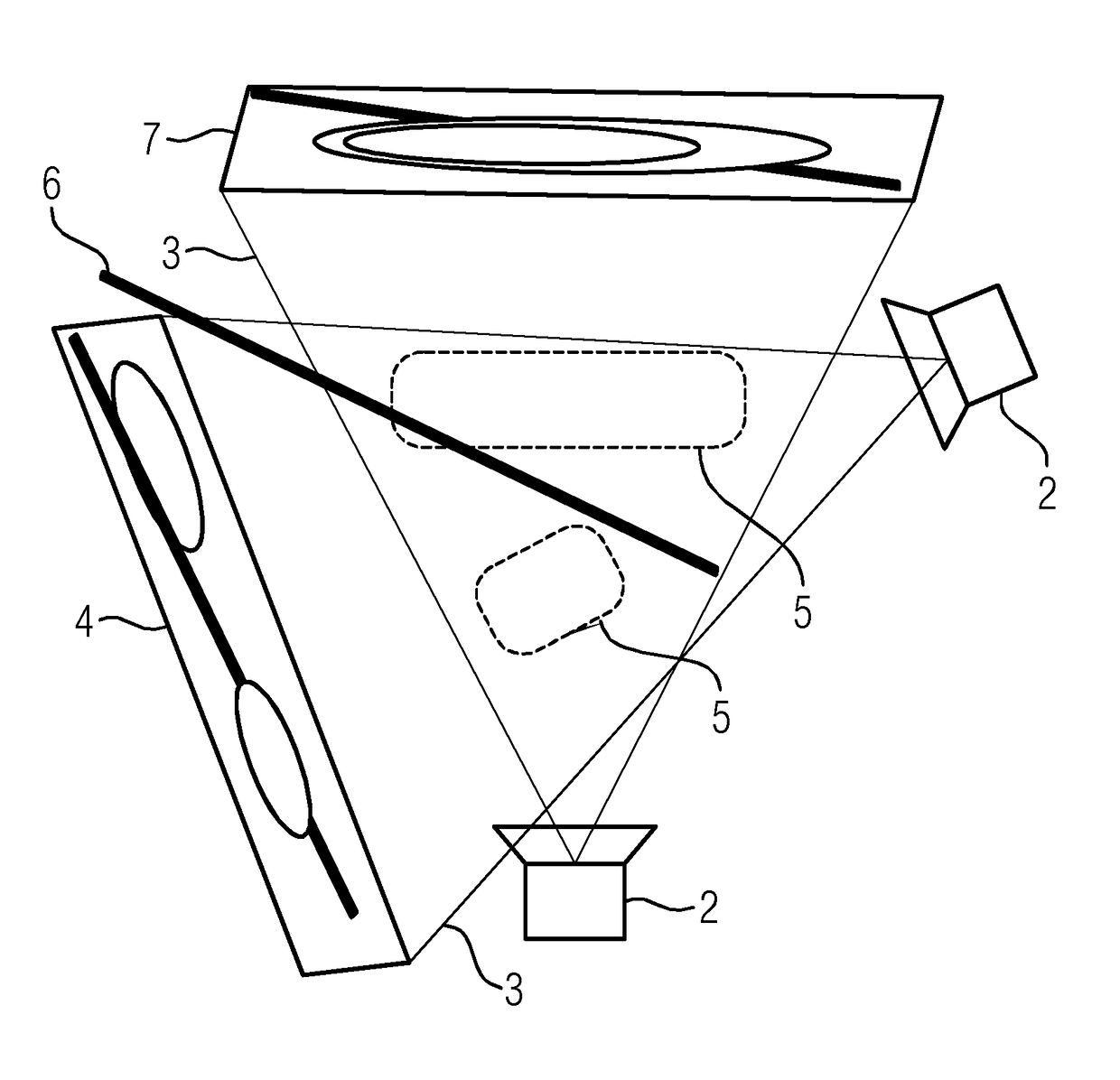

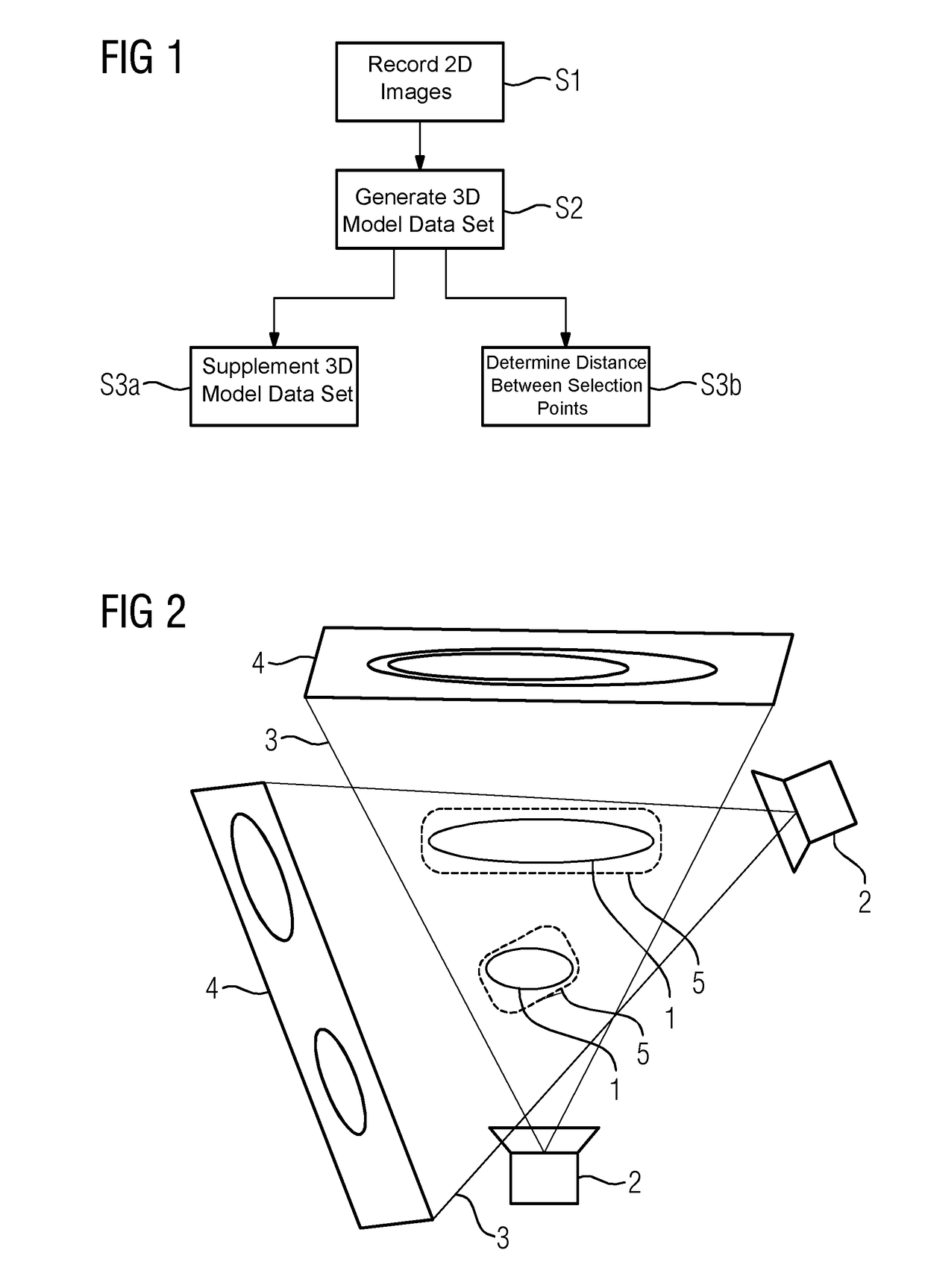

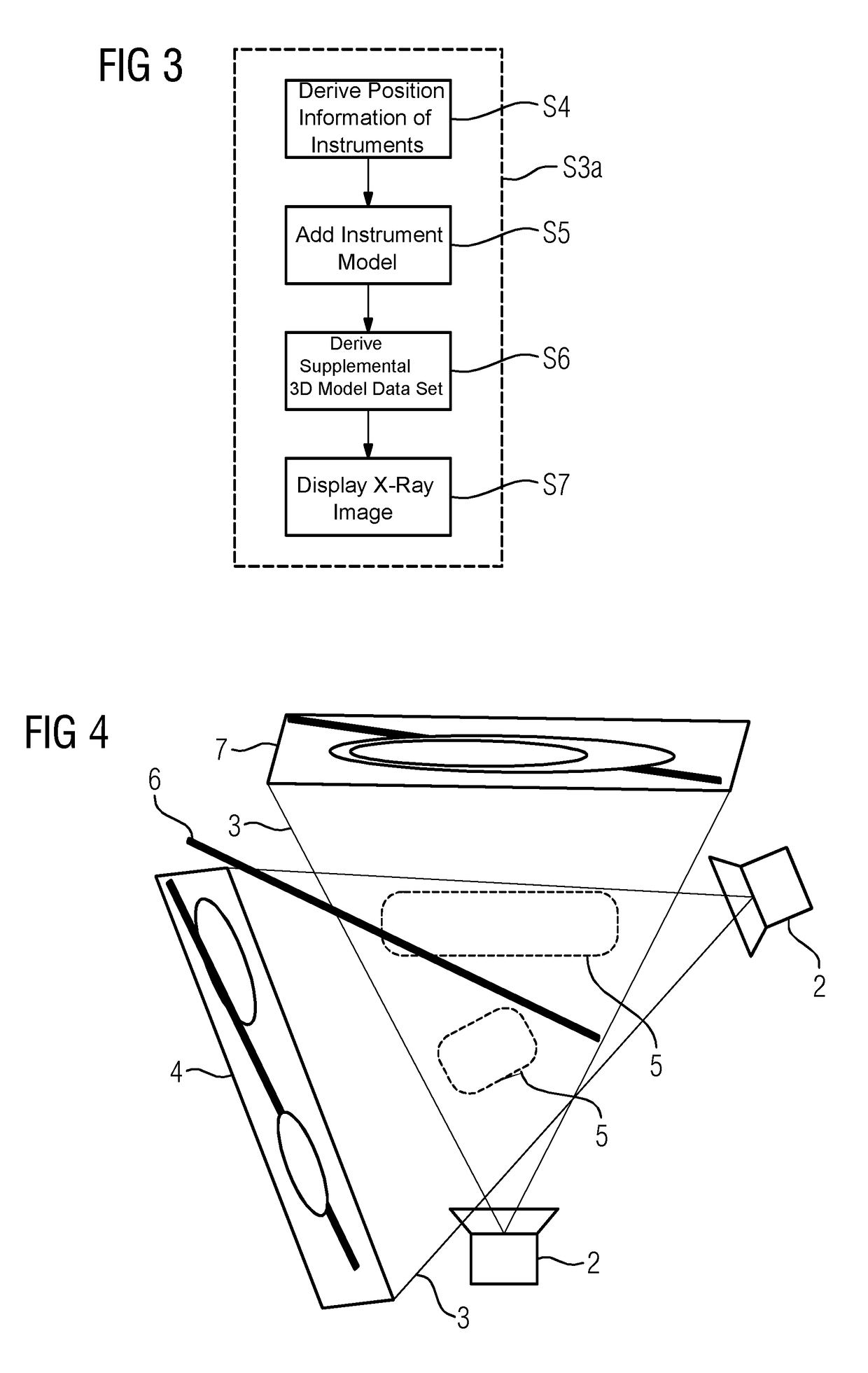

Method of image support for a person carrying out a minimally invasive procedure with an instrument in a procedure site of a patient, x-ray apparatus, computer program and electronically readable data carrier

ActiveUS20180250076A1Error minimizationShorten the timeReconstruction from projectionSurgical navigation systemsData setX-ray

In a method of image support for a person carrying out a minimally invasive procedure with an instrument in a procedure site of a patient, one two-dimensional X-ray image respectively of the procedure site is recorded by an X-ray apparatus in at least two recording geometries implementing different projection directions and chosen specific to the procedure, in particular by the person. A three-dimensional model data set of the procedure region is reconstructed by iterative reconstruction from the X-ray images. At least one two-dimensional supporting image corresponding to one of the recording geometries is determined by incorporating at least one item of further information by re-projection of the model data set supplemented by the further information and is displayed for the user.

