Patents

Literature

30 results about "Tooth abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tooth abrasion is defined as the pathologic wearing away of a substance or structure (such as a tooth), through some unusual or abnormal mechanical process. In dentistry, this takes the form of enamel – the outer covering of the tooth – wearing away from the surface of the tooth due to rubbing, scratching or scraping.

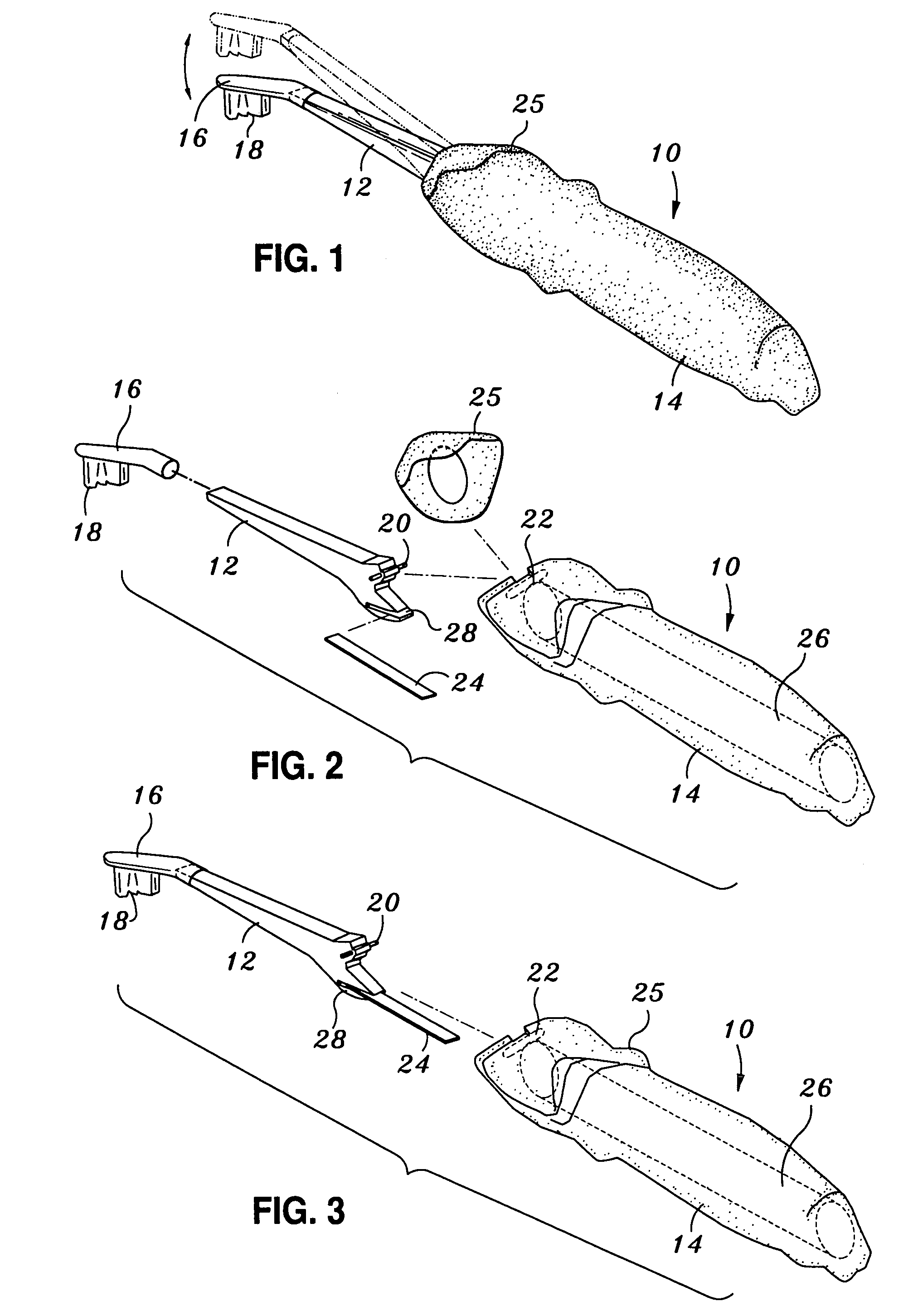

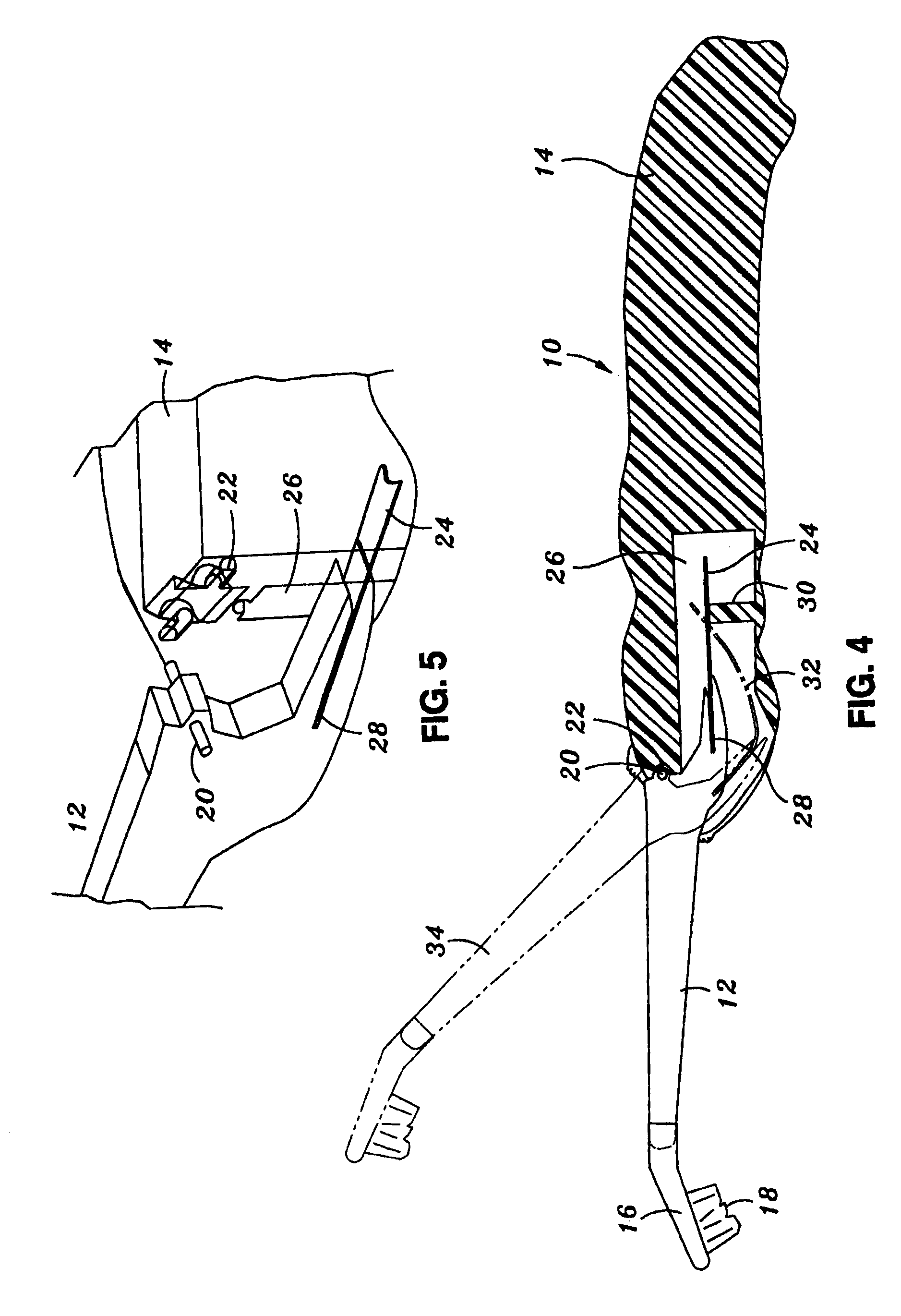

Flexible neck toothbrush

InactiveUS20050108841A1Avoid abrasionsAvoid prolonged useCarpet cleanersBrush bodiesTooth wearEngineering

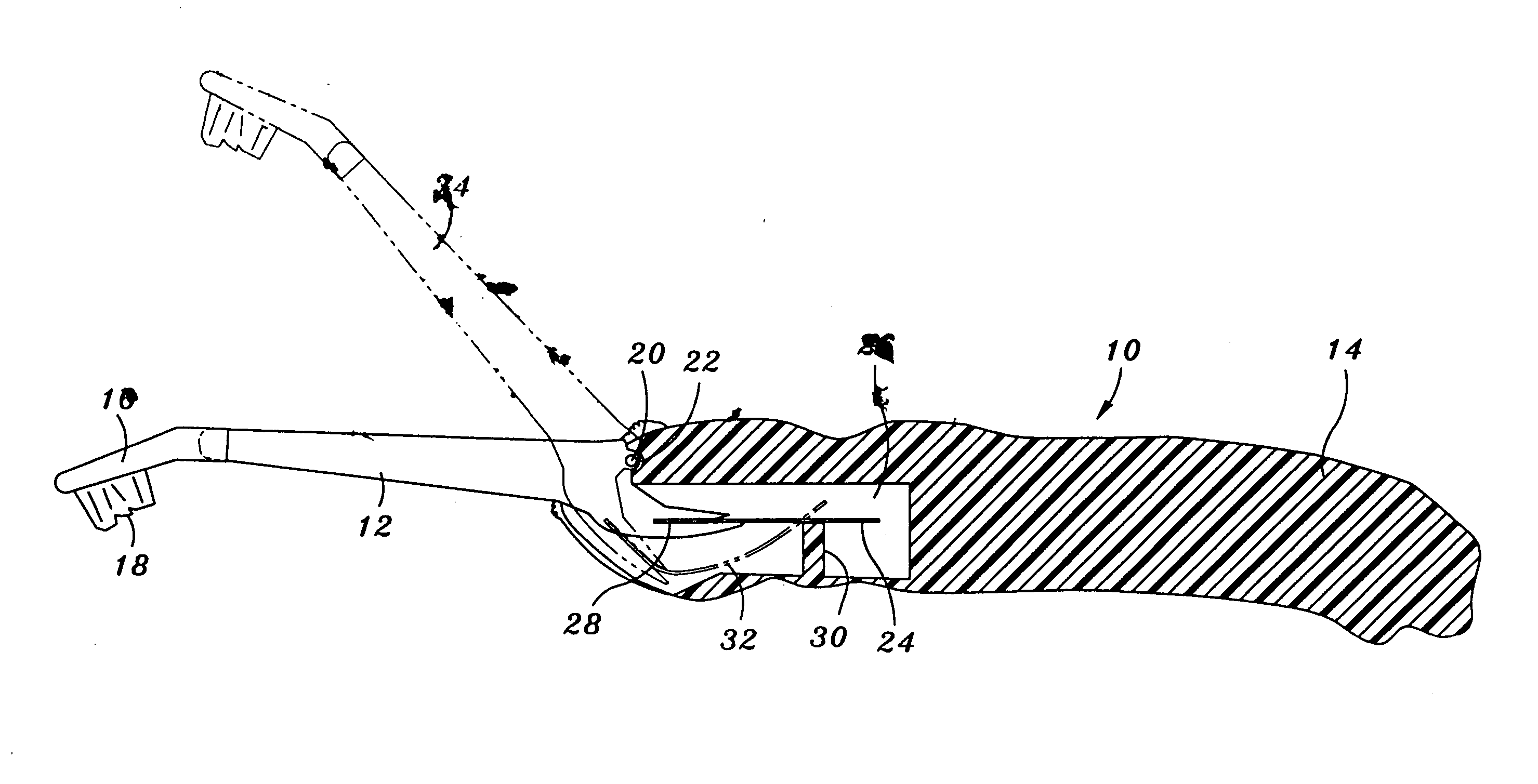

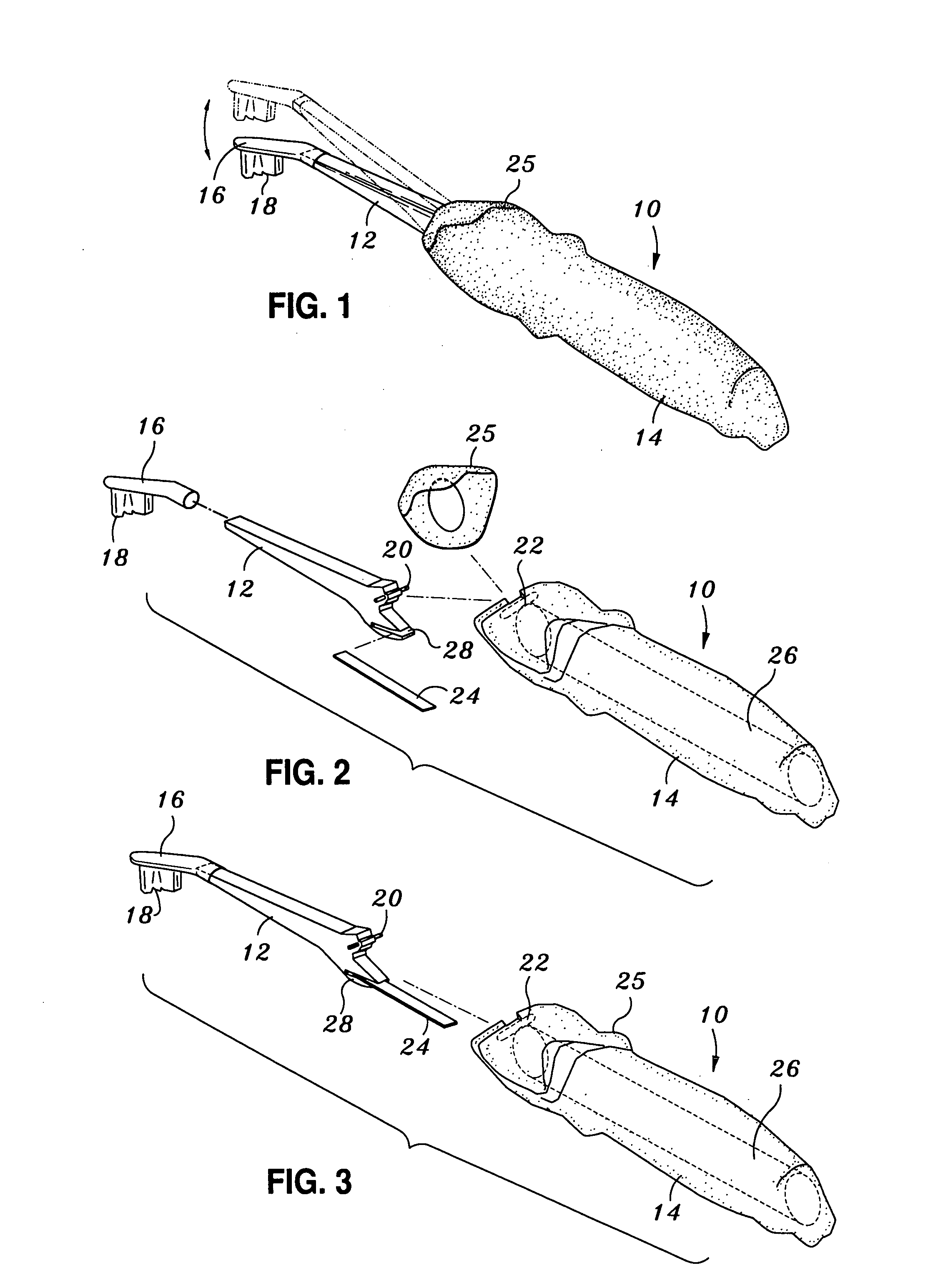

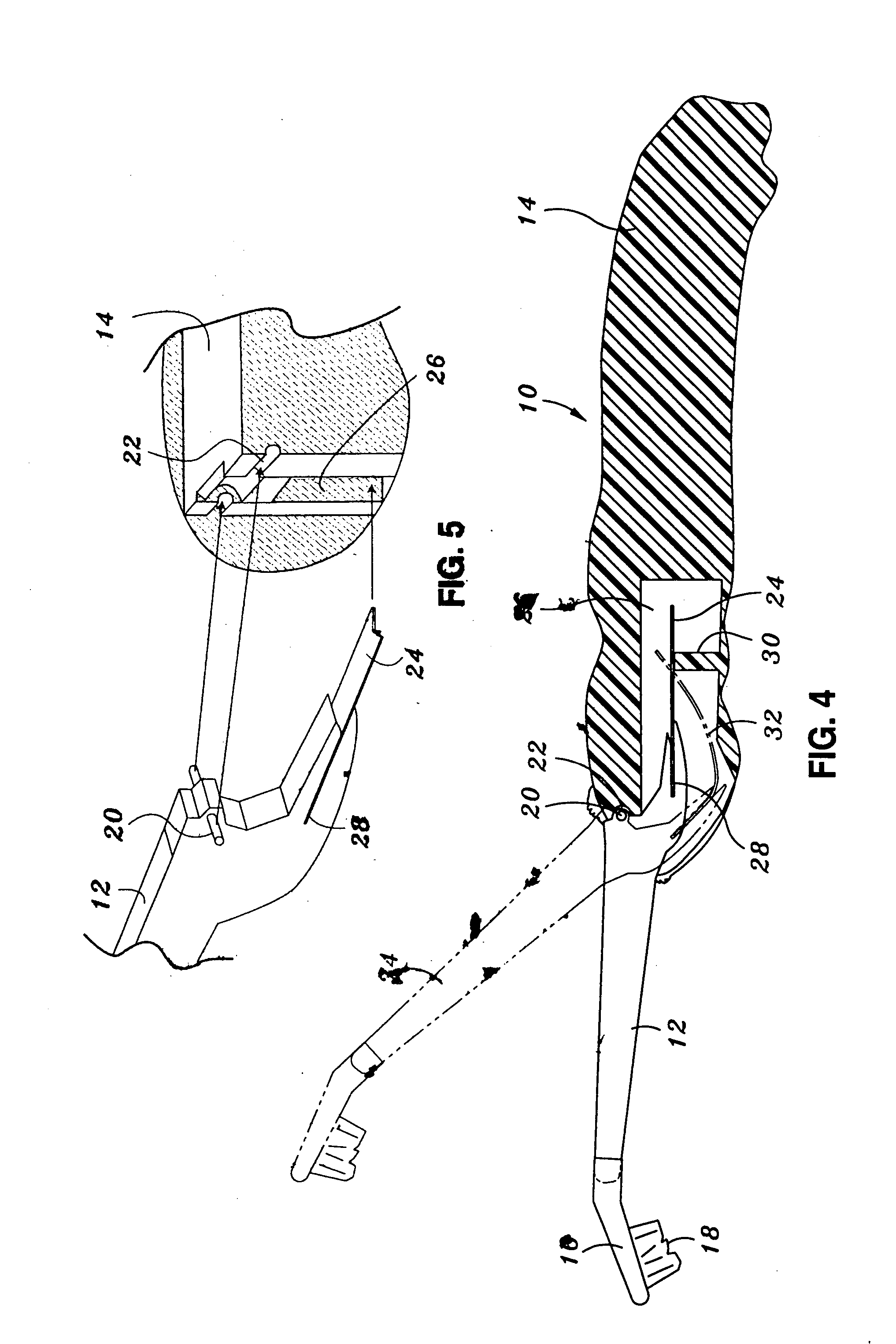

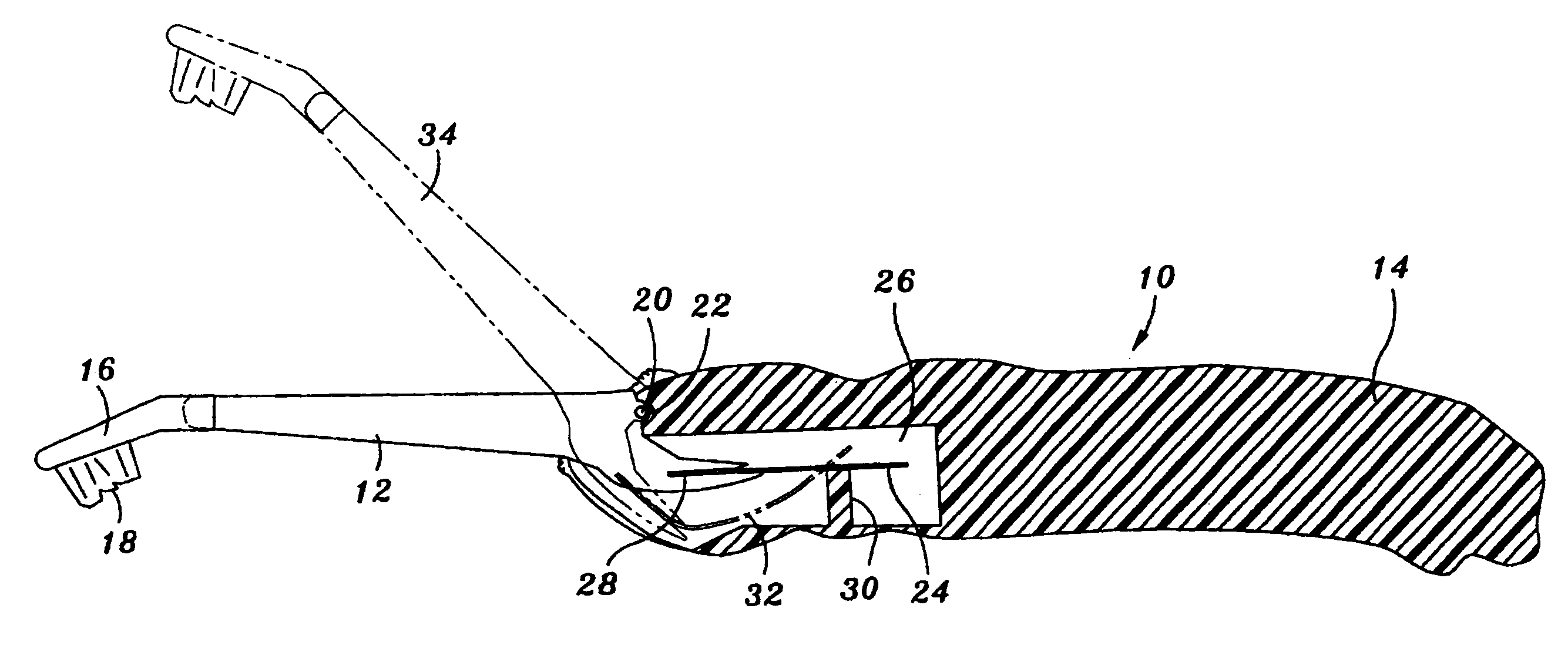

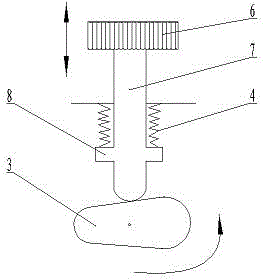

All embodiments of the present invention relate to a toothbrush to prevent tooth abrasion and gum damage during use. A first embodiment of the invention includes a handle including an open cavity and a neck interconnected to the handle by a pivot. The neck is movable between an aligned first position and a second angled position relative to the handle. A leaf spring is bonded to the end of the neck at a first end, and the second end of the leaf spring engages the handle to provide biasing resistance. The leaf spring is configured such that if pressure to the neck exceeds a threshold limit, there is movement of the neck portion from the first position to a second position. The threshold limit is the pressure just below the pressure at the brush that may cause damage to the hard and soft tissue of the mouth. A protective sheath envelops the junction between the handle member and the neck member to prevent accumulation of unwanted material within the cavity of the handle. A second embodiment is equivalent in structure and components to the first embodiment except that it also includes a manual adjustment of the biasing force of the leaf spring to provide variable pressure and a motor for providing mechanical movement of the brush head. Third and fourth embodiments are equivalent in structure and components of the first and second embodiments, respectively, except that the leaf spring is bonded to the handle instead of the neck.

