Feeding device for lead frame assembly

A lead frame and feeding device technology, which is applied to conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of affecting production efficiency, low degree of automation of the device, occupation of labor, etc., and achieves simple structure, stable position, and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

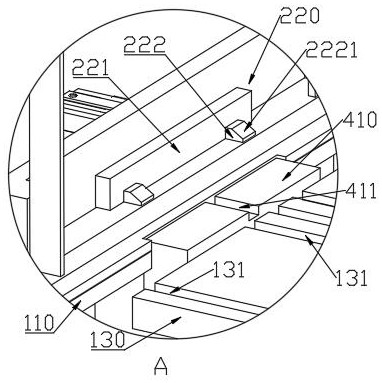

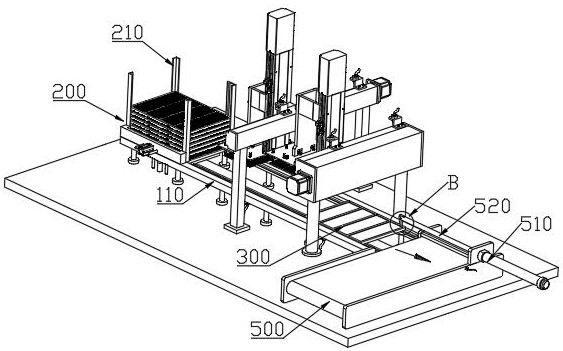

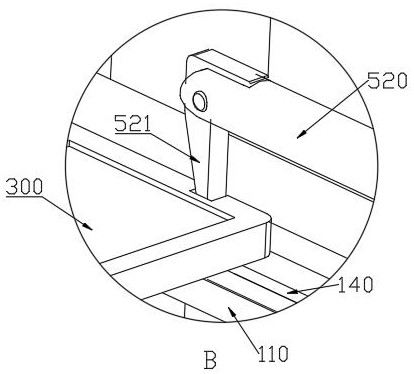

[0052] Specific implementation method: combined Figure 1 to Figure 15 Further explain the working principle of this application.

[0053] The discharge method of the storage mechanism 200 is to first place the frame tray 300 with the lead frame 1 stacked in the rectangular space formed by the angle steel 210 before the work, so that the card slot 303 is matched with the card bar 211, and the support seat 220 is facing to the middle. protruding, the bottom surface of the rectangular slot 301 is supported by the top surface of the support block 222 . When discharging, the lifting block 410 rises up to the set height, so that the rib 302 is inserted into the strip groove 411, and then the support seat 220 is retracted to both sides, and the lifting block 410 fully supports the frame tray 300 at this time; The lifting block 410 moves downward to set the height. At this time, the bottom frame tray 300 is in contact with the top surface of the transport tray 130, and the rib 302 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com