Owner:SIEMENS HEALTHCARE GMBH

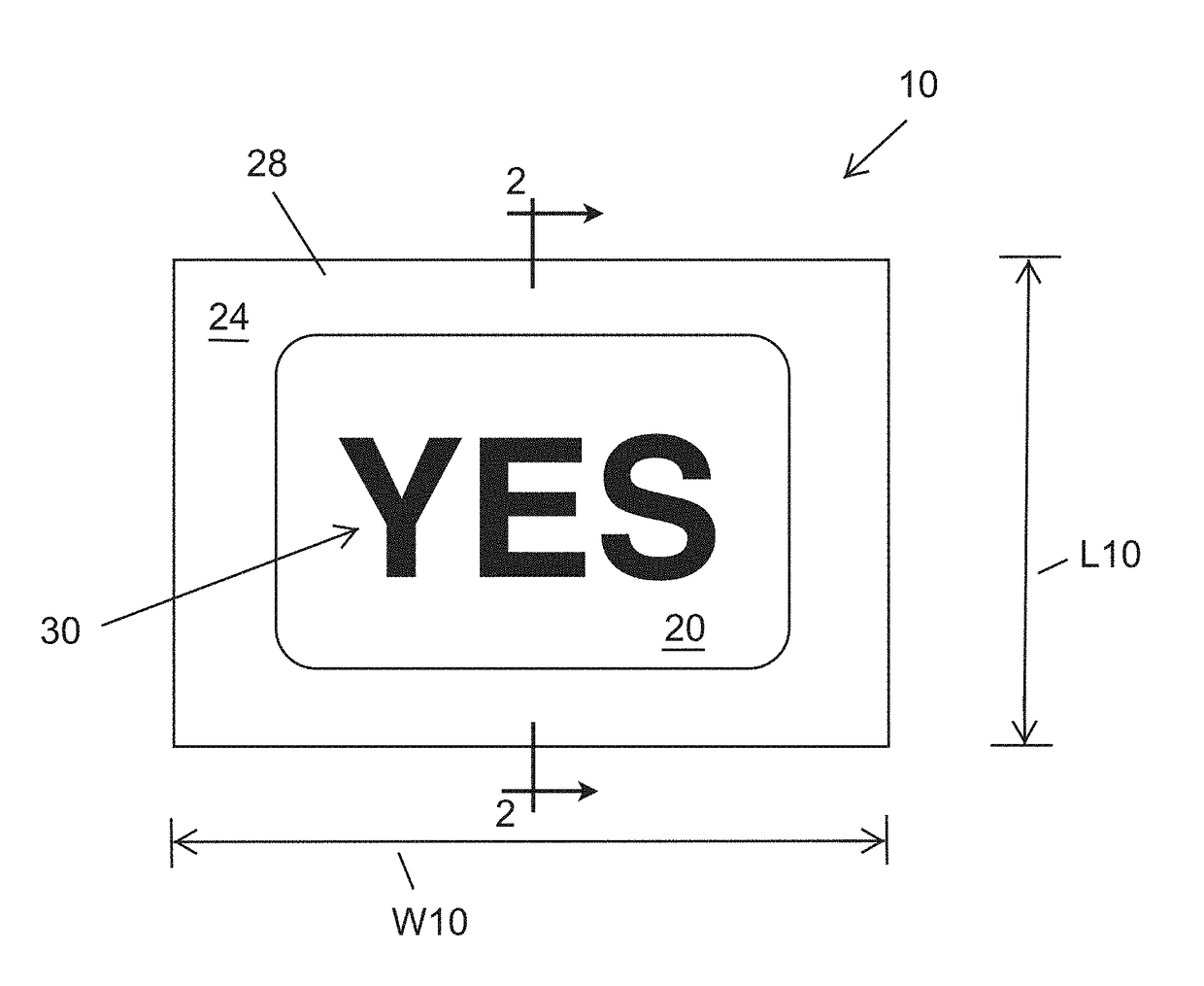

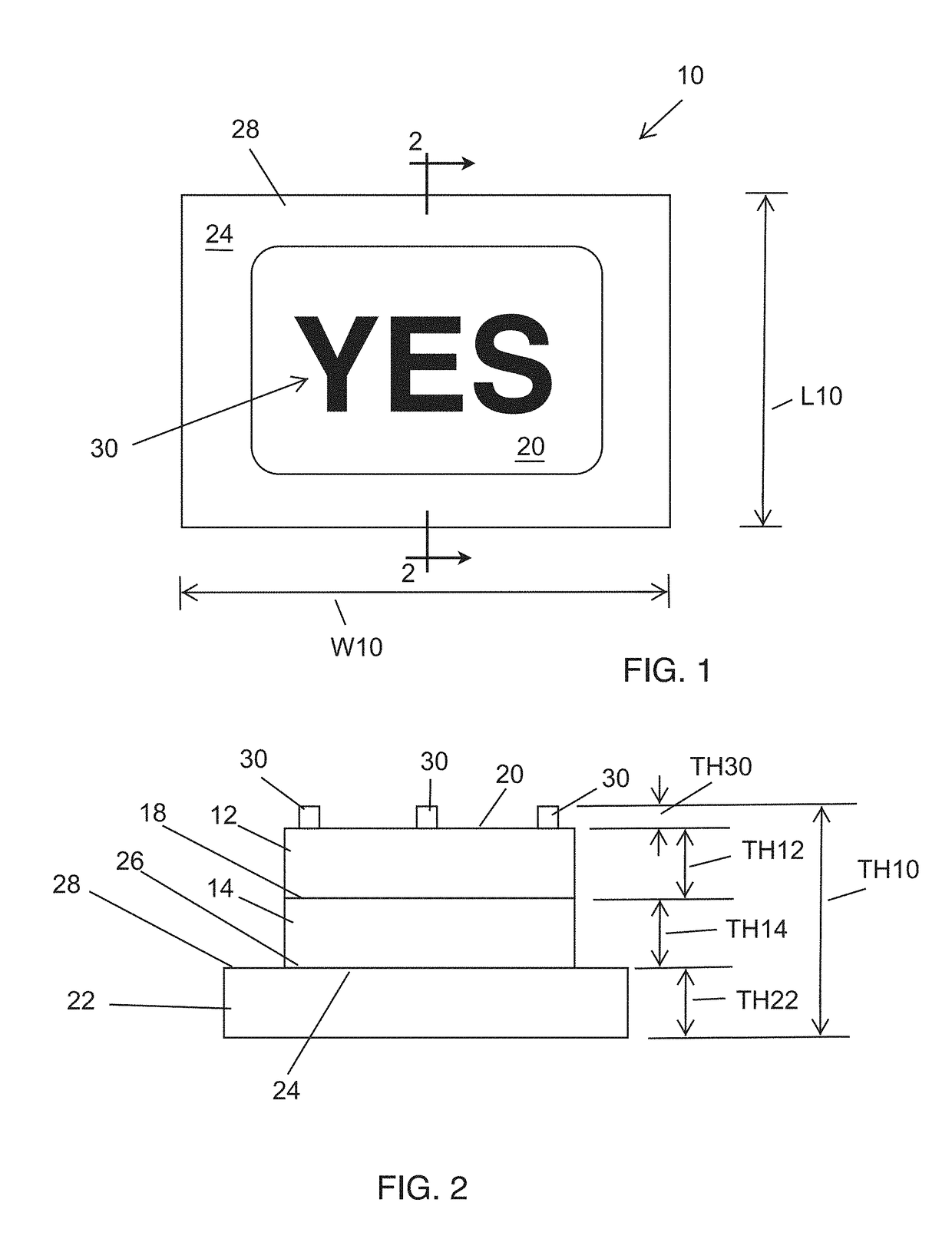

Radiopaque Procedure Site Marker and Method for Intraoperative Medical Imaging

ActiveUS20180116757A1Eliminate riskReadily apparentSurgical navigation systemsSurgical drapesX-rayEndoscopic Procedure

An apparatus and method that provide an improved method of marking a patient requiring an endourologic procedure such as an ureteroscopy are disclosed. The apparatus is an adhesively-backed sheet with a radiopaque marking symbol designed to eliminate risk of a wrong site surgery by creating a visible, unambiguous marking symbol on an intraoperative medical image. The marker sheet is removably applied to the correct side of the patient's body on the groin or abdomen area before the patient is draped for surgery. The marker is visible to the naked eye before it is covered by drapes and visible on an X-ray or other intra operative imaging device whether covered by drapes or not. The visible marking symbol indicia on the X-ray will be unambiguous and will communicate whether the procedure should or should not be performed on that location.

Owner:TARGET TAPE

Filter device for embolic protection systems

A system for enabling the insertion and removal of an embolic protection device, for capturing and retaining embolic debris which may be created during the performance of a therapeutic interventional procedure in a stenosed or occluded region of a blood vessel. The system, in an embodiment thereof, enables the device to be snap-fitted so as to engage the distal end of a guide wire, to provide a reference for positioning the device at a location distal to the interventional procedure site, and to enable an end of the device to be in tension, enabling a portion of the device to be in tension and another portion to be in compression, so as to assist in bending thereof in tortuous vasculature.