Owner:EDWARDS STEVEN J

Flexible neck toothbrush

InactiveUS7383603B2Avoid abrasionsAvoid prolonged useCarpet cleanersBrush bodiesTooth wearEngineering

All embodiments of the present invention relate to a toothbrush to prevent tooth abrasion and gum damage during use. A first embodiment of the invention includes a handle including an open cavity and a neck interconnected to the handle by a pivot. The neck is movable between an aligned first position and a second angled position relative to the handle. A leaf spring is bonded to the end of the neck at a first end, and the second end of the leaf spring engages the handle to provide biasing resistance. The leaf spring is configured such that if pressure to the neck exceeds a threshold limit, there is movement of the neck portion from the first position to a second position. The threshold limit is the pressure just below the pressure at the brush that may cause damage to the hard and soft tissue of the mouth. A protective sheath envelops the junction between the handle member and the neck member to prevent accumulation of unwanted material within the cavity of the handle. A second embodiment is equivalent in structure and components to the first embodiment except that it also includes a manual adjustment of the biasing force of the leaf spring to provide variable pressure and a motor for providing mechanical movement of the brush head. Third and fourth embodiments are equivalent in structure and components of the first and second embodiments, respectively, except that the leaf spring is bonded to the handle instead of the neck.

Owner:EDWARDS STEVEN J

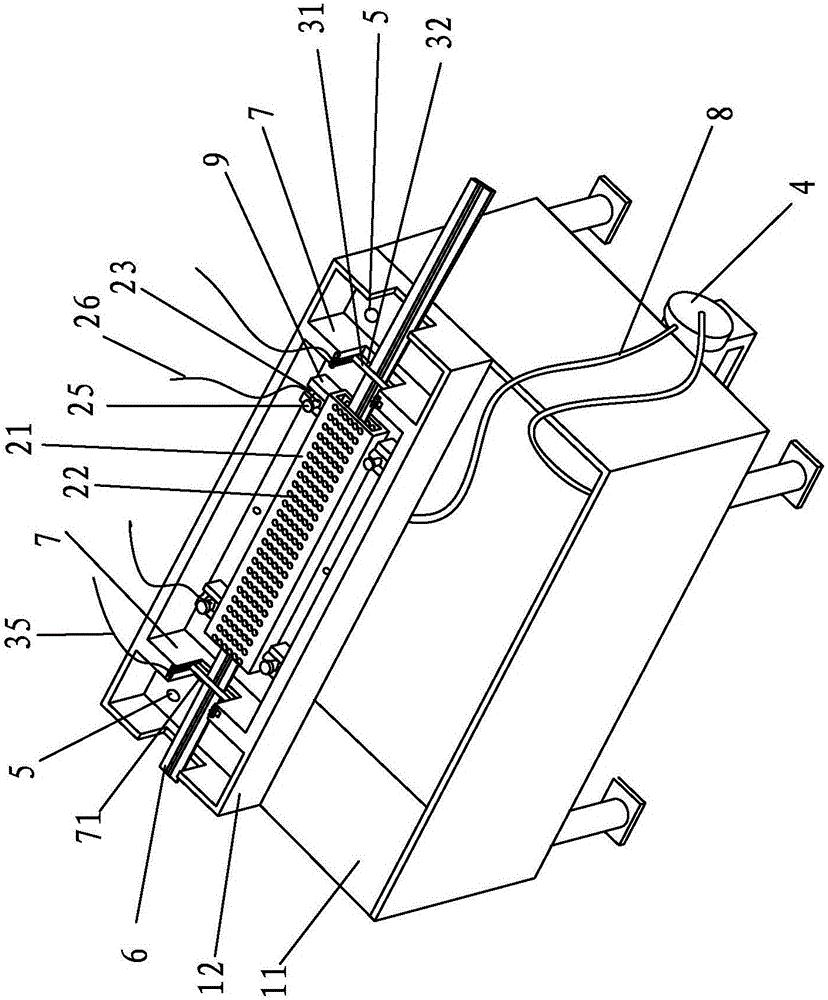

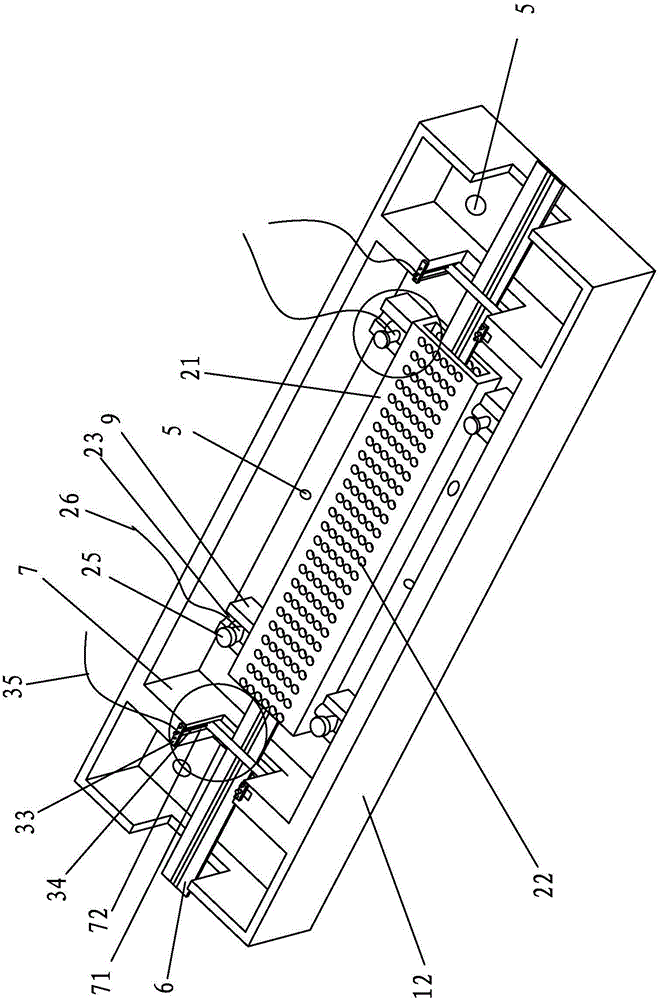

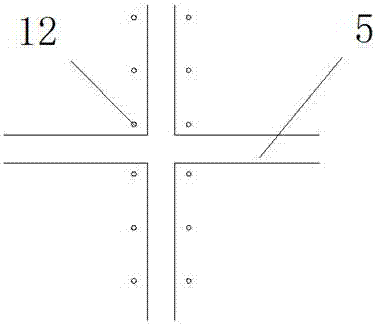

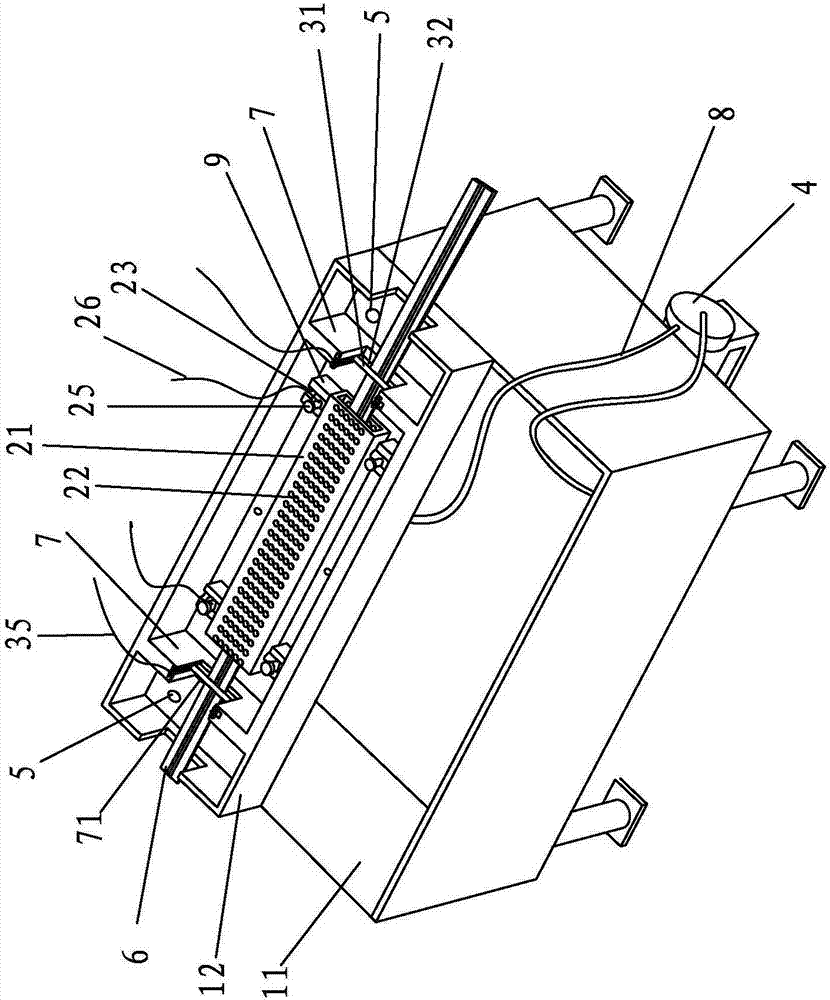

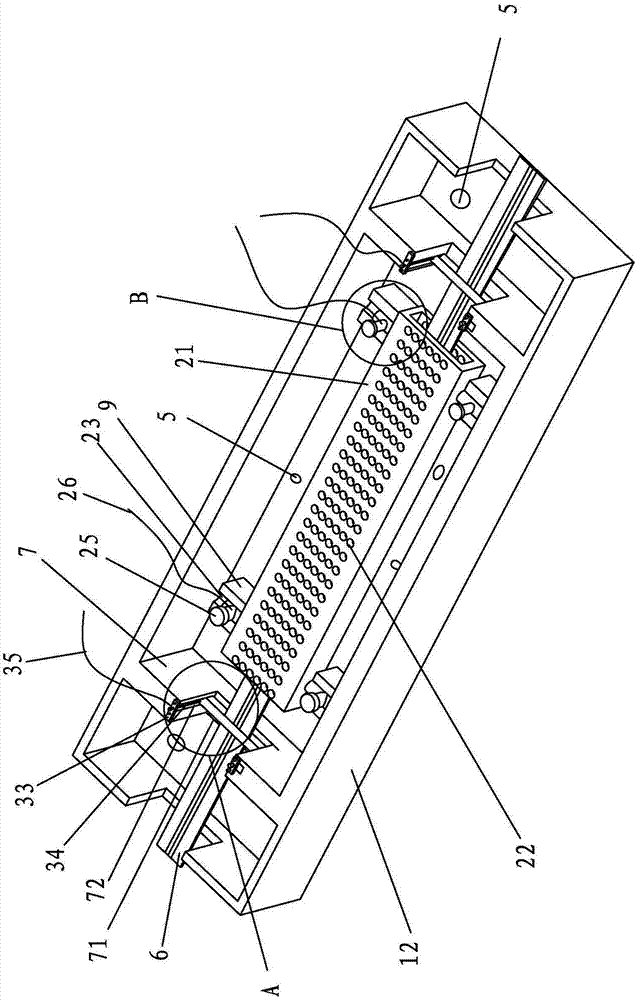

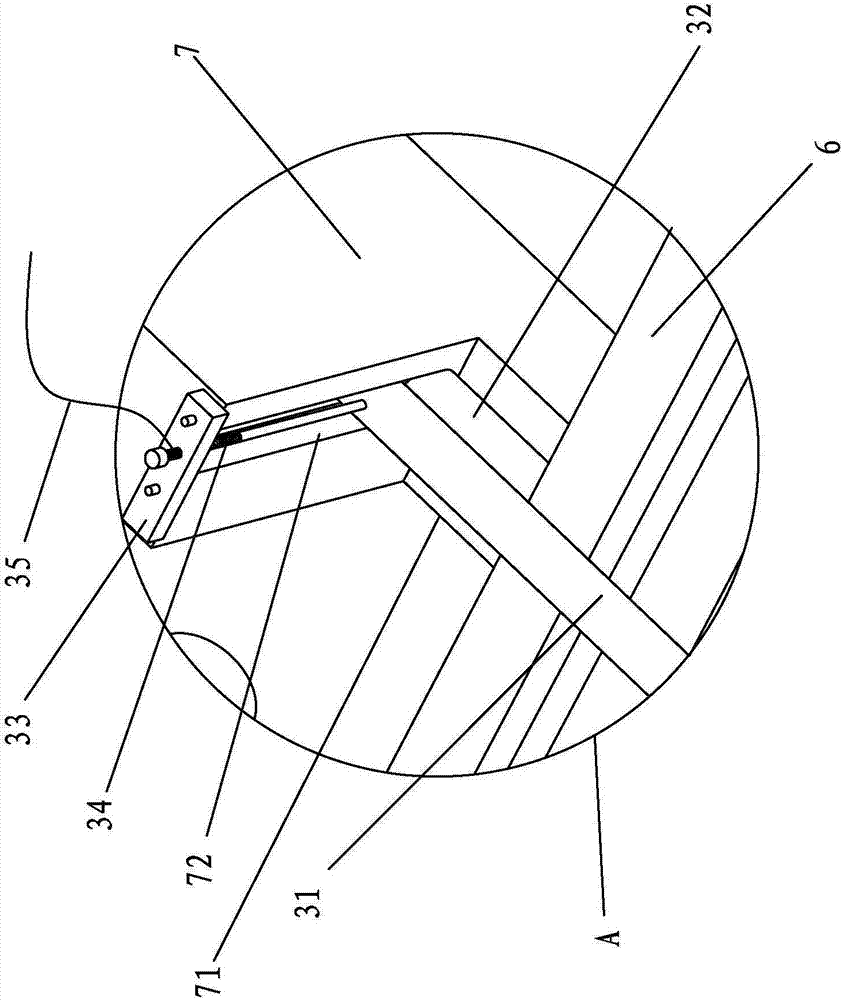

Improved zinc alloy zipper electroplating device

InactiveCN105755515AWon't wear outWill not depositSlide fastenersElectrodesZinc alloysElectroplating

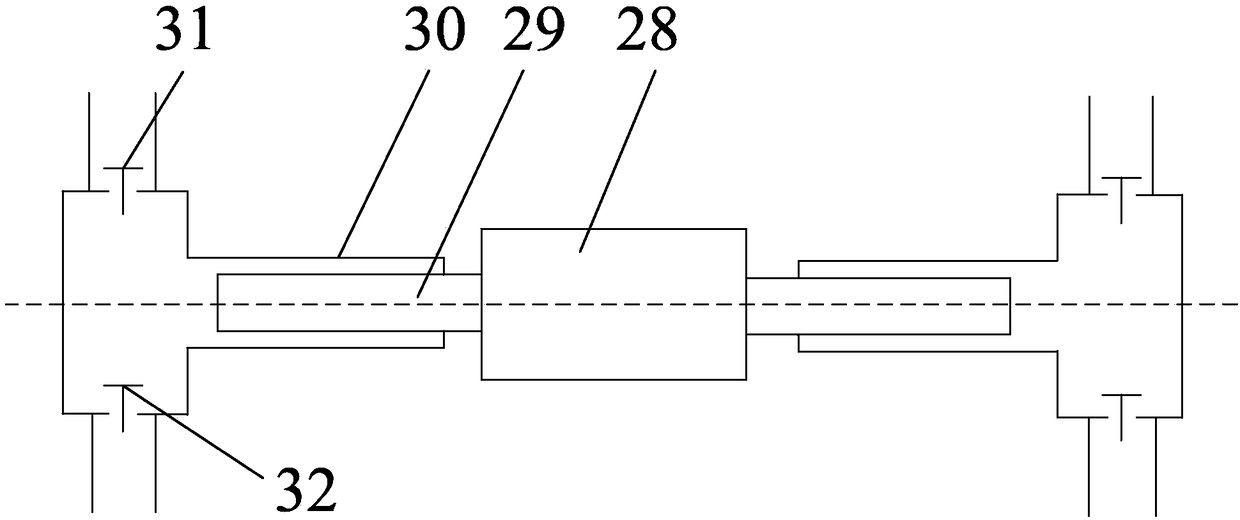

The invention relates to an improved zinc alloy zipper electroplating device and belongs to the field of zipper electroplating devices.The improved zinc alloy zipper electroplating device comprises a plating tank, an anode device, a cathode device electrically in contact with a zipper and a zipper driving device for driving a zipper to move in the length direction of the plating tank, wherein the anode device comprises an anode plate, the anode plate is provided with a channel formed in the length direction of the anode plate, and the zipper penetrates through along the central axis of the channel.After the technical scheme is adopted, the zipper penetrates through the channel formed in the anode plate, zipper teeth on the zipper are electroplated when the zipper passes through the channel formed in the anode plate, the zipper teeth of the zipper in the channel do not produce friction with other devices in the electroplating process, and zipper tooth abrasion is not caused.The zipper located outside the channel cannot reach the deposition potential due to the fact that the current density is very small, so that a plating layer does not deposit basically.In addition, the zipper penetrates through along the central axis of the channel, the zipper teeth located in the channel are basically consistent in current density during electroplating, and it can be ensured that the plating layer is uniform during electroplating.

