Laser cladding repairing method for end tooth wear or cracks of general high speed pump gear shafts

A technology of laser cladding and repair method, applied in metal material coating process, coating and other directions, can solve the problems of high price, affecting the production and economic benefits of enterprises, long procurement cycle, etc., achieving a small heat-affected zone and comprehensive repair. The effect of thorough, good metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

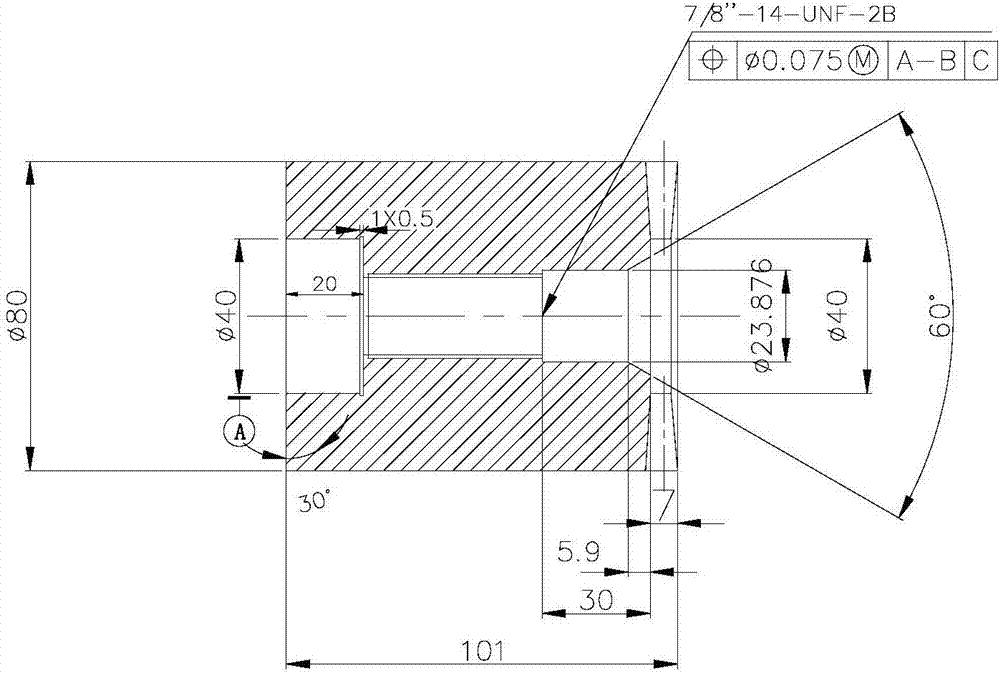

[0029] In this embodiment, the general-purpose high-speed pump gear shaft end tooth wear or crack laser cladding repair method includes the following steps:

[0030] (1) Determine the repair plan for the pump shaft according to the damage degree of the high-speed shaft;

[0031] (2) Remove the end teeth of the damaged high-speed gear shaft and process the mating surface;

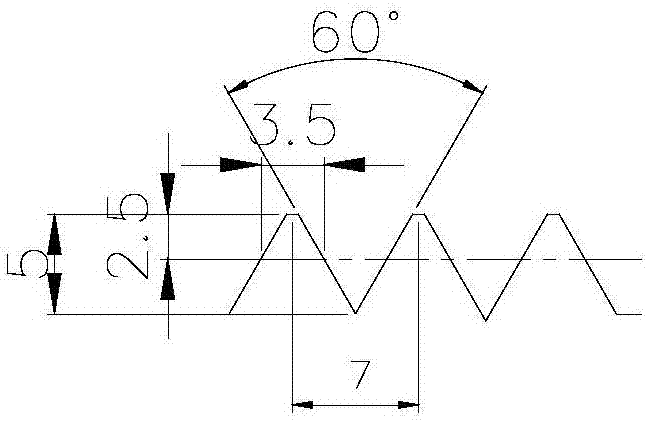

[0032] (3) Make new end teeth according to the survey drawing;

[0033] (4) Thermally install the new end gear and shaft with temperature difference;

[0034] (5) Laser cladding welding;

[0035] (6) Relief of stress in the surfacing layer;

[0036] (7) Finishing.

[0037] In step (1), the high-speed shaft is disassembled in the high-speed pump, cleaned with acetone, and inspected for cracks, surface defects, dimensional accuracy and runout of related journals and gears to determine the repair plan. The runout value can be checked with a dial indicator on an ordinary lathe, and the amount cannot exceed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com