Excavating tooth wear indicator and method

A technology of indicator and digging teeth, applied in the field of wear indicator system, can solve the problems of weakening digging teeth, damaging tooth seat, covering appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

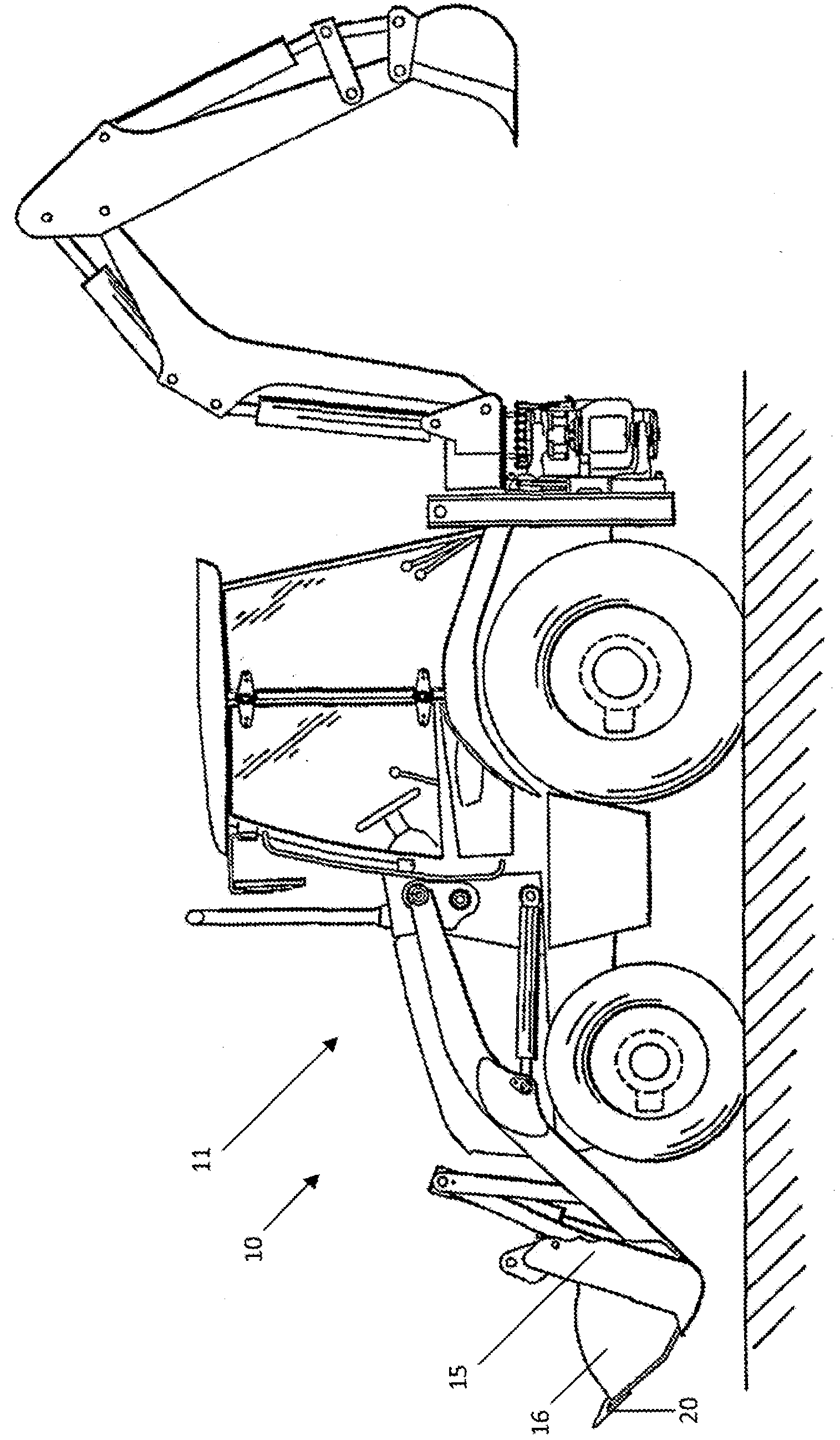

[0051] figure 1 A work machine 10 according to one embodiment of the invention is shown. As shown, work machine 10 may be a loader 11 . It is also shown that the construction machine 10 is provided with at least one work implement 15, shown in this embodiment as a bucket 16, for digging and / or moving material, such as gravel or earth.

