Small conveying device for plastic product packaging

A technology for conveying devices and plastic products, which is applied in the direction of packaging, etc., and can solve the problems of slowing down packaging conveying efficiency, increasing labor burden, and material offset, so as to slow down packaging conveying efficiency, increase labor burden, and avoid material offset and material turnover Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

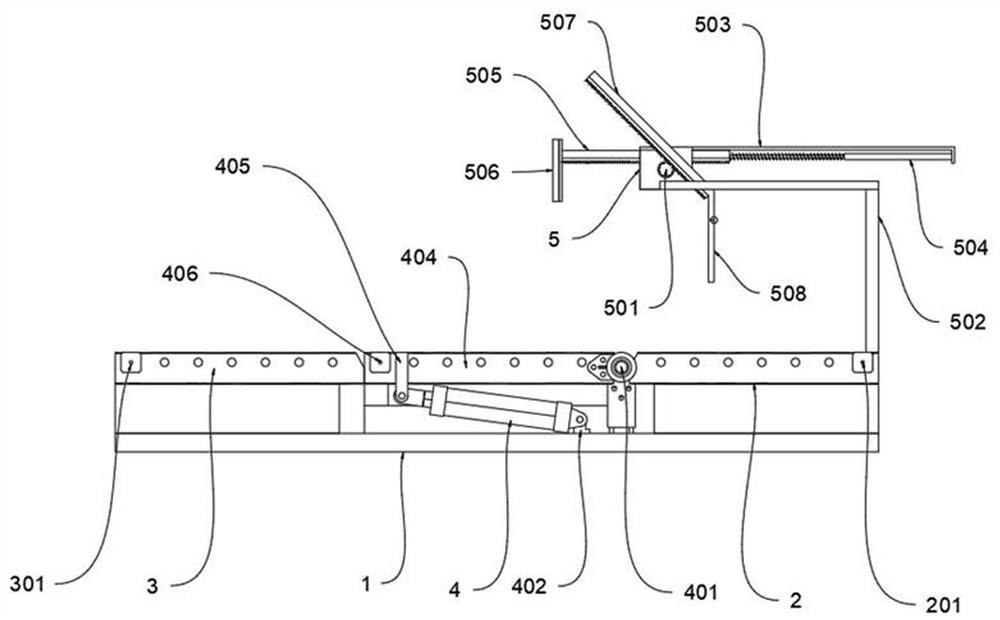

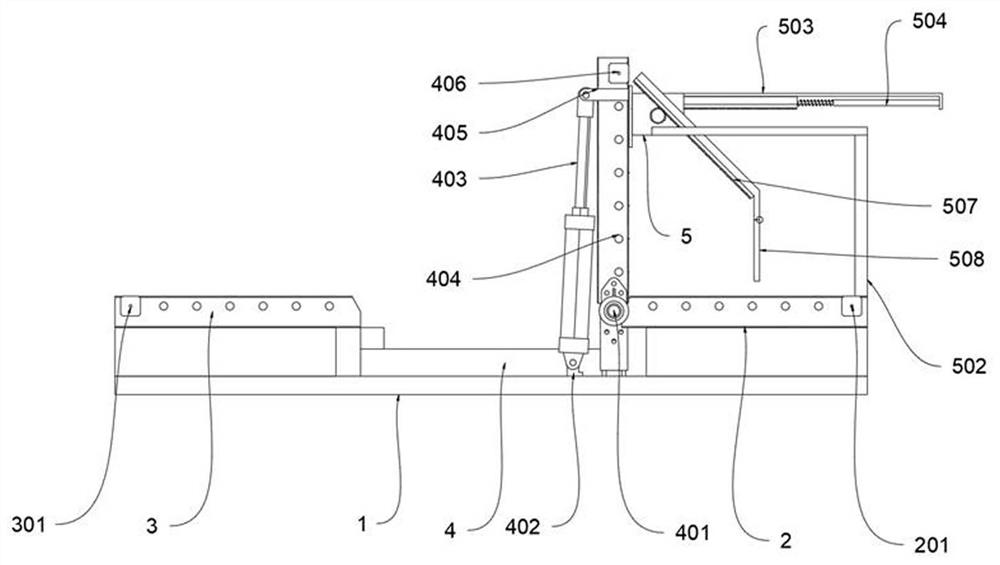

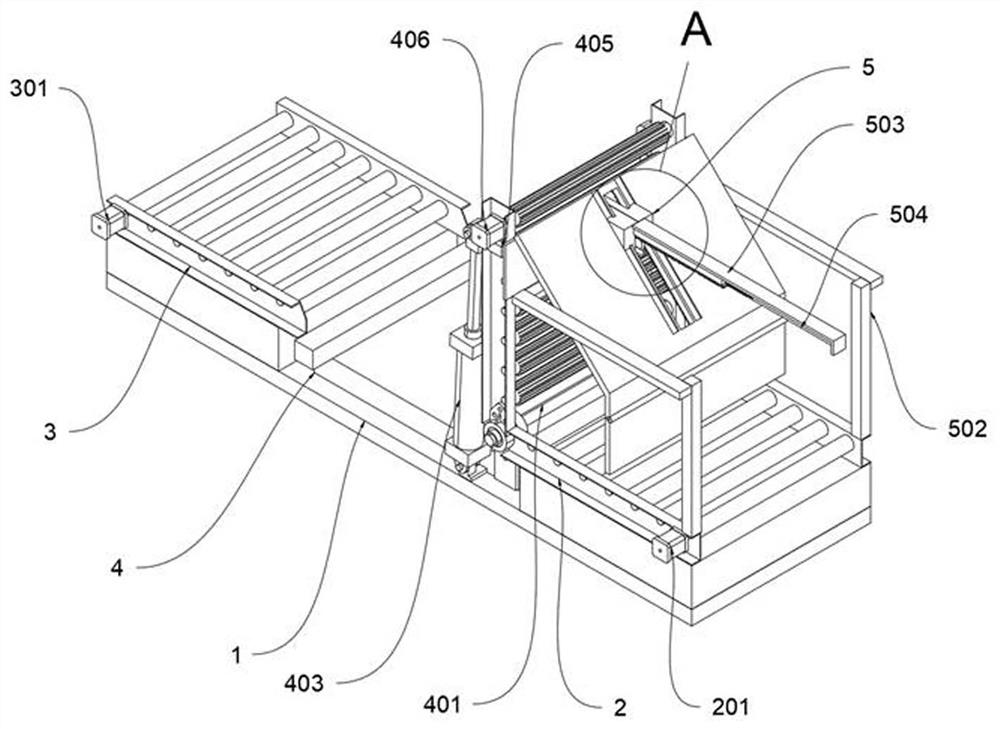

[0033] Such as figure 1 To attach Figure 8 Show:

[0034]The present invention provides a small conveyor device for plastic products packaging, including: predatable seat 1; assembly 1 is the shape of the word, the top position of the top end of the assembly 1 is set with a conveyor belt A2, the back -end position of the conveyor belt is oblique angle. Design. The conveyor belt A2 is driven by the servo motor A201. The middle position of the top of the assembly 1 is fixed to the bottom position of the place 4, and the front end position of the placement seat 4 is rotated to connect to a limited position rotation axis 401, the limited rotation axis 401 back end and guide conveyor conversion Rotate the connection with the front end of the 404, and the position 4 of the place 4 on both sides is fixed to the connection with one support seat 402. The two supporting seats 402 are rotated with the front and lower positions of the two -oriented cylinder 403, respectively. The end position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com