Owner:ABBOTT CARDIOVASCULAR

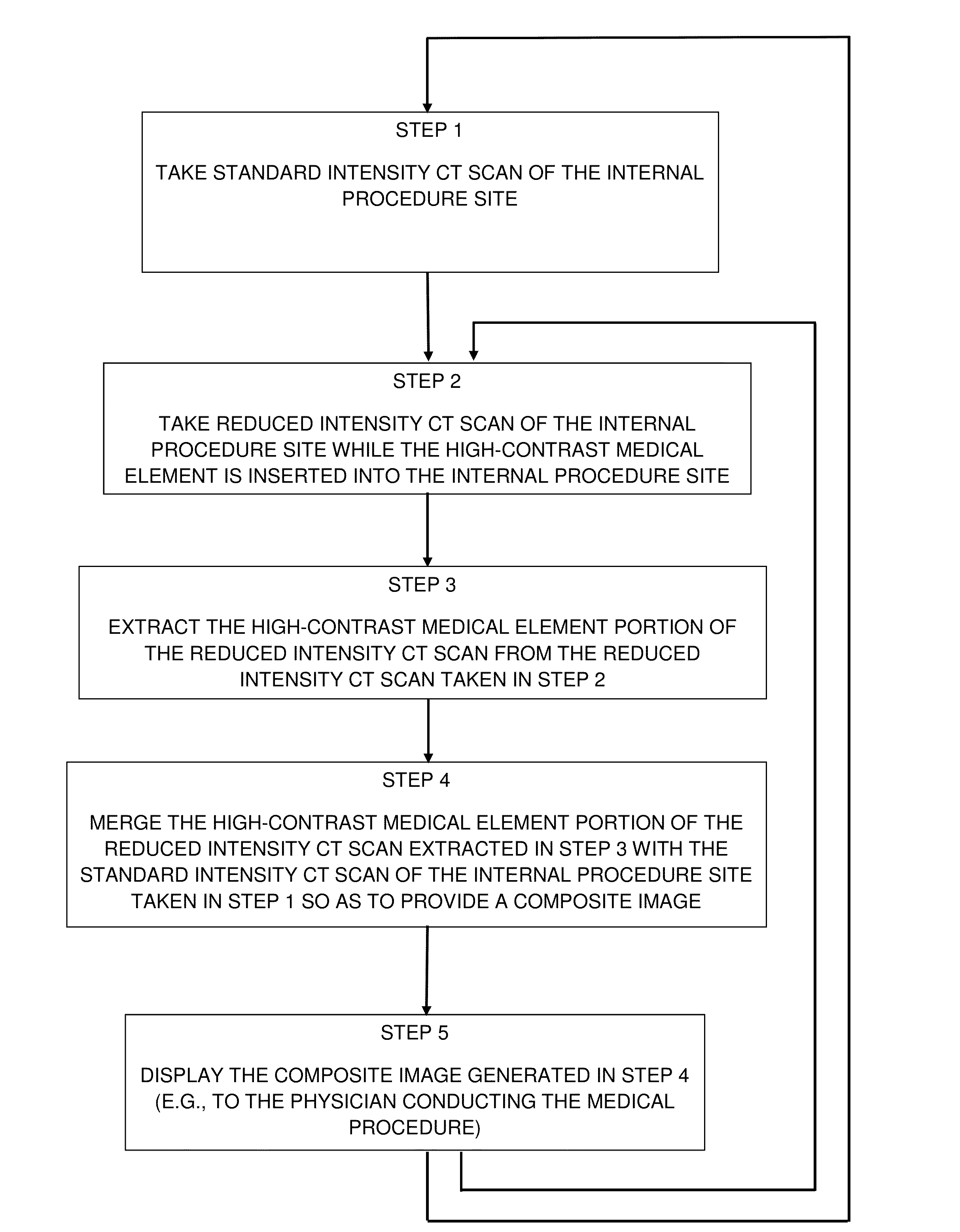

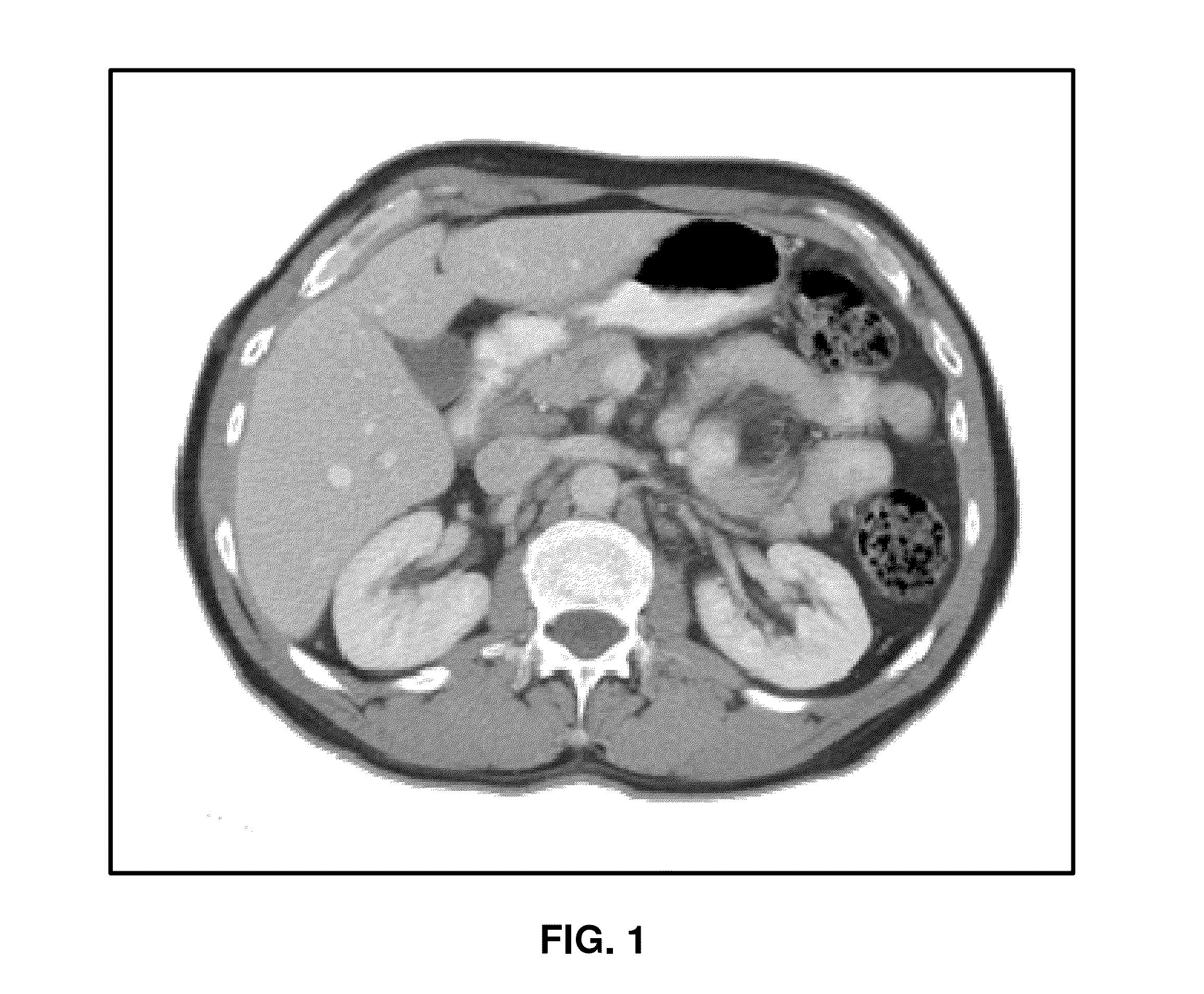

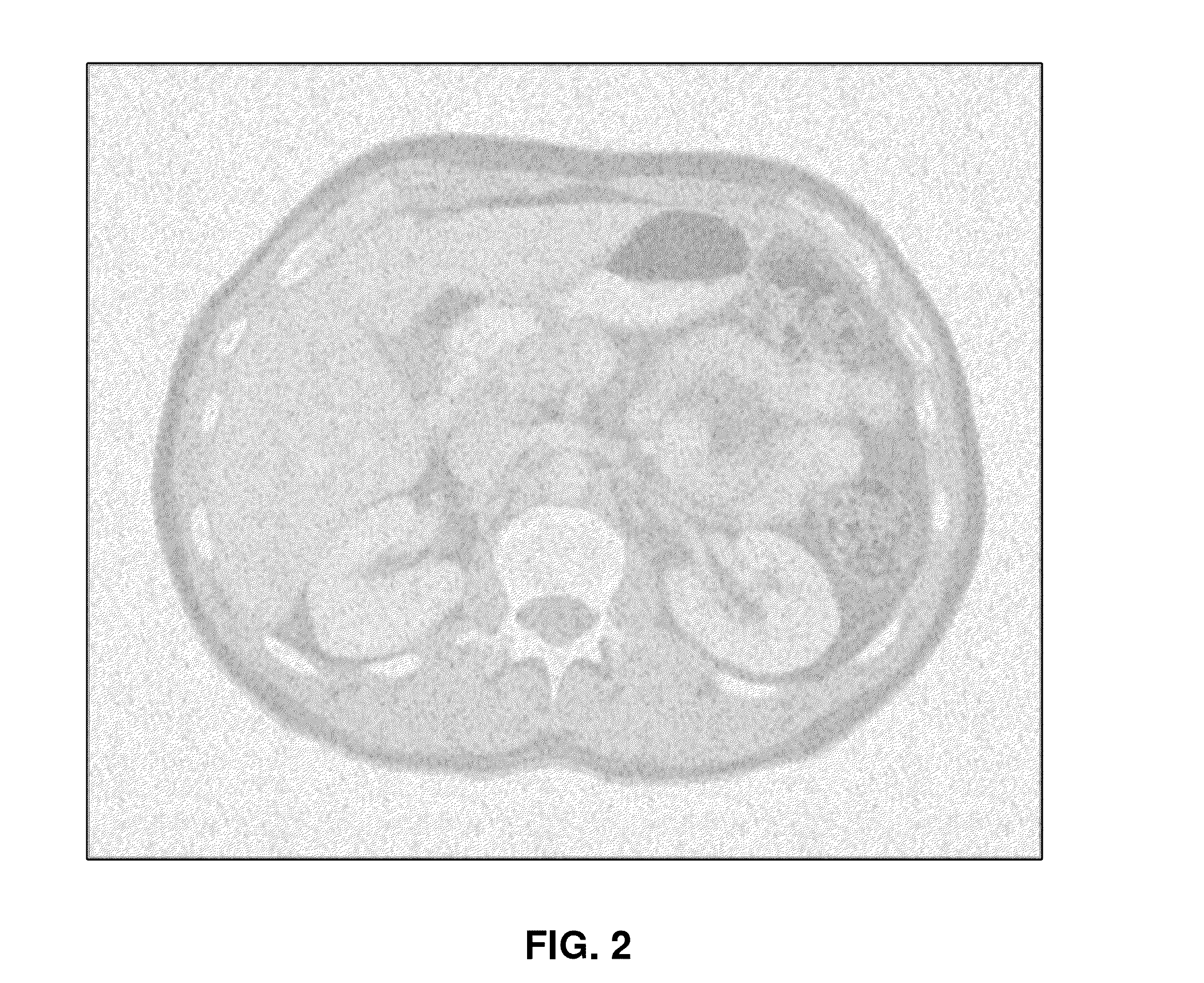

Computerized tomography (CT) fluoroscopy imaging system using a standard intensity ct scan with reduced intensity ct scan overlays

A method for providing CT fluoroscopy of an internal procedure site during a medical procedure so as to visualize patient anatomy and a high-contrast medical element during the procedure without subjecting the patient to unacceptable quantities of X-ray radiation, comprising: (1) taking a standard intensity CT scan of the internal procedure site; (2) taking a reduced intensity CT scan of the procedure site while the high-contrast medical element is inserted into the procedure site; (3) extracting the high-contrast medical element portion of the reduced intensity CT scan from the reduced intensity CT scan; (4) merging the high-contrast medical element portion of the reduced intensity CT scan extracted in Step 3 with the standard intensity CT scan of the procedure site taken in Step 1 so as to provide a composite CT scan; (5) displaying the composite CT scan; and (6) returning to either Step 1 or Step 2.

