High-rise vertical shearing energy-consuming steel plate wall structure system

A steel plate wall and system technology, applied in the direction of walls, building components, building structures, etc., to achieve the effect of clear failure mode, high bearing capacity, and large lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

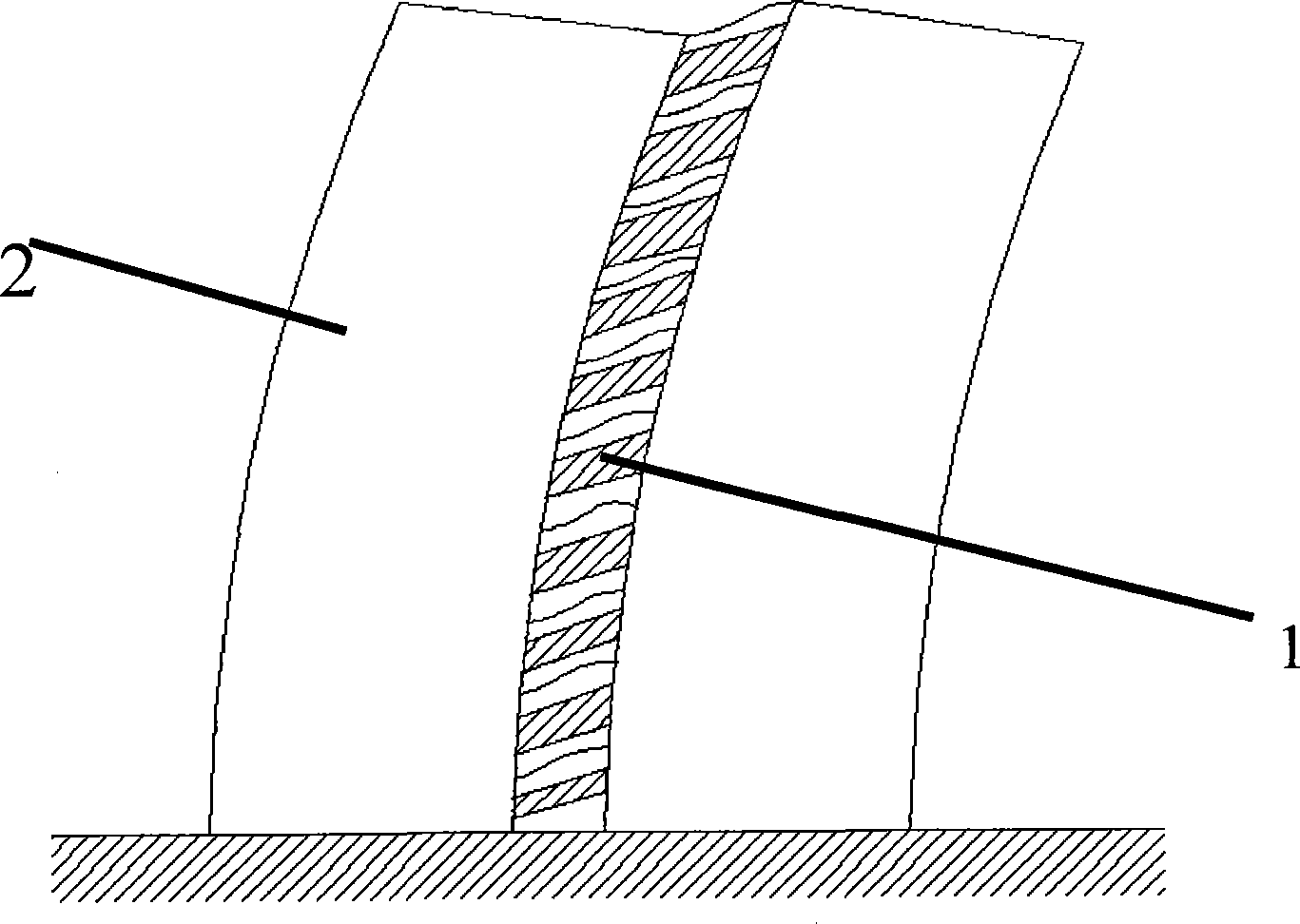

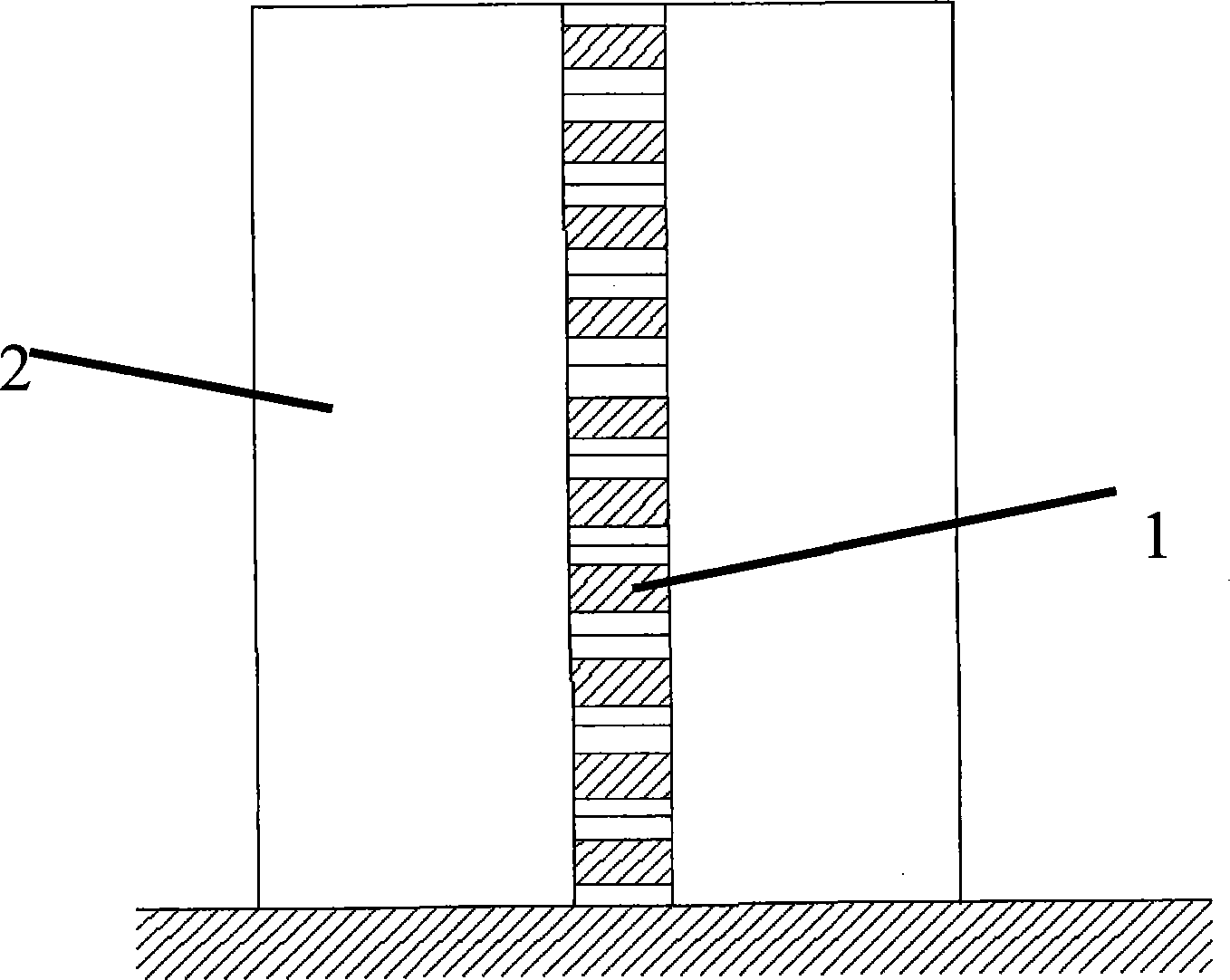

[0015] Embodiment 1: The super high-rise composite wall system of the present invention is composed of four-side connected composite steel plate shear walls, two sides connected steel plate walls, and beam-column members; controlling the thickness of the thin steel plate and the thickness of the composite wall steel plate makes the thin steel plate wall yield under a large earthquake The steel plate in the combined wall still maintains an elastic state. All beam-to-column connections are rigid.

[0016] In order to verify the feasibility of the present invention, the specially designed structural scale test model is as follows. The test model is a three-span 50-layer composite wall scale model. Out-of-plane displacement and torsion of the structure, the two side spans and the inner spans are connected with 2mm thick plexiglass plates on the four sides, and the middle span is connected with 1mm thick plexiglass plates connected to the columns on both sides. The materials of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com