Owner:陈远婷

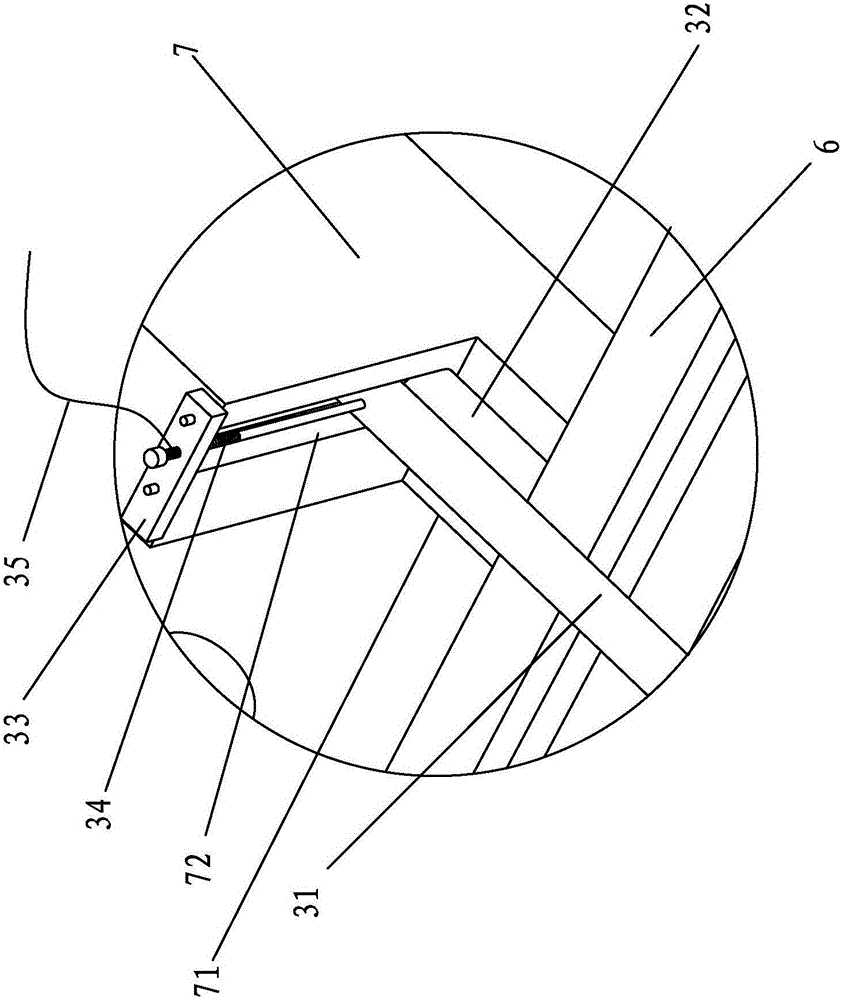

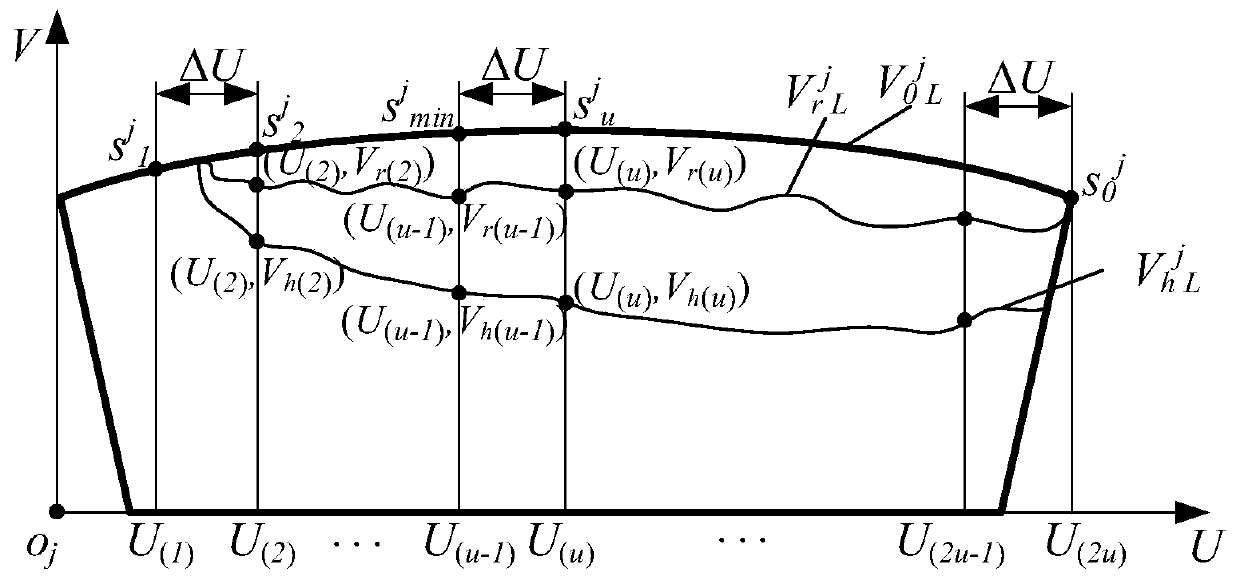

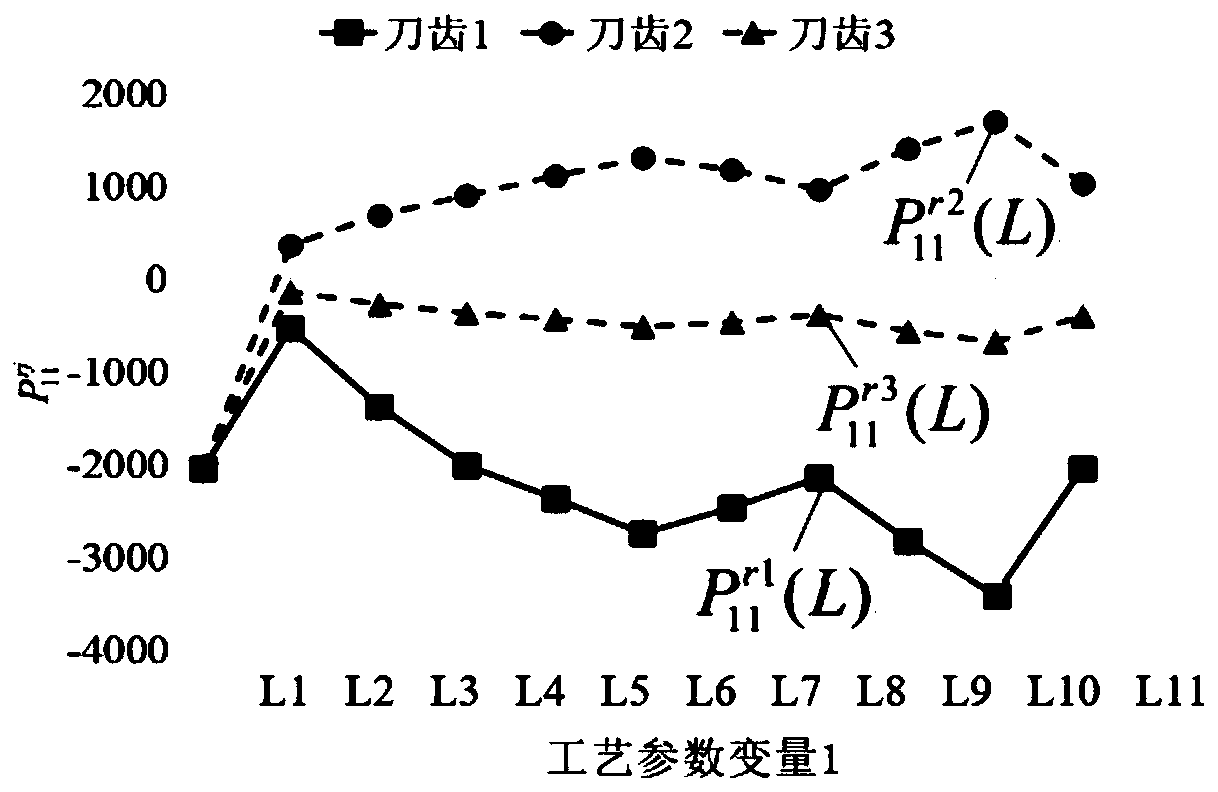

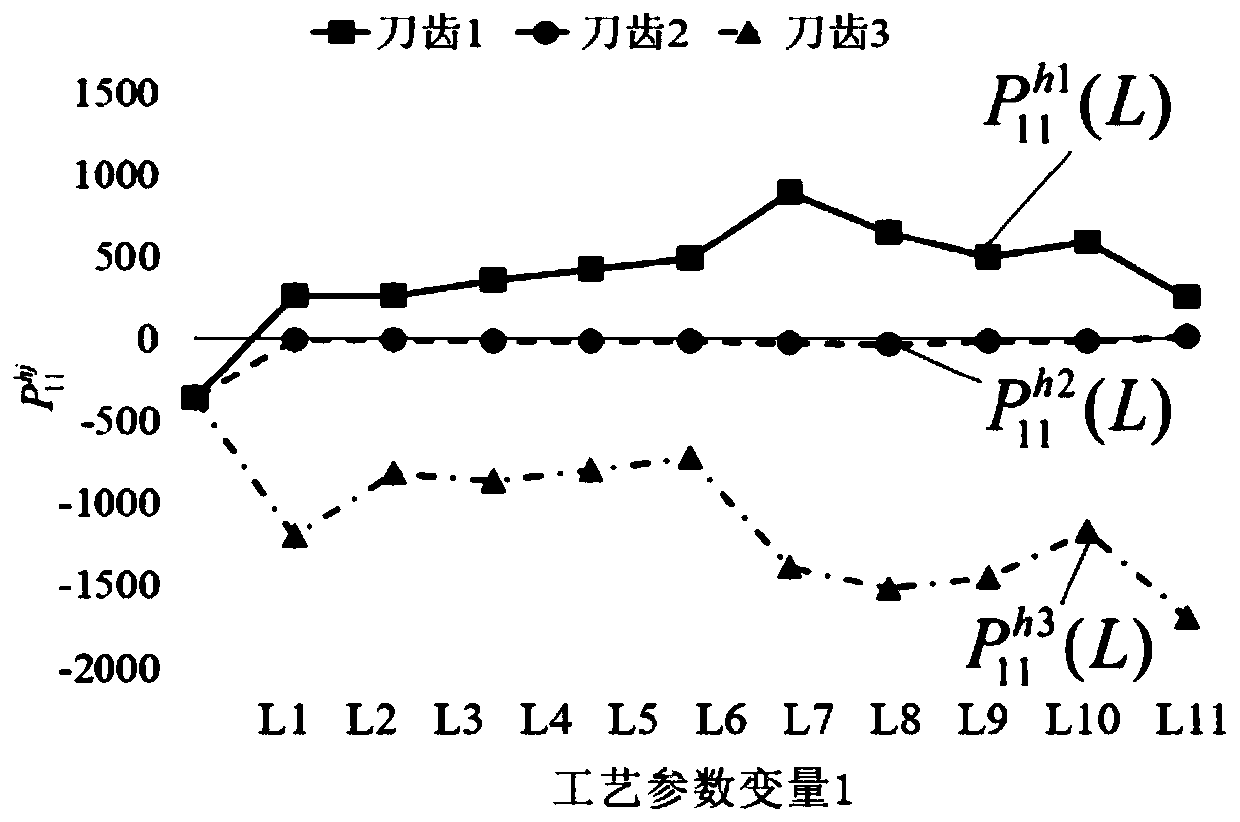

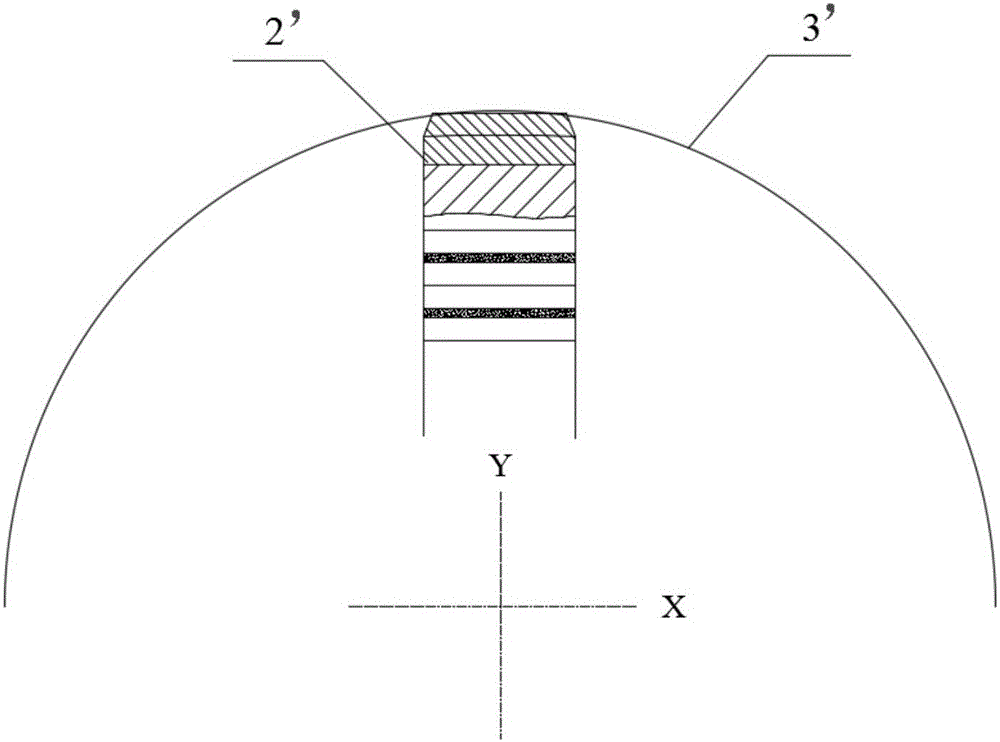

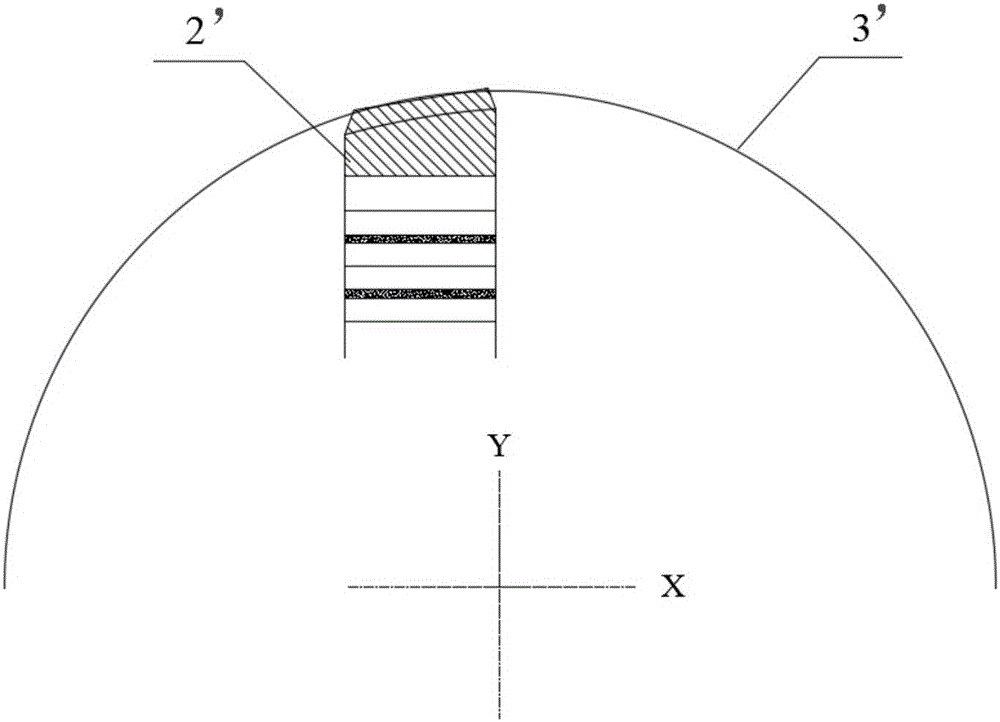

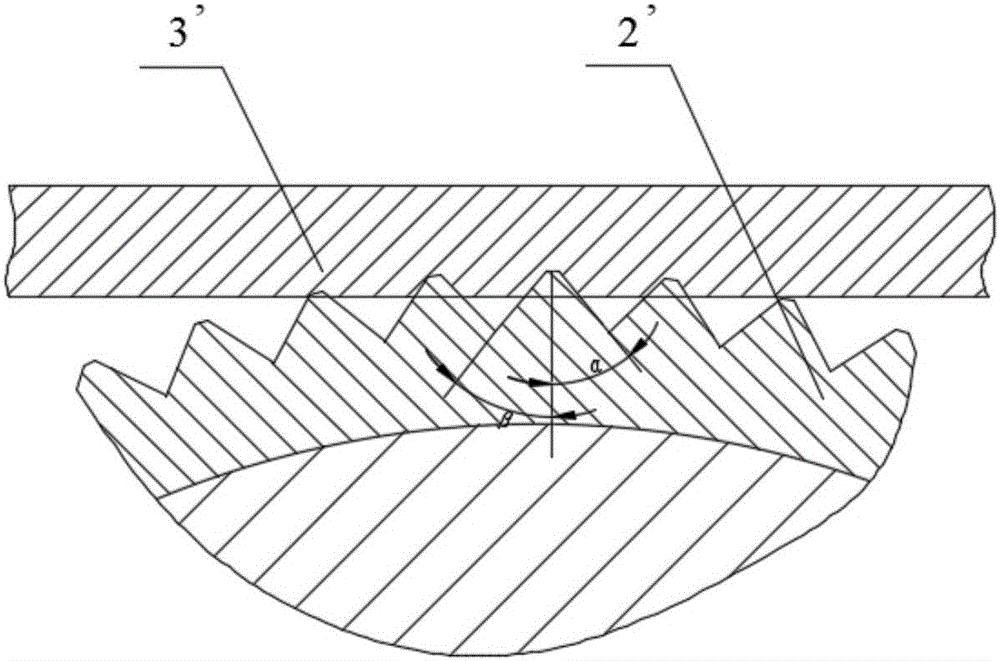

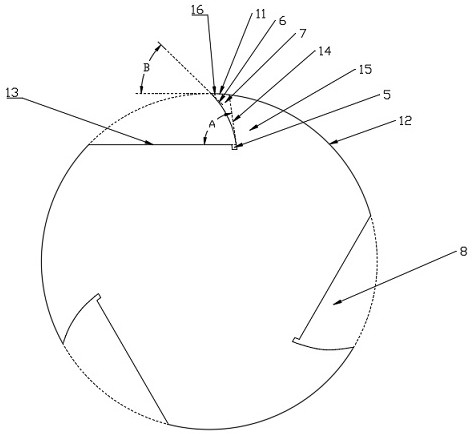

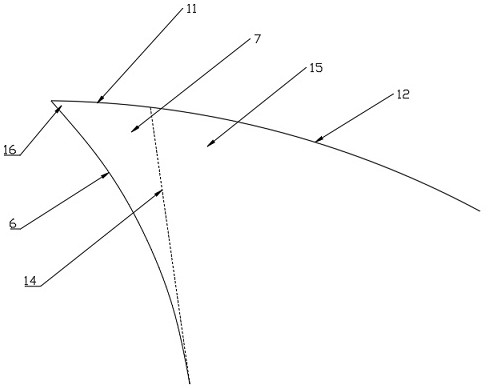

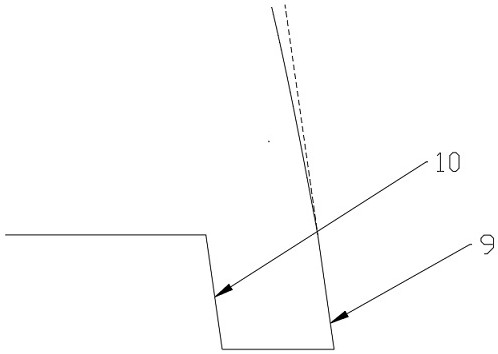

Analysis model construction and verification method for revealing wear difference of cutter teeth of high-feed milling cutter

ActiveCN110704969AAccurate and comprehensive identificationFully and accurately describeGeometric CADTooth wearAnalytic model

The invention discloses an analysis model construction and verification method for revealing wear difference of cutter teeth of a high-feed milling cutter. The invention belongs to the technical fieldof milling cutter teeth. In the prior art, in the milling process of the high-feed milling cutter, the contact length and the contact depth of the cutter teeth are increased nonlinearly, and heat isdissipated rapidly due to idle cutting, and the instantaneous cutting positions and postures of the cutter teeth are changed due to impact and vibration generated by intermittent cutting of a millingcutter, and the abrasion degrees of the cutter teeth of the milling cutter are remarkably different, and difference influence factors of the cutter teeth are difficult to recognize effectively. The analysis model construction and verification method can accurately and effectively identify the influence factors of the wear difference of the cutter teeth of the high-feed milling cutter, constructs acutter tooth wear difference analysis model, accurately describes milling cutter errors, pose changes and workpiece geometric structure characteristic changes in the high-feed milling cutter millingprocess, provides a cutter tooth abrasion area boundary recognition method, accurately recognizes cutter tooth rear cutter face abrasion upper and lower boundary distribution and change characteristics, and finally verifies the effectiveness of the analysis model.

Owner:HARBIN UNIV OF SCI & TECH

Open type gear semifluid lubricating grease composition

The invention relates to an open type gear semifluid lubricating grease composition, which can meet the requirements of complicated work conditions of easy sundry invasion, poor lubrication, low-speedtransmission, easy wheel tooth abrasion and the like in open type gear transmission. Besides basic oil, the composition provided by the invention uses the specific composite multifunctional anti-oxidization wear resistant agent; the proper extreme pressure wear resistant additives, thickening agents, viscosity index improving agents and the like are compounded; the cooperated effects between theadditives can be sufficiently achieved. The lubricating grease composition has excellent anti-leakage performance, low-temperature flowing performance, good extreme pressure wear resistant performance, anti-sintering capability, anti-oxidization stability, certain anti-corrosion and anti-rust performance and water-resistant performance, so that the lubrication requirement of the open type gear inindustries of cement, coal and the like in the special environment can be met.

