Automatic-discharging type steel pipe cutting device

A technology of automatic blanking and cutting devices, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., and can solve the unsolved problems of automatic blanking and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

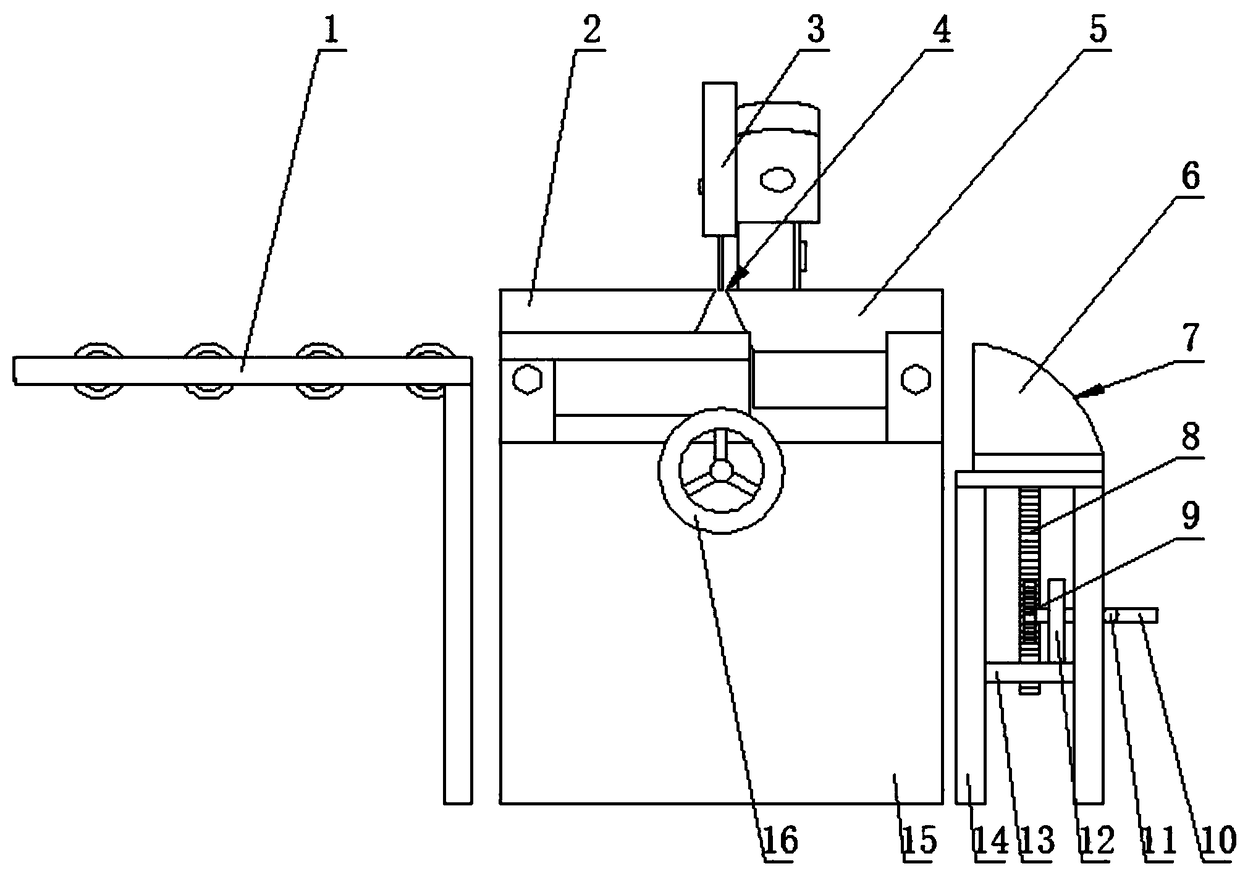

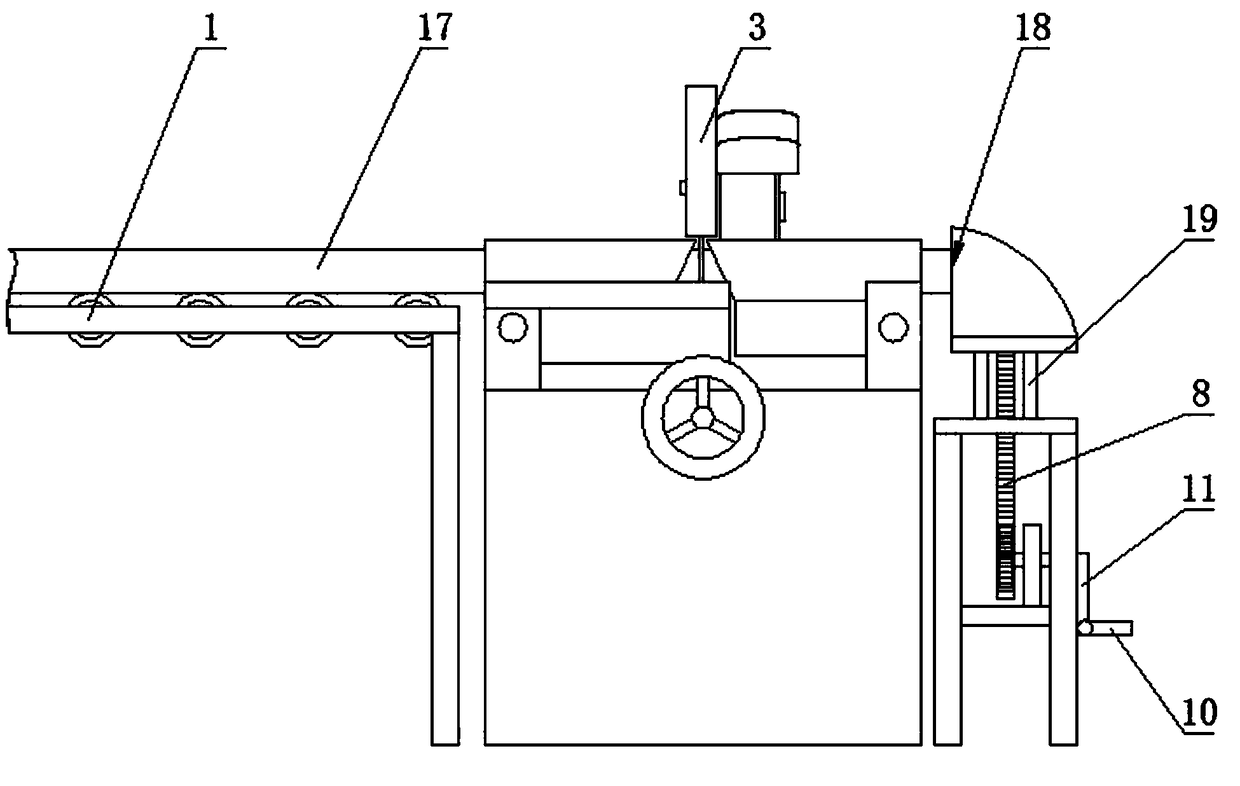

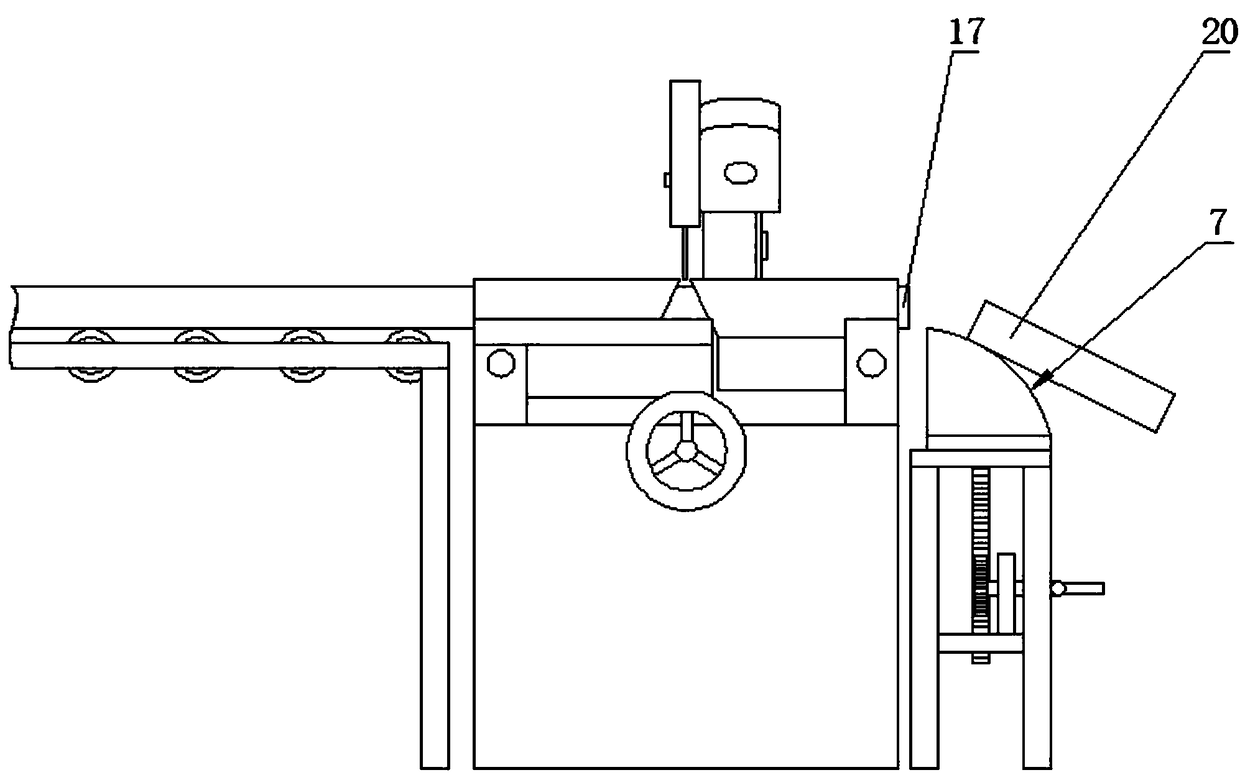

[0016] A steel pipe cutting device for automatic blanking, including a machine base 15, a guide sleeve 2 and a locking sleeve 5 are respectively installed at intervals on the left and right sides of the upper end of the machine base, and a gap is formed between the guide sleeve and the locking sleeve 4. An electric saw is installed above the gap. 3. The guide sleeve and the locking sleeve are respectively formed with accommodating passages for passing through the steel pipe. The positions of the two accommodating passages of the guide sleeve and the positioning sleeve are corresponding. A handle 16 for adjusting the inner diameter of the accommodating channel is installed in the end face of the frame next to the sleeve and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com