Owner:NEUROLOGICA CORP

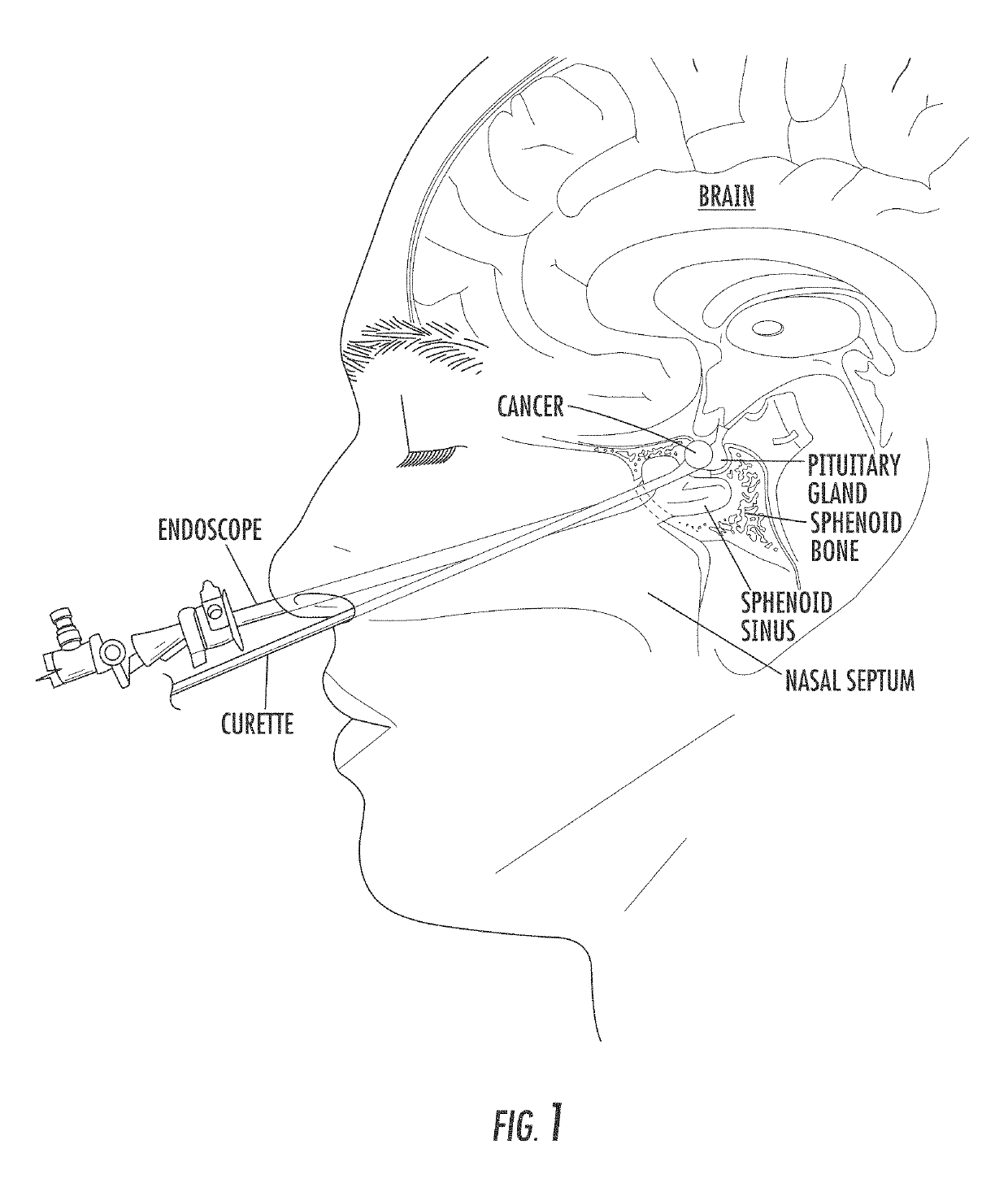

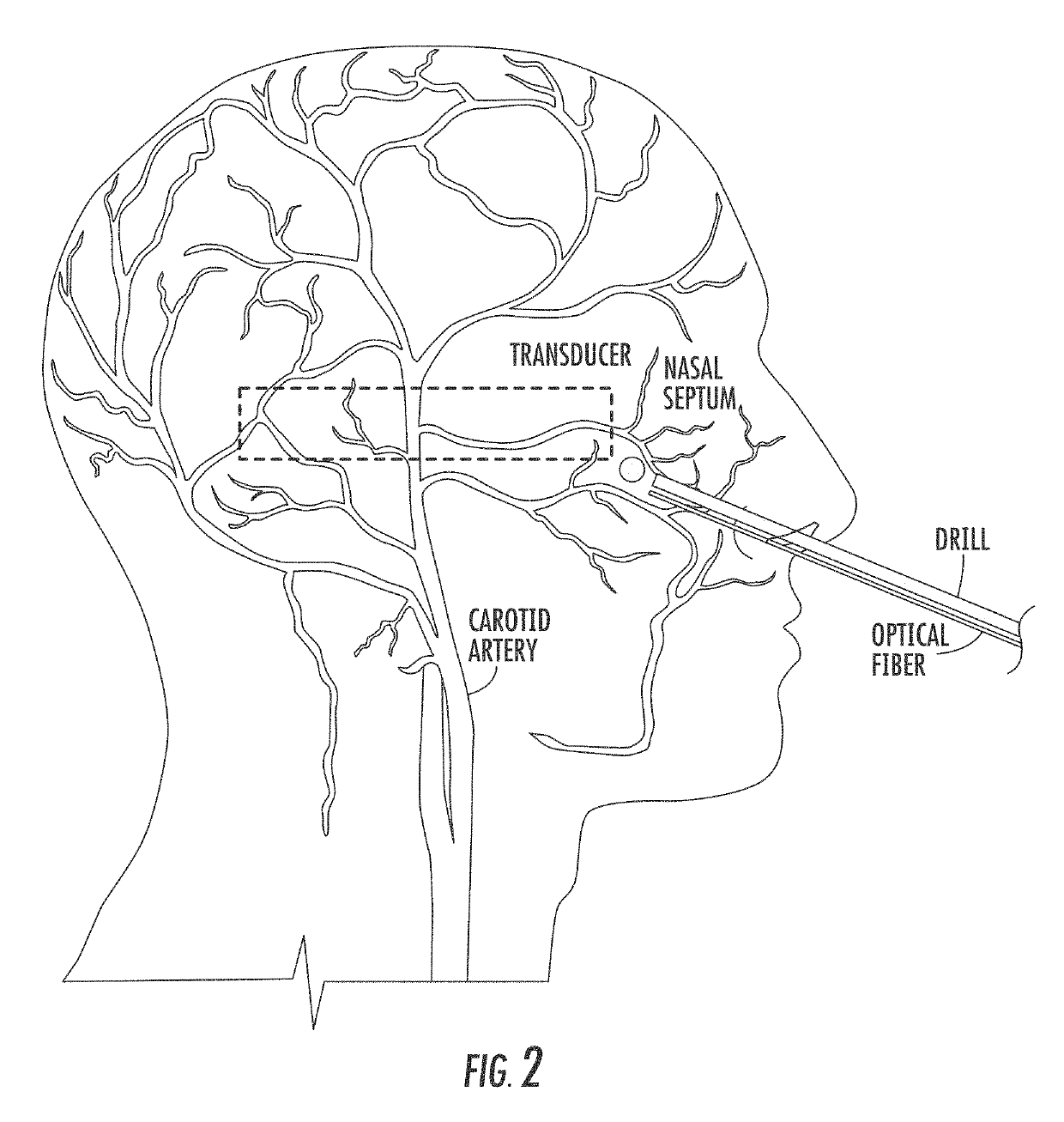

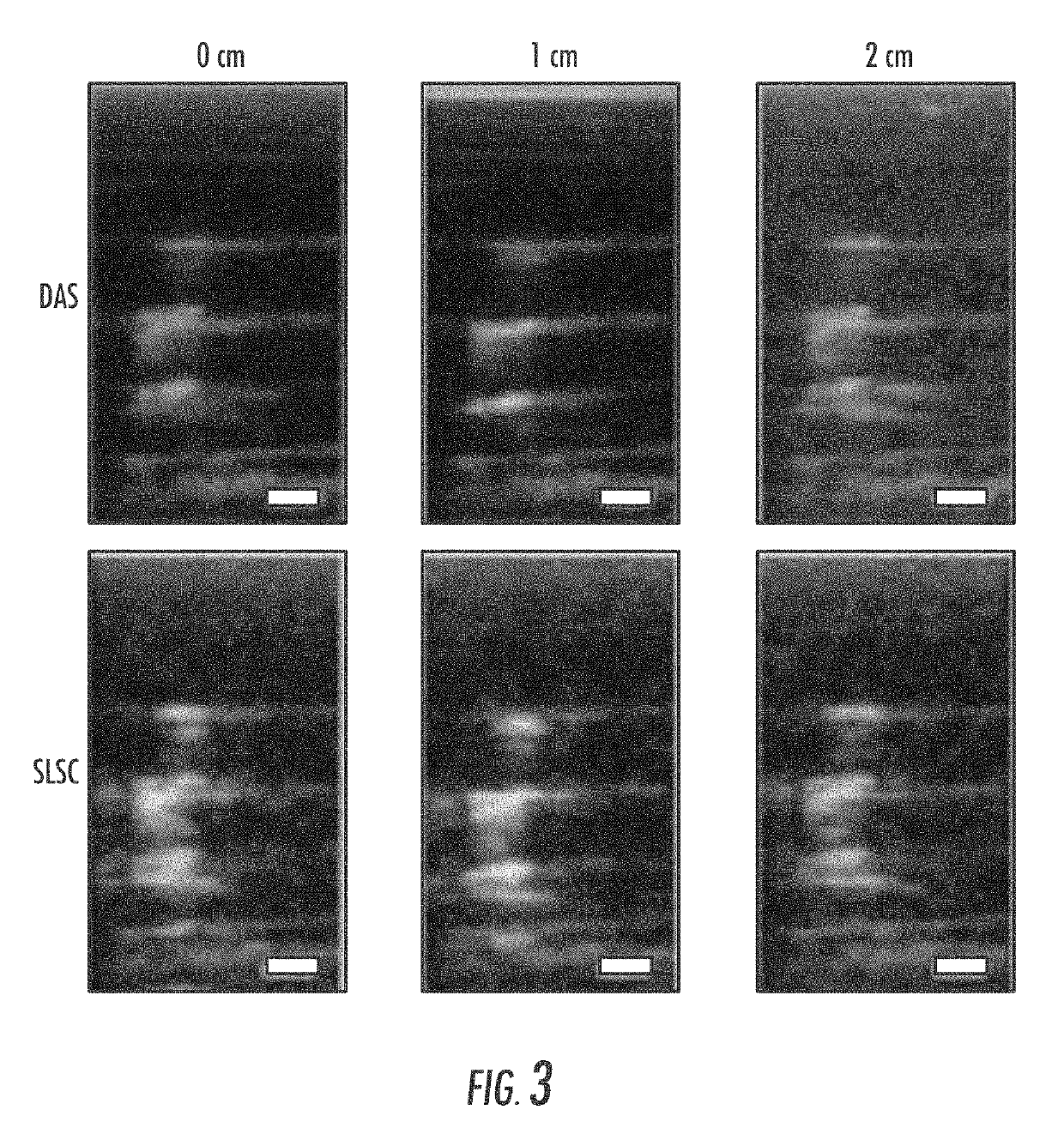

Method and system for transcranial photoacoustic imaging for guiding skull base surgeries

The present invention is directed to a method and system for photoacoustic imaging for guiding medical procedures. A transducer is placed near the site of the procedure. The optical fiber, coupled to an electromagnetic source, such as a laser, is attached to a medical device. During the procedure, the device and optical fiber are inserted into the procedure site where the optical fiber illuminates the procedure site, which has a thickness of approximately 2 mm. Photoacoustic images are acquired to visualize the procedure site as the procedure is proceeding in order to provide real-time guidance. This system is applicable to multiple surgical and interventional procedures, such as transsphenoidal surgery.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Ultrasound remote monitoring, operating and training system

ActiveUS20180263493A1Infrasonic diagnosticsDiagnostic recording/measuringULTRASOUND PROCEDURESSonification

The present invention is a method, system, and apparatus used to transmit information to an individual and or receiver who is not located at the actual ultrasound procedure that may monitor, communicate, and assist in the procedure in real time as well as provide protocols for specific procedures; wherein the ultrasound machine communicates to a receiver operational information such as but not limited to audio, visual, performance, and so forth; wherein the information may be received in real time to another party not located at the site of the procedure who may assist with the procedure, training, protocols, and so forth; and wherein the receiver may then transmit back to the ultrasound machine specific directions as well as communicate with the ultrasound operator.

Owner:ONCURA PARTNERS DIAGNOSTICS LLC

Assist device for medical procedures

ActiveUS10758695B2Avoid mistakesEffective and broadly applicableTracheal tubesWound drainsAnatomical landmarkCricothyroid membrane

A device to assist performing medical procedures that references anatomical landmarks through adjustable components to identify and stabilize a procedure site and provide guidance in performing the procedure. In one embodiment, an airway creation assist device (ACAD) can be dimensionally adjusted for different patient sizes and properly aligned using anatomical landmarks. The ACAD provides an adjustable template that enables accurate identification of the airway creation site, including but not limited to the cricothyroid membrane. The ACAD uses an insertion guide to guide the obturator and airway tube safely and consistently into the trachea, with a mechanical stop to prevent damaging the posterior trachea wall. The ACAD improves efficacy of the procedure, and makes perforating an incorrect airway creation procedure difficult. In another embodiment, a chest decompression assist device (DAD) Is disclosed for decompression treatment of air and / or fluid in the chest.

Owner:INNOVITAL LLC

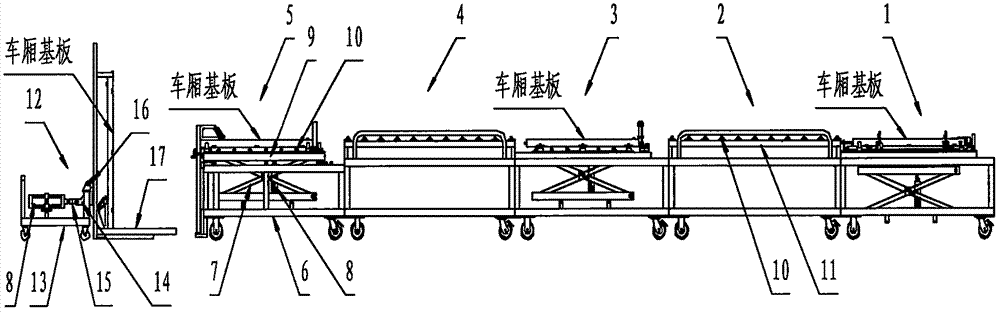