Owner:西安石油大佳润实业有限公司

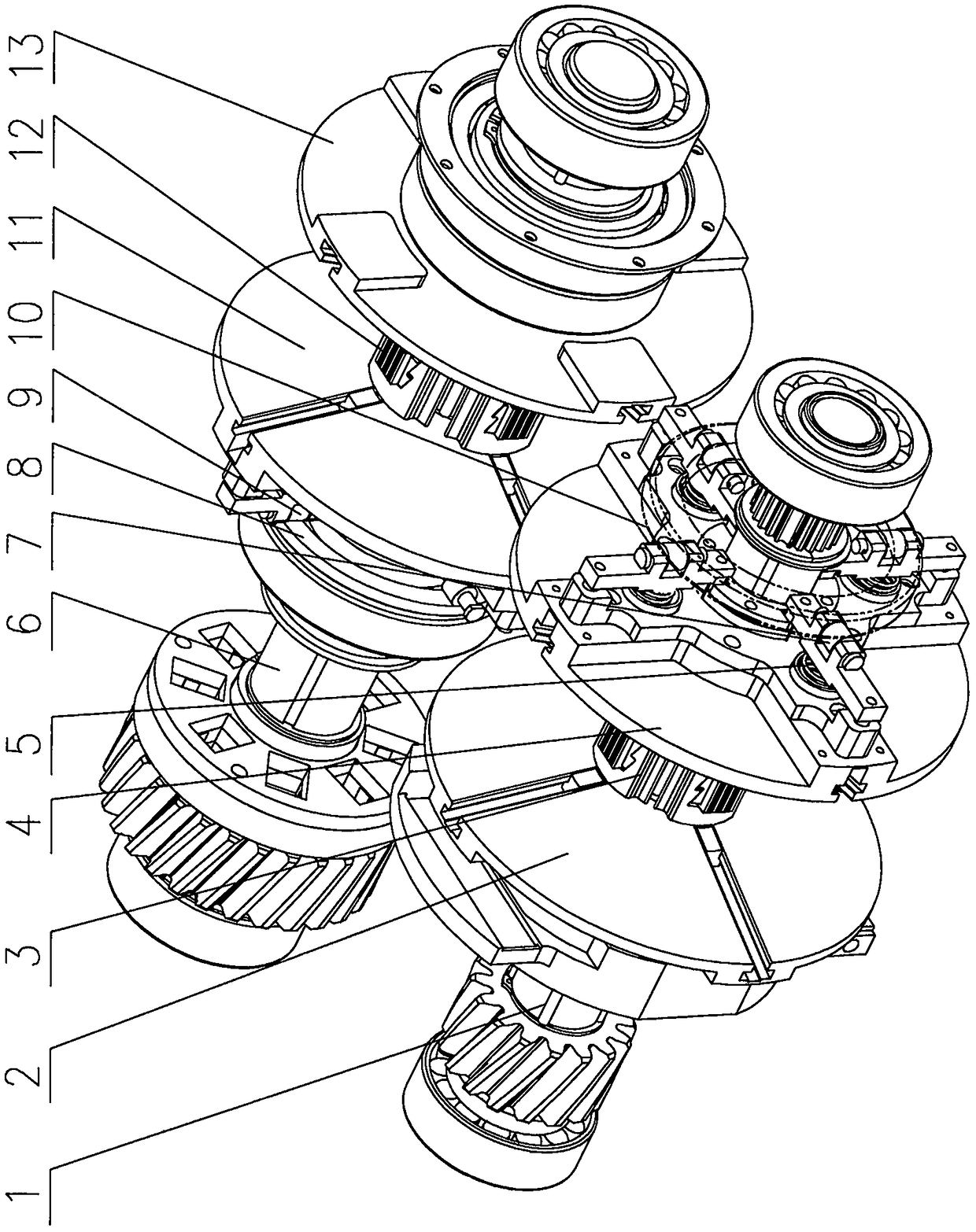

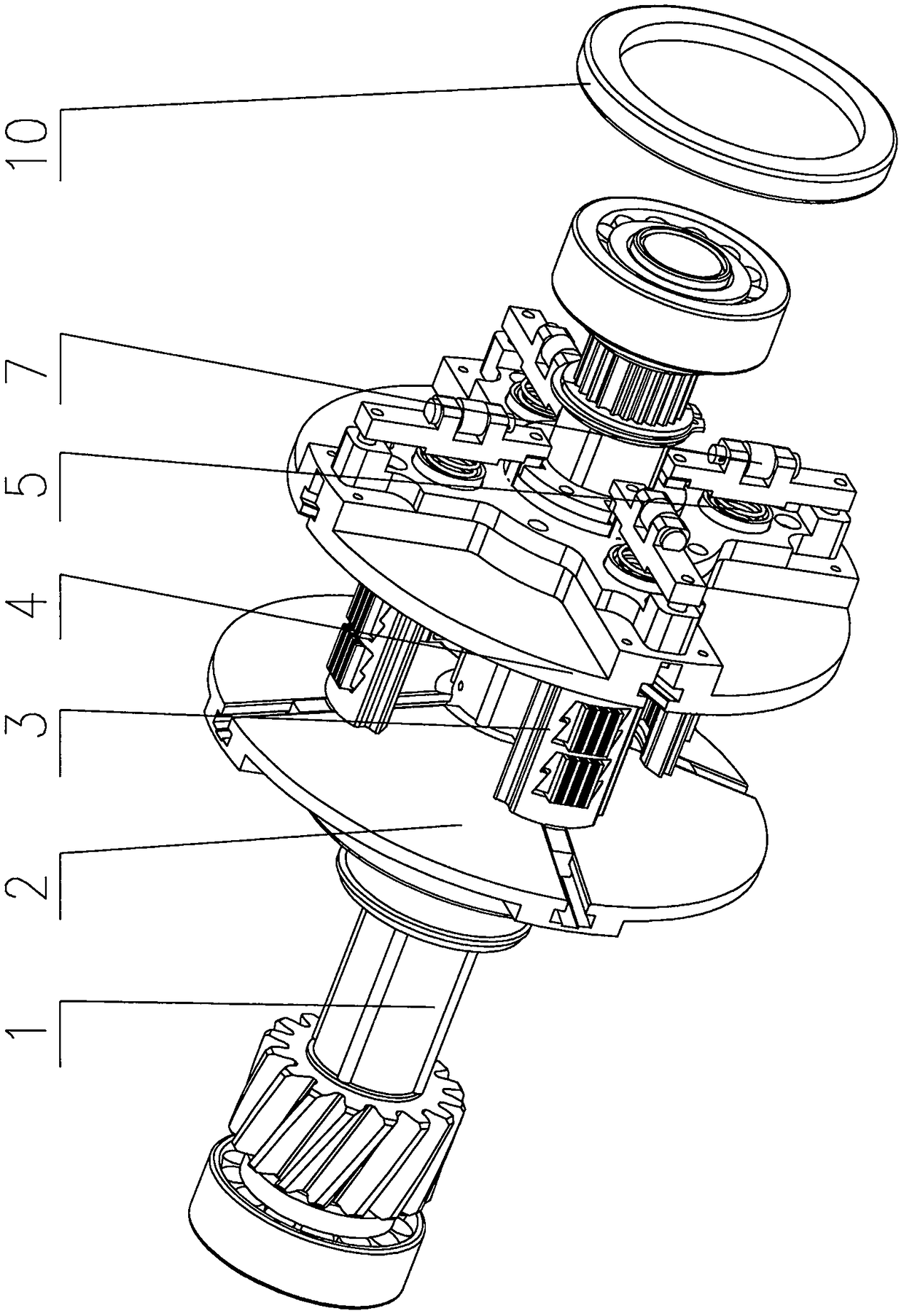

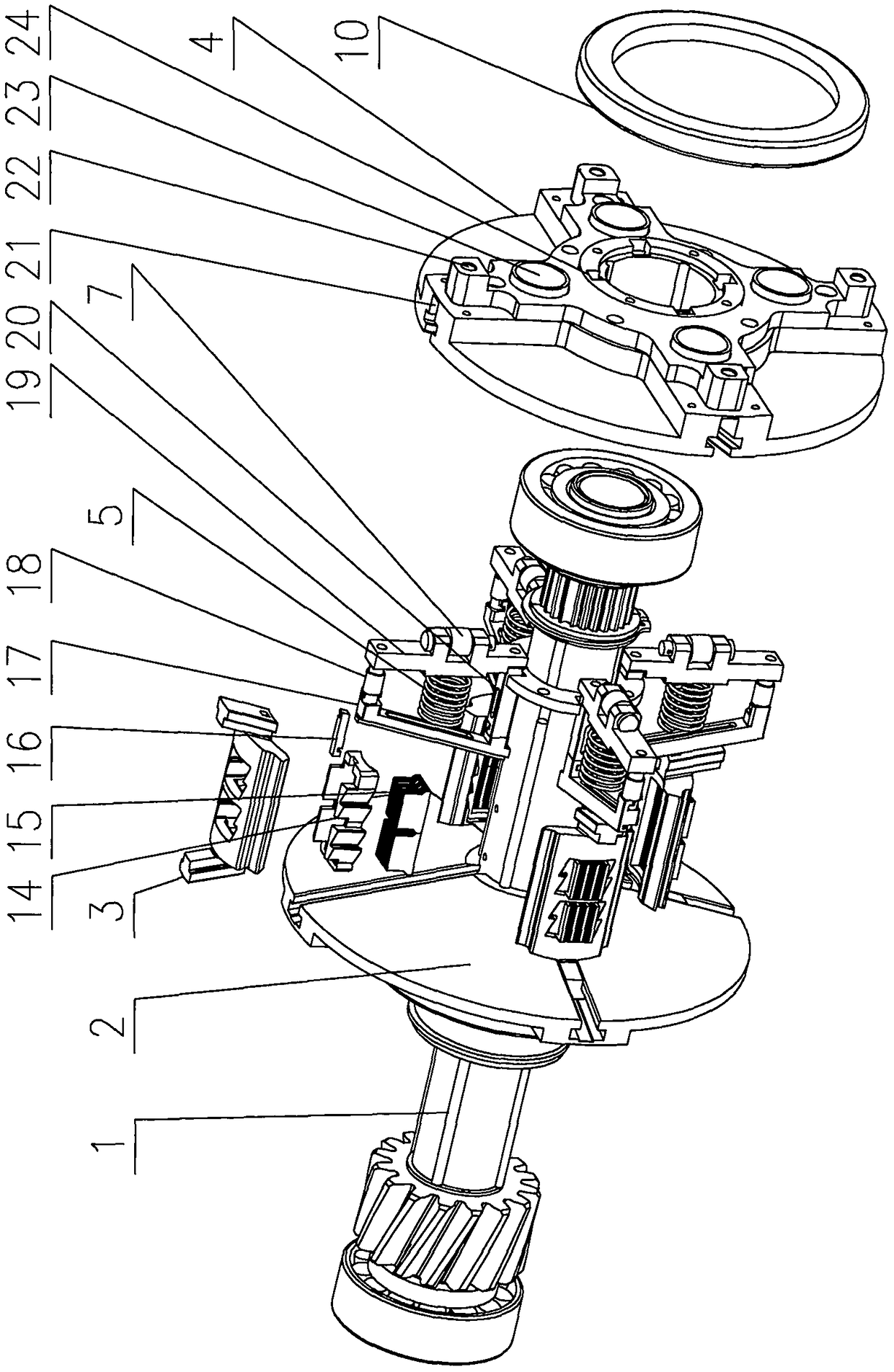

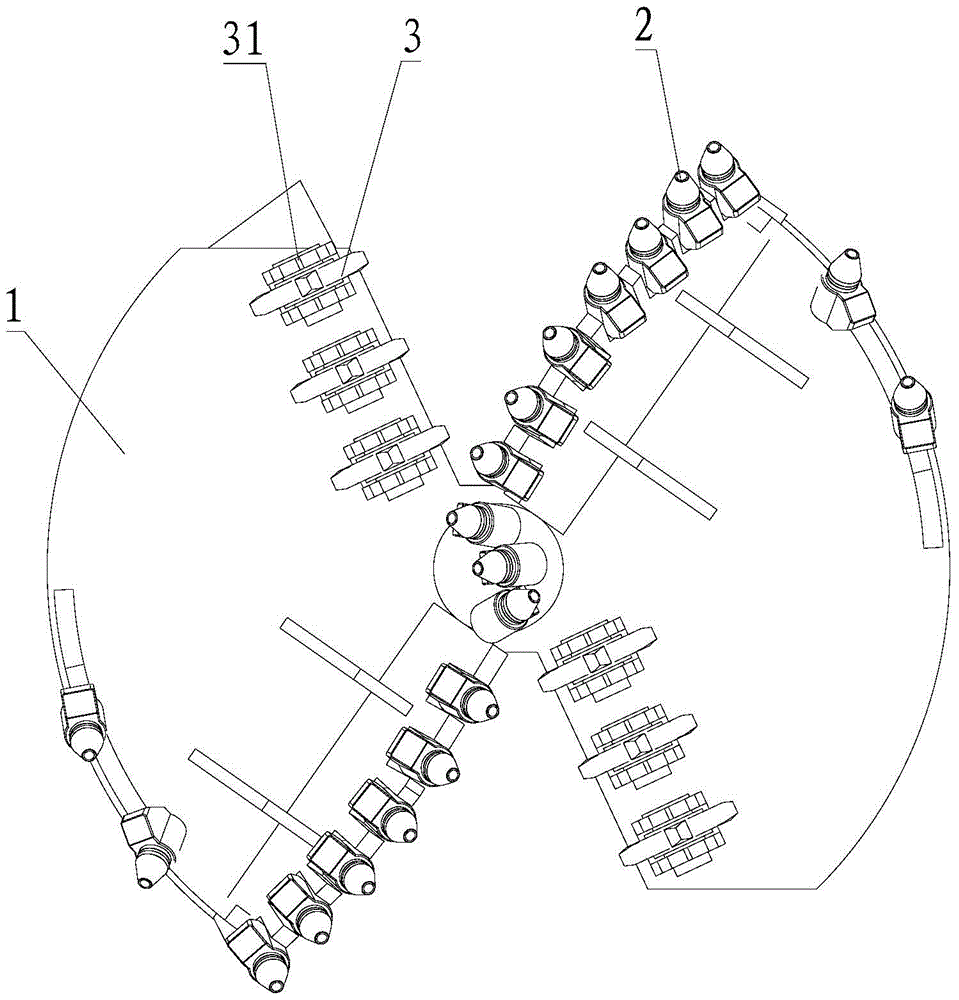

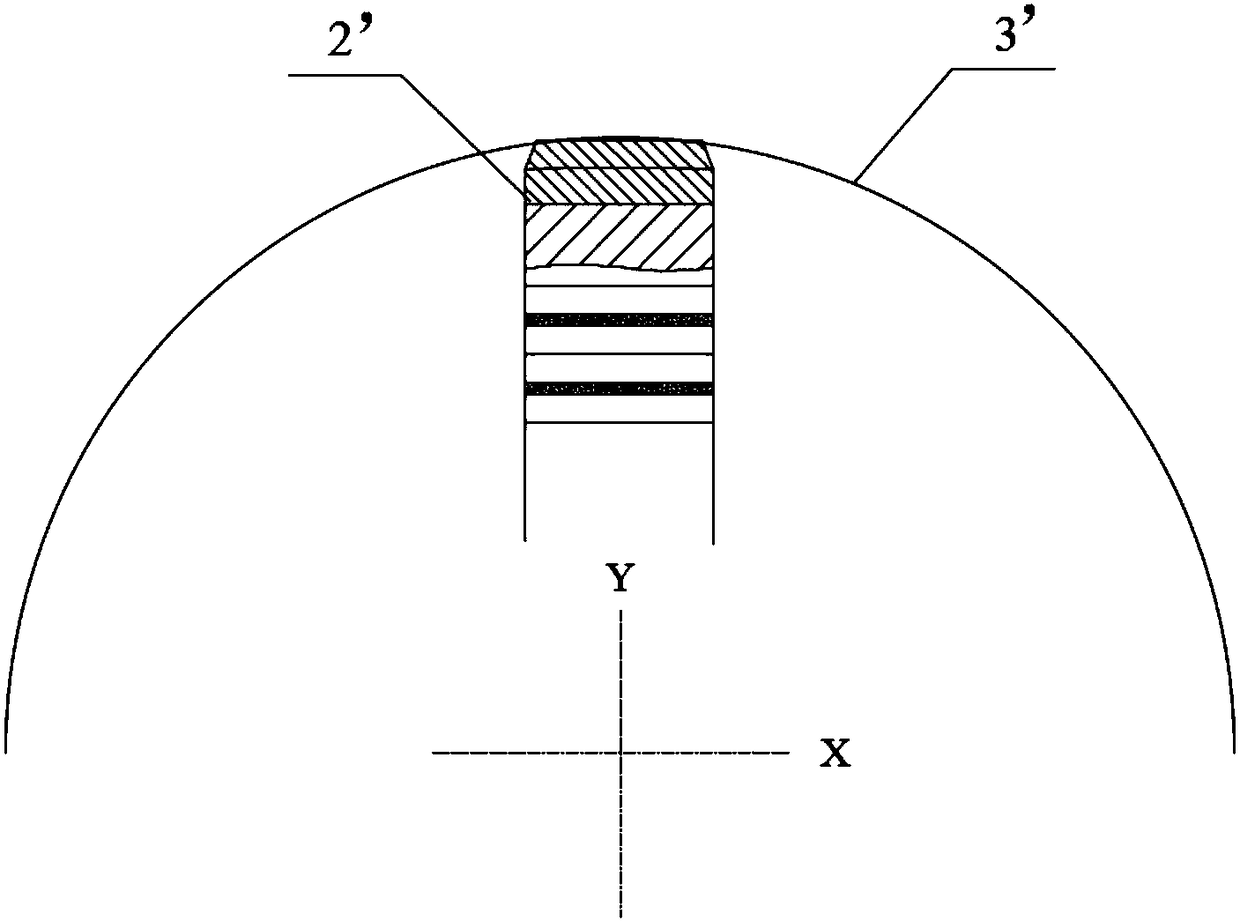

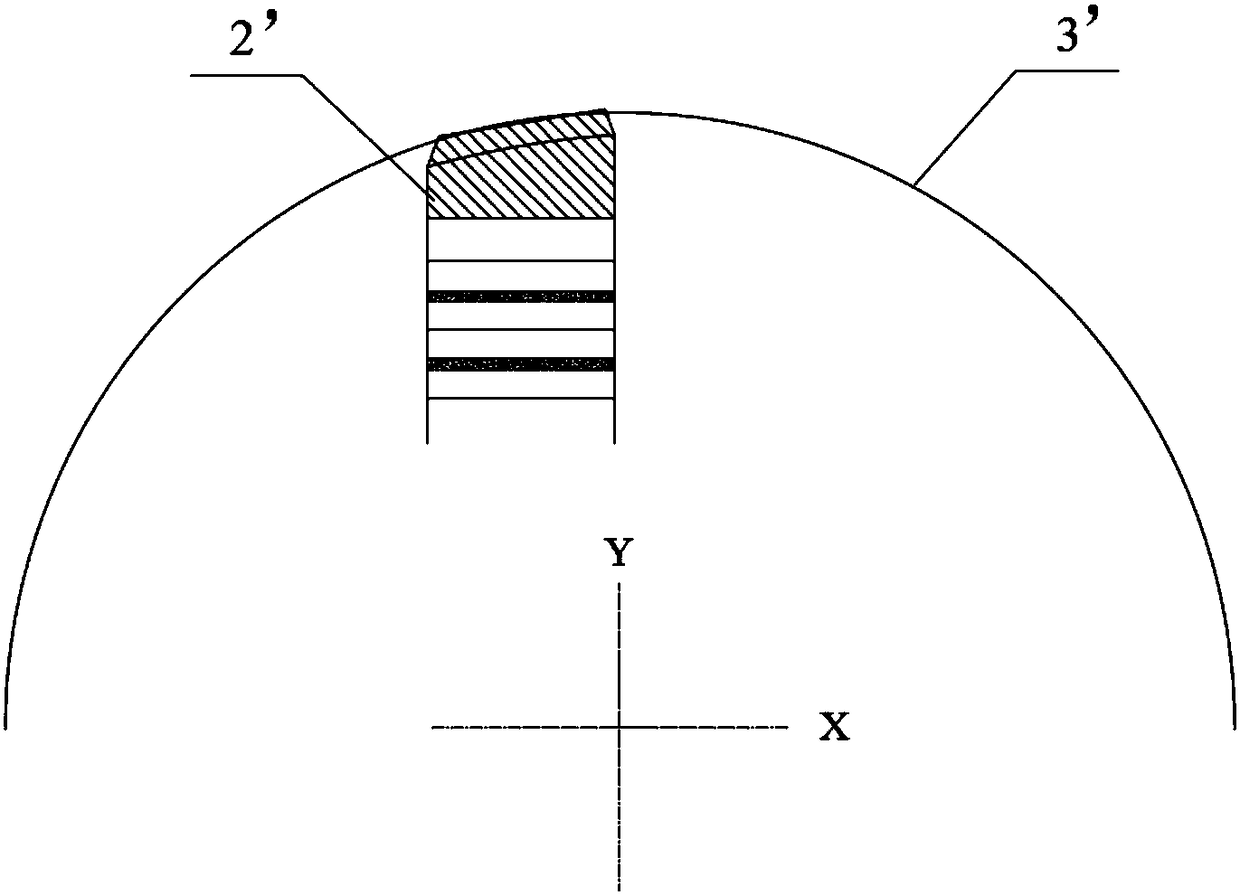

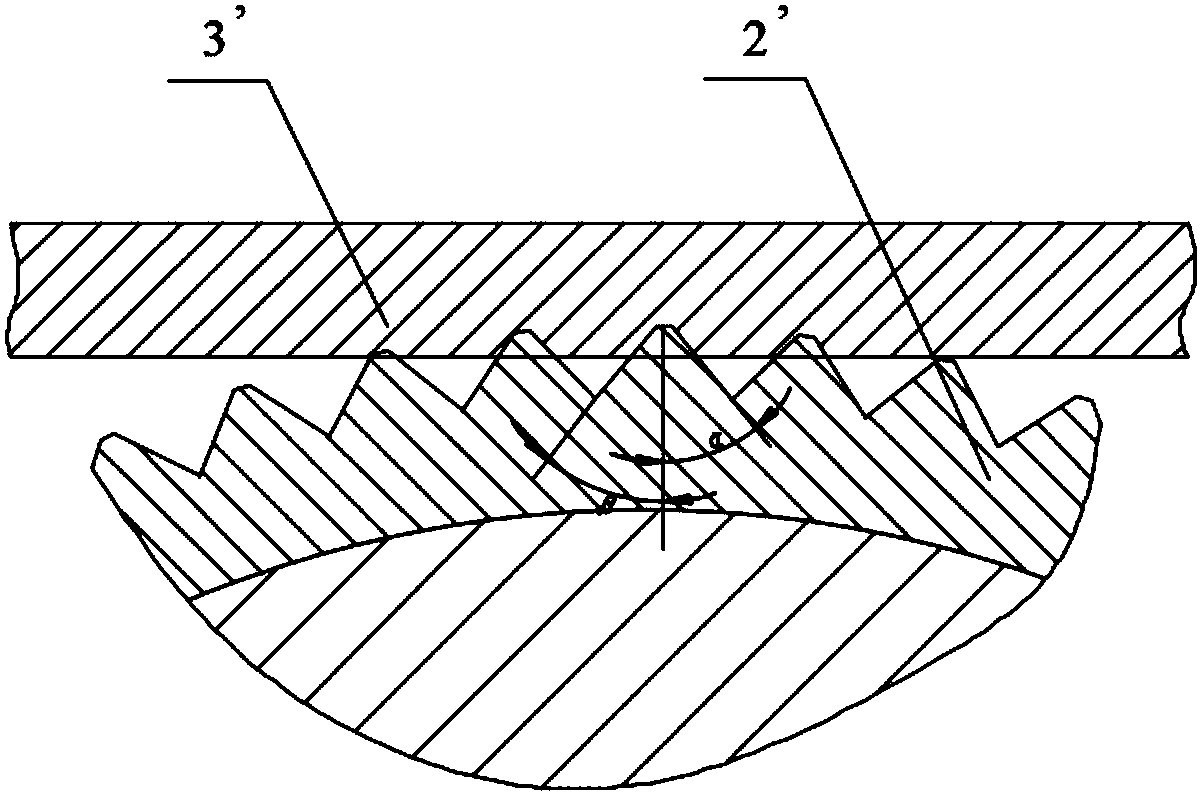

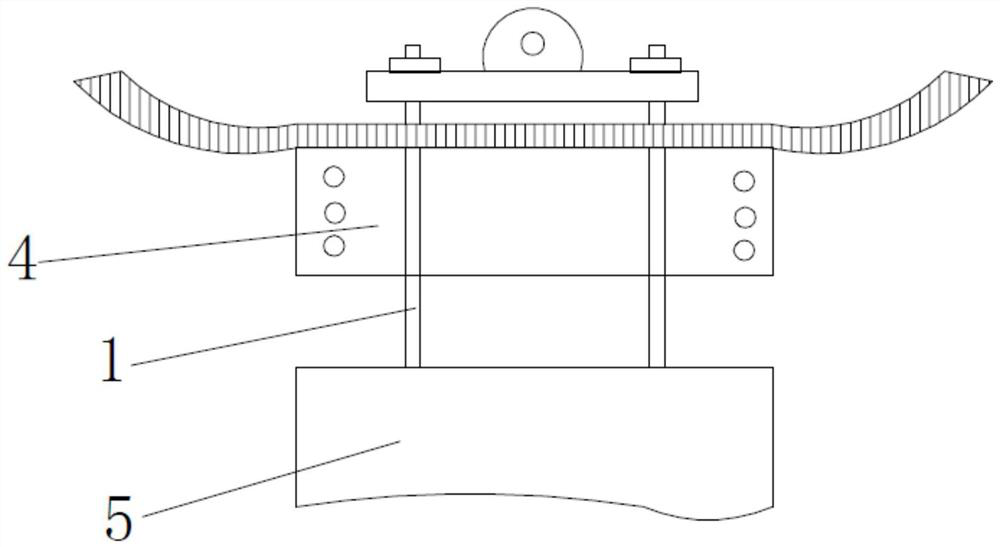

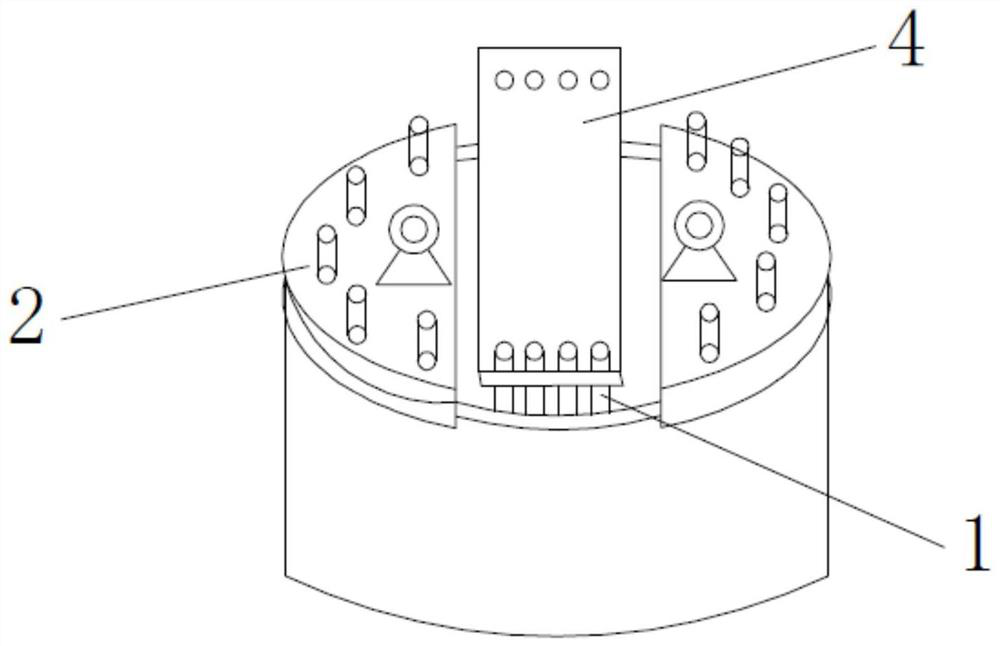

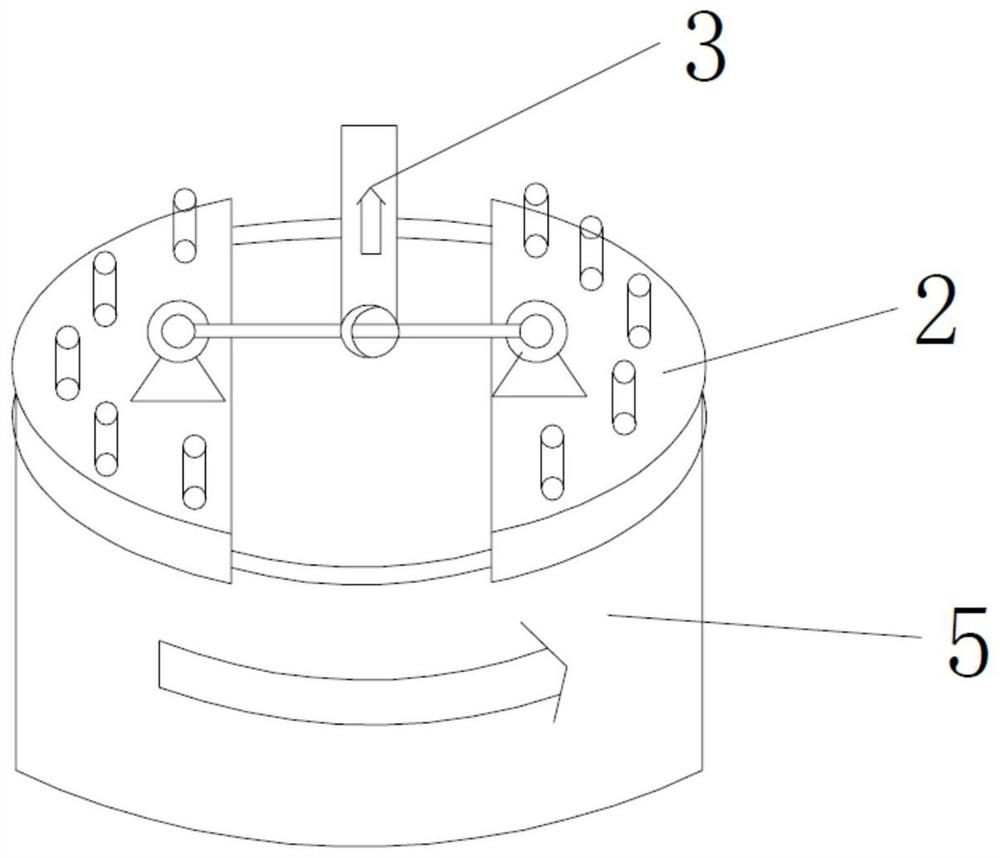

Mechanism for eliminating engaging backlash between oscillating teeth and sliding sheets as well as design method capable of prolonging life of engaging teeth

PendingCN108730497AExtend your lifeHigh transmission precisionGearing detailsManufacturing technologyEngineering

The invention provides a mechanism for eliminating engaging backlash between oscillating teeth and sliding sheets as well as a design method capable of prolonging the life of engaging teeth, and belongs to the technical fields of mechanical transmission as well as continuously variable transmission design and manufacturing. The mechanism and the design method provided by the invention are regardedas improved technologies based on Patent 200580039668.6, and Patent 200580039668.6 records an engaging-type continuously variable transmission which has the following characteristics: the engaging-type stepless speed changing function is created depending on the sliding sheets and the oscillating teeth, the defect that a conventional continuously variable transmission depends on friction transmission is overcome, and the characteristics of high power and high efficiency are achieved; however, due to the certain thicknesses of the sliding sheets, the no-backlash engaging effect cannot be guaranteed in any states when the oscillating teeth formed by combining the sliding sheets are engaged with chain teeth; and accordingly, rotating speed pulsation and torque pulsation are generated. Through the mechanism for eliminating the engaging backlash between the oscillating teeth and the sliding sheets as well as the design method capable of prolonging the life of the engaging teeth, the aboveproblem about rotating speed pulsation and torque pulsation can be effectively solved, the no-load engaging-in and no-load engaging-out effect can be achieved, the transmission precision can be improved, the life can be prolonged, and the metal chain, conical disc and oscillating tooth abrasion automatic-compensation function can also be achieved.

