Bamboo pulp paper package production equipment

A production equipment and technology for bamboo pulp paper, applied in the field of bamboo pulp paper packaging production equipment, can solve the problems that the precision cannot be accurately controlled, the feeding cannot be carried out quickly and stably, the cylinder stroke is not easy to control, etc., and achieves large stroke error and response time. Fast, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is further described in detail through specific implementation methods:

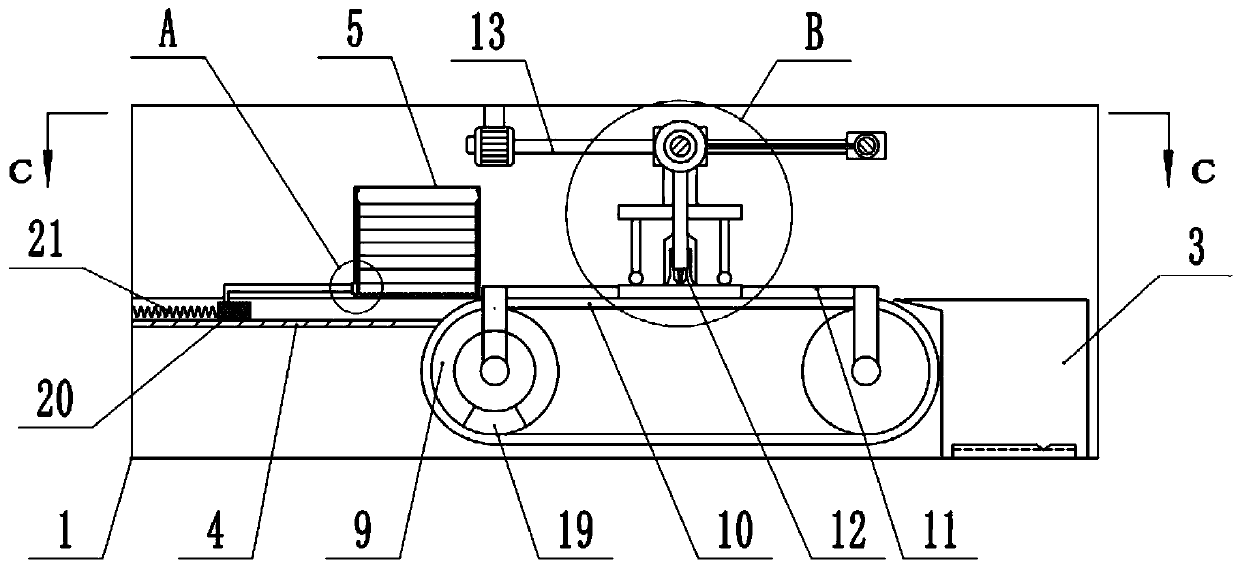

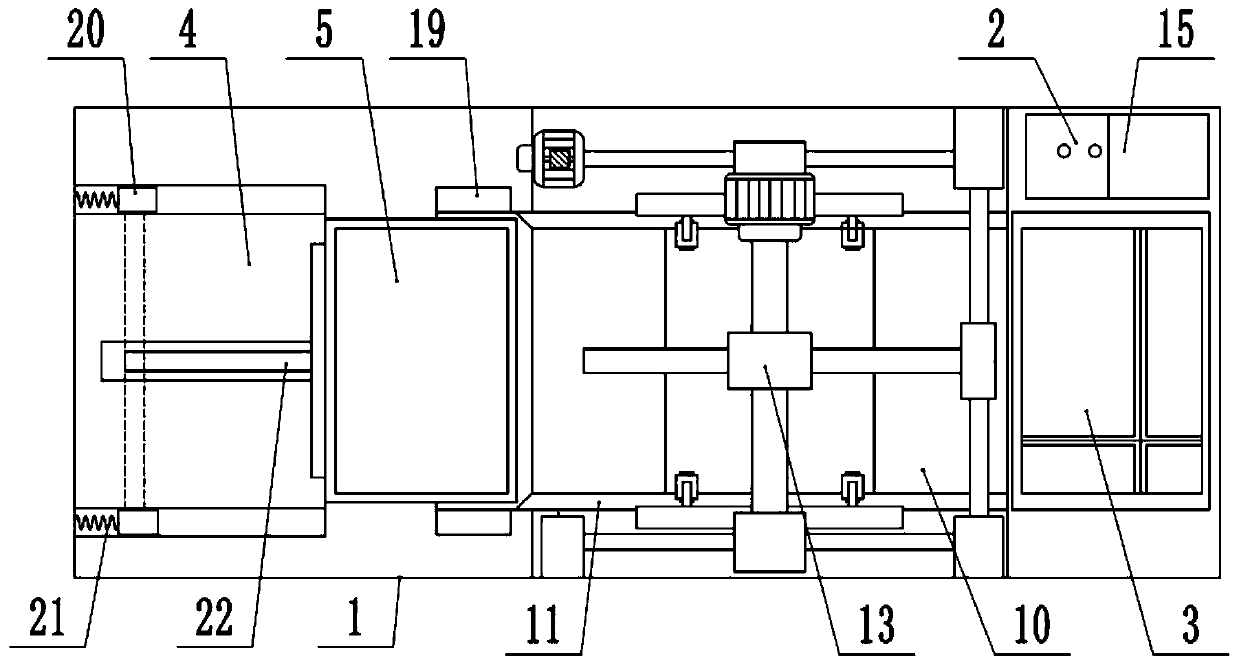

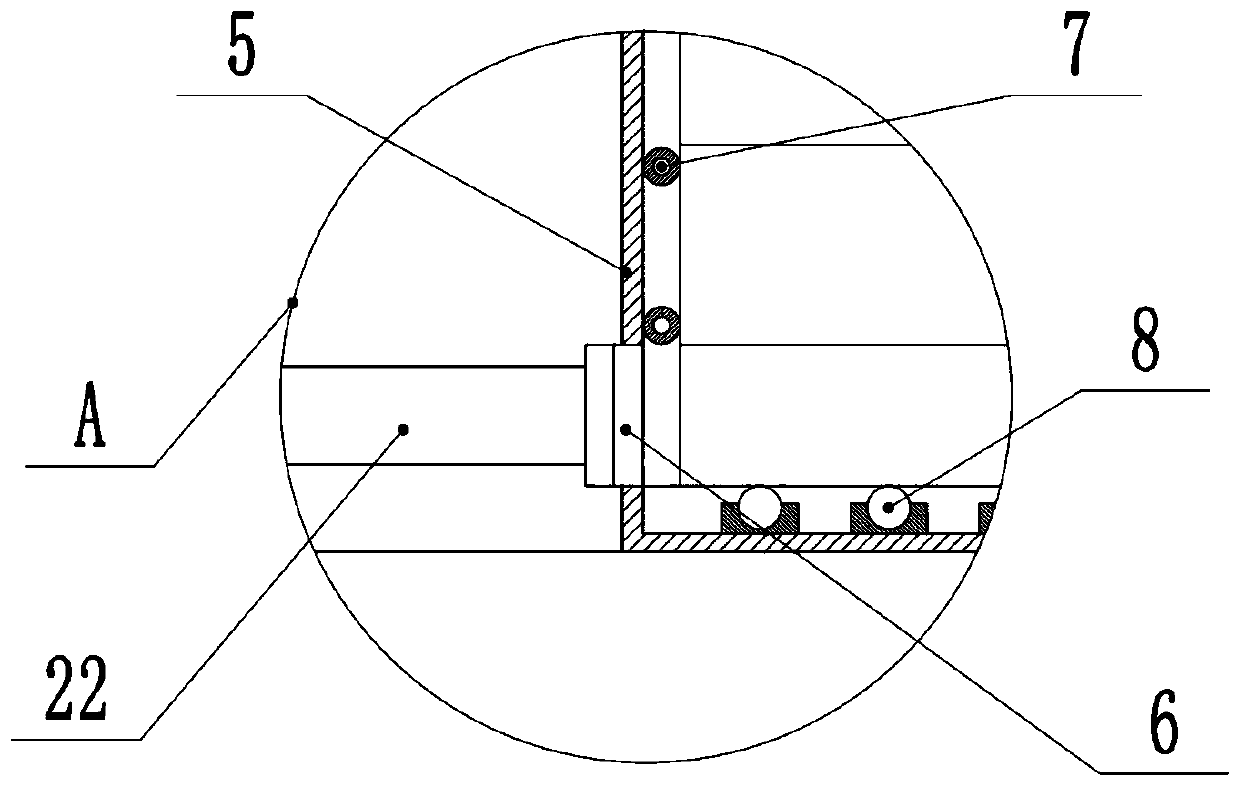

[0033] The reference signs in the drawings of the description include: cutting box 1, control unit 2, collection box 3, fixed plate 4, feeding box 5, channel 6, rolling wheel 7, universal wheel 8, transmission wheel 9, conveyor belt 10 , guide plate 11, cutting knife 12, screw rod group 13, suction pipe 14, air pump 15, filter mechanism 16, extrusion rod 17, extrusion steel ball 18, first permanent magnet 19, second permanent magnet 20, return spring 21 , push plate 22.

[0034] The embodiment is basically as attached figure 1 Shown: Bamboo pulp paper packaging production equipment, including cutting box 1, combined with figure 2 , the cutting box 1 is provided with a feeding mechanism, a transmission mechanism, a cutting mechanism, a control unit 2 and a collection box 3 from left to right, and the feeding direction of the cardboard to be cut is figure 1 in from left to right. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com