Construction method for lattice type steel column tower crane pedestal

A technology of tower crane foundation and construction method, which is applied in the direction of basic structure engineering, construction, etc., and can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

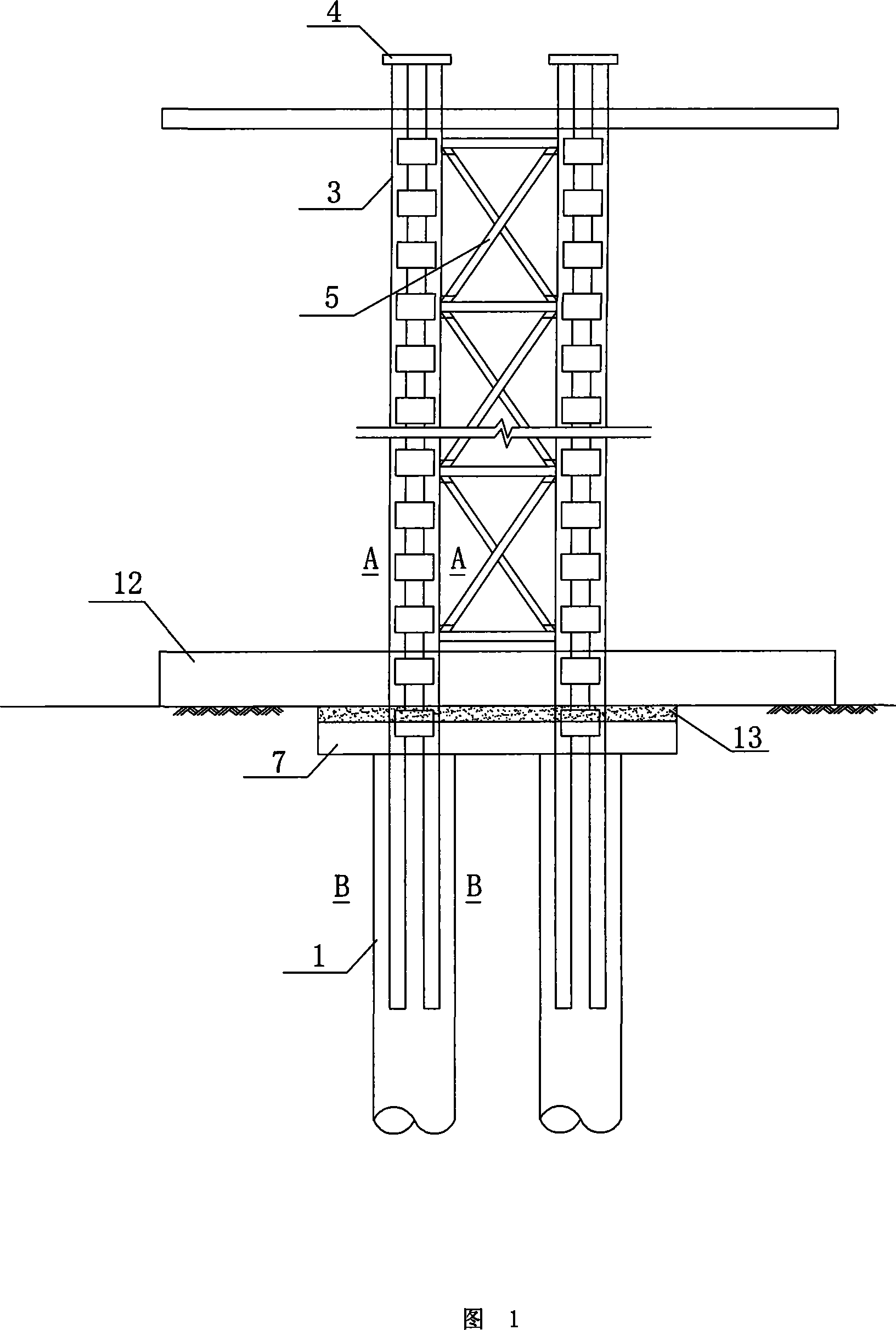

[0024] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, this embodiment is the construction method of the foundation base of the lattice type steel column tower crane, and the specific construction steps are as follows:

