Liquid medicine mixing preparation equipment for medicament department

A technology for liquid medicine and departments, applied in mixers, mixers with rotating containers, dissolving and other directions, which can solve the problems of manual manual operation and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

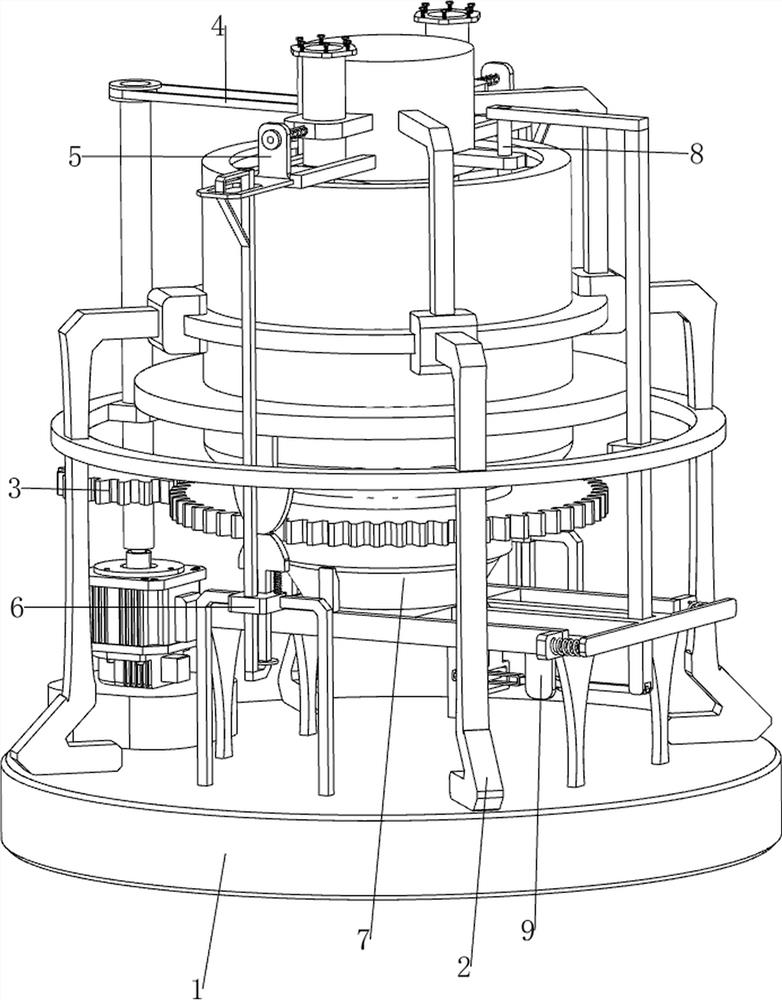

[0070] A medicine liquid mixing and preparation equipment for a pharmacy department, such as Figure 1-2As shown, it includes a bottom plate 1, a frame 2, a primary stirring mechanism 3 and a secondary stirring mechanism 4. The top of the bottom plate 1 is provided with a plurality of frames 2, the top of the bottom plate 1 is provided with a primary stirring mechanism 3, and the primary stirring mechanism 3 is provided with There are secondary stirring mechanisms 4 .

[0071] When the medical personnel need to mix and prepare the medicinal liquid, they can use this equipment. First, the medical personnel pour the medicinal liquid to be mixed into the 3 parts of the primary stirring mechanism, and then start the primary stirring mechanism 3, so that the 3 parts of the primary stirring mechanism rotate The liquid medicine is stirred, and at the same time, the rotation of the 3 parts of the primary stirring mechanism will drive the rotation of the 4 parts of the secondary stirri...