An operation method of electric vehicle compartment welding assembly line

ActiveCN105269166BDifficulties during resolutionResolving Time VariancesWelding/cutting auxillary devicesAuxillary welding devicesAssembly lineElectric vehicle

The invention discloses an operation method for an electric vehicle carriage welding assembly line. A first lifting frame, a first temporary storage frame, a second lifting frame, a second temporary storage frame and a third lifting frame are sequentially connected to form the whole welding assembly line. A self-overturning frame moves to the back of the third lifting frame, a carriage base plate is placed on an ox horn bearing of a supporting table of the first lifting frame, all parts are welded to the carriage base plate, and the carriage base plate slides to an ox horn bearing of the second lifting frame through the first temporary storage frame along the ox horn bearing; a carriage front plate is welded to the front portion of the carriage base plate and then slides to an ox horn bearing of the third lifting frame through the second temporary storage frame; and a carriage back plate is welded to the tail portion of the carriage base plate, and a movable cart carries the welded carriage base plate to move to a next manufacturing procedure site, so that fast demolding of a welded piece is achieved, the labor operation intensity of workers is reduced, fast transferring and omnibearing welding are achieved, welding deformation can not be caused in the welding process, the welding efficiency is improved, and the welding quality is guaranteed.

Owner:HENAN JINPENG VEHICLE IND CO LTD

Operation method for electric vehicle carriage welding assembly line

ActiveCN105269166ADifficulties during resolutionResolving Time VariancesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention discloses an operation method for an electric vehicle carriage welding assembly line. A first lifting frame, a first temporary storage frame, a second lifting frame, a second temporary storage frame and a third lifting frame are sequentially connected to form the whole welding assembly line. A self-overturning frame moves to the back of the third lifting frame, a carriage base plate is placed on an ox horn bearing of a supporting table of the first lifting frame, all parts are welded to the carriage base plate, and the carriage base plate slides to an ox horn bearing of the second lifting frame through the first temporary storage frame along the ox horn bearing; a carriage front plate is welded to the front portion of the carriage base plate and then slides to an ox horn bearing of the third lifting frame through the second temporary storage frame; and a carriage back plate is welded to the tail portion of the carriage base plate, and a movable cart carries the welded carriage base plate to move to a next manufacturing procedure site, so that fast demolding of a welded piece is achieved, the labor operation intensity of workers is reduced, fast transferring and omnibearing welding are achieved, welding deformation can not be caused in the welding process, the welding efficiency is improved, and the welding quality is guaranteed.

