High-strength cast aluminum-silicon alloy for engine body and preparation method thereof

A technology of casting aluminum-silicon alloy and engine body, which is applied to high-strength casting aluminum-silicon alloy and its preparation. The alloy is in the field of smelting and heat treatment process corresponding to its composition range, which can solve the obstacles to popularization and application, and the increase of production cost to reduce the content of precious elements, refine grains, and strengthen the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

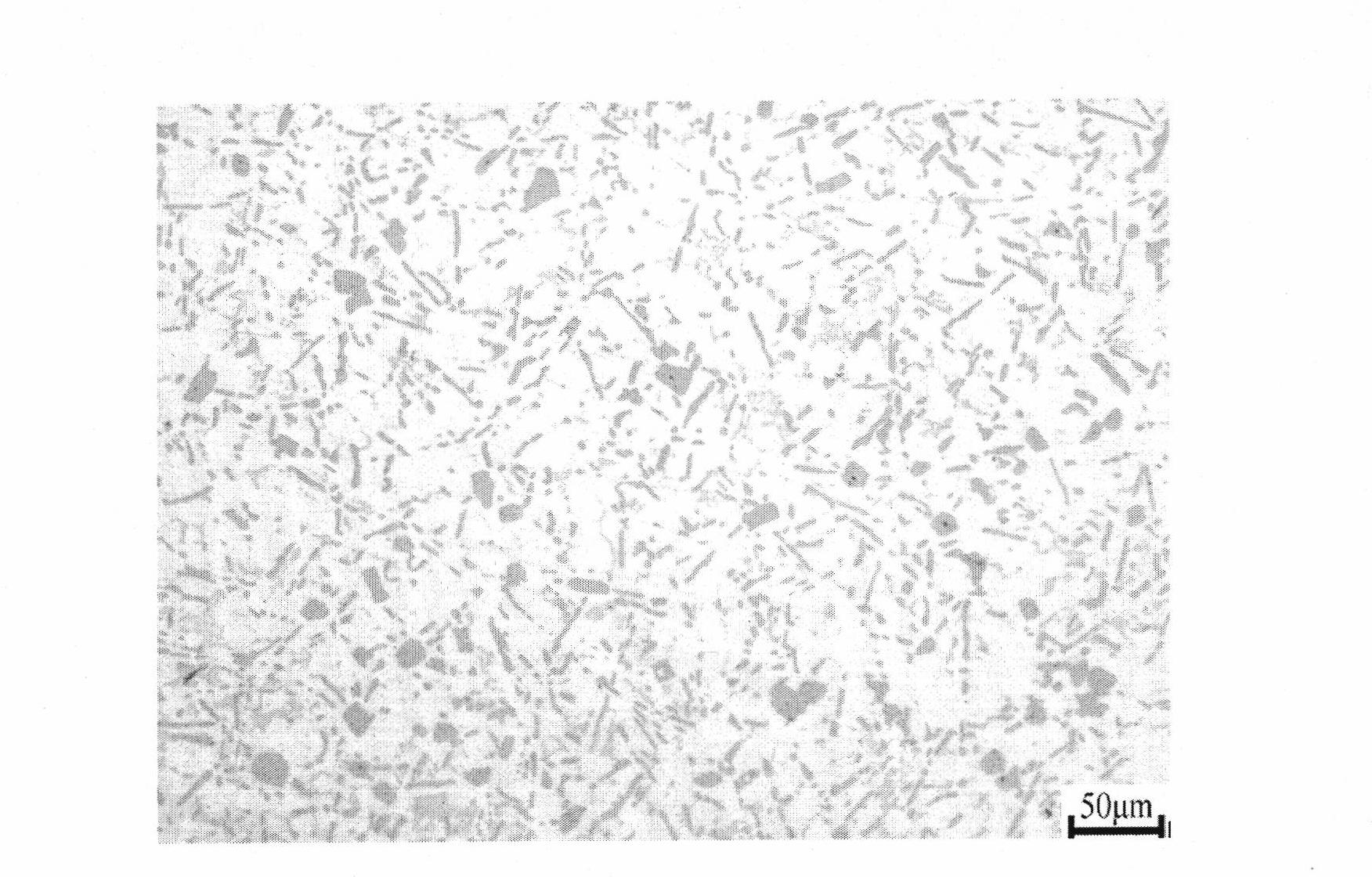

[0056] Embodiment 1: smelting alloy is composed as follows:

[0057] Si: 12.5wt%; Ni: 0.25wt%; Cu: 5.0wt%; Fe: 0.3wt%; Mn: 0.5wt%; Mg: 0.3wt%; Ti: 0.15wt%; Al.

example

[0058] Example alloy number: CF3.

[0059] The alloy preparation steps are as follows: Spread a layer of flux on the bottom of the crucible, then put industrial pure aluminum (purity > 99.0wt%) and intermediate alloys into the crucible in layers, place the ones with low melting point and low density in the lower layer, and put the ones with high melting point and high density Place it on the upper layer; raise the furnace temperature to 780°C, keep warm until the raw materials are in paste form, press the Al-Ti, Al-Zr intermediate alloy into the bottom of the crucible with a bell jar, and then spread flux on the surface of the melt; wait for the raw materials to melt completely Finally, insert a clean Ti rod into the melt and stir gently for 3-5 circles to remove the slag on the surface of the melt; use a bell jar to press AlP into the melt twice for deterioration treatment, and take out the bell jar after it is completely melted. Raise the temperature to 800°C and keep it war...