Owner:王国斌

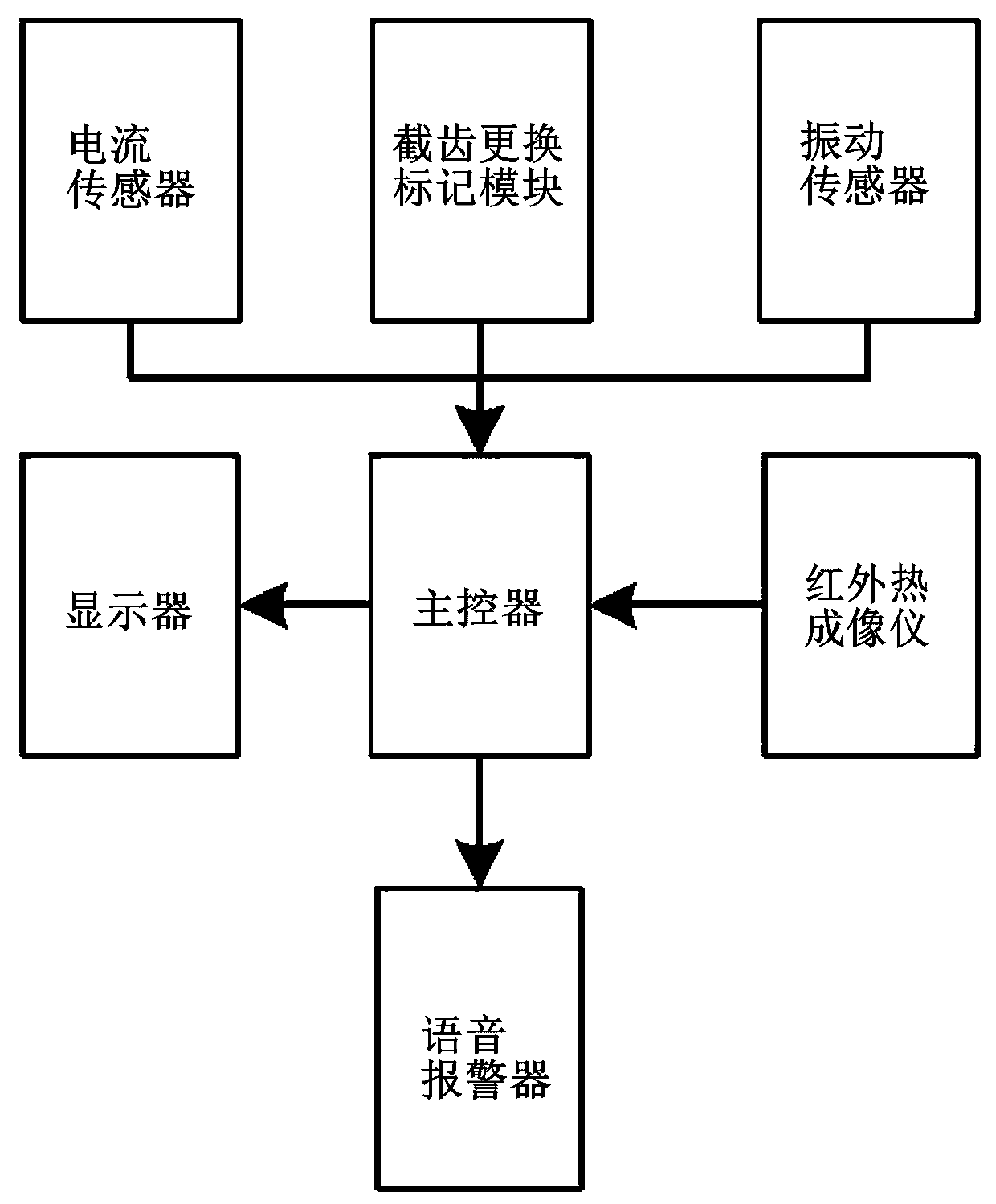

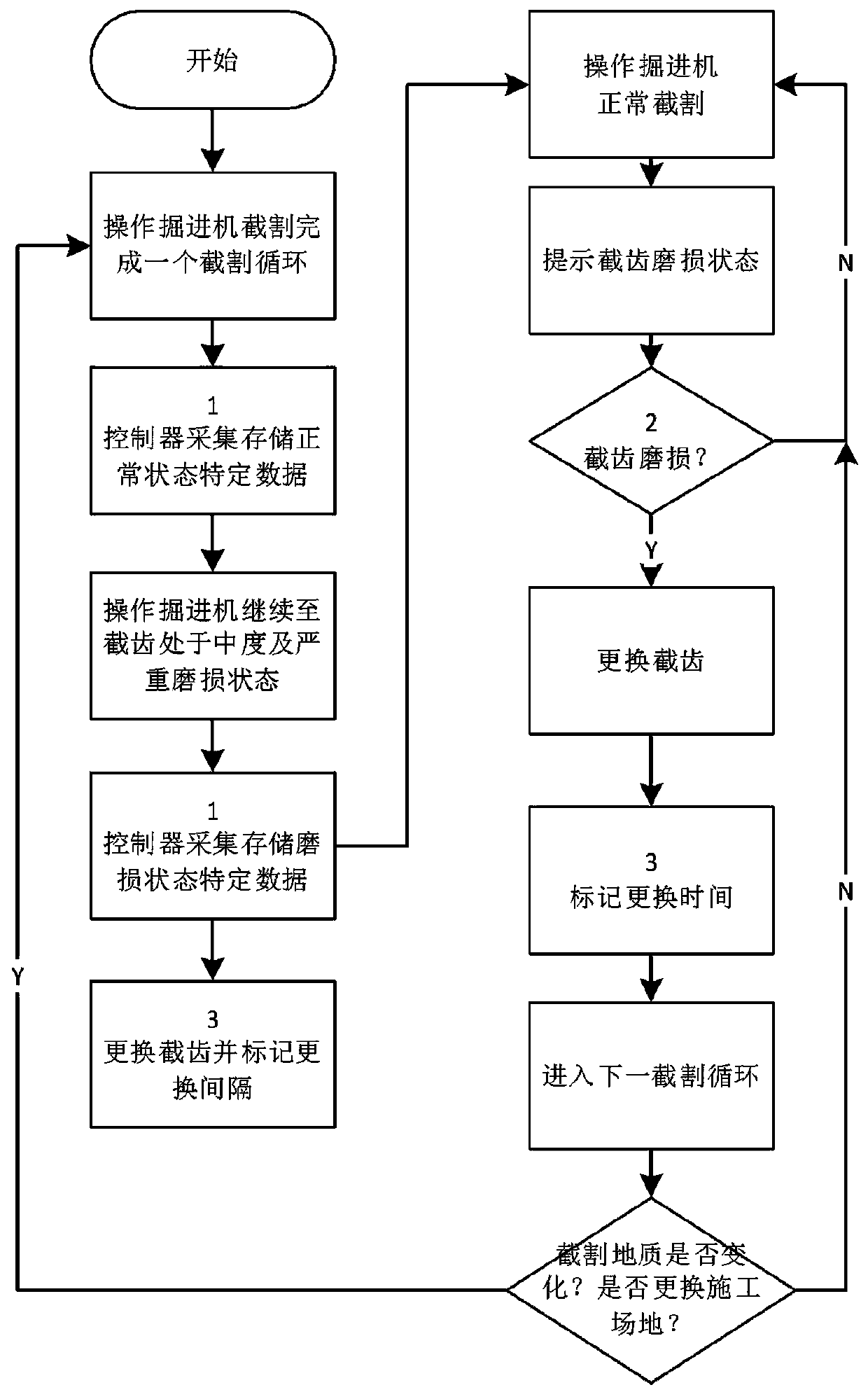

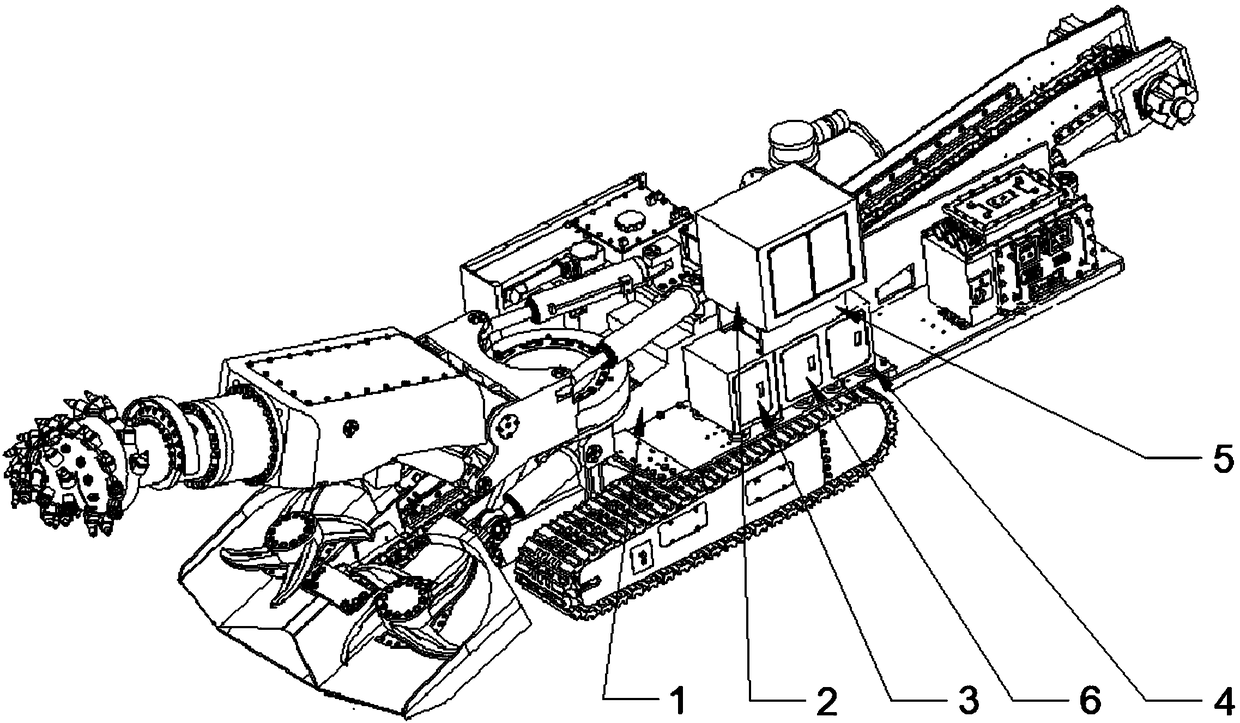

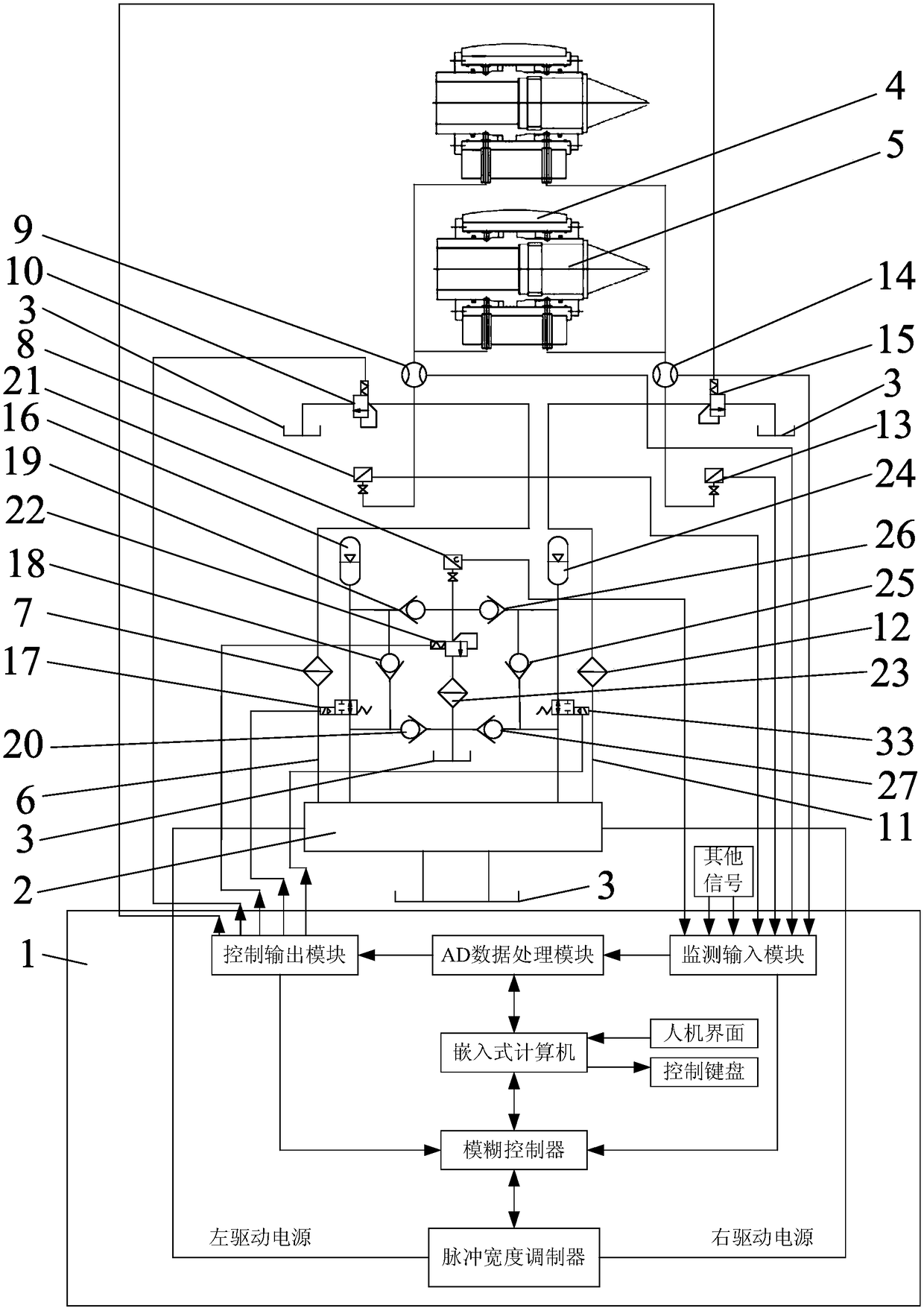

System and method for detecting abrasion state of cutting teeth of cantilever tunneling machine

PendingCN110439558AReduce wearTimely detection of eccentric wear of picksSlitting machinesElectric machineryCurrent sensor

The invention relates to the field of cantilever tunneling machines, in particular to a system and method for detecting the abrasion state of cutting teeth of a cantilever tunneling machine. The system comprises a main controller, a vibration sensor, a current sensor, an infrared thermal imager and a display output mechanism; the vibration sensor and the current sensor are both fixedly arranged ona cutting arm of the cantilever tunneling machine, and the current sensor is electrically connected with a cutting motor of the cantilever tunneling machine; the infrared thermal imager is mounted onthe upper section of the cutting arm of the cantilever tunneling machine; and the display output mechanism is electrically connected with the main controller and used for outputting a detection result to an operator in a figure and / or sound form. According to the system and method for detecting the abrasion state of the cutting teeth of the cantilever tunneling machine, abrasion of the cutting teeth can be found in time, the situation that abrasion of the adjacent cutting teeth is intensified and consequently, the cutting teeth lose efficacy is avoided, cutting tooth abrasion degree information can be output, the tunneling efficiency is improved, actual cutting operation of a construction site is adopted to collect characteristic data of cutting tooth abrasion detection, the authenticityof the characteristic data is improved, and the detection pre-judgment result is ensured.

Owner:中铁工程装备集团隧道设备制造有限公司

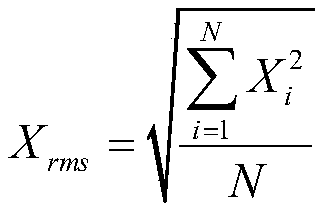

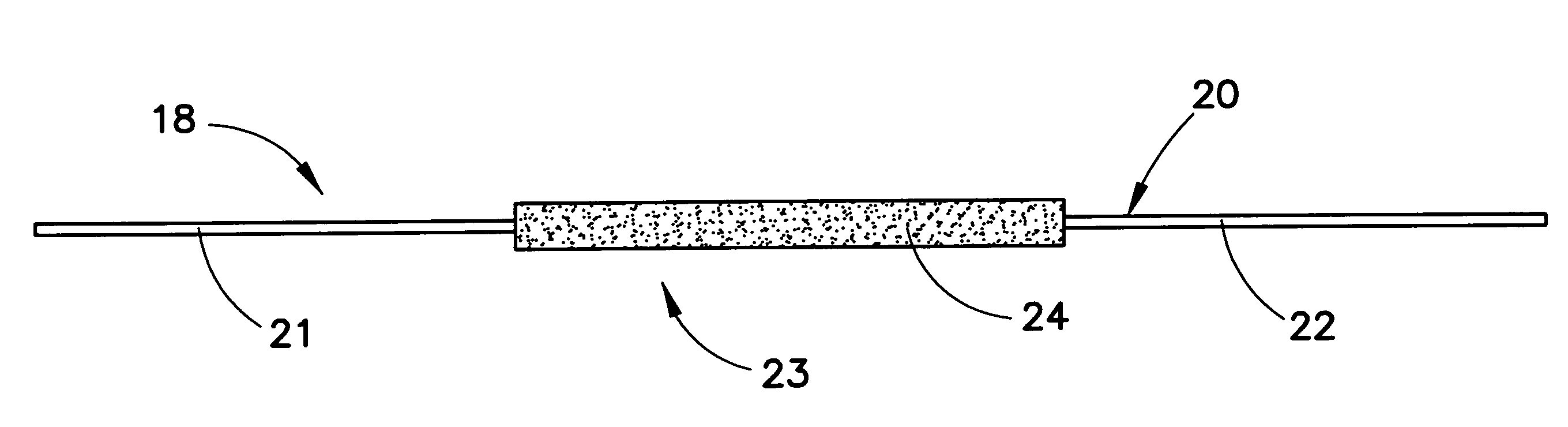

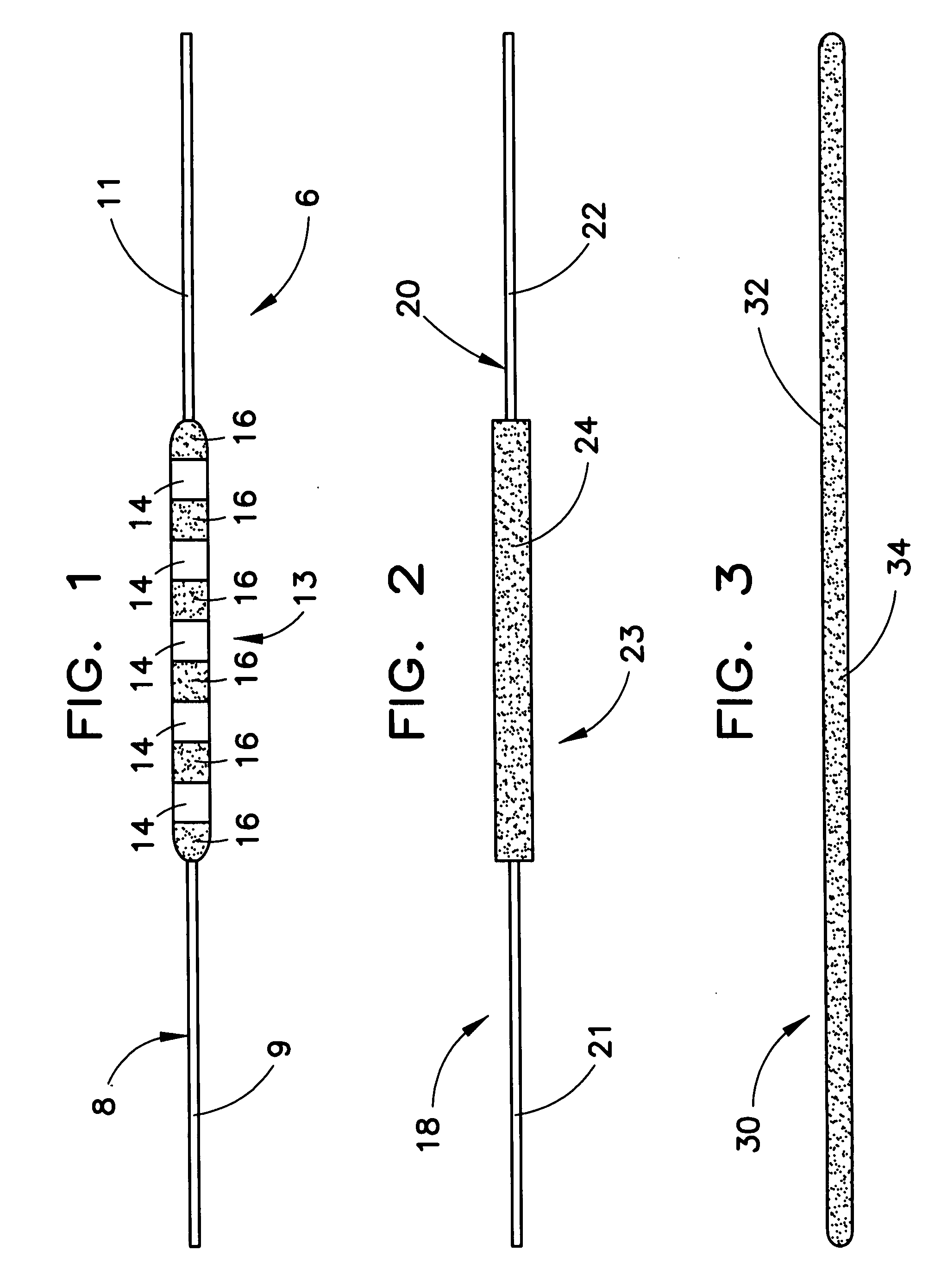

Dental finishing, sanding and/or polishing floss

An abrading dental floss is characterized by dental floss having a dental abrasive on at least a portion thereof suitable for polishing, sanding and / or finishing dental restorative material such as dental resin. The dental abrading material is impregnated into or provided onto the dental floss. In one form, the dental abrading floss has an abrading / abrasion / polishing / finishing / sanding section situated between lengths of the dental floss. The abrading polishing section may be formed of an alternating pattern of non-abrasive portions and abrasive portions along a length of the floss. The abrasive portions may be of a single grit or texture of the dental abrasive or may be of different grits of the dental abrasive. In another form, the dental abrading floss has a single grit of a dental abrasive along its entire length. In yet another form, the dental abrading floss comprises a plastic sheet of having a dental abrasive thereon or therein situated between lengths of the dental floss. The dental abrasive may be of a single grit or different grits of the dental abrasive. For different grits of the dental abrasive, it is preferred, but not necessary, that they gradually change in grit size.