Embodiment 2

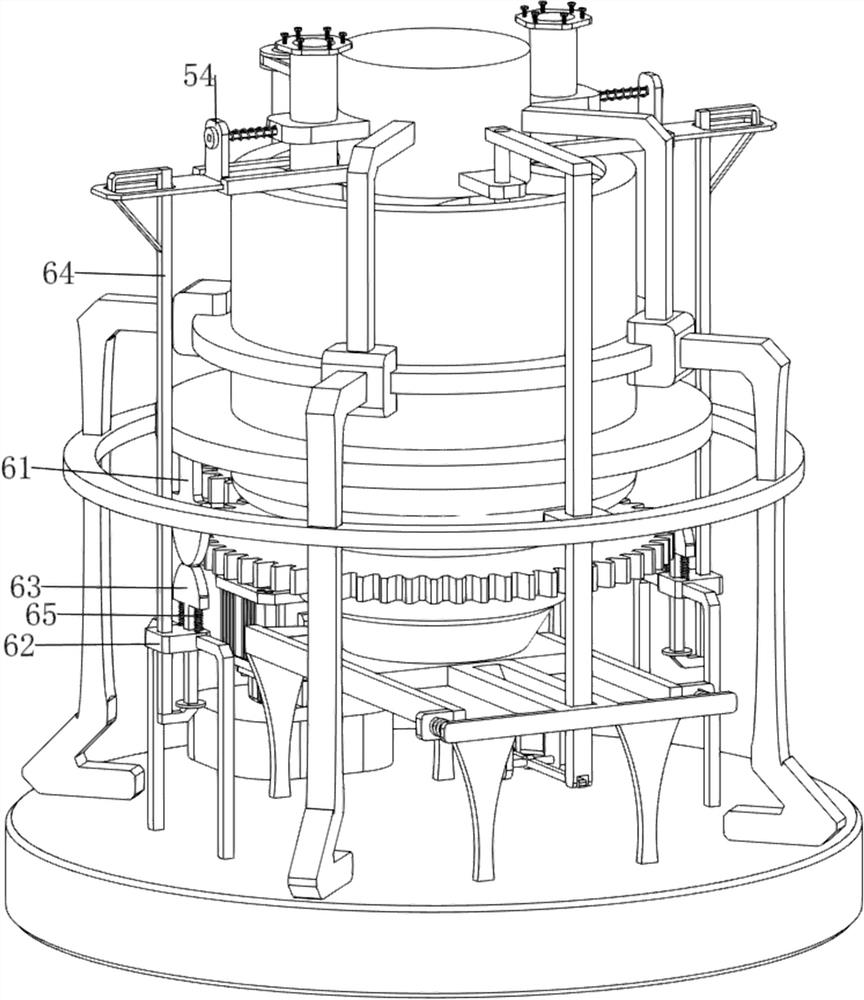

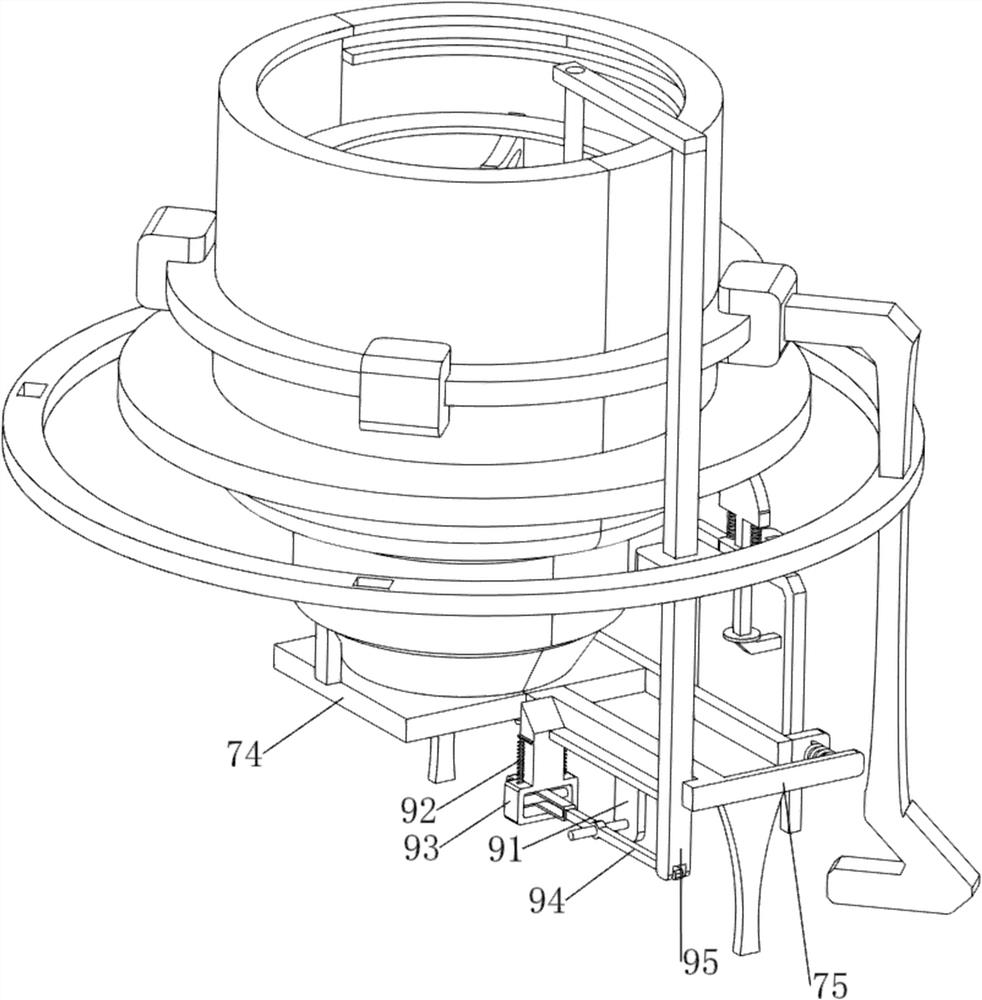

[0077] On the basis of Example 1, such as Figure 3-8 As shown, a material injection mechanism 5 is also included. The material injection mechanism 5 includes a first fixed block 51, an external conduit 52, a guide groove 53, a first spoiler 54, a first guide rod 55 and a first spring 56. A bearing seat 42 is symmetrically provided with a first fixed block 51 on the front and rear sides, and the middle part of the first fixed block 51 is provided with an external conduit 52, and the first bearing seat 42 is symmetrically provided with guide grooves 53 on the front and rear sides. The first baffle 54 is provided in the formula, and the first guide rod 55 is provided on the outside of the first fixed block 51. The first guide rod 55 is connected with the first baffle 54 in a sliding manner, and the first baffle 54 is connected with the first baffle. A first spring 56 is provided between the fixing blocks 51 , and the first spring 56 is sleeved on the first guide rod 55 .

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com