Owner:HENAN JINPENG VEHICLE IND CO LTD

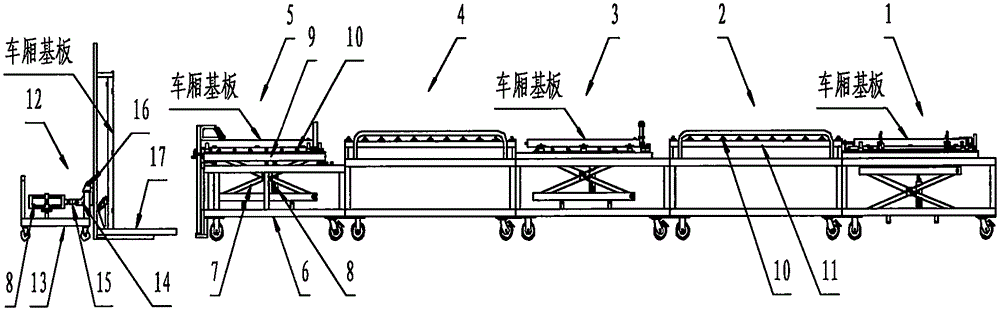

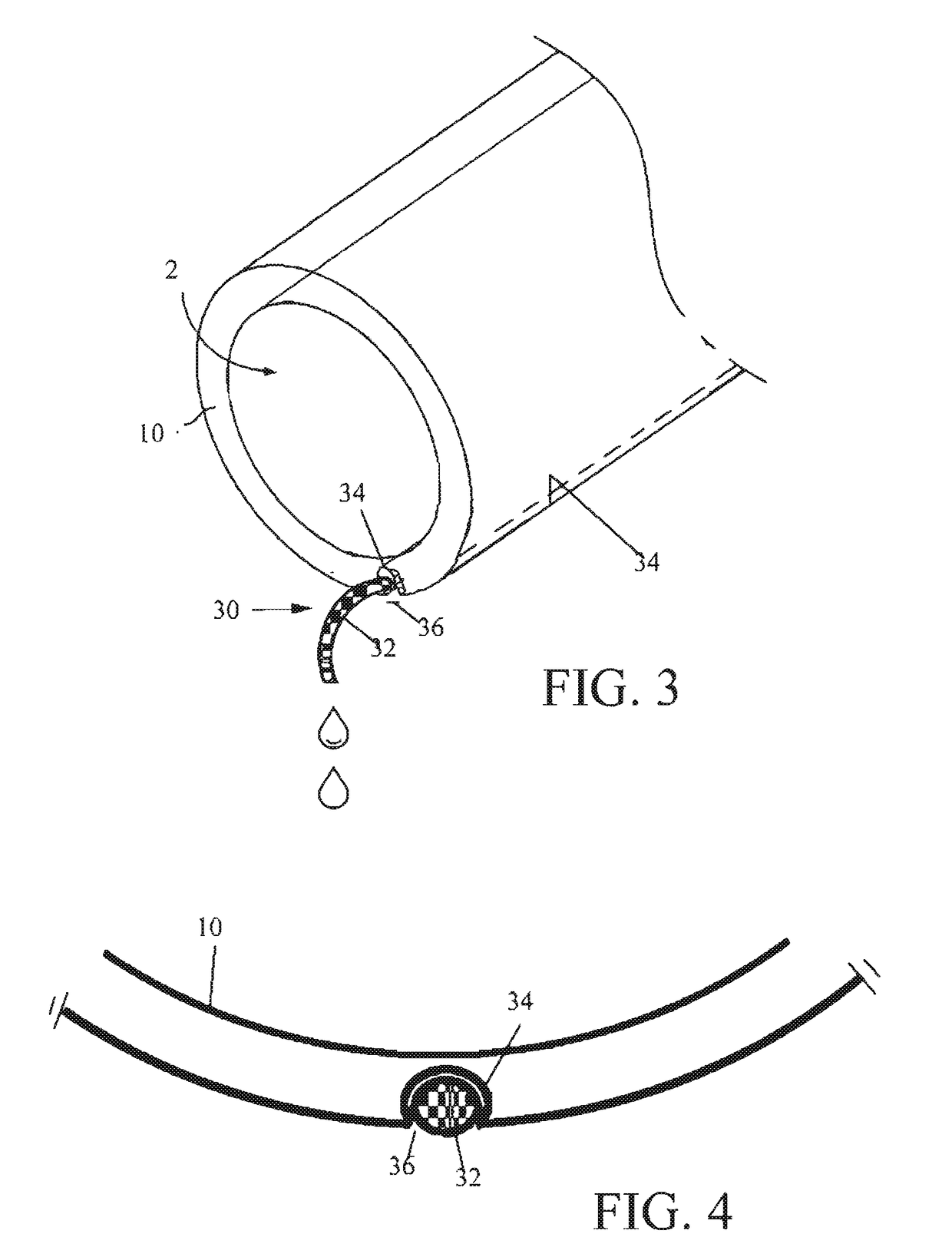

Anti-fouling cannulas for endoscopic ports

A cannula incorporating a blood wicking / diversion mechanism to absorb and / or obstruct blood from running down the cannula onto an endoscope inserted therein, and / or the procedure site, thereby obfuscating the field-of-view during a thoracic procedure. In an embodiment the device comprises an elongate woven fabric wick contained within an open-faced lumen molded into the bottom wall of the cannula tubular body and running along its length to absorb blood or fluid running down its length. In another embodiment the wick is formed in a sleeve-like configuration slightly larger in diameter than tubular body (configured for slidable insertion thereon) woven back into a string at the distal end. Alternatively the device comprises an expandable dome-shaped hood attached to the cannula.

Owner:OHNMACHT GALEN

Ultrasound remote monitoring, operating and training system

The present invention is a method, system, and apparatus used to transmit information to an individual and or receiver who is not located at the actual ultrasound procedure that may monitor, communicate, and assist in the procedure in real time as well as provide protocols for specific procedures; wherein the ultrasound machine communicates to a receiver operational information such as but not limited to audio, visual, performance, and so forth; wherein the information may be received in real time to another party not located at the site of the procedure who may assist with the procedure, training, protocols, and so forth; and wherein the receiver may then transmit back to the ultrasound machine specific directions as well as communicate with the ultrasound operator.

