Multi-gradient machining equipment for local flatness treatment of building material

A technology for building materials and processing equipment, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of inability to achieve layered multi-gradient, low efficiency, etc., and achieve wide grinding range, high precision, High sanding quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention is to provide a multi-gradient processing equipment for local flatness processing of building materials, so as to solve the problem of low efficiency in the traditional layer-by-layer progressive grinding method, and the efficient layered and multi-gradient grinding cannot be achieved. problem; in order to achieve the above purpose, specifically provide the following technical solutions:

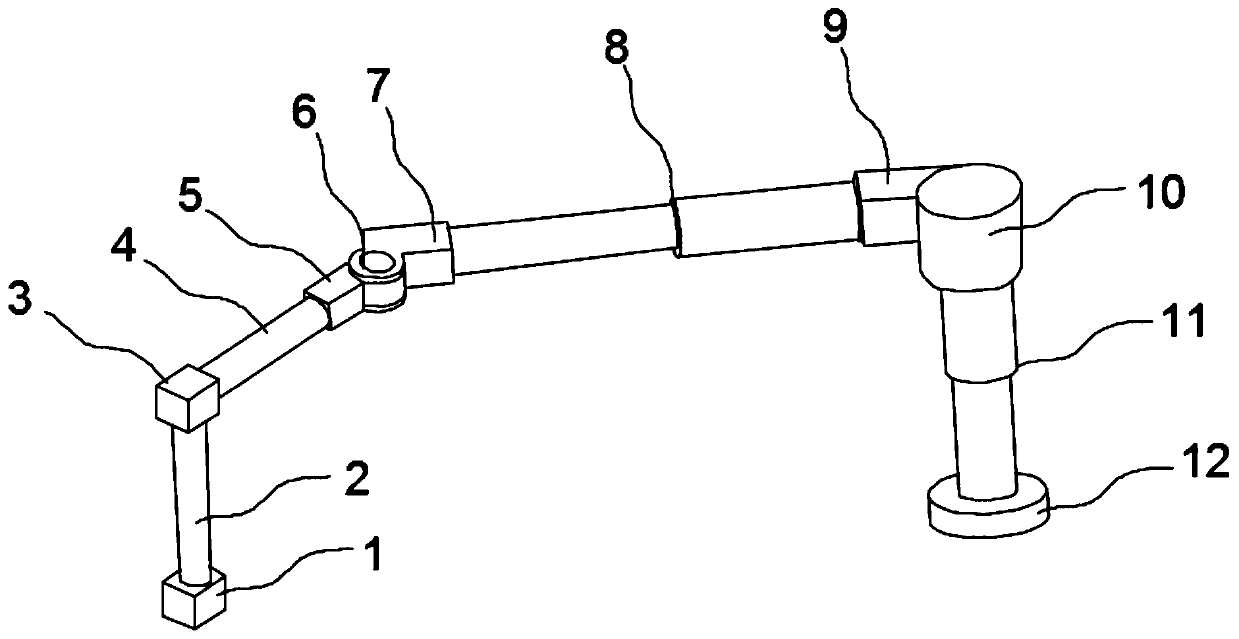

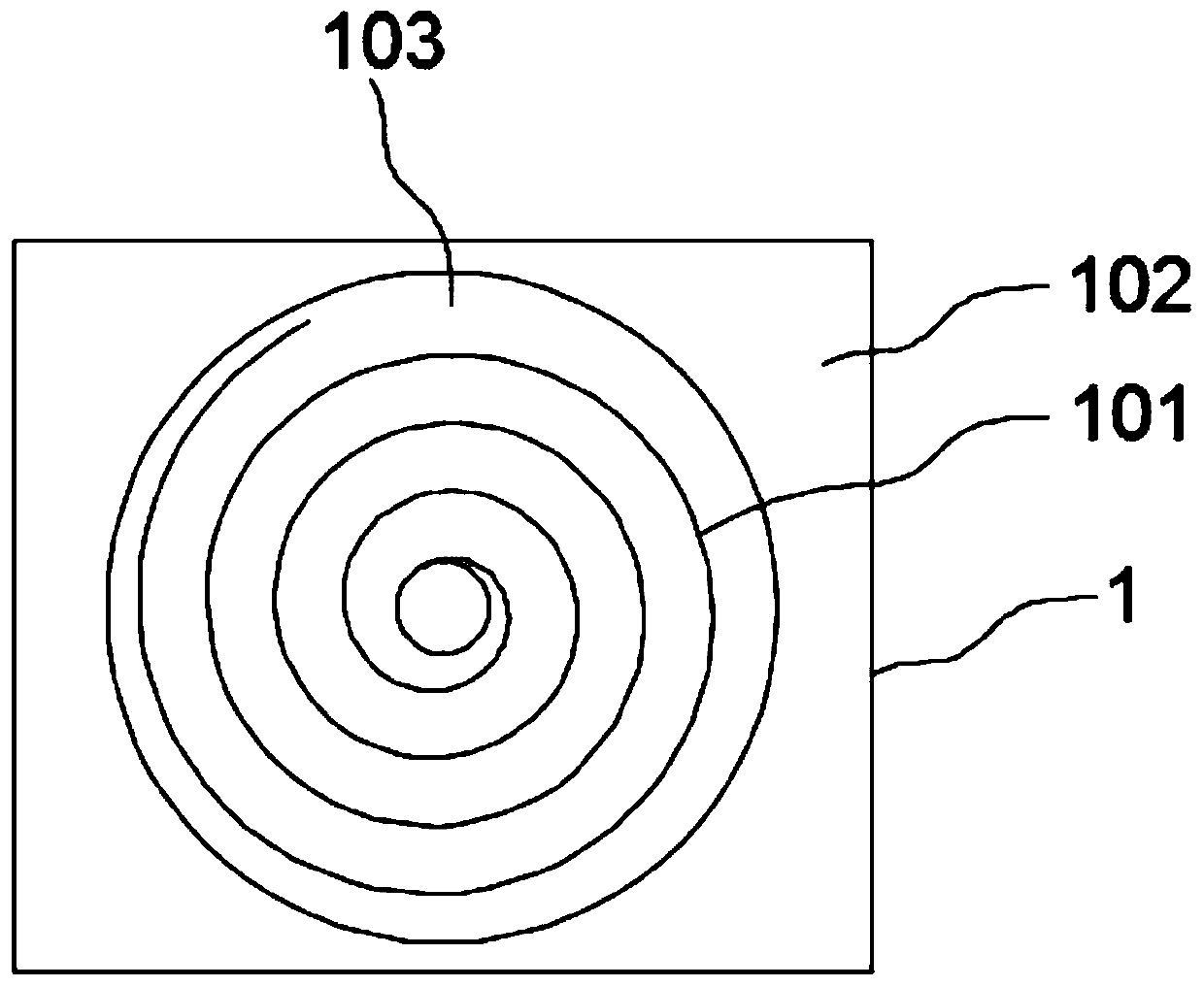

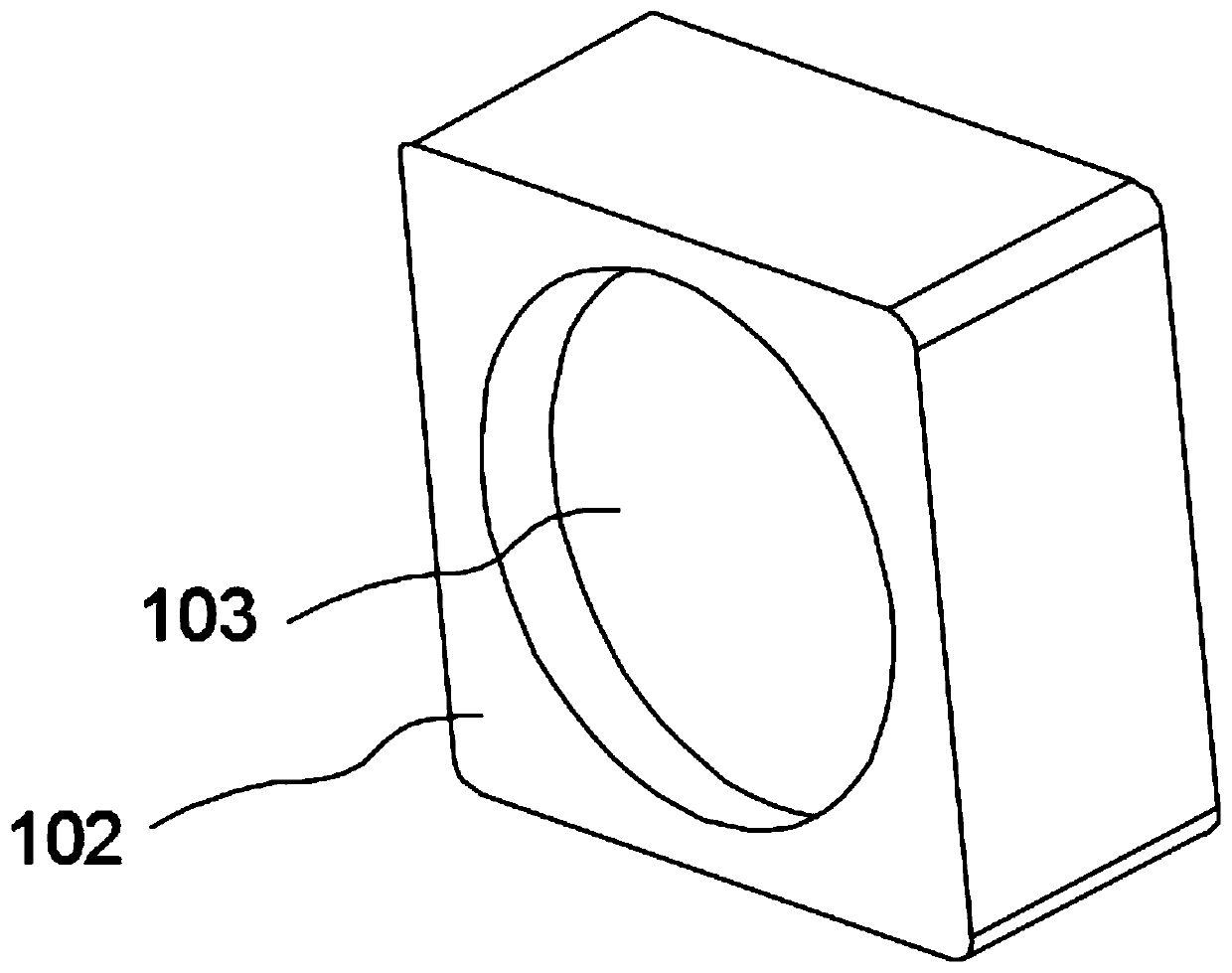

[0029] In the embodiment of the present invention, such as Figure 1-3 As shown, a multi-gradient processing equipment for local flatness processing of building materials includes a control system capable of multi-latitude position adjustment. The control system includes an X-axis arm structure, a Y-axis angle adjustment structure, and a Z-axis arm structure. structure; wherein, the Y-direction angle adjustment structure is installed on the X-axis arm structure, which can adjust the Y-direction 360-degree angle to the X-axis arm structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com