Fabricated shear-wall vertical-joint tooth-space-type energy-consuming connecting device

A shear wall and prefabricated technology, applied to walls, protective buildings/shelters, and building components, can solve problems such as difficult quality assurance, unfavorable energy conservation and environmental protection, and complex construction, and achieve good energy consumption and earthquake resistance Performance, ease of industrial production, and the effect of improving structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

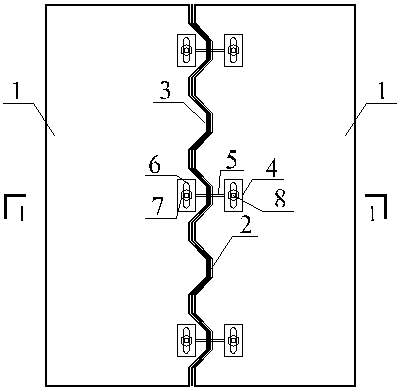

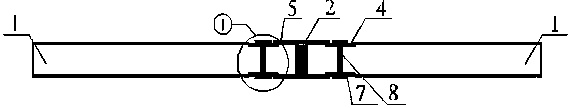

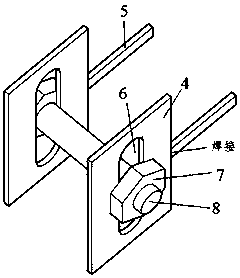

[0018] As shown in the accompanying drawings, the present invention includes prefabricated shear wall sheets (1), viscoelastic energy-dissipating materials (2), tooth grooves (3), anchor pads (4), tie rods (5), and vertical oblong bolt holes (6), nut (7) and screw rod (8).

[0019] The joint edge of the prefabricated shear wall sheet (1) of the present invention is prefabricated into the alveolar (3), and the viscoelastic energy-dissipating material (2) is filled in the alveolar joint in advance or assembled on site, and the viscoelastic energy-dissipating material (2) is pre-determined. The thickness of the elastic material and the protruding height of the alveolar, the height of the alveolar should not be too high, so as to facilitate the efficient vertical hoisting of the prefabricated shear wall in place.

[0020] In the prefabricated shear wall (1) of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com