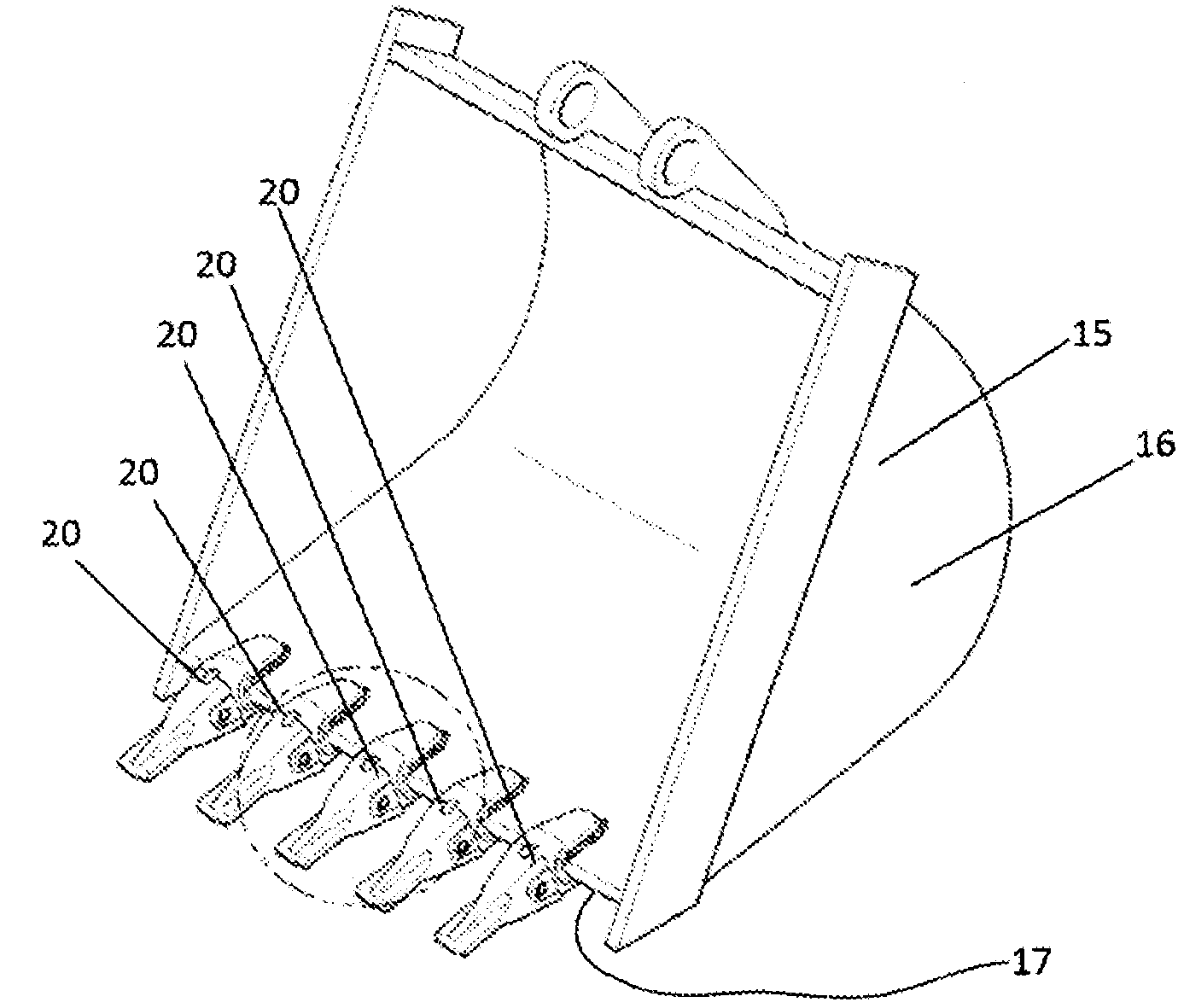

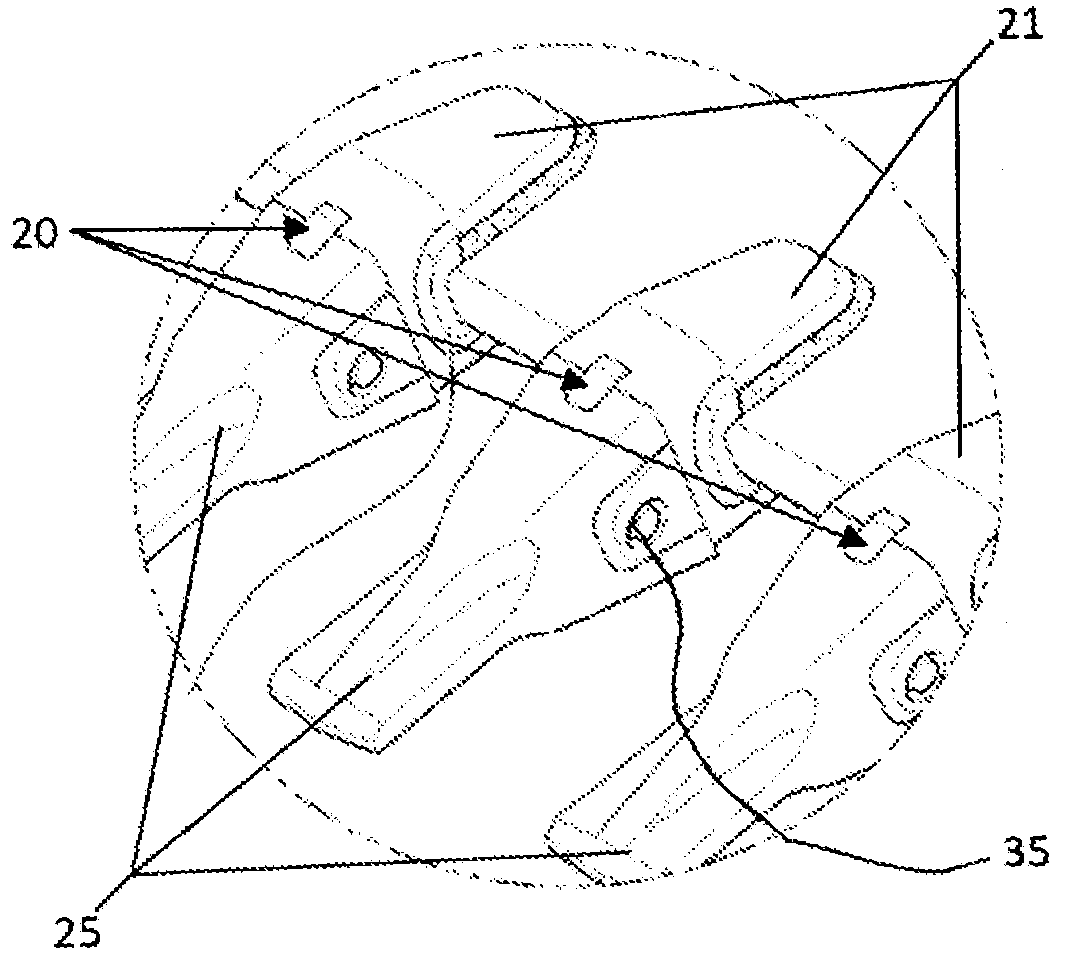

[0052] Such as Figure 1 to Figure 2B As shown, work tool 15 is provided with at least one excavating tooth assembly, preferably a plurality of excavating tooth assemblies (eg 20 in this figure). As best shown in FIG. 2 , these excavating tooth assemblies 20 are each provided with an adapter 21 and an excavating tooth 25 . According to one aspect of the present embodiment, the adapter 21 functions as an interface that releasably secures the excavating tooth 25 to the work tool 15 .

[0053] As shown in FIG. 2 , the adapter 21 may be fixed to the front lower edge portion 17 of the work tool 15 . Those of ordinary skill in the art will appre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com