NM600 high-grade low-alloy wear-resistant steel and application thereof

A low-alloy, high-level technology, applied in the field of wear-resistant steel manufacturing, can solve problems such as difficulty in meeting large-scale, lightweight and long-life manufacturing, unsatisfactory hardness, toughness, plasticity and formability, poor welding performance, etc., to achieve good Corrosion resistance, low temperature impact toughness and cold bending performance are good, and the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

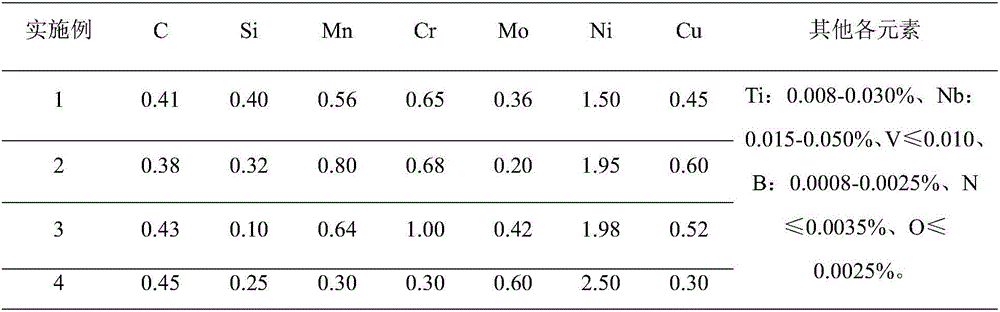

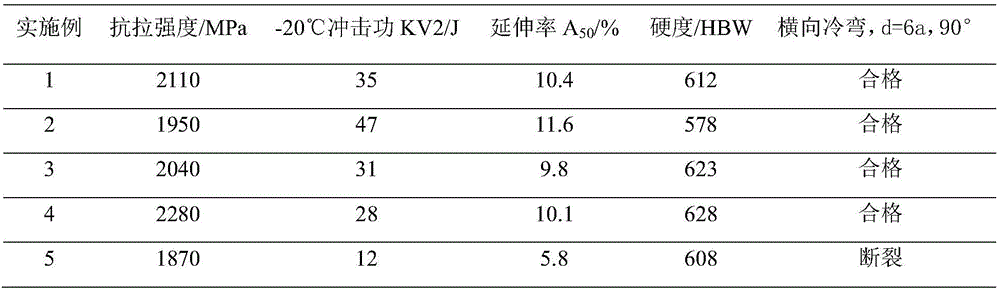

Embodiment 1

[0043] The molten steel smelted according to the proportions in Table 1 is subjected to vacuum degassing treatment before continuous casting. The thickness of the continuous casting slab is 150mm. The steel slab is heated to a furnace temperature of 1180°C. Rolling in the non-recrystallized area, where the final rolling temperature in the recrystallized area is 1025°C, the final rolling temperature in the non-recrystallized area is 910°C, and the final rolling thickness of the steel plate is 12mm. After rolling, it is air-cooled to room temperature, and then quenched and tempered For processing, the quenching temperature is 880°C and the tempering temperature is 170°C.

Embodiment 2

[0045] The molten steel smelted according to the proportions in Table 1 is vacuum degassed and then continuously cast. The thickness of the continuous casting slab is 220mm. The steel slab is heated to a furnace temperature of 1200°C. Rolling in the non-recrystallization area, where the final rolling temperature in the recrystallization area is 1030°C, the final rolling temperature in the non-recrystallization area is 850°C, the final rolling thickness of the steel plate is 40mm, air-cooled to room temperature after rolling, and then quenched and tempered For processing, the quenching temperature is 920°C and the tempering temperature is 250°C.

Embodiment 3

[0047] The molten steel smelted according to the proportions in Table 1 is vacuum degassed and then continuously cast. The thickness of the continuous casting slab is 300mm. The steel slab is heated to a furnace temperature of 1220°C. Rolling in the non-recrystallization zone, where the final rolling temperature in the recrystallization zone is 1040°C, the final rolling temperature in the non-recrystallization zone is 890°C, the final rolling thickness of the steel plate is 25mm, air-cooled to room temperature after rolling, and then quenched and tempered For processing, the quenching temperature is 930°C and the tempering temperature is 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com