Turnover device

A technology of turning device and turning part, which is applied in the direction of workbench, manufacturing tools, etc., can solve the problems of low production efficiency and cumbersome process, and achieve the effect of increasing production efficiency, simplifying process and reducing manual labor of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

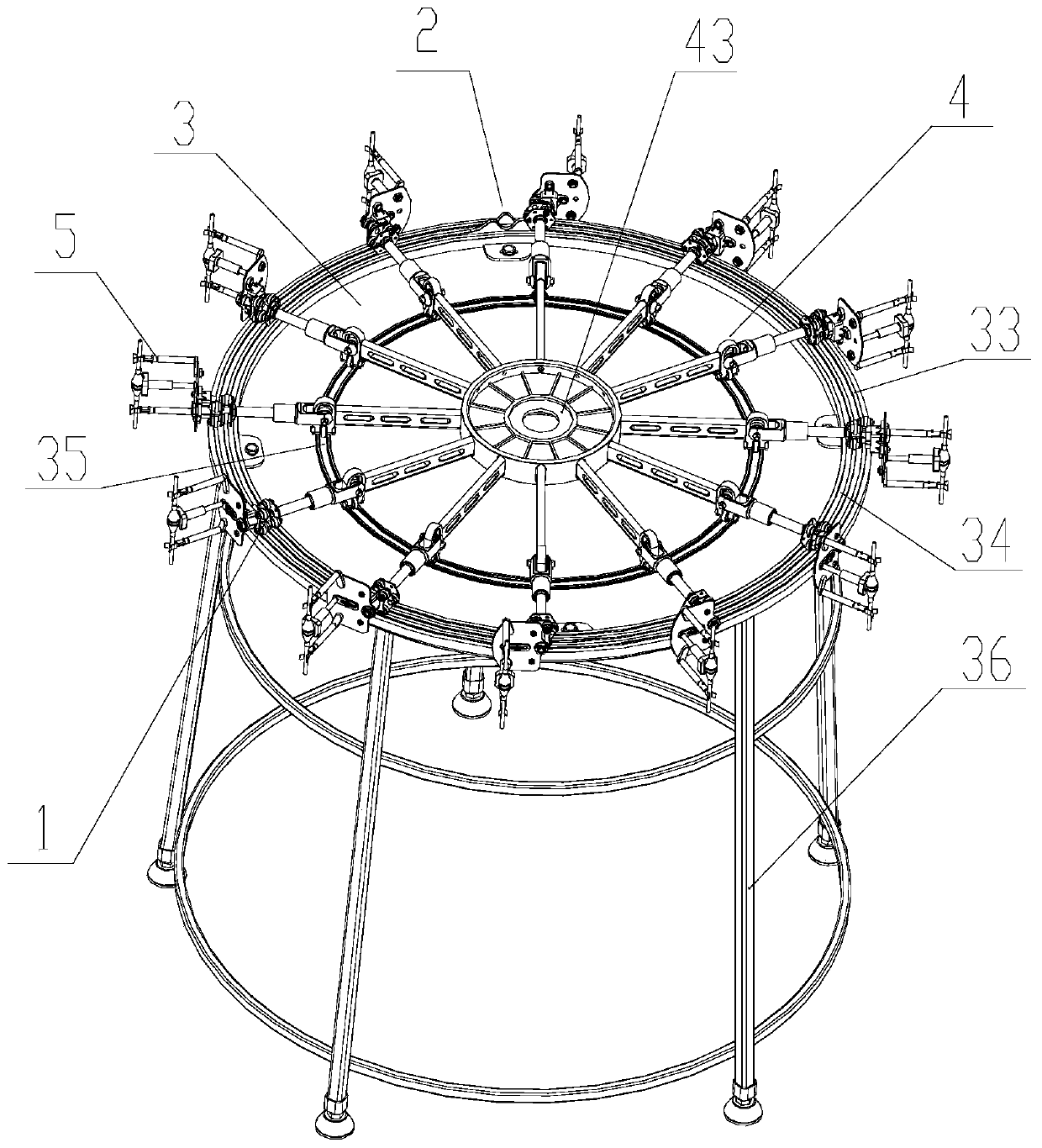

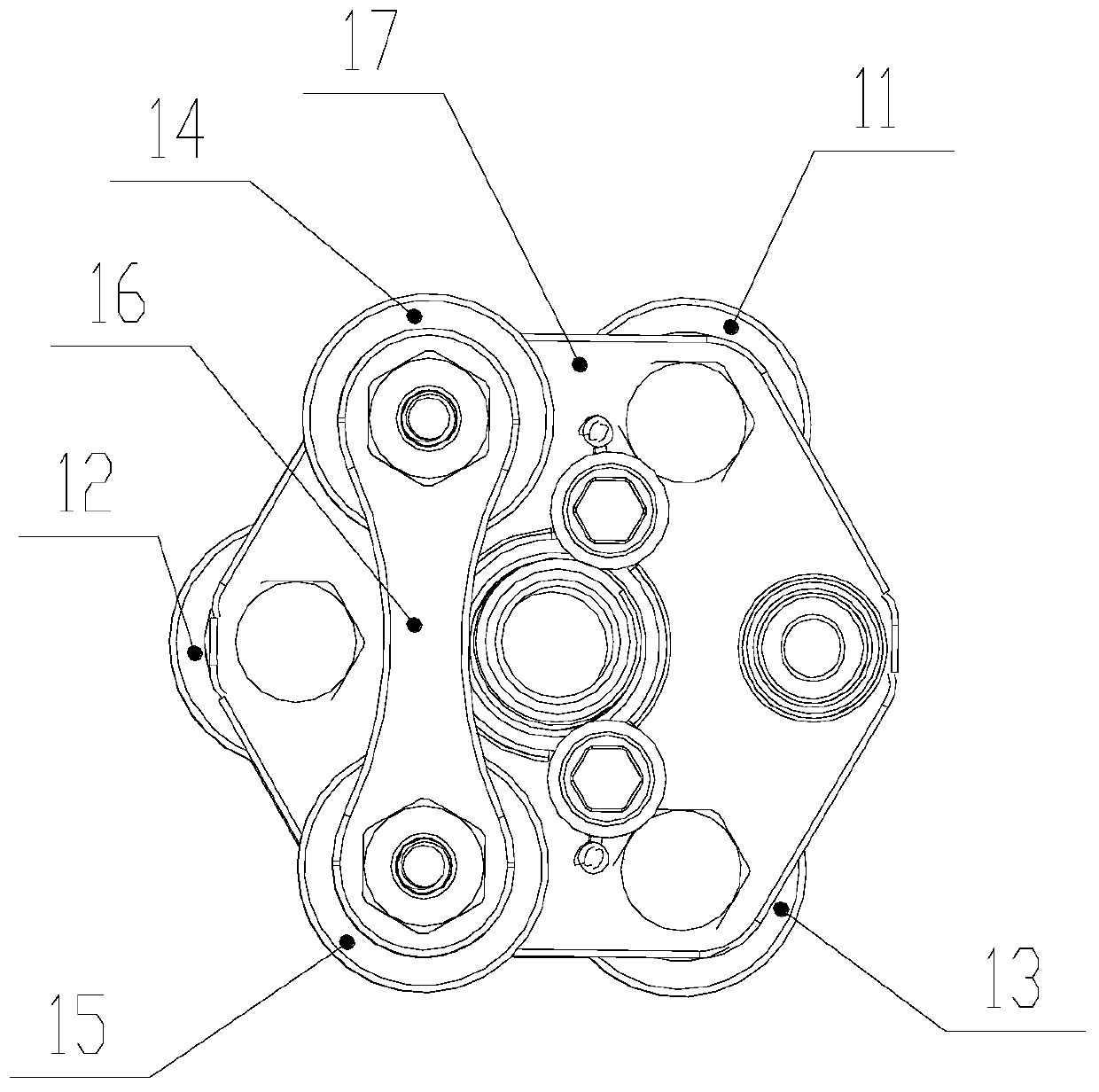

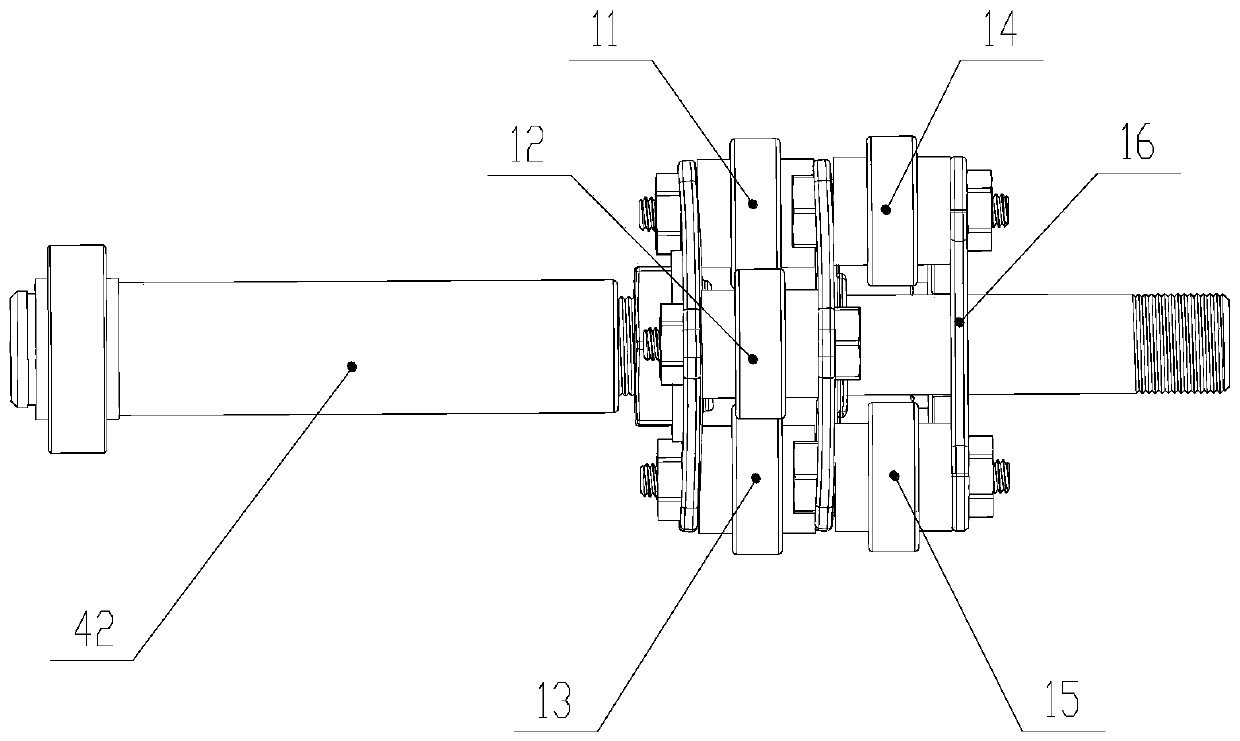

[0031] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, a turning device includes at least one turning part 1, a toggle part 2 and a support platform 3, the toggle part 2 is arranged on the support platform 3, and the turning part 1 can be placed on the support platform 3 Upper movement; the turning part 1 includes a first moving part 11, a second moving part 12, a third moving part 13, a first auxiliary part 14 and a second auxiliary part 15, and the first moving part 11, the second moving part 12 and the second moving part The movement path of the three moving parts 13 on the support platform 3 is the first path, and the workpiece to be turned over is connected to the turning part 1; the toggle part 2 includes a first protrusion 21 and a second protrusion 22, the first protrusion 21 and the second protrusion 22 The second protrusion 22 is located on the first path; when the turning part 1 is in the first state, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com