Movable wharf

A wharf and engine technology, applied in the field of mobile wharf, can solve the problems of increasing soil grabbing and fixing effects, not having anti-landing boards, and not being able to resist strong winds, so as to prevent detachment from fixed pillars, reduce direct damage, and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

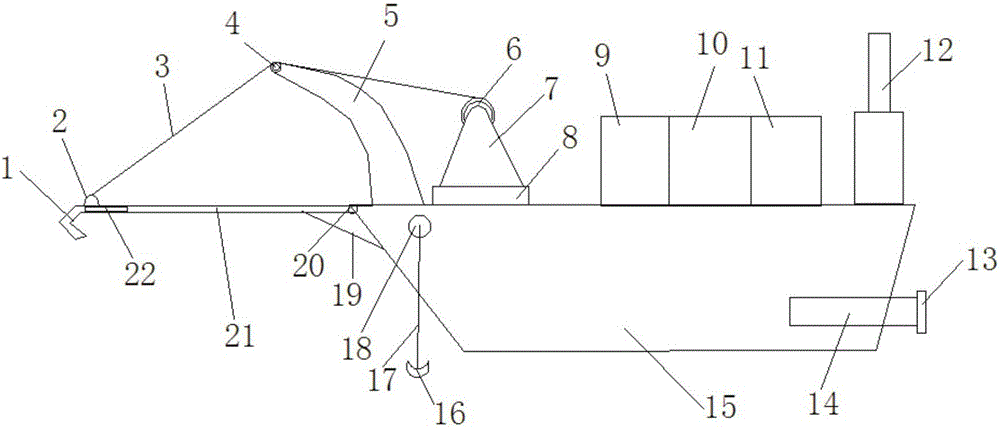

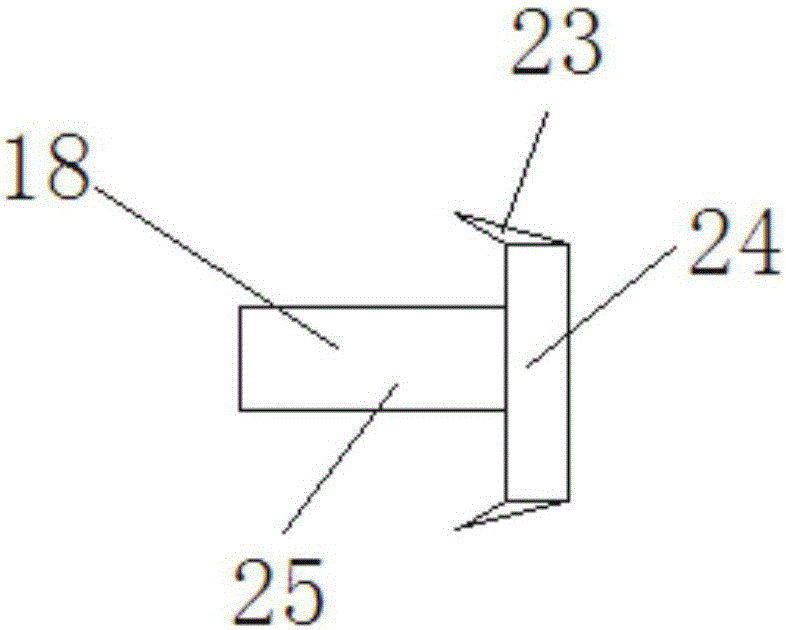

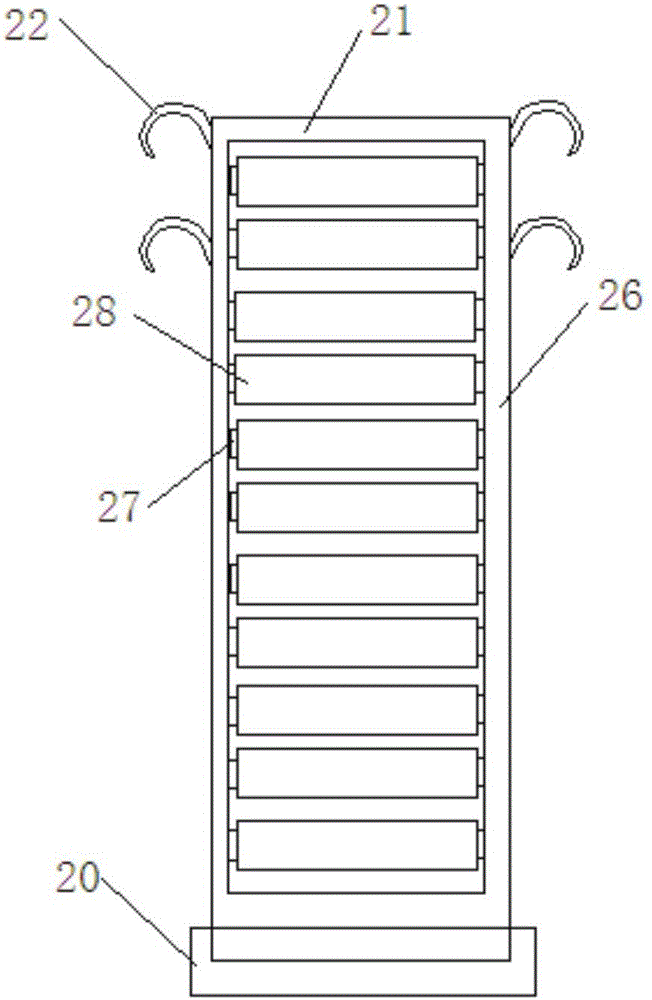

[0023] Example one: such as figure 1 As shown, the present invention includes a hull 15 and an engine 14 and a propeller 13 arranged inside the hull 15. One end of the hull 15 is provided with a landing plate 21 through a rotating connector 20, and an arc-shaped fixing member is provided on the upper surface of the landing plate 21 2. A front hook body 1 is provided at the end of the landing plate 21, and a side hook body 22 is provided on the side of the landing plate 21. The upper surface of the hull 15 is provided with a supporting bending rod 5, a winch 6, a controller 9, a generator 10, and a fuel tank. 11 and a signal transceiving device 12, a support block 4 is arranged on the top of the support bending rod 5, the support block 4 is arranged on the bow of the ship close to the landing board 21, the winch 6 is provided with a draw rope 3, and the draw The rope 3 is connected to the arc-shaped fixing member 2 by the hoist 6, the draw rope 3 is in contact with the top of the...

Embodiment 2

[0025] Embodiment two: such as figure 1 As shown, the present invention includes a hull 15 and an engine 14 and a propeller 13 arranged inside the hull 15. One end of the hull 15 is provided with a landing plate 21 through a rotating connector 20, and an arc-shaped fixing member