Owner:ALLEN JEFFREY T

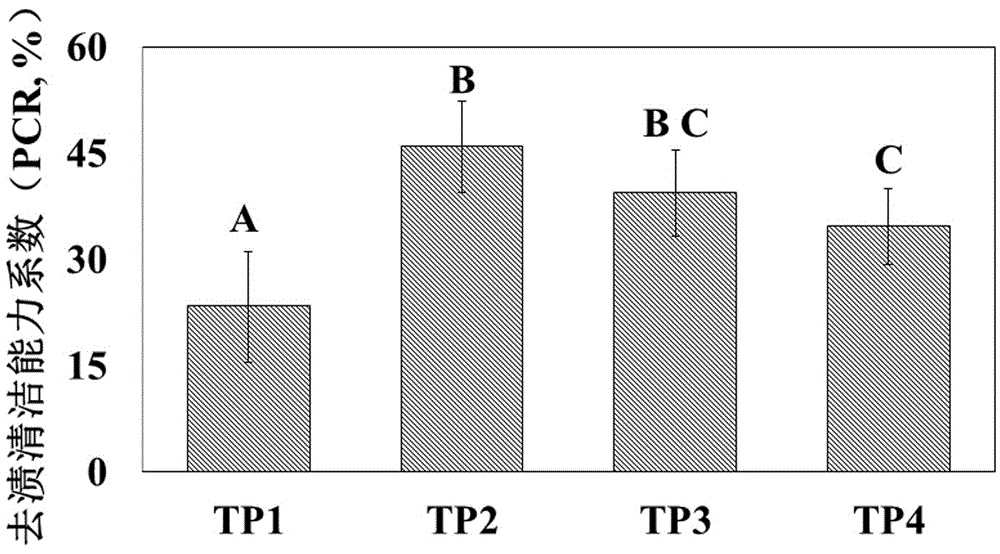

Toothpaste containing insoluble dietary fiber and sodium phytate, and preparation method of toothpaste

ActiveCN106691886AGood stain removal and cleaning abilityAvoid wear and tearCosmetic preparationsToilet preparationsToothpasteDietary fibre

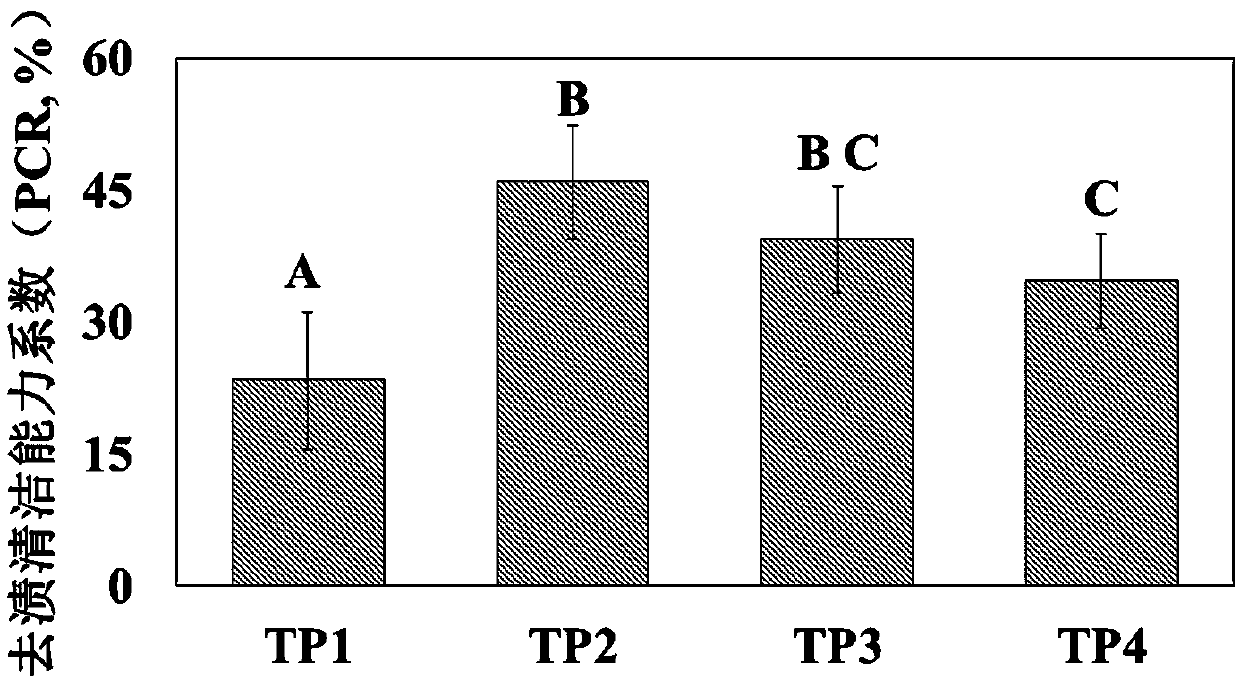

Insoluble dietary fiber and sodium phytate are widely applied to the field of oral care. Toothpaste containing the insoluble dietary fiber and sodium phytate, provided by the invention, has remarkable stain-removing and cleaning capability and has obviously better effect than that of toothpaste singly added with the insoluble dietary fiber or the sodium phytate; under a certain condition, the toothpaste containing the insoluble dietary fiber and sodium phytate with the mass ratio of 8:2 has the best stain-removing and cleaning capability, can avoid tooth abrasion caused by adoption of high-friction raw materials and enables the product to be safer and more reliable. Therefore, the toothpaste containing the insoluble dietary fiber and sodium phytate has good application prospect in the field of oral care articles.

Owner:HANGZHOU JIAOJIE ORAL HEALTH CARE PRODS

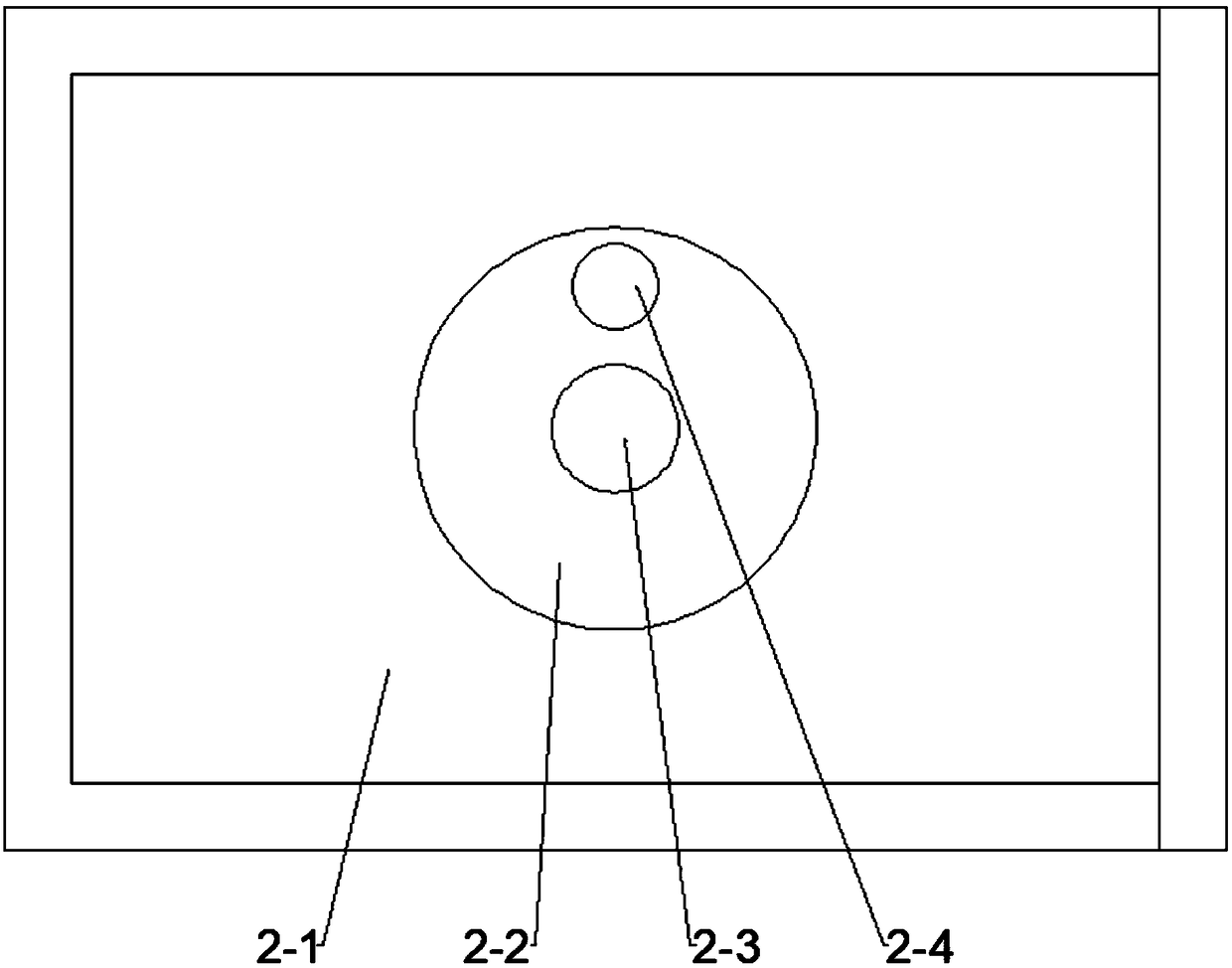

Tunneling machine cutting trace planning system and method

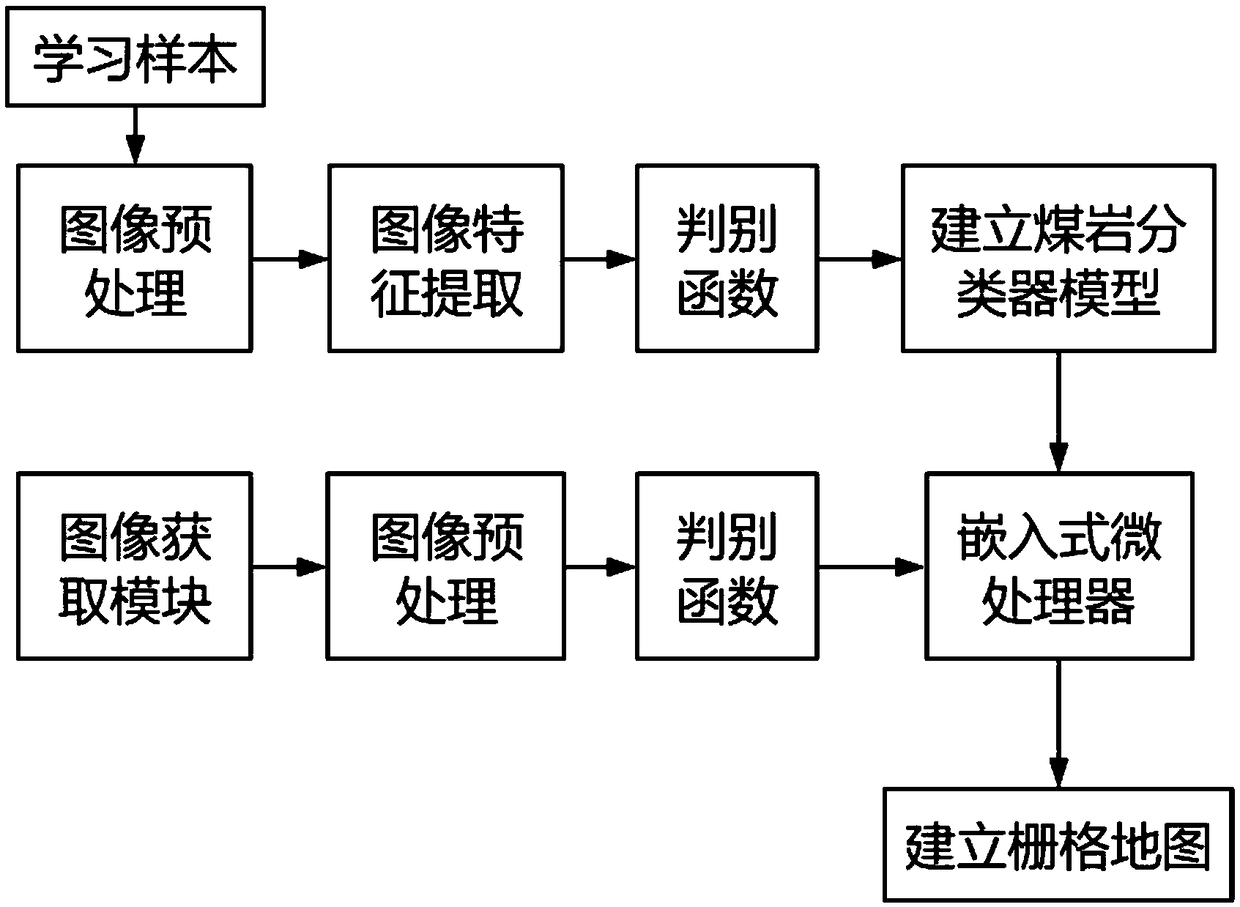

ActiveCN109236292AReduce computationFast response timeCharacter and pattern recognitionDriving meansComputer moduleComputer science

The invention discloses a tunneling machine cutting trace planning system and method. The system comprises an image acquisition module, a data processing module and a control module, wherein the imageacquisition module, the data processing module and the control module are mounted on a tunneling machine main body. The trace planning method comprises the following steps: modeling on the basis of an orthohexagonal grid method, and dividing an area to be cut into a plurality of orthohexagonal grid units of an identical size with binary value information; dividing an ideal area into a plurality of free area units which are overlapped with one another by using a unit division method with obstacles as boundaries, and representing transferring of one area unit to another area with adjacent images; calculating planning of an optimal route by using an algorithm. By adopting the system, a tunneling machine cutting head can automatically avoid dirt bands in the tunnel cutting process, cutting tooth abrasion can be reduced, the service life of each cutting tooth can be prolonged, the cutting speed can be increased, the cutting efficiency can be improved, and conditions are provided for automatic and efficient operation of a tunneling machine.

Owner:CHINA UNIV OF MINING & TECH

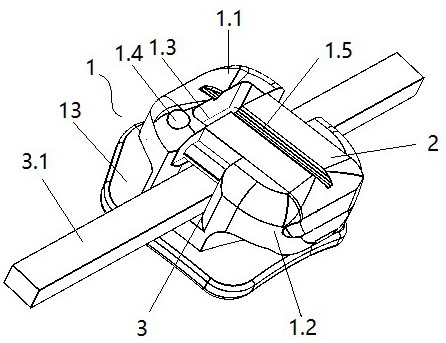

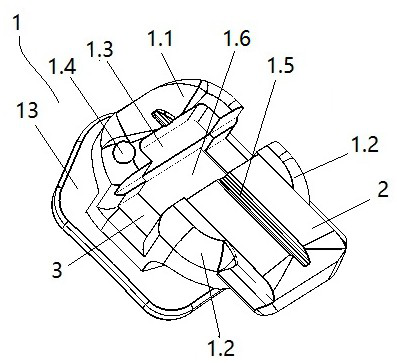

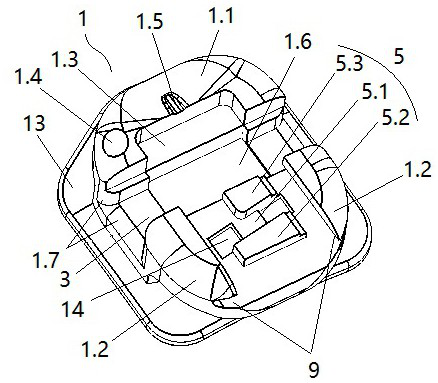

Orthodontic self-locking system adapted to strip-shaped arch wire

PendingCN112168390ARound and beautiful appearanceEliminate sharp partsArch wiresBracketsArch wiresEngineering

The invention relates to an orthodontic self-locking system adapted to a strip-shaped arch wire. The system comprises the strip-shaped arch wire and a bracket matched with the strip-shaped arch wire,an arch wire groove is transversely formed in the bracket, an upper single wing is arranged at the upper portion of the arch wire groove, a lower single wing structure is arranged at the lower portionof the arch wire groove, a sliding cover is installed on the lower single wing structure, and the sliding cover is in sliding fit with the lower single wing structure. The lower single wing structureis provided with a fixing base, at least one end of a straight elastic wire can be bent and deformed, a fixing base receding cavity is formed at the bottom of the sliding cover, and a mousing hook and a limiting convex rib are arranged at at least one side of the fixing base receding cavity. After the sliding cover is closed, the lower single wing structure and the tail part of the sliding coverjointly form a round lower single wing. By innovatively designing the self-locking structure between the bracket and the sliding cover, the self-locking structure and an elastic piece thereof are simplified, the manufacturing difficulty and the manufacturing cost are reduced, and the self-locking stability and reliability of the self-locking structure are improved. The system is round and attractive in appearance, comfortable to use, capable of reducing impact of food on the bracket and teeth, capable of avoiding wing breakage and capable of reducing tooth abrasion.