[0025] ① Drill four bored piles 1 on the ground that match the body of the tower crane;

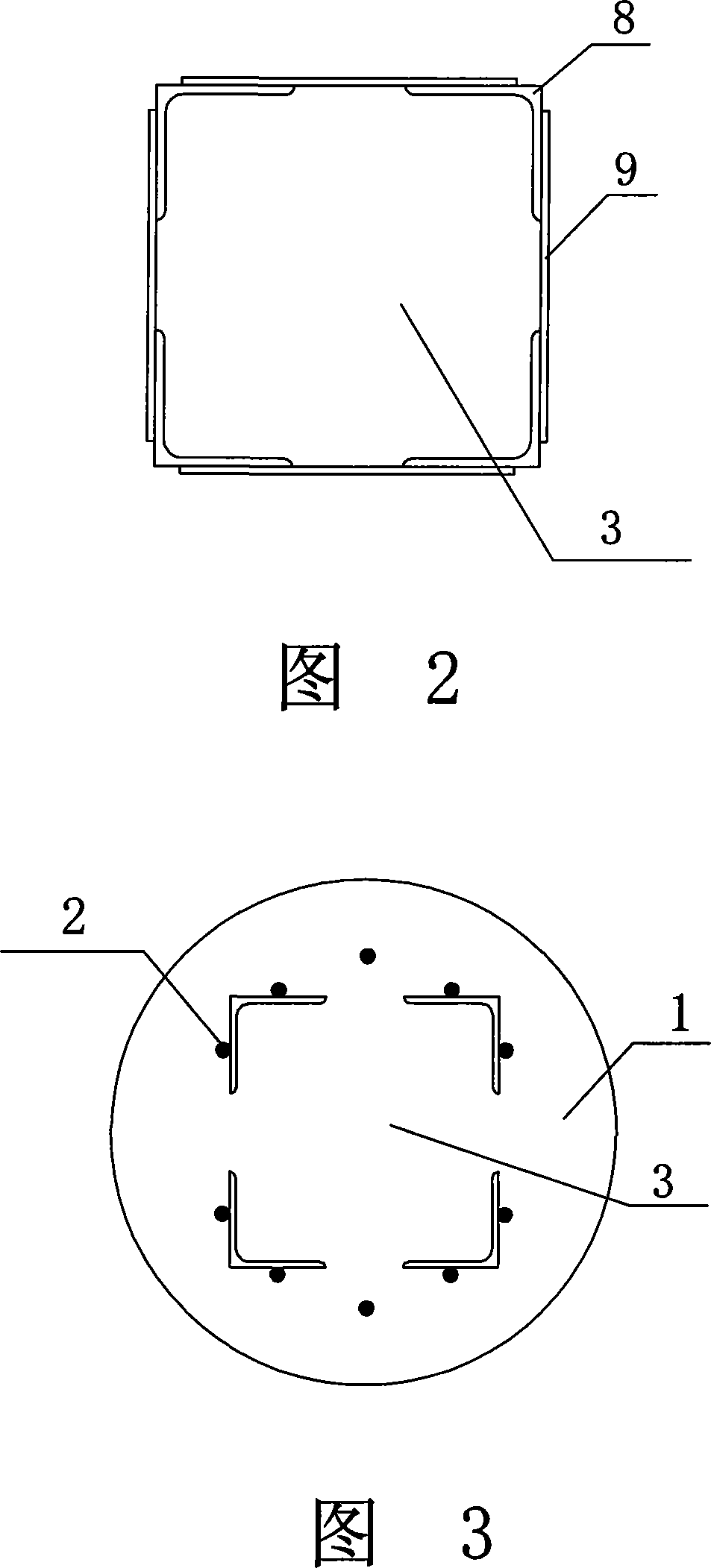

[0026] ② Making the lattice steel column 3: welding four angle irons 8 and dual-purpose panels 9 into columns;

[0027] ③ Weld the lattice steel column 3 with the main reinforcement and side bars of the pile reinforcement cage 2, and the overlapping length is 3.5 meters;

[0028] ④ Pouring the pile reinforcement cage 2 welded with the latticed steel column 3 in the bored cast-in-place pile 1;

