Steel-concrete combined conversion joist

A technology for concrete and conversion beams, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problem of insufficient effective width of concrete wings, low position of neutral axis in composite beams, and reduced composite beam work. Efficiency and other issues, to achieve the effect of improving vertical shear resistance, reducing the dead weight of the structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

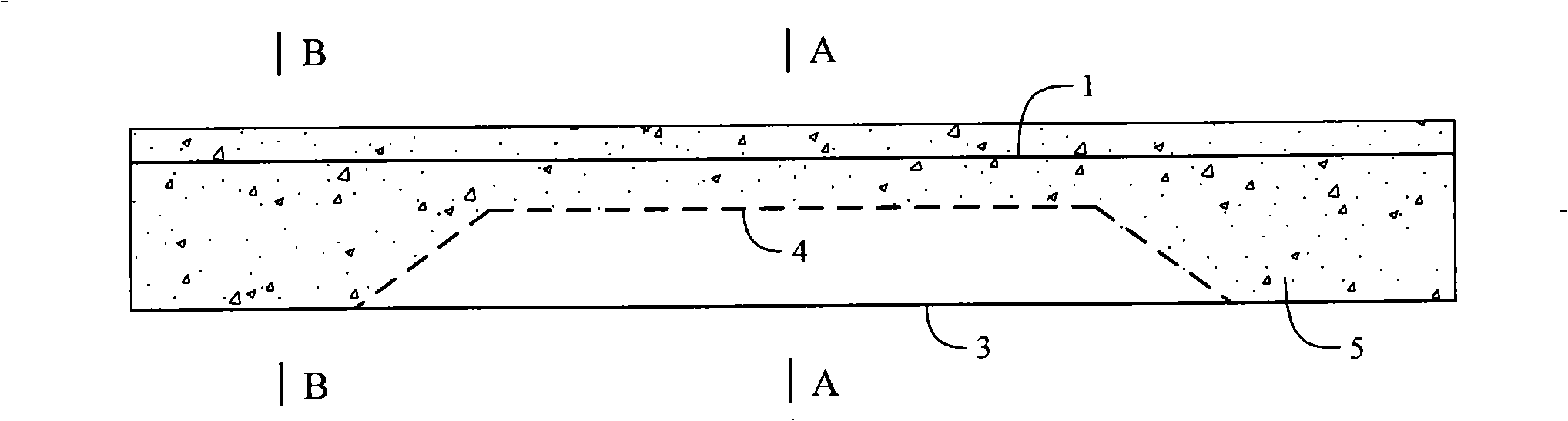

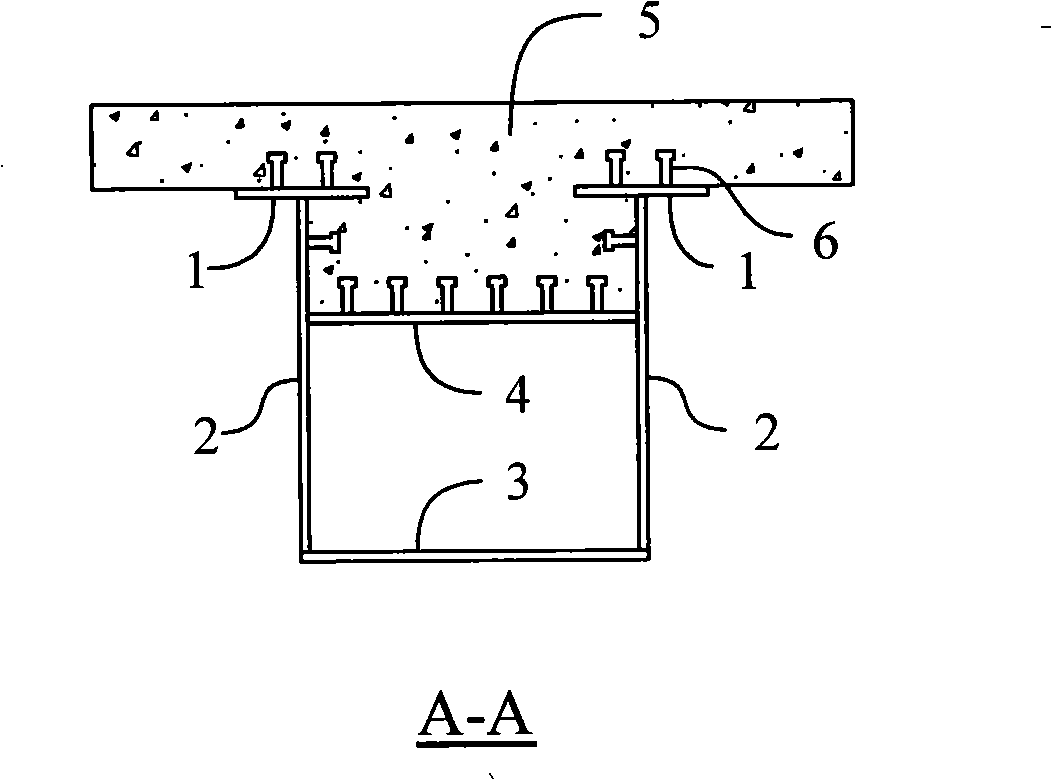

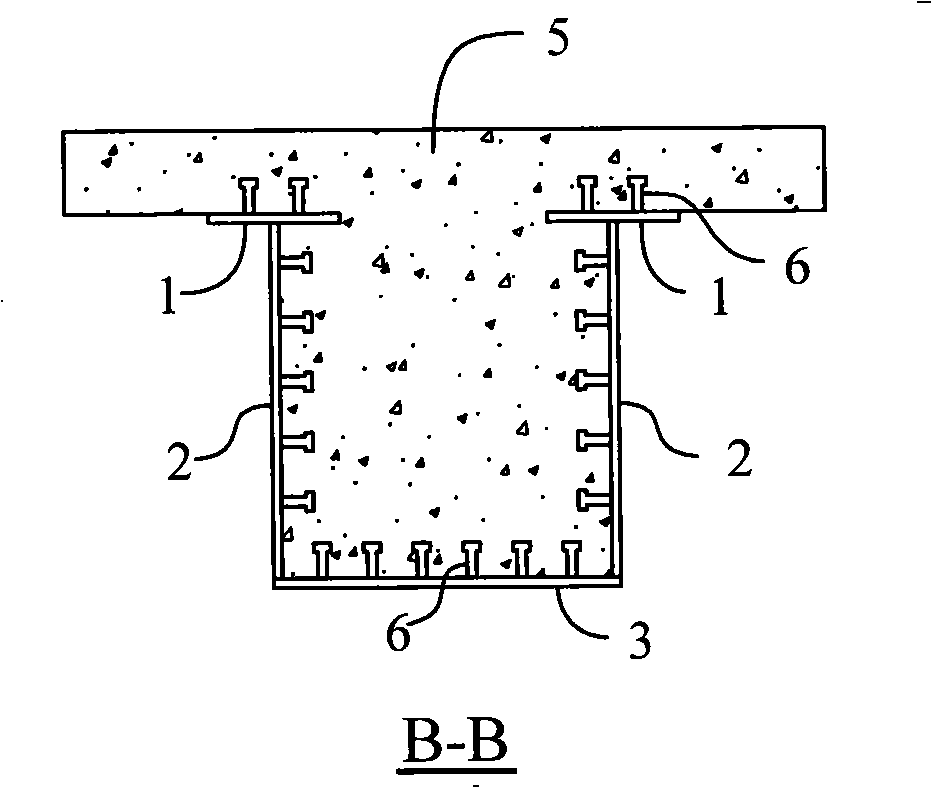

[0012] The steel-concrete composite transfer beam provided by the present invention is composed of a steel box girder, concrete 5 and shear connector 6; the steel box girder is composed of a top plate 1, a web 2, a bottom plate 3 and an inner partition 4, and the thickness of the steel plate depends on the beam span and load The size is determined by calculation. The inner partition 4 is located in the mid-span positive bending moment zone. The inner partition 4 divides the steel box girder into upper and lower box chambers, and its length generally accounts for 1 / 2 to 2 / 3 of the span of the beam. Concrete 5 is poured on the top of the steel box girder along the entire length, and the width of the concrete is determined according to the use requirements of the building. Concrete 5 is poured on the part above the inner partition plate 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com