is provided on the upper surface of the landing plate 21 2. A front hook body 1 is provided at the end of the landing plate 21, and a side hook body 22 is provided on the side of the landing plate 21. The upper surface of the hull 15 is provided with a supporting bending rod 5, a winch 6, a controller 9, a generator 10, and a fuel tank. 11 and a signal transceiving device 12, a support block 4 is arranged on the top of the support bending rod 5, the support block 4 is arranged on the bow of the ship close to the landing board 21, the winch 6 is provided with a draw rope 3, and the draw The rope 3 is connected to the arc-shaped fixing member 2 by the hoist 6, the draw rope 3 is in contact with the top of ...

Embodiment 3

[0029] Example three: such as figure 1 As shown, the present invention includes a hull 15 and an engine 14 and a propeller 13 arranged inside the hull 15. One end of the hull 15 is provided with a landing plate 21 through a rotating connector 20, and an arc-shaped fixing member is provided on the upper surface of the landing plate 21 2. A front hook body 1 is provided at the end of the landing plate 21, and a side hook body 22 is provided on the side of the landing plate 21. The upper surface of the hull 15 is provided with a supporting bending rod 5, a winch 6, a controller 9, a generator 10, and a fuel tank. 11 and a signal transceiving device 12, a support block 4 is arranged on the top of the support bending rod 5, the support block 4 is arranged on the bow of the ship close to the landing board 21, the winch 6 is provided with a draw rope 3, and the draw The rope 3 is connected to the arc-shaped fixing member 2 by the hoist 6, the draw rope 3 is in contact with the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com