Production process of wear-resistant steel NM400E medium plate

A production process and wear-resistant steel technology, applied in the field of medium and thick plate production, can solve problems such as difficult production, easy segregation, looseness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

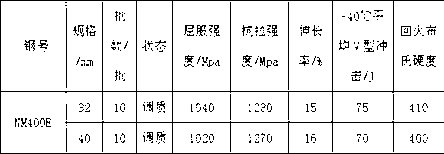

Examples

Embodiment Construction

[0010] The present invention uses turntable smelting and mold casting. The method of rolling the 3800m wide plate rolling machine to produce NM400E wear -resistant steel plates; its process process is: high -quality iron water, KR iron water interview, 100 / 120 tons of top background re -blowing furnace, LF furnace refining refinement, Vacuum -time off -air treatment, Cold Dilele Cold 24-60 hours, push steel heating furnace, 3800m rolling machine, ACC layer flow cooling, 11 roll heat orthopedic machines, stacking cold, refined fire, external inspection, detection, enrollment, input, input, input, enteringLibrary.

[0011] The NM400E steel plate with a thickness of 30 to 40mm in the present invention contains the following chemical composition (unit, WT%) of the percentage of quality (unit, WT%): ingredient design: C: 0.16 ~ 0.19, Si: 0.20 ~ 0.40, mn: 1.25 ~ 1.35, P: ≤0.015, s: ≤0.005, CR: 0.20 ~ 0.30, MO: 0.20 ~ 0.30, V: 0.04 ~ 0.06, NB: 0.17 ~ 0.03, TI: 0.17 ~ 0.26, ni: 0.25 ~ 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com