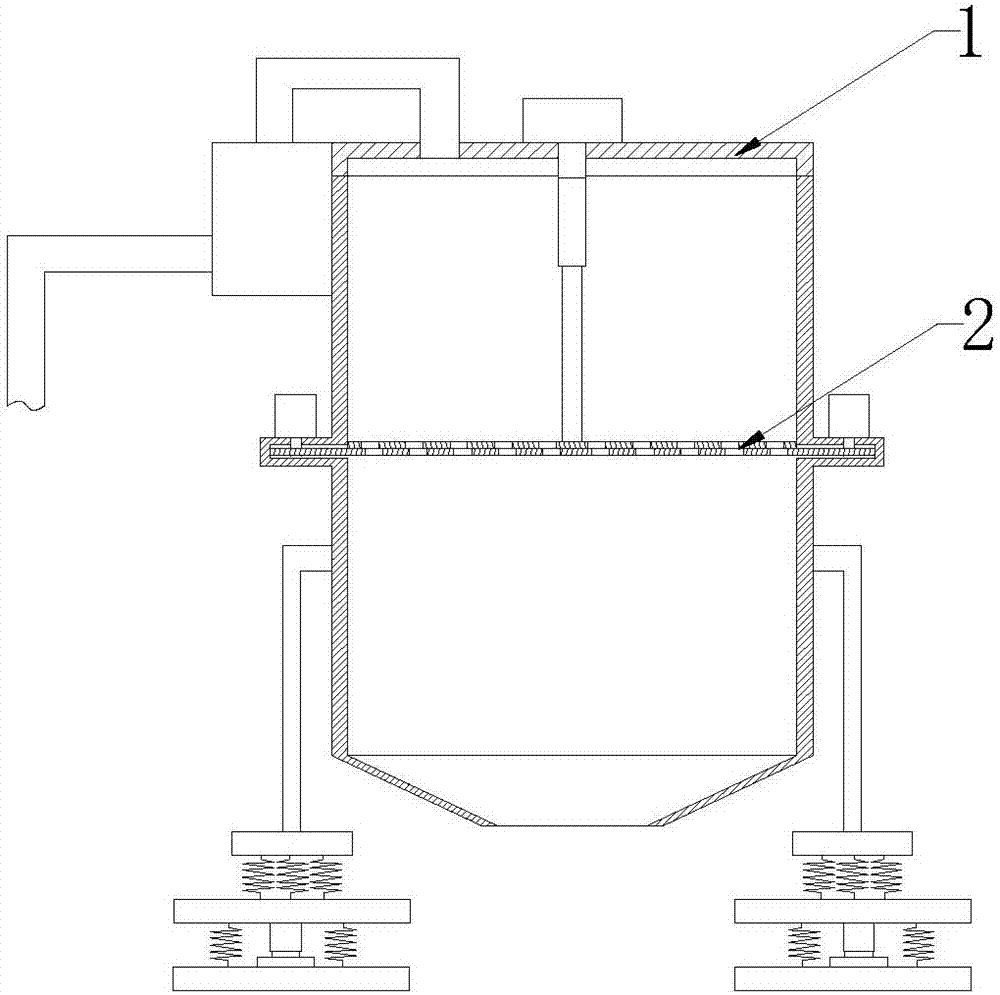

Mortar vibrating screen device for concrete wet screening

A vibrating screen and concrete technology, which is applied in the direction of filter screen, machine/engine, liquid variable capacity machinery, etc., can solve the problems of fixed screen mesh size, lower production efficiency, and inability to adjust, so as to increase production efficiency, Improved productivity and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