Embodiment 2

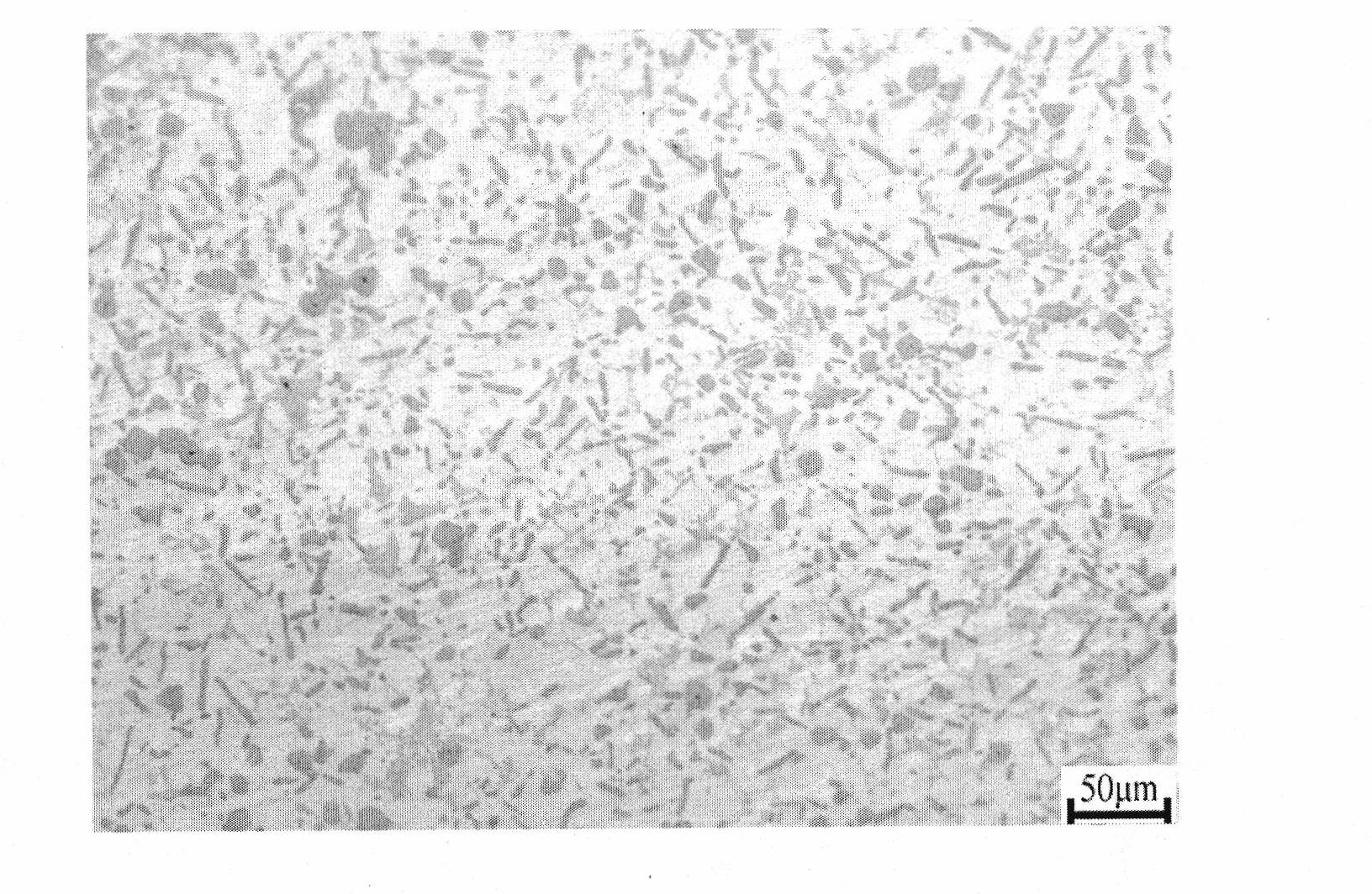

[0064] Embodiment 2: The smelted alloy is composed of the following components:

[0065] Si: 13.5wt%; Ni: 0.3wt%; Cu: 5.0wt%; Fe: 0.8wt%; Mn: 0.6wt%; Mg: 0.4wt%; Ti: 0.10wt%; Zr: 0.27wt%. Al.

[0066] Example alloy number: CF8.

[0067] The alloy preparation steps are as follows: Spread a layer of flux on the bottom of the crucible, then put industrial pure aluminum (purity > 99.0wt%) and intermediate alloys into the crucible in layers, place the ones with low melting point and low density in the lower layer, and put the ones with high melting point and high density Place it on the upper layer; raise the furnace temperature to 780°C, keep warm until the raw materials are in paste form, press the Al-Ti, Al-Zr intermediate alloy into the bottom of the crucible with a bell jar, and then spread flux on the surface of the melt; wait for the raw materials to melt completely Finally, insert a clean Ti rod into the melt and stir gently for 3-5 circles to remove the slag on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com