Polishing device for automobile accessory

A technology for auto parts and grinding wheels, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., and can solve problems such as damage to auto parts, unstable grinding quality, and oxidation of parts, so as to ensure the quality of grinding and grinding Wide range and convenient sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

[0015] Combine below figure 1 The present invention will be described in detail.

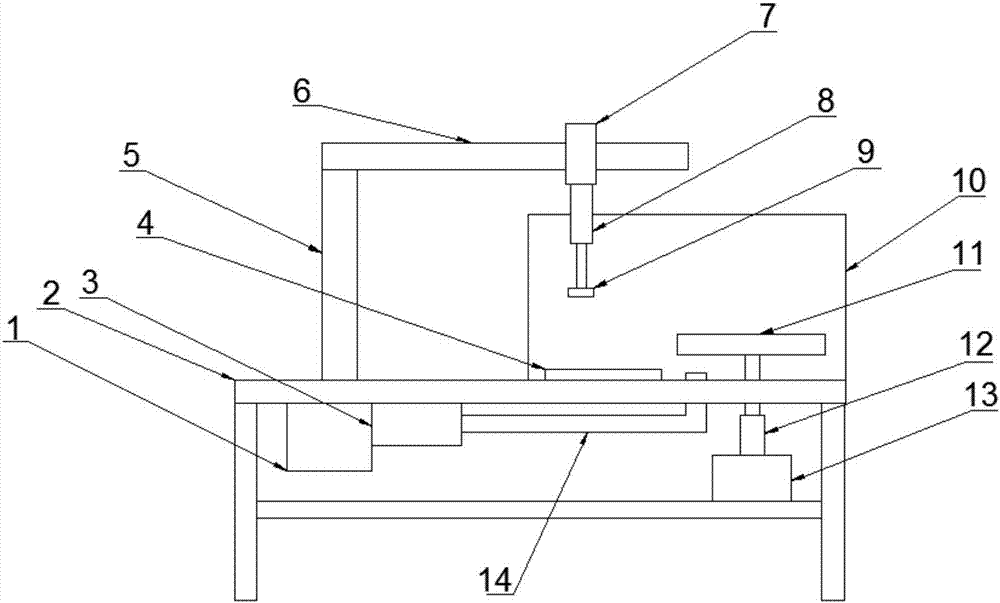

[0016] Such as figure 1 Shown is the structural diagram of the grinding device for auto parts of the present invention. Wherein, including workbench 2, described workbench 2 has two layers, and described workbench 2 top is provided with placement groove 4, dustproof cover 10, vertical bar 5 and grinding wheel 11, and described vertical bar 5 top is provided with A crossbeam 6, the crossbeam 6 is provided with a cylinder 7; the bottom of the upper layer of the workbench 2 is provided with a dust collection bag 1 and a blower 3, and the dust collection bag 1 is directly connected with the blower 3; the lower floor of the workbench 2 is provided with Rotate the motor 13.

[0017] A first telescopic rod 8 is arranged at the bottom of the cylinder 7 , and a sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com