Owner:ONCURA PARTNERS DIAGNOSTICS LLC

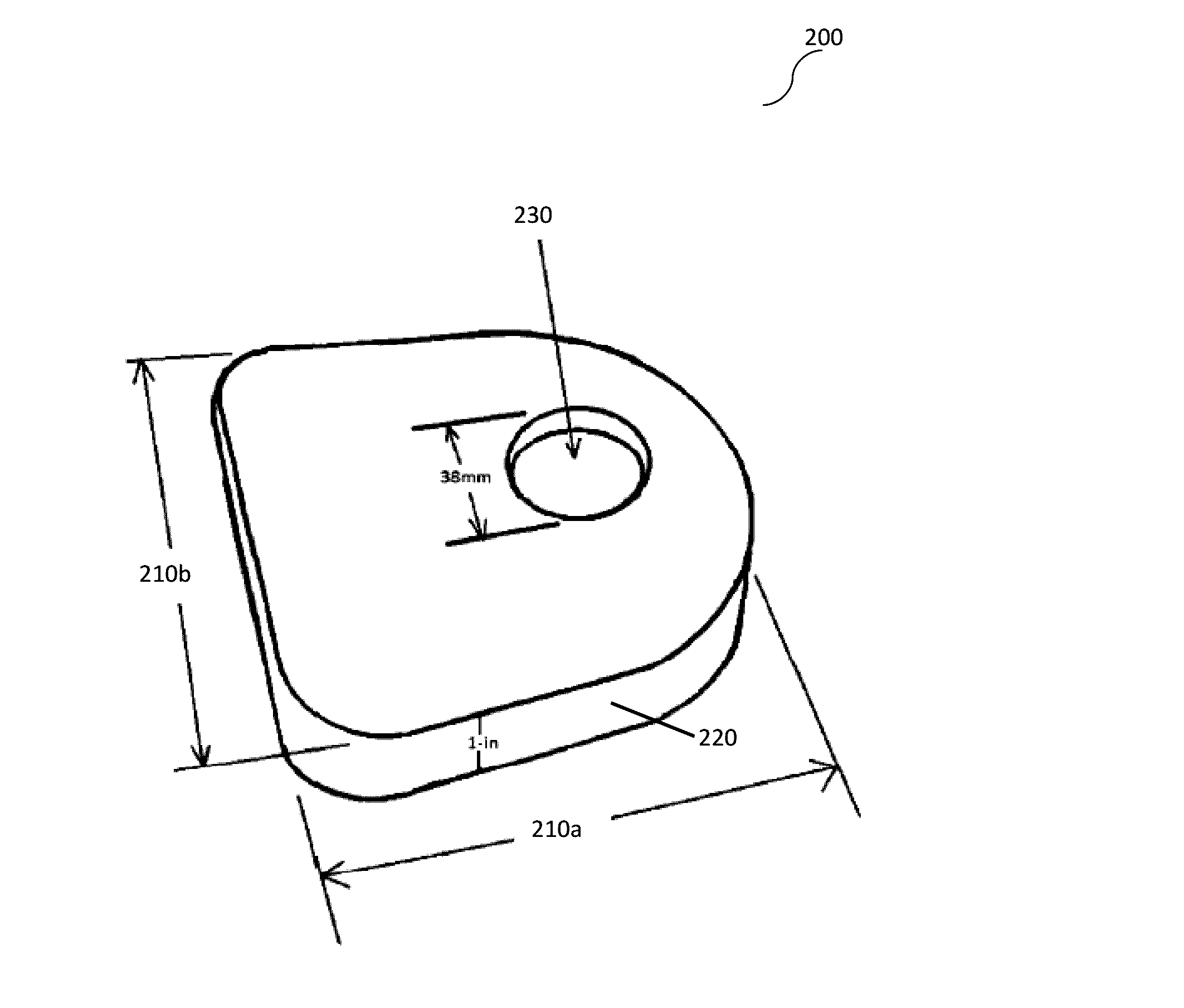

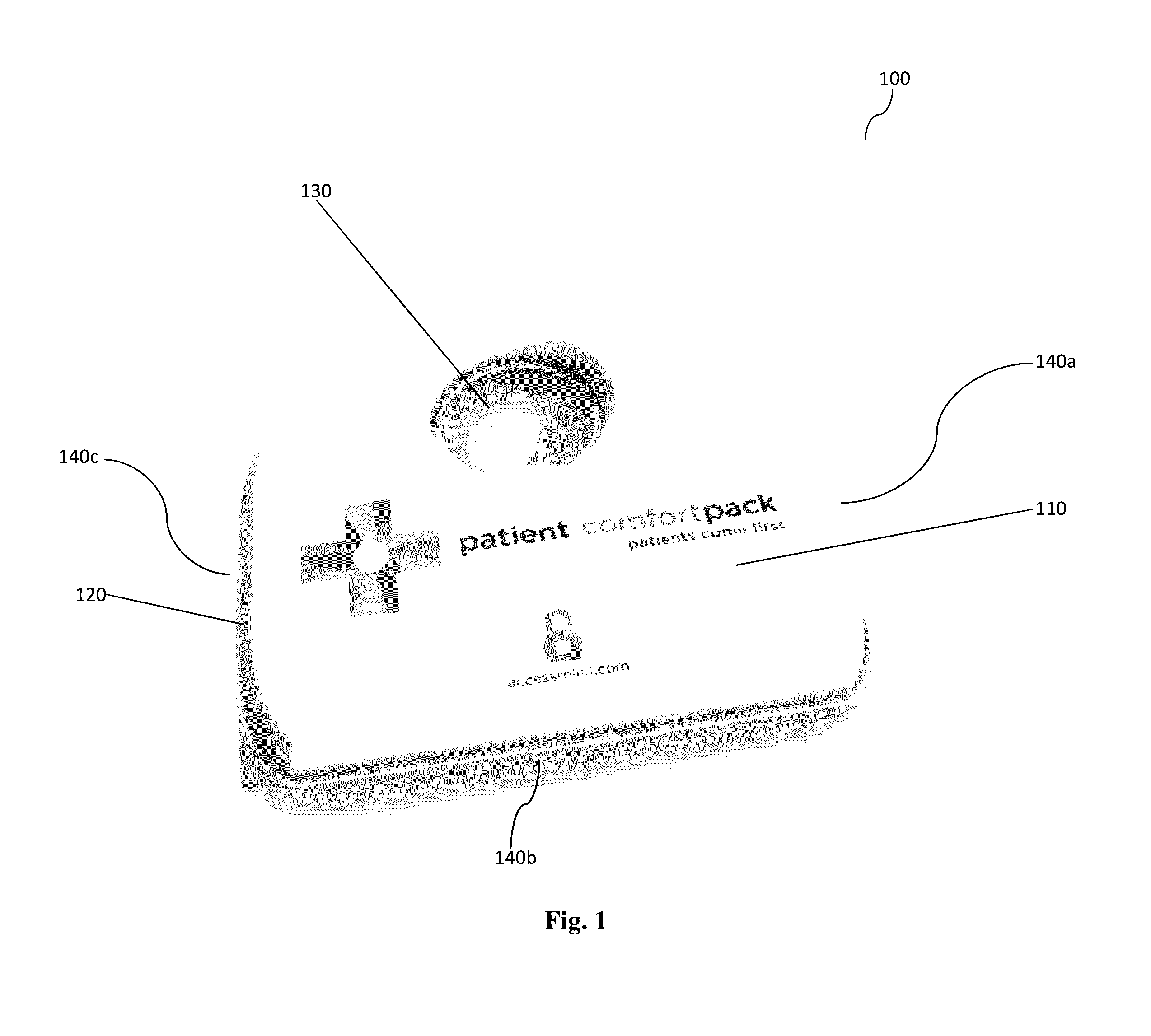

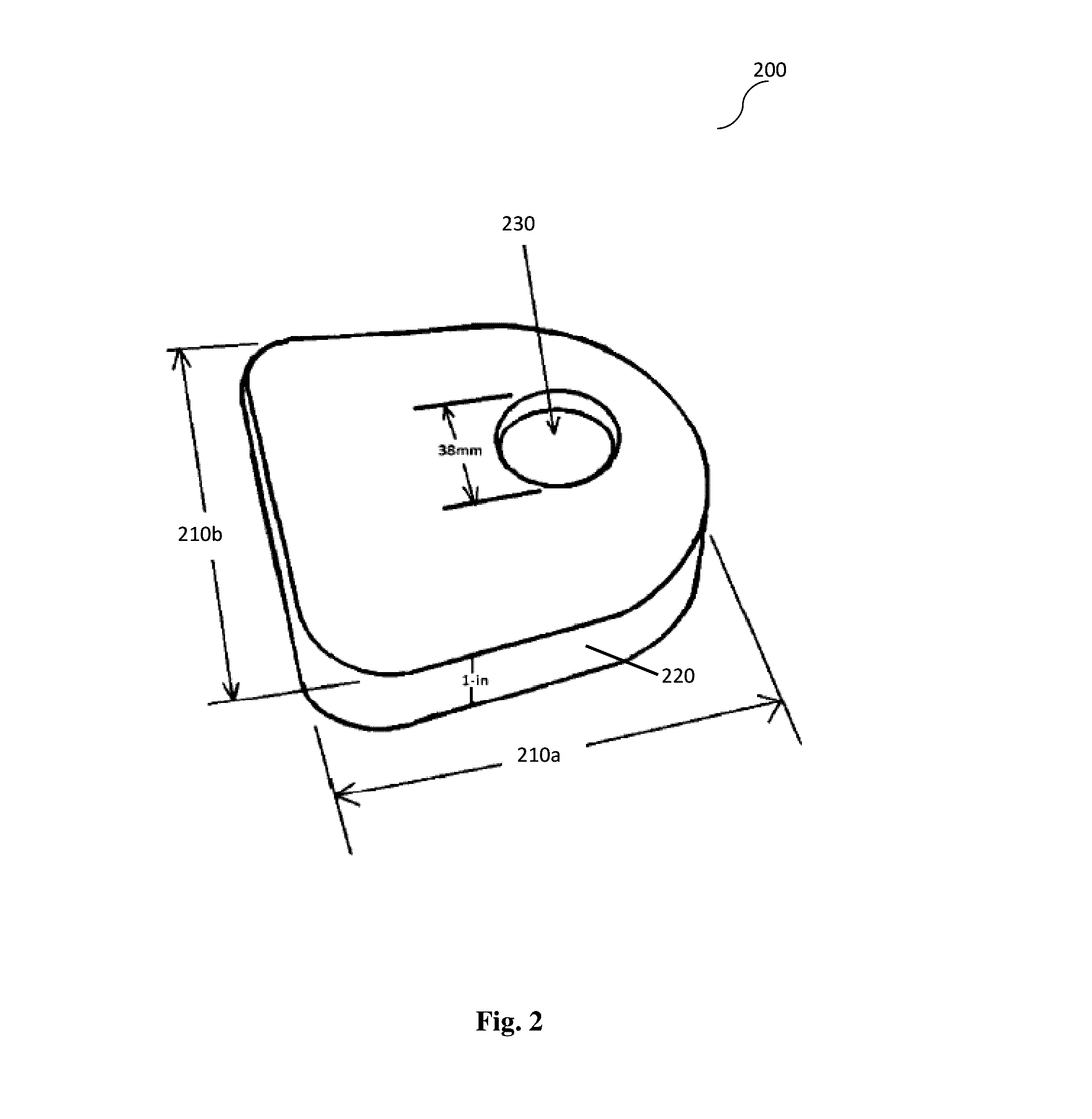

Patient comfort pack

InactiveUS20170020723A1Overcome deficienciesComfortably placedIntravenous devicesTherapeutic coolingSurgical siteEngineering

The present invention provides a device and method for delivering thermal therapy about a percutaneous access site while also permitting visual and physical examination of the access site. The device comprises a semi-circumferential shaped housing having a top wall, a bottom wall, and a side wall. The top wall, the bottom wall, and the side wall define a cavity with a fluid tight bladder disposed within the cavity. The semi-circumferential shaped housing has an aperture formed in the housing and a straight edge portion along the circumference of the housing. The device delivers thermal therapy to percutaneous arterial, venous, laparoscopic, and other access procedures sites by allowing visual and physical examination of the access site through the aperture and comfortable placement of the device's straight edge portion against a bend or joint of the patient's body.

Owner:SZOKOLA SARA ANNE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com