Prediction method for fracture pressure of well wall of coal seam directional well

A technology of fracturing pressure and prediction method, which is applied in wellbore/well components, earthwork drilling, etc., can solve problems such as inapplicability, and achieve the effect of strong practicability, lower construction cost, and higher fracturing success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described further below:

[0043] This coal seam directional well wall fracture pressure prediction method:

[0044] Step 1. Carry out the rock mechanics experiment of the coal-rock formation in the research block, test the magnitude of the in-situ stress, the magnitude of the pore pressure of the formation, the tensile strength of the coal rock, the compressive strength, the cohesion force, the cleat cohesion force, and the internal friction coefficient;

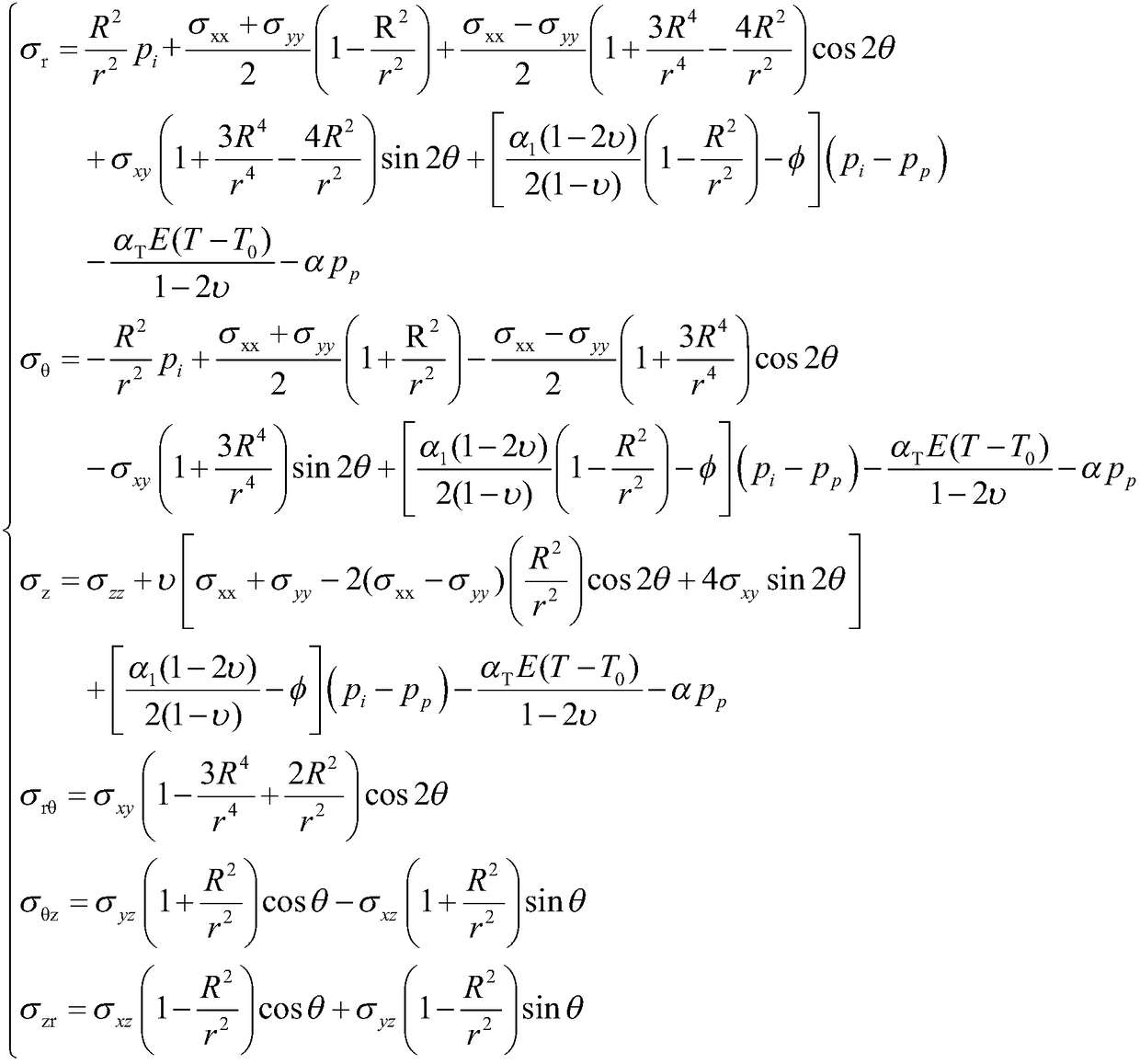

[0045] Step 2. According to the coal-rock formation directional well body structure data and its relationship with the in-situ stress coordinate system and the geodetic coordinate system, convert between the borehole coordinate system, the in-situ stress coordinate system and the geodetic coordinate system, and convert the in-situ stress coordinate system to the geodetic coordinate system. The stress is converted to the borehole coordinate system for force analysis;

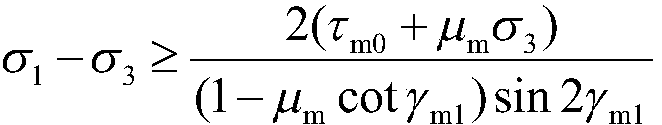

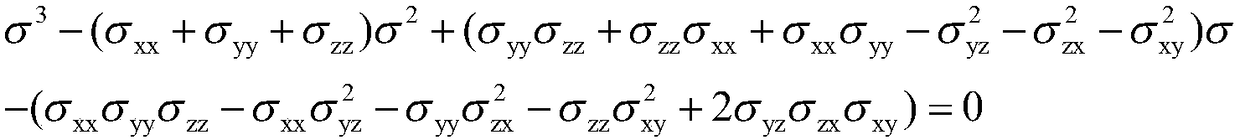

[0046] Step 3, accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com