A funnel-type air-jet spinning device

A spinning device and a funnel-type technology, which is applied in the field of funnel-type air-jet spinning devices, can solve the problem of inability to form a Taylor cone jet, and achieve the effects of eliminating the effect of bubble bursting, avoiding unstable electrical conductivity and uniform electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

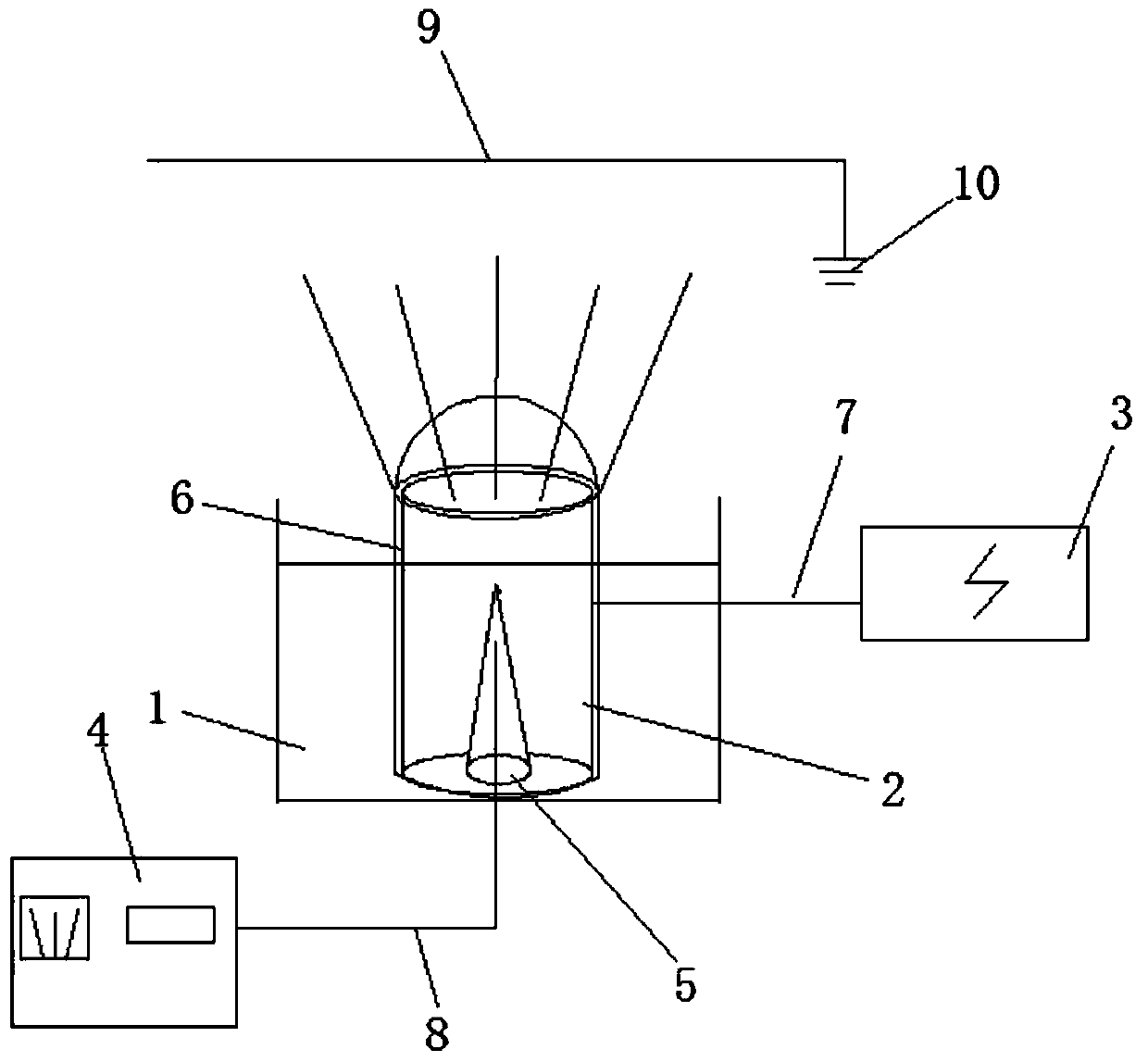

[0025] Bubble electrospinning technology, under the action of the electric field force in the high-voltage electrostatic field, the polymer solution or melt generates bubbles on the surface of the polymer solution, and after the bubbles burst, countless small liquid columns are formed, each liquid column is equivalent to a Taylor cone At the same time, with electrostatic force as the driving force, the liquid column is stretched and thinned under the action of electric current to produce a large number of micro-nano fibers, which greatly improves the output of micro-nano fibers. However, the existing traditional bubble spinning technology sometimes cannot produce uniform bubbles that burst continuously, so that effective Taylor cone jets cannot be formed.

[0026] Aiming at the deficiencies in the prior art, the present invention provides a funnel-type air-jet spinning device. By using a funnel-type nozzle, a circular tube-shaped metal conductive copper sheet, and using tiny ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com