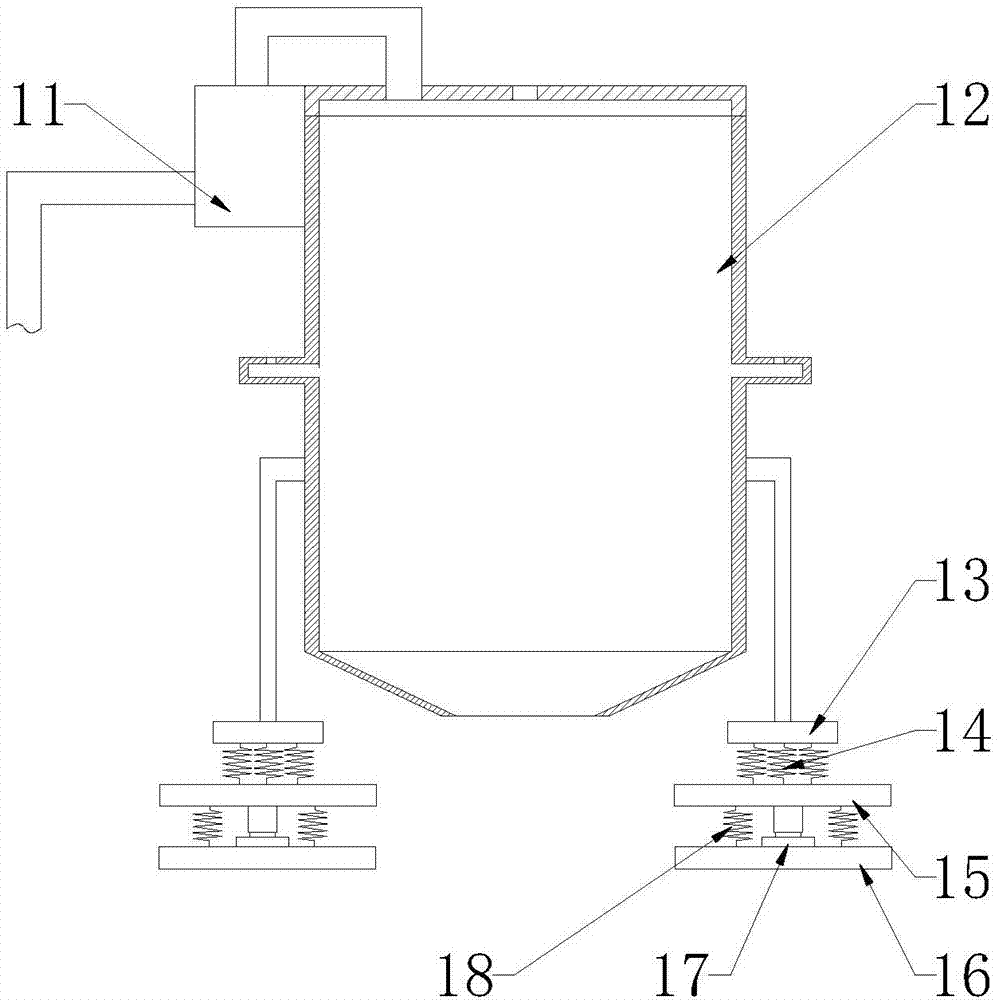

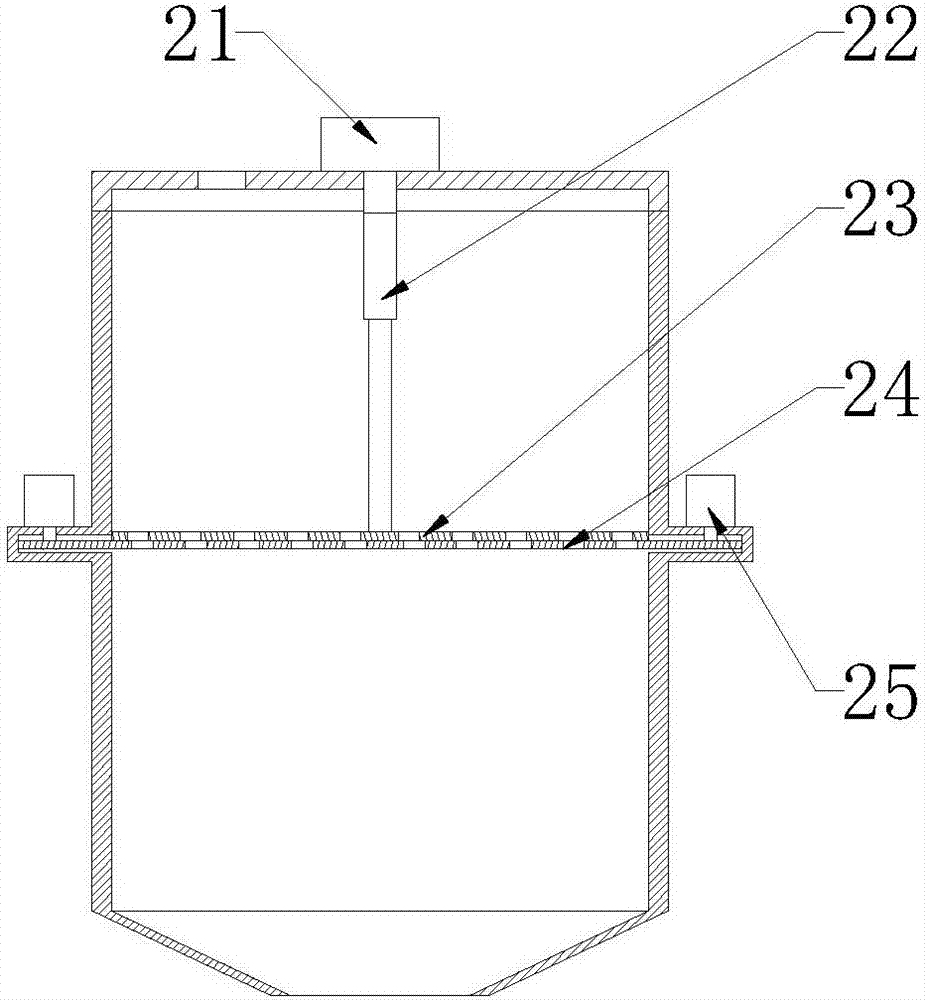

[0026] Specific implementation method: when in use, the staff turns on the servo motor 21, the servo motor 21 works to drive the telescopic rod 22 to rotate, the telescopic rod 22 rotates to drive the adjustment sieve 23 to rotate, and the adjustment sieve 23 rotates to change the through hole on the adjustment sieve 23 and the top of the bottom sieve 24 The corresponding position of the through hole can adjust the size of the material through the sieve hole. When the adjustment sieve 23 rotates to a suitable angle, the staff will turn off the servo motor 21. This design improves flexibility and is easy to use.

[0027] The staff turns on the concrete delivery pump 11, and the concrete delivery pump 11 works to deliver an appropriate amount of material to the inside of the box body 12, and then the staff turns on the vibration motor 25, which drives the vibration of the bottom screen 24, and the vibration of the bottom screen 24 drives the vibration of the adjustment screen 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com