Intelligent connection mechanism for mold and automatic equipment

A technology of automation equipment and molds, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of reduced product production efficiency, high cost of mold modification, artificial damage, etc., to improve the competitiveness of enterprises and improve post-processing Efficiency, the effect of avoiding the damage of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

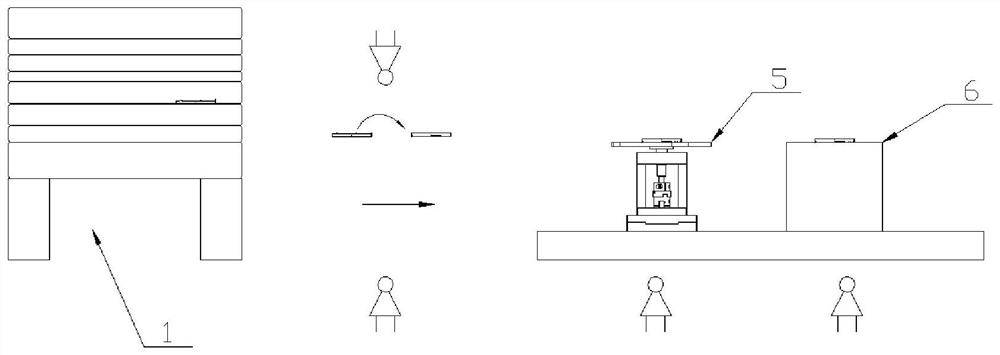

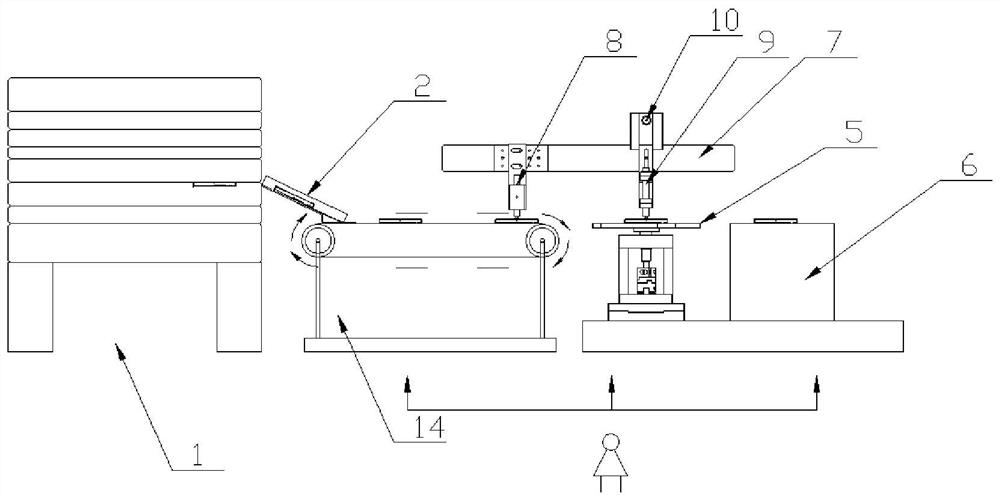

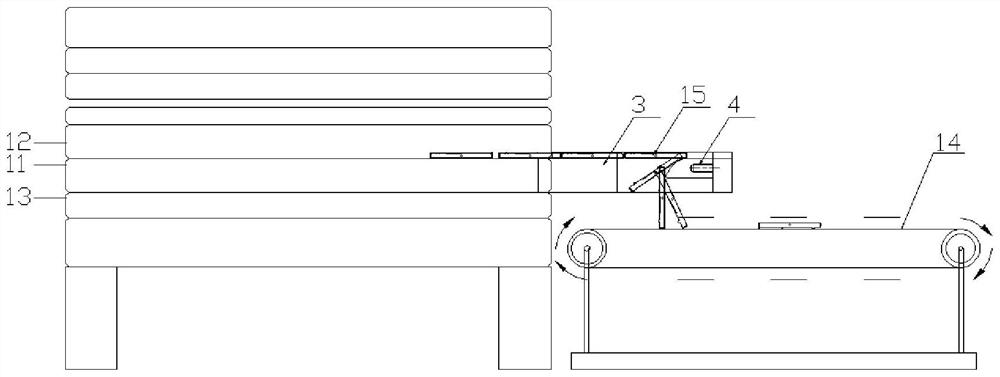

[0030] Example: an intelligent connection mechanism between a mold and an automation equipment, including a forming mold 1 and a subsequent station, the forming mold 1 is provided with a discharge port on one side, a discharge channel, a conveyor belt mechanism 14 and automation equipment, One end of the discharge channel is directly connected to the discharge port of the molding die 1, and the other end of the discharge channel is directly connected to the upper surface of the starting end of the conveyor belt of the conveyor belt mechanism 14. The automatic equipment can grasp the conveyor belt of the conveyor belt mechanism 14 for conveying. The product 15 on the end surface is sent to a subsequent station for subsequent processing.

[0031] The product 15 formed by the forming die 1 is discharged from the discharge port of the forming die 1. The discharged product 15 reaches the conveyor belt surface of the conveyor belt mechanism 14 through the discharge channel, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com