Owner:梁甲兴

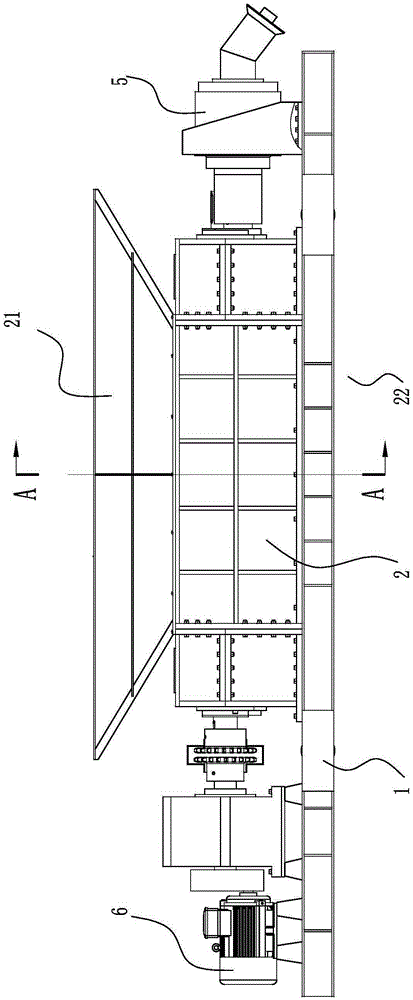

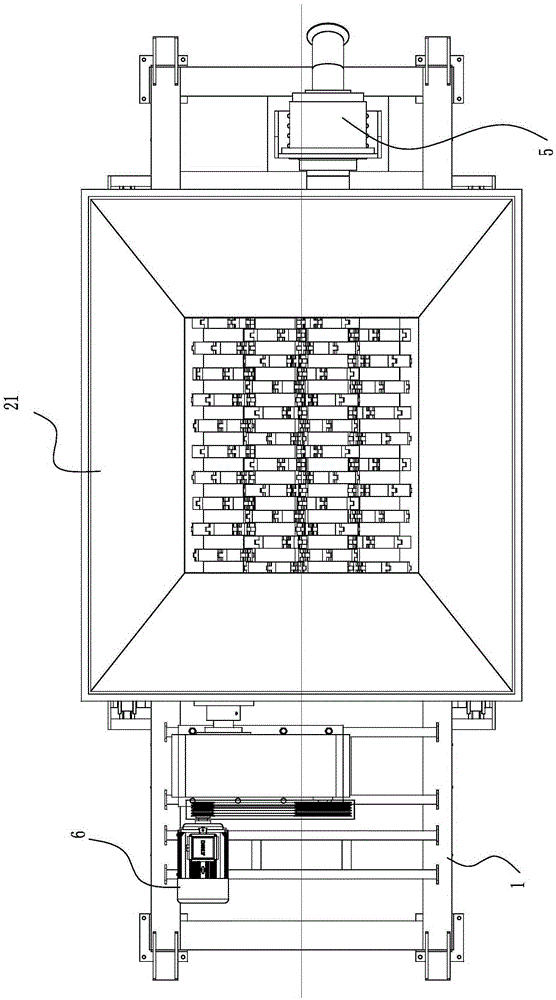

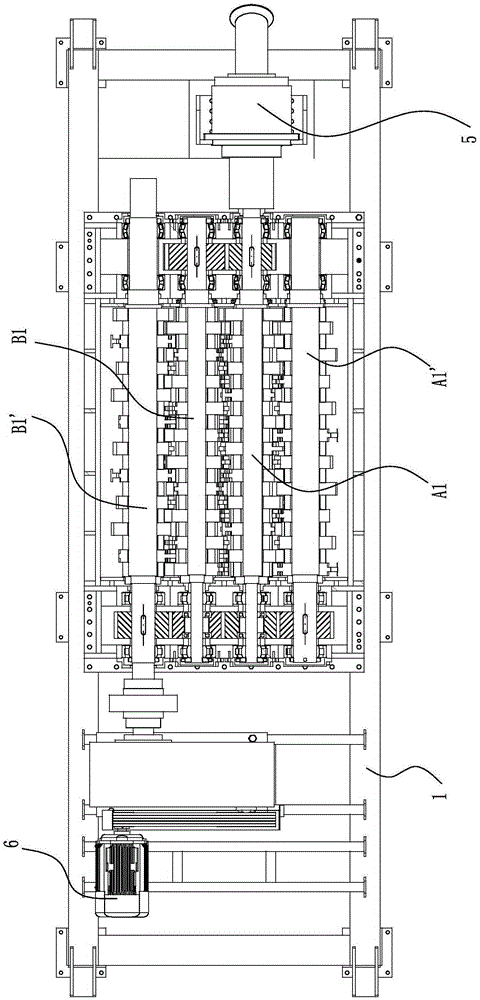

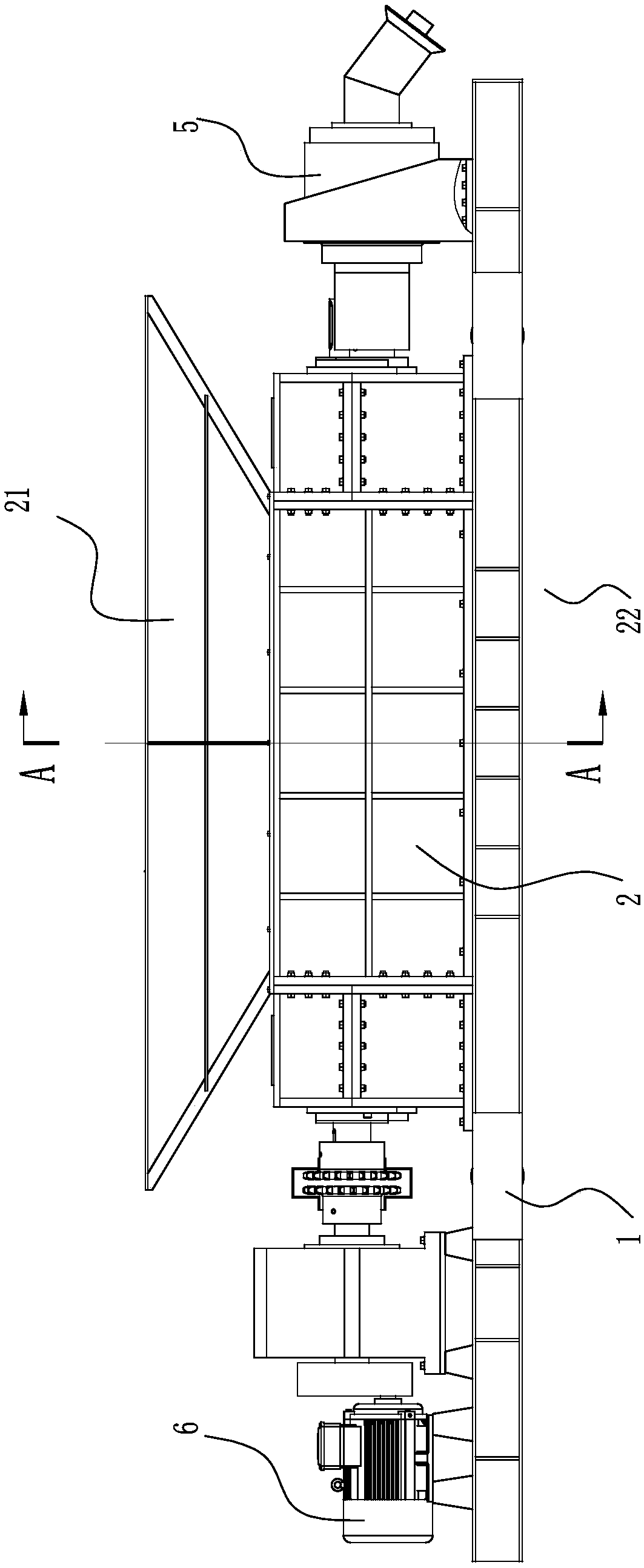

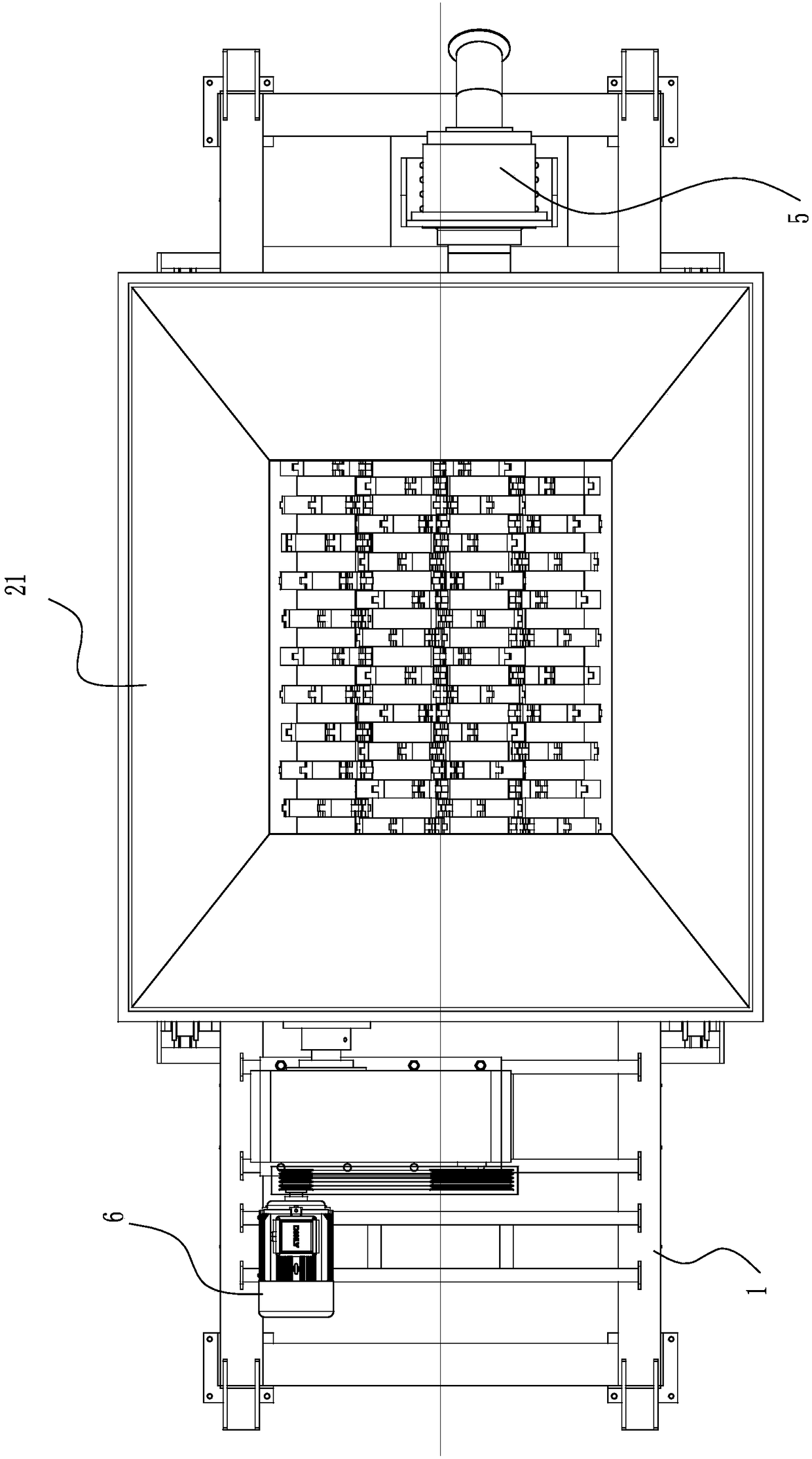

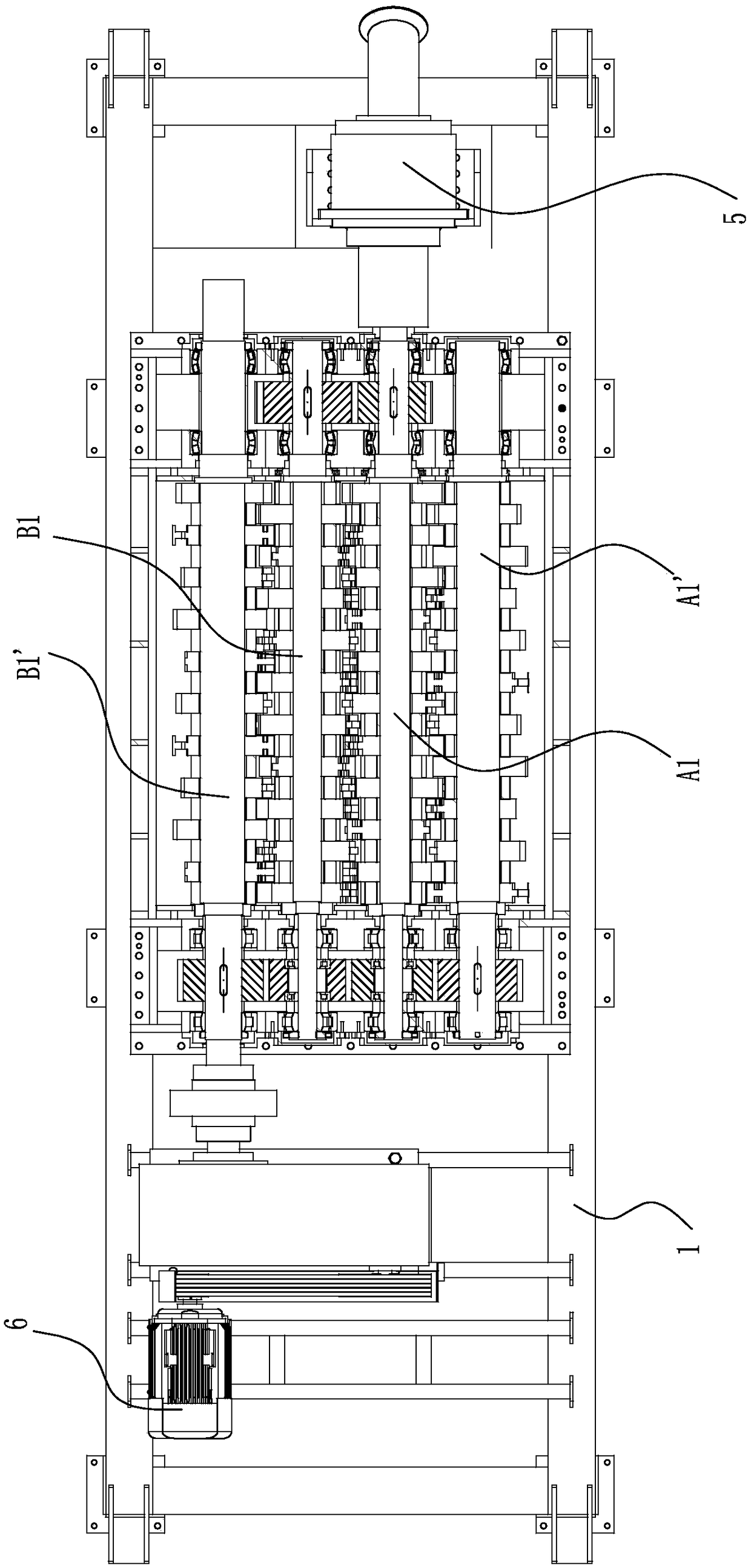

Garbage tearing crushing machine

The invention discloses a garbage tearing crushing machine comprising a crushing box body, wherein the crushing box body is internally provided with at least one pair of mutually-paired tearing rollers; tearing cutterheads are fixedly arranged on each tearing roller at intervals; each of the tearing cutterheads of the mutually-paired tearing rollers is provided with a tearing cutter tooth inserted to a gap between the tearing cutterheads of the opposite tearing rollers; a blanking gap for avoiding shear force generation is arranged between each tearing cutter tooth and the side wall of the gap between the tearing cutterheads of the opposite tearing rollers; and when the garbage tearing crushing machine works, hard matters such as little silt and pebbles are discharged through the blanking gaps, and hard matters such as large stones as well as cloth, plastics and the like are also discharged through the blanking gaps after being continuously gnawed, beaten, torn and crushed by the tearing tool teeth, so that the abrasion of shearing blades is greatly reduced. Garbage is crushed through tearing, beating and gnawing, so that tearing tool tooth abrasion caused by shearing is avoided; and experiments prove that the maintenance-free time of the crushing machine in continuous working can belonger than one year, and the technical effect is extremely remarkable.

Owner:潍坊金丝达环境工程股份有限公司

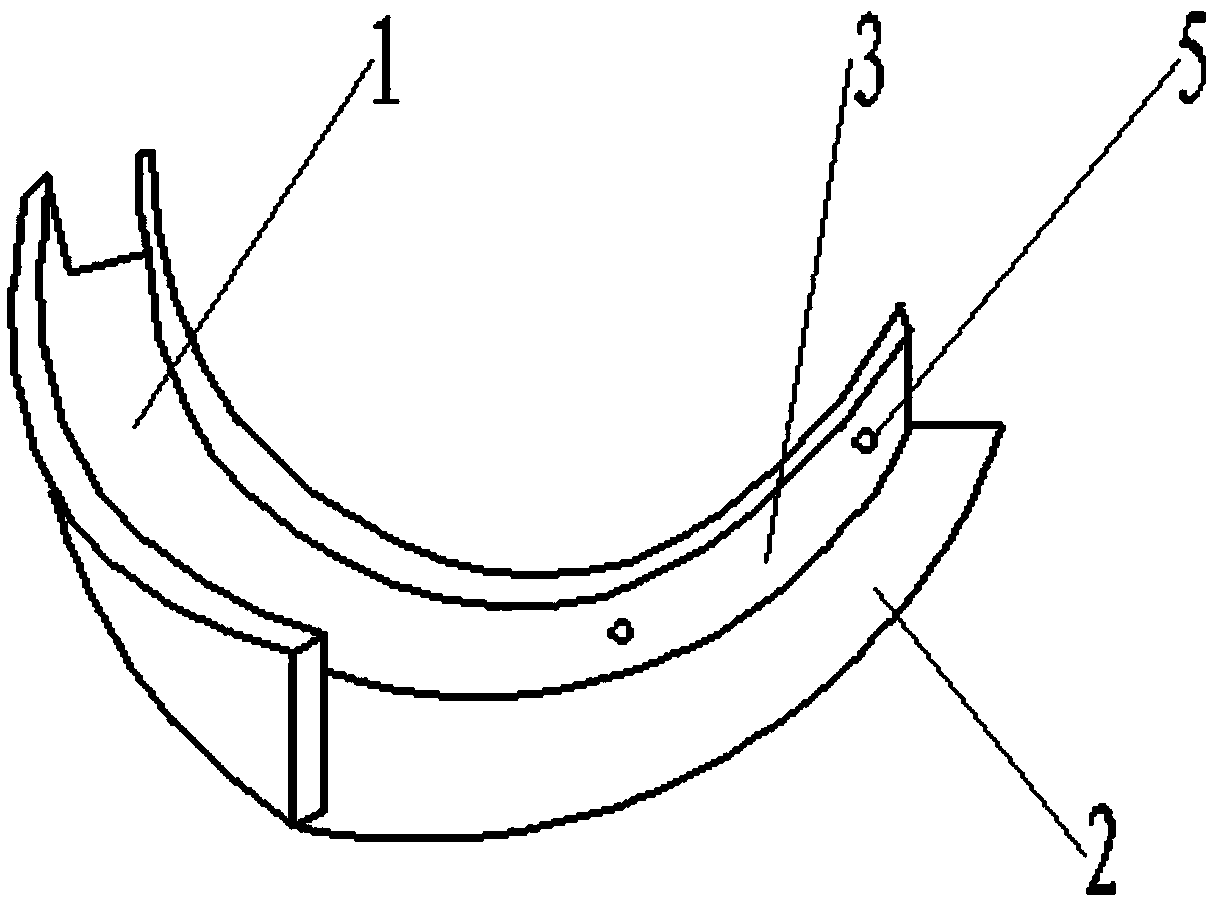

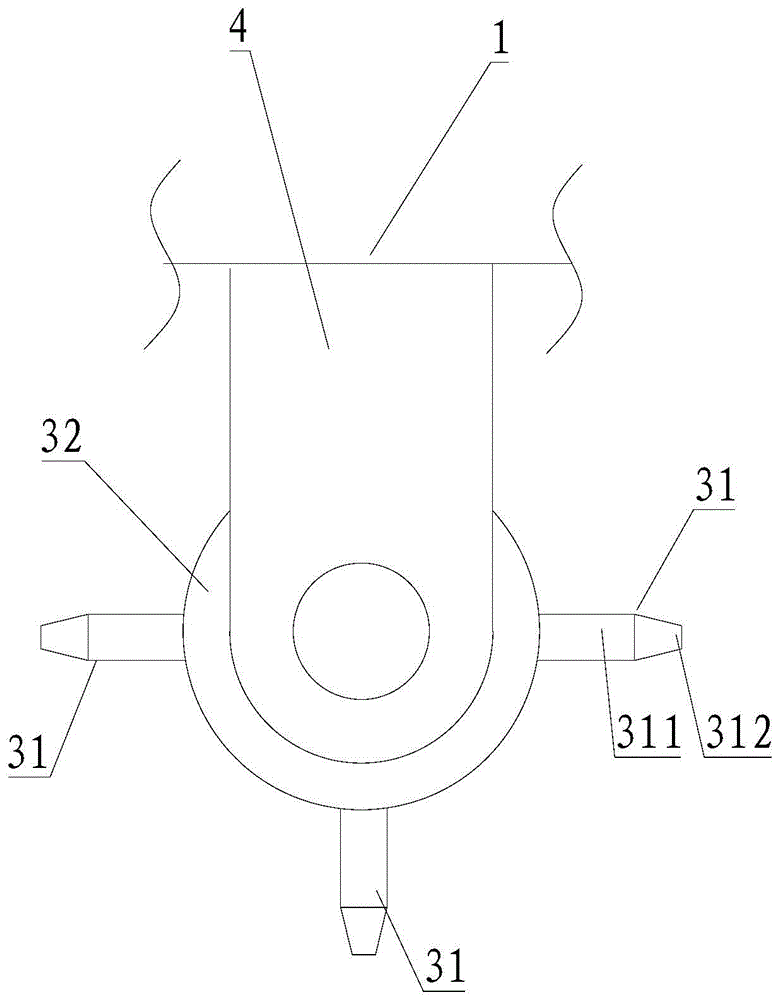

Tooth protector for treating bruxism and application thereof

ActiveCN106236346AImprove playbackIncrease heatNervous disorderMuscular disorderTooth wearUpper teeth

The invention discloses a tooth protector for treating bruxism. The tooth protector is used for being worn on lower teeth. The tooth protector comprises a U-shaped sleeve of which the shape is designed according to the shapes of the lower teeth in the human oral cavity, a groove is formed in the middle of the U-shaped sleeve, the inner side face of the groove is attached to the lower teeth to hinder occlusion of upper teeth and the lower teeth, one end of the groove is open, and the open side face is used for sticking a traditional Chinese medicine patch. According to the tooth protector, modeling is simple, wearing is convenient, tooth abrasion can be effectively prevented, the traditional Chinese medicine patch with the effects of soothing the nerves and regulating qi is stuck to the open end of the groove, the trouble of directly drinking traditional Chinese medicine is avoided, a patient can be helped to regulate the sleep quality and improve the mental stress state, and then bruxism symptoms are relieved; the traditional Chinese medicine patch can be replaced every day, and the tooth protector is simple, convenient to use, clean and sanitary and cannot bring the oral bacterium problem.

Owner:崔艳

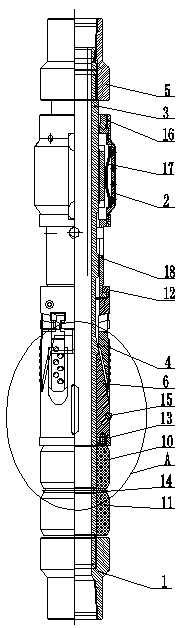

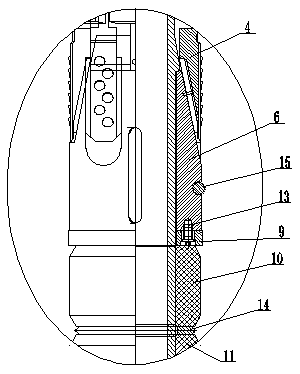

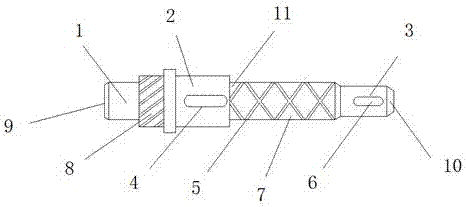

Slip expansion-type deep-water packer

The invention relates to a slip expansion-type deep-water packer, and belongs to the technical field of deep-sea oil and gas drilling and production equipment. The packer comprises an upper joint, a friction reversing piece, a central pipe and a slip. A lower joint is installed at one end of the central pipe, the upper joint is installed at the other end of the central pipe, and a slip seat is installed on the central pipe between the upper joint and the lower joint in a sliding mode. A rubber cylinder A and a rubber cylinder B are installed on the central pipe on one side of the slip seat through a pressing ring, and the slip is installed on the center pipe on the other side of the slip seat through a slip limit sleeve and a pin column. The slip expansion-type deep-water packer is simplein structure and high in reliability, and can effectively solve the problem that shoulder protrusions occur on the end surfaces of the rubber cylinders and the sealing performance is poor when the packer is squeezed and blocked for packing; at the same time, the problems of low blocking efficiency, poor sealing performance, slip failure and the like caused by friction dead-clamping and clamping-tooth abrasion when an existing slip expands and locks walls of the cylinders, and the problems of pollution and damage to the formation environment are solved; and the slip expansion-type deep-water packer is especially suitable for the deep sea oil and gas drilling and production operations.

