Automatic plate collecting and turning system for aluminum-plastic plate production line

A technology of aluminum-plastic panels and production lines, which is applied to the stacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of reducing production efficiency, time-consuming and labor-intensive, and increasing labor intensity of workers, so as to improve efficiency and reduce labor The effect of strength and easy transportation and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following detailed description provides various embodiments or examples for implementing the invention. Of course, these are merely examples or examples and are not intended to be limiting. Additionally, repeated reference numerals, such as repeated numbers and / or letters, may be used in different embodiments. These repetitions are for simplicity and clarity of description of the present invention and do not represent a specific relationship between the different embodiments and / or structures discussed.

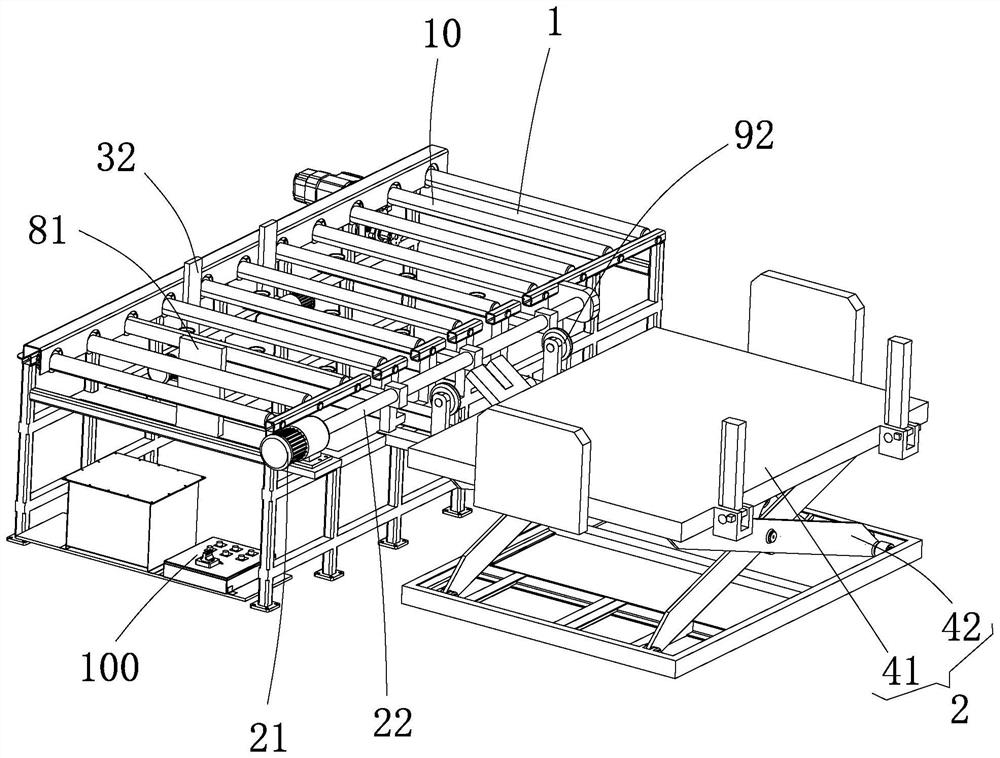

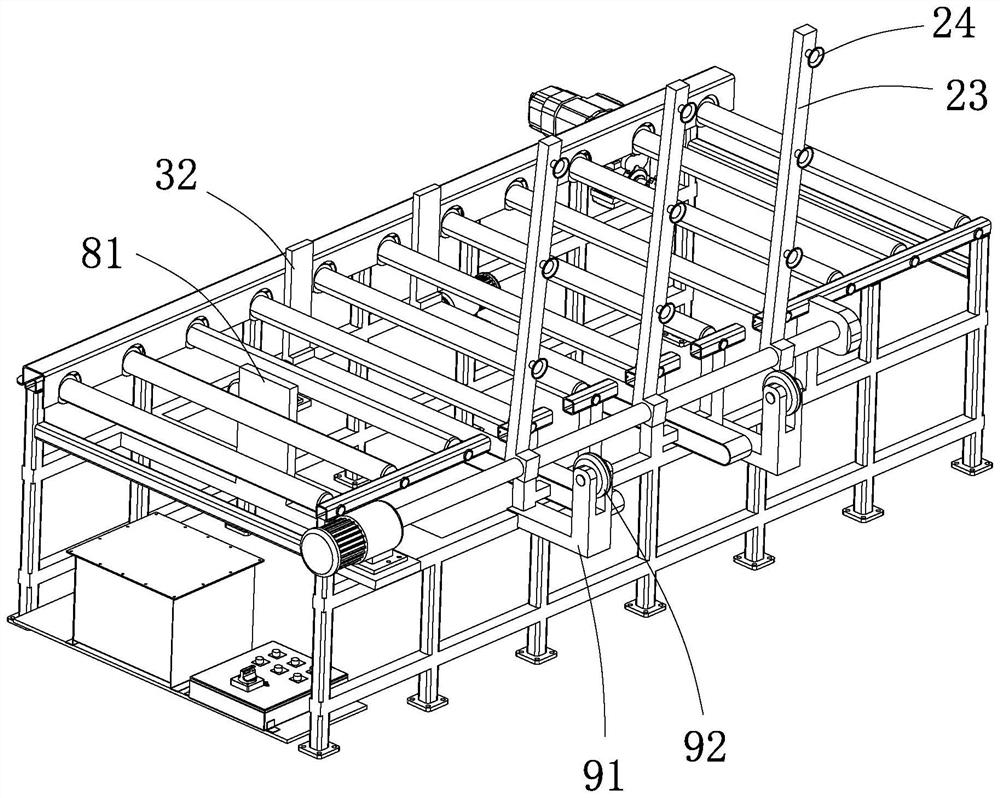

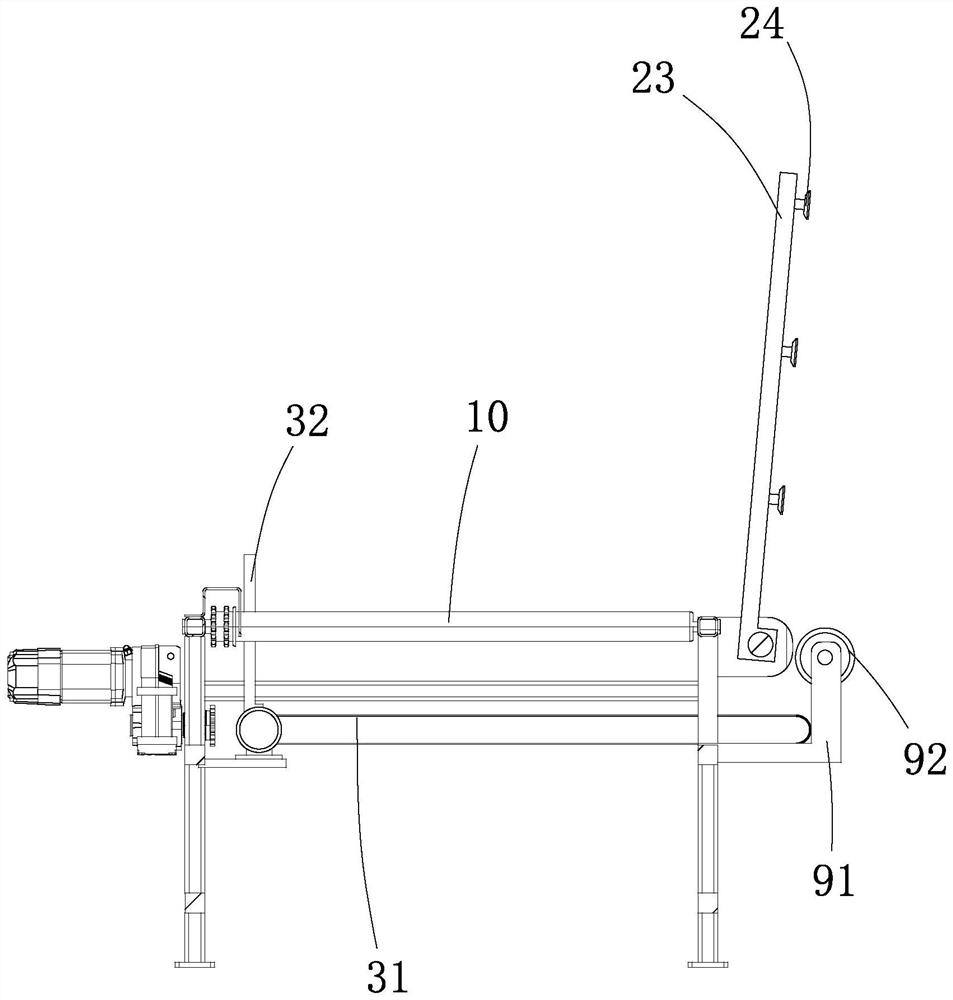

[0023] The following description of the drawings and specific embodiments will further describe the present invention: as Figure 1 to Figure 6 The shown aluminum-plastic panel production line automatic plate closing and turning system includes a roller conveyor 1 for conveying aluminum-plastic panels and a collection table 2 arranged on one side of the roller conveyor 1 for collecting and storing aluminum-plastic panels. The roller conveyor 1 is respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com