Building wall polishing device with dust collection function

A technology for building walls and functions, applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve problems such as high labor intensity, low grinding efficiency, operator fatigue, etc., to avoid health problems Hazard, good dust removal effect, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

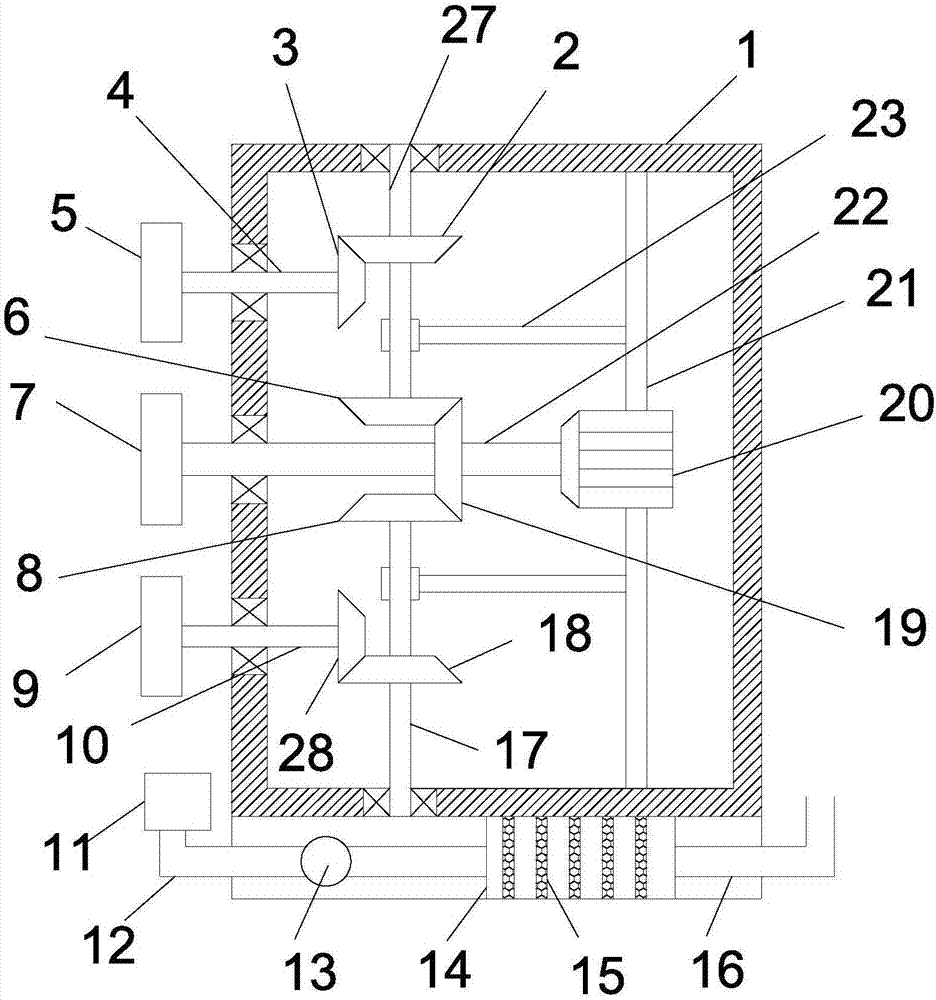

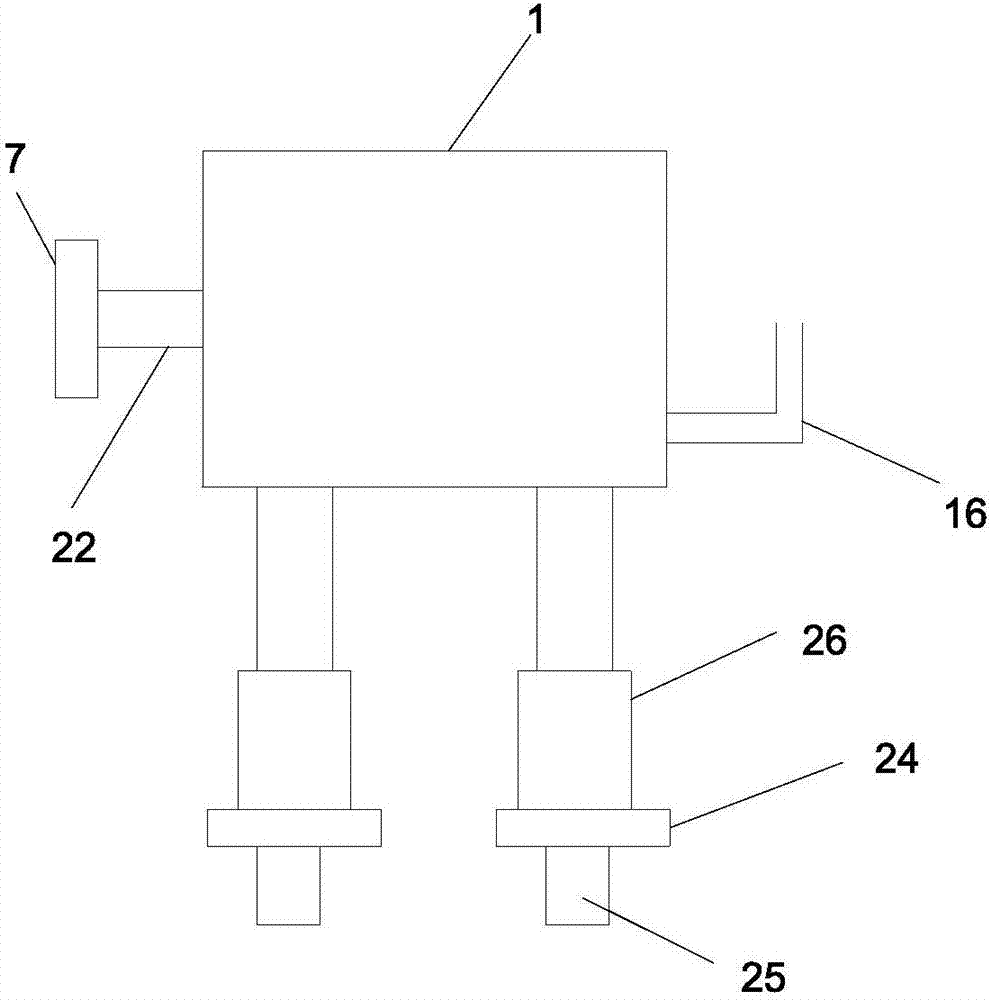

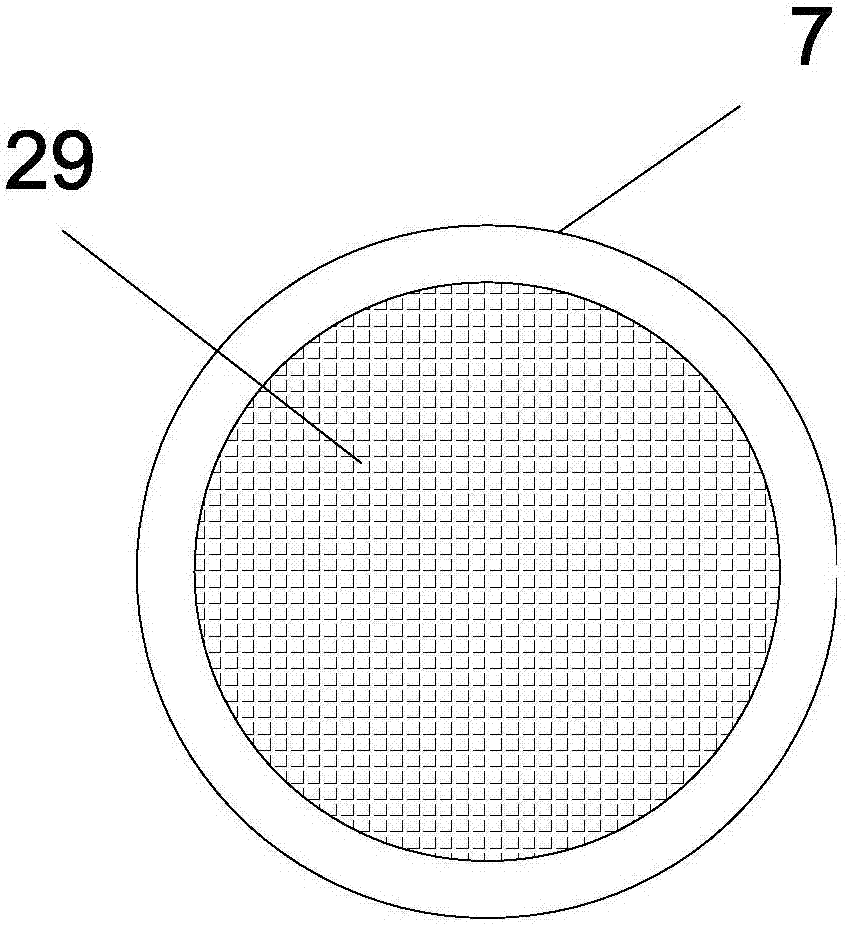

[0019] see Figure 1-3 , a building wall grinding device with dust suction function, comprising a main body 1, a main bracket 21 is arranged in the main body 1, a driving motor 20 is fixedly installed on the main bracket 21, and the motor shaft of the driving motor 20 passes through a coupling A drive shaft 22 is fixedly connected, and the drive shaft 22 extends horizontally to the left and runs through the left side wall of the body 1. The left end of the drive shaft 22 is fixed with an active grinding disc 7, and the left side of the active grinding disc 7 is fixed with a grinding wheel 29. ; Coaxially fixedly installed with drive bevel gear 19 on the said drive shaft 22, two sub-supports 23 are welded and fixedly installed on the main support 21, two sub-supports 23 are arranged parallel to each other, and two sub-supports 23 are respectively rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com