Rolled steel rail with high low-temperature impact performance and production method thereof

A low-temperature impact and production method technology, applied in the field of steelmaking, can solve the problems of low yield and surface quality, high production cost of heat-treated rails, and achieve high yield and rail surface quality, good promotion value, and good tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

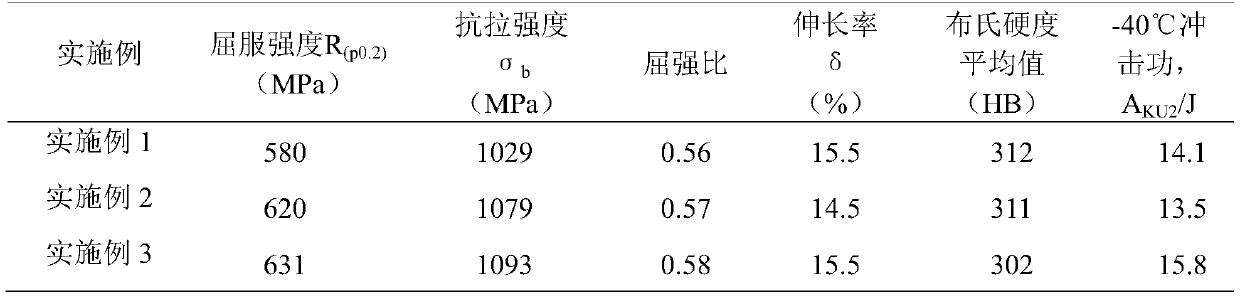

[0009] Objectively existing environmental conditions require that the low-temperature performance of rails be more prominent, especially in alpine regions where the operating capacity is enhanced, and the performance requirements for rails working in low-temperature environments are significantly increased, including higher requirements for tread hardness and toughness. The object of the present invention is to provide a steel rail with high strength, wear resistance and high impact toughness, which is suitable for alpine regions and its preparation method.

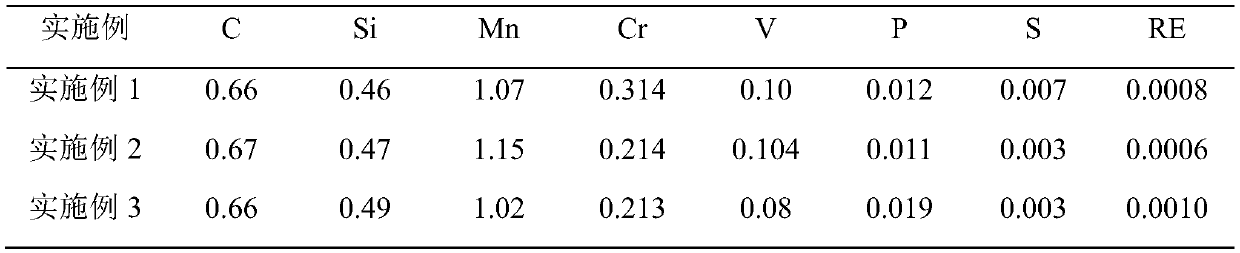

[0010] When the present invention produces rolled steel rails with high low-temperature impact performance, the iron and steel materials used contain the following chemical components in mass percentages: C 0.60-0.75; Si 0.45-0.80; Mn0.85-1.20; Cr0.15-1.0; V0. 02~0.10; P≤0.025; S≤0.025; the amount of RE alloy added is 0.002~0.01%; the rest is Fe and unavoidable impurities.

[0011] The main alloying elements Si, Mn, Cr, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com