High-strength high-toughness abrasion-resistant cast steel material and preparation method thereof

A high-toughness, cast steel technology, applied in the development and process preparation of high-performance new materials, can solve the problems of insufficient wear resistance and toughness, and high cost of channel side materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

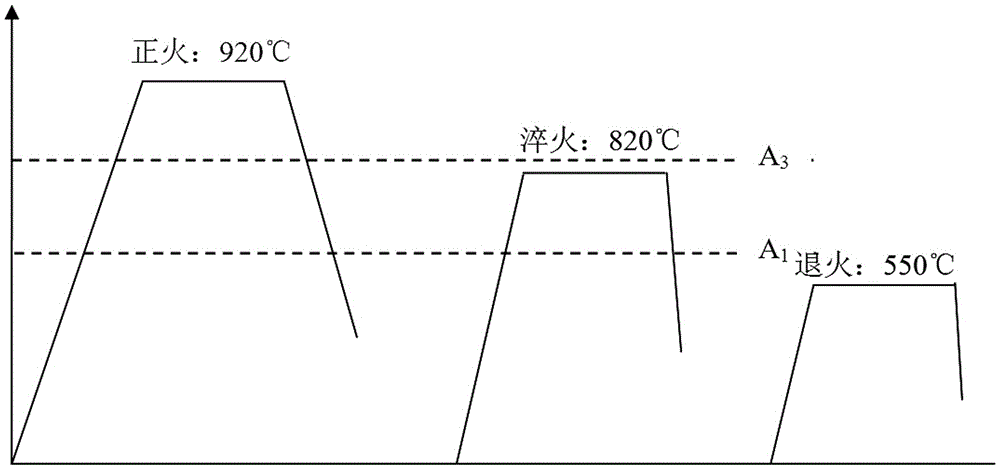

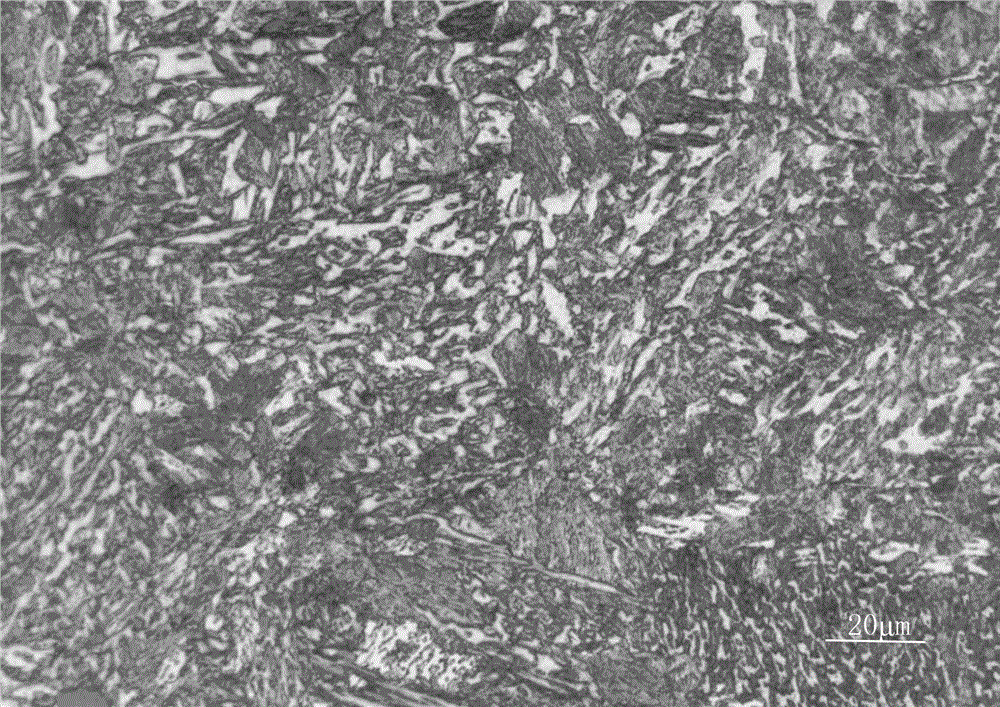

Method used

Image

Examples

Embodiment 1

[0033] Example 1 one A high-strength and high-toughness wear-resistant cast steel material and a preparation method thereof, using the following raw materials: scrap steel, pig iron, ferrochrome alloy, ferromanganese alloy, ferrosilicon alloy, ferromolybdenum alloy, ferroniobium alloy, ferroboron alloy, and mixed rare earths;

[0034] Include the following steps:

[0035] (1) Selection of chemical substances and materials

[0036] The quality and purity of the chemical substances used are controlled as follows (impurity content is lower than):

[0037] Ferrochrome: solid solid 0.2%

[0038] Ferromanganese alloy: solid solid 0.2%

[0039] Ferrosilicon alloy: solid solid 0.2%

[0040] Molybdenum iron alloy: solid solid 0.2%

[0041] Niobium ferroalloy: solid solid 0.2%

[0042] Ferro-boron alloy: solid solid 0.2%

[0043] Mixed rare earths: solid solid 0.2%

[0044] (2) Smelting

[0045] Mix and heat scrap steel, pig iron, ferrochrome alloy and ferromolybdenum alloy, an...

Embodiment 2

[0052] Example 2 one A high-strength and high-toughness wear-resistant cast steel material and a preparation method thereof, using the following raw materials: scrap steel, pig iron, ferrochrome alloy, ferromanganese alloy, ferrosilicon alloy, ferromolybdenum alloy, ferroniobium alloy, ferroboron alloy, and mixed rare earths;

[0053] Include the following steps:

[0054] (1) Selection of chemical substances and materials

[0055] The quality and purity of the chemical substances used are controlled as follows (impurity content is lower than):

[0056] Ferrochrome: solid solid 0.2%

[0057] Ferromanganese alloy: solid solid 0.2%

[0058] Ferrosilicon alloy: solid solid 0.2%

[0059] Molybdenum iron alloy: solid solid 0.2%

[0060] Niobium ferroalloy: solid solid 0.2%

[0061] Ferro-boron alloy: solid solid 0.2%

[0062] Mixed rare earths: solid solid 0.2%

[0063] (2) Smelting

[0064] Mix and heat scrap steel, pig iron, ferrochrome alloy and ferromolybdenum alloy, an...

Embodiment 3

[0071] Example 3 one A high-strength and high-toughness wear-resistant cast steel material and a preparation method thereof, using the following raw materials: scrap steel, pig iron, ferrochrome alloy, ferromanganese alloy, ferrosilicon alloy, ferromolybdenum alloy, ferroniobium alloy, ferroboron alloy, and mixed rare earths;

[0072] Include the following steps:

[0073] (1) Selection of chemical substances and materials

[0074] The quality and purity of the chemical substances used are controlled as follows (impurity content is lower than):

[0075] Ferrochrome: solid solid 0.2%

[0076] Ferromanganese alloy: solid solid 0.2%

[0077] Ferrosilicon alloy: solid solid 0.2%

[0078] Molybdenum iron alloy: solid solid 0.2%

[0079] Niobium ferroalloy: solid solid 0.2%

[0080] Ferro-boron alloy: solid solid 0.2%

[0081] Mixed rare earths: solid solid 0.2%

[0082] (2) Smelting

[0083] Mix and heat scrap steel, pig iron, ferrochrome alloy and ferromolybdenum alloy, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com