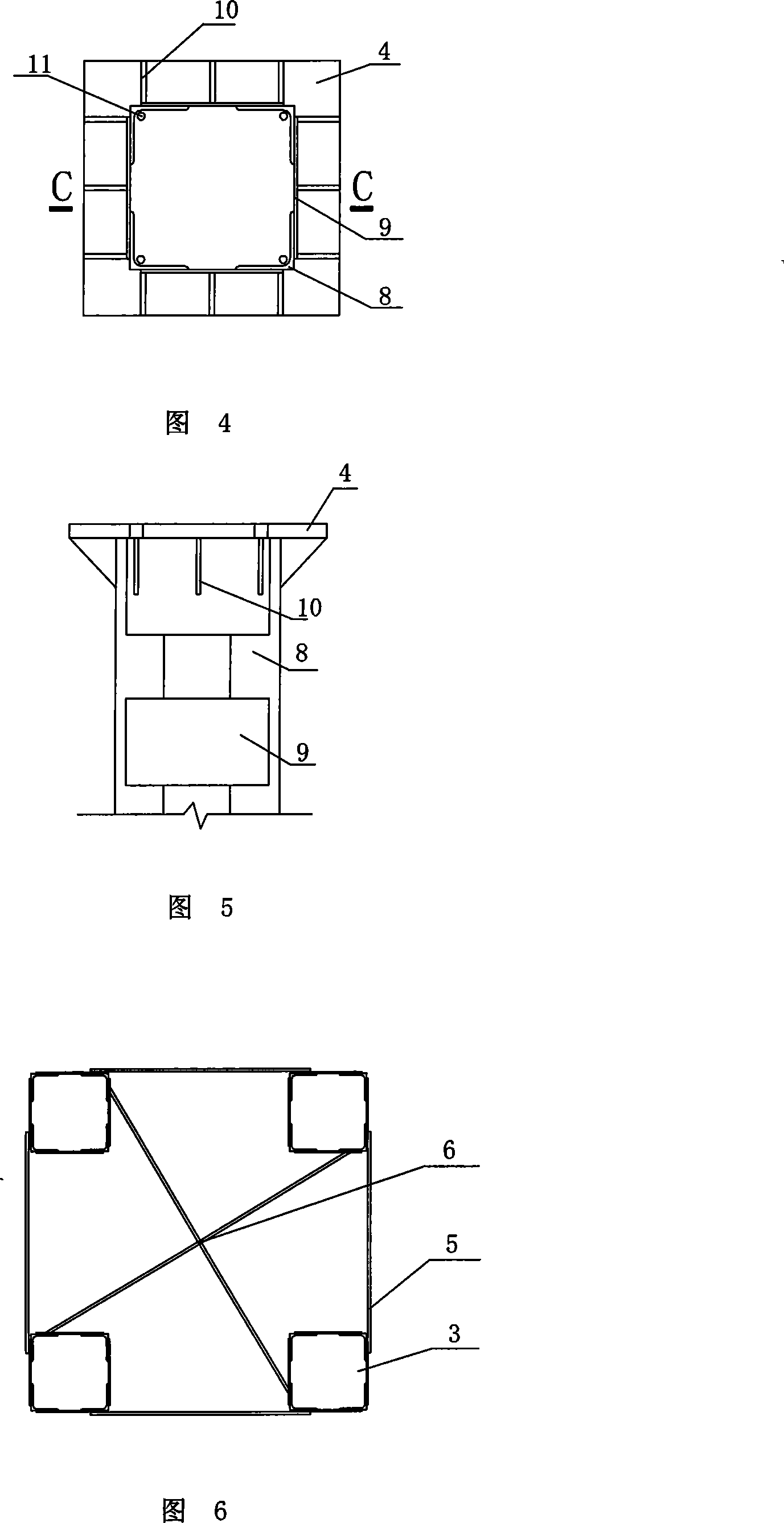

[0029] ⑤ Use one end of the anchor bolt 11 to pass through the transfer load-bearing steel plate 4 and weld the top angle steel 8 of the lattice steel column 3, then weld the top angle steel 8 of the lattice steel column with the conversion load-bearing steel plate 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com