Owner:YANGTZE UNIVERSITY

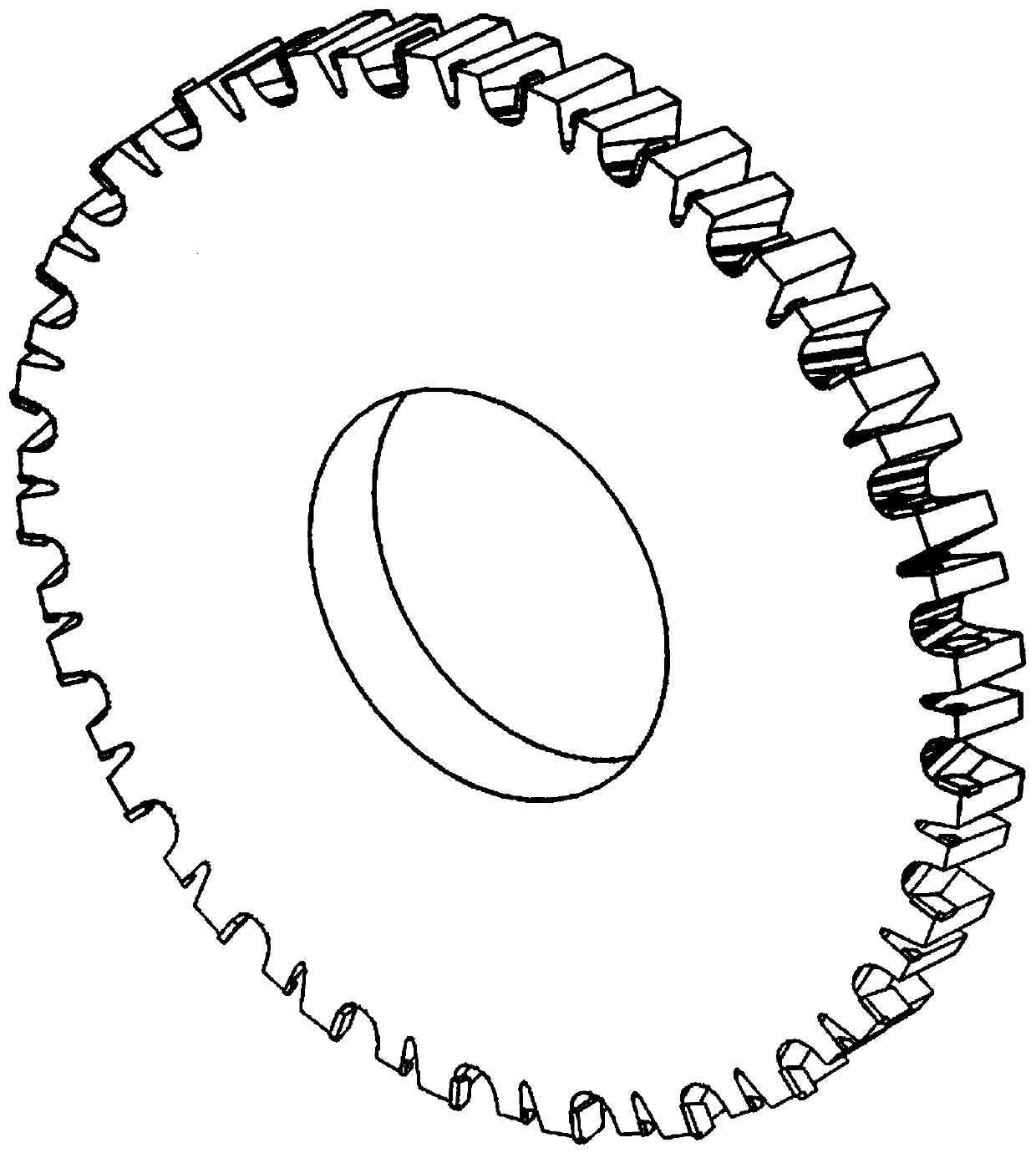

Traction wheel for casing pipe horizontal well tractor

The invention discloses a traction wheel for a casing pipe horizontal well tractor and relates to the field of wireline logging.The traction wheel comprises a body and an external gear ring, wherein the body is detachably sleeved with the external gear ring, a plurality of annular grooves are formed in teeth of the external gear ring in the axial direction of the external gear ring at intervals, the annular grooves are formed in the circumferential direction of the external gear ring and divide the external gear ring into a plurality of toothed rings, and the endpoints of tooth-tip lines of the toothed rings are located on the same arc.On one hand, the external tooth form is better matched with the inner wall of the sleeve in the circumferential direction of the sleeve, and external tooth abrasion is more uniform; on the other hand, the condition of external teeth being meshed with the inner wall of the sleeve is improved in the axial direction of the sleeve, and greater traction force can be provided compared with traditional traction wheels.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

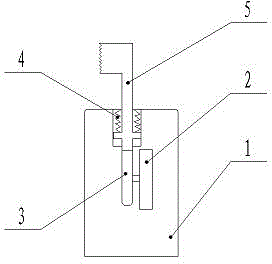

Non-rotating type electric toothbrush

InactiveCN104546190ASolve wear and tearAvoid time consumingTooth cleaningReciprocating motionEngineering

The invention particularly relates to a non-rotating type electric toothbrush which comprises a shell and a rotating wheel, wherein the rotating wheel is arranged in the shell and used for providing rotating power; a cam is connected to the right ahead direction of the rotating surface of the rotation wheel; a brush head device is arranged at the upper part of the cam in the tangential direction; springs are arranged in the shell and close to the periphery of the brush head device. By utilizing the cam structure, the rotation is converted into reciprocating motion, so that the adverse factors of time consumption, tooth abrasion and the like caused by the rotation are avoided, and the problem that the electric toothbrush in the prior art is time-consuming and causes certain abrasion to the teeth is solved.

Owner:XIAN SINENG NETWORK SCI & TECH

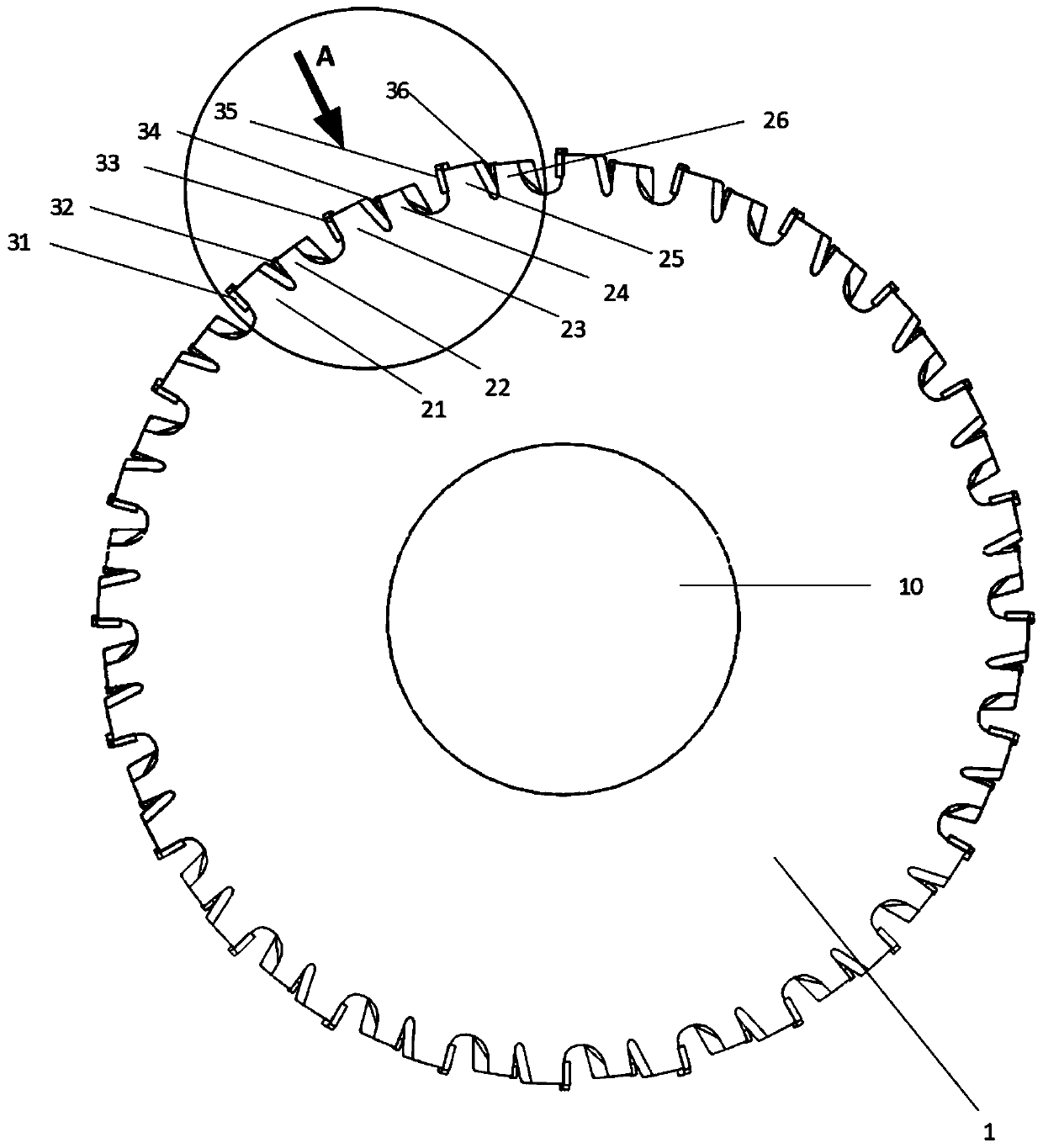

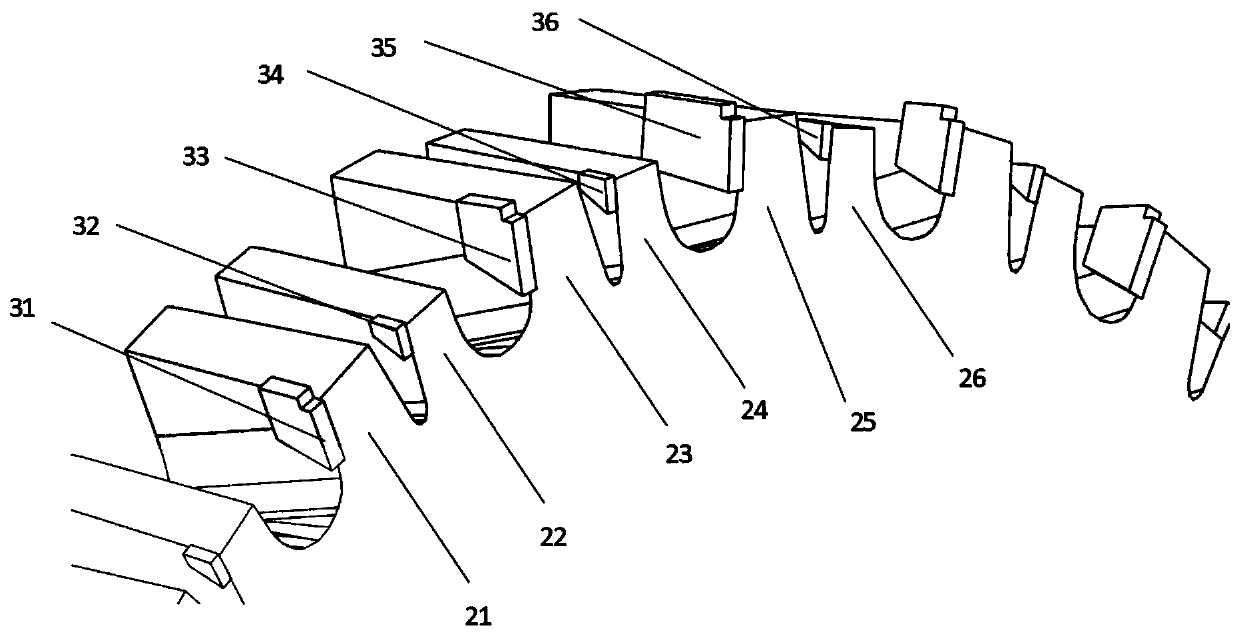

Multifunctional woodworking milling cutter used for milling edge portion of veneer shaving board

The invention discloses a multifunctional woodworking milling cutter used for milling the edge portion of a veneer shaving board. The multifunctional woodworking milling cutter comprises a cutter bodyof a disc shape. A center shaft hole is formed in the center of the cutter body. Four to eight multifunctional combination spiral cutter tooth sets are arranged on the periphery side face of the cutter body and are distributed in a central symmetry manner. The central angle corresponding to each multifunctional combination spiral cutter tooth set is 360 degrees. Each multifunctional combination spiral cutter tooth set is composed of six cutter tooth bases fixedly connected with the cutter body, and spiral cutter teeth fixedly arranged on each cutter tooth base. According to the multifunctional woodworking milling cutter used for milling the edge portion of the veneer shaving board, the quality of the machined surface can be improved, cutter tooth abrasion and tipping are reduced, then themilling efficiency is improved, the production cost is reduced, and the machining environment is improved.

Owner:NANJING FORESTRY UNIV

Cotton picker spindle with hook teeth of anti-attrition structure

InactiveCN113439543AAvoid direct contact with abrasionReduce wearPicking devicesAgricultural engineeringEconomic benefits

The invention discloses a cotton picker spindle with hook teeth of an anti-attrition structure, and relates to the technical field of cotton picking machinery. The cotton picker spindle comprises a picking head, a picking spindle rod and a bevel gear, the picking head is connected with one end of the picking spindle rod, the bevel gear is connected with the other end of the picking spindle rod, and three rows of hook teeth are evenly distributed on the periphery of the picking head. In order to avoid the phenomena of hook tooth abrasion and tooth breakage in the cotton picking process, an anti-abrasion structure is arranged on the inner side of each hook tooth of the spindle, and further, the anti-abrasion structures are treated through an ultrasonic nanometer modification technology. Meanwhile, flow guide grooves are formed in tooth grooves of the picking head, so that flow guide of the wetting liquid is facilitated. Therefore, the phenomena of abrasion and tooth breakage of the spindle can be effectively reduced, the maintenance cost of a cotton picker is reduced, and the economic benefit is improved; and heat generated when the spindle works can be reduced in time, and potential safety hazards caused by cotton picking work are reduced.

Owner:SHIHEZI UNIVERSITY

A kind of toothpaste containing insoluble dietary fiber and sodium phytate and preparation method thereof

ActiveCN106691886BGood stain removal and cleaning abilityAvoid wear and tearCosmetic preparationsToilet preparationsBiotechnologyTooth wear

Insoluble dietary fiber and sodium phytate are widely applied to the field of oral care. Toothpaste containing the insoluble dietary fiber and sodium phytate, provided by the invention, has remarkable stain-removing and cleaning capability and has obviously better effect than that of toothpaste singly added with the insoluble dietary fiber or the sodium phytate; under a certain condition, the toothpaste containing the insoluble dietary fiber and sodium phytate with the mass ratio of 8:2 has the best stain-removing and cleaning capability, can avoid tooth abrasion caused by adoption of high-friction raw materials and enables the product to be safer and more reliable. Therefore, the toothpaste containing the insoluble dietary fiber and sodium phytate has good application prospect in the field of oral care articles.

Owner:HANGZHOU JIAOJIE ORAL HEALTH CARE PRODS

Garbage shredder

The invention discloses a garbage tearing crushing machine comprising a crushing box body, wherein the crushing box body is internally provided with at least one pair of mutually-paired tearing rollers; tearing cutterheads are fixedly arranged on each tearing roller at intervals; each of the tearing cutterheads of the mutually-paired tearing rollers is provided with a tearing cutter tooth inserted to a gap between the tearing cutterheads of the opposite tearing rollers; a blanking gap for avoiding shear force generation is arranged between each tearing cutter tooth and the side wall of the gap between the tearing cutterheads of the opposite tearing rollers; and when the garbage tearing crushing machine works, hard matters such as little silt and pebbles are discharged through the blanking gaps, and hard matters such as large stones as well as cloth, plastics and the like are also discharged through the blanking gaps after being continuously gnawed, beaten, torn and crushed by the tearing tool teeth, so that the abrasion of shearing blades is greatly reduced. Garbage is crushed through tearing, beating and gnawing, so that tearing tool tooth abrasion caused by shearing is avoided; and experiments prove that the maintenance-free time of the crushing machine in continuous working can belonger than one year, and the technical effect is extremely remarkable.

Owner:潍坊金丝达环境工程股份有限公司

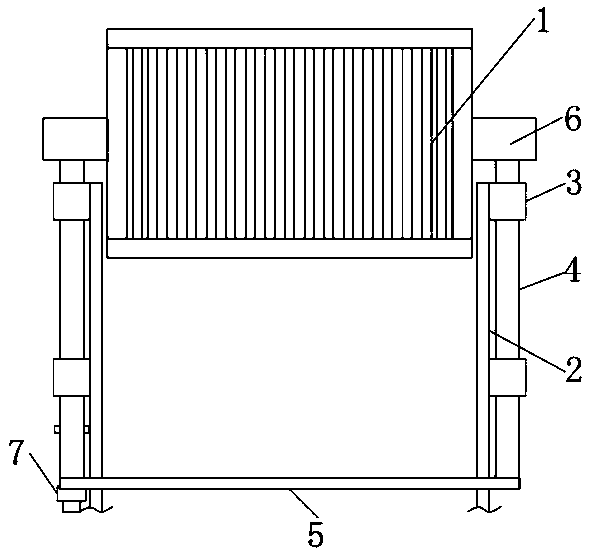

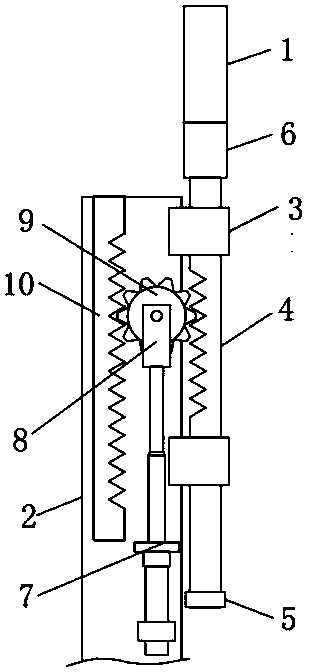

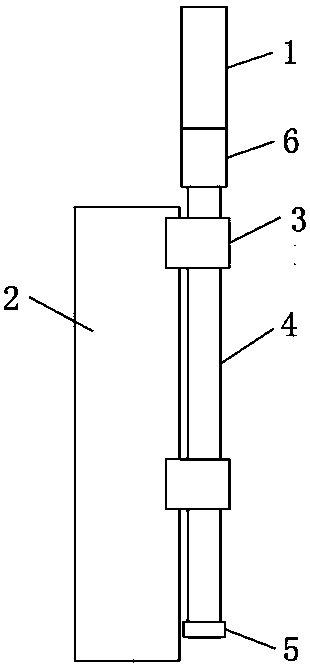

Warp dividing reed applied to warping machine

InactiveCN110607587AExtended service lifeAvoid long-term frictionOther manufacturing equipments/toolsTextiles and paperYarnPulp and paper industry

The invention relates to the technical field of warping machines, in particular to a warping dividing reed applied to a warping machine. The problem of reed tooth abrasion caused by long-term frictionbetween warp yarns and reed teeth of a warping reed main body is solved. The warp dividing reed applied to the warping machine comprises a warp dividing reed main body, mounting plates are symmetrically arranged on two sides of the warp dividing reed main body, two fixing sleeves are fixedly connected onto the mounting plates, a sliding rod penetrates through each fixing sleeve, the bottoms of the two sliding rods are fixedly connected through a connecting rod, and the two sides of the warp dividing reed main body are fixedly connected with the tops of the two sliding rods through connectingblocks. Through the action of an electric push rod, a gear is driven to rotate on a rotating support, the sliding rods are driven to move up and down, and through the action of the connecting rod, thesliding rods at the two ends simultaneously slide up and down in the fixing sleeves, so that the warp dividing reed main body is driven to move up and down in a reciprocating manner, and the circumstance that reed teeth is easy to wear due to long-term friction between warp yarns and reed teeth of the warp dividing reed main body is prevented.

Owner:苏州展颂纺织有限公司

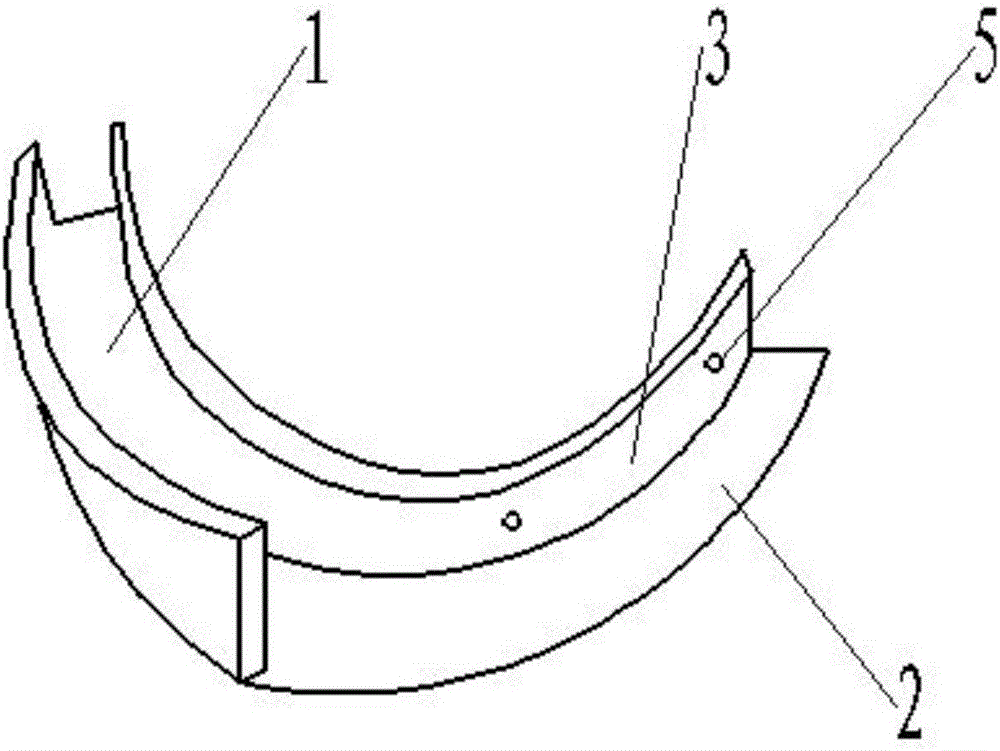

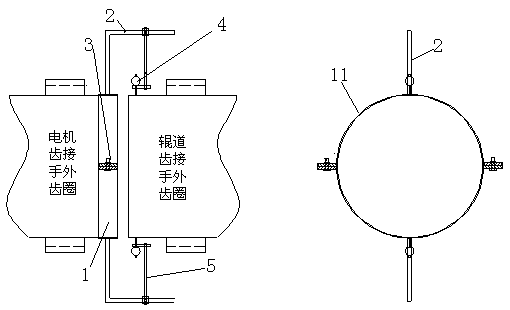

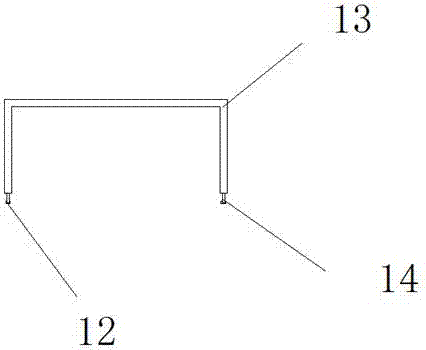

Hot rolling line tooth coupling alignment tool and using method thereof

PendingCN107695105AGuaranteed uptimeImprove surface qualityRolling equipment maintainenceMeasuring devicesFailure rateCoupling

The invention relates to the field of rolling mill maintenance, in particular to a hot rolling line tooth coupling alignment tool. The hot rolling line tooth coupling alignment tool is characterized by comprising a holding ring and brackets; the holding ring comprises two semi-circular holding arms, hinges and lock catches, and the hinges and the lock catches are used for enabling the two semi-circular holding arms to be connected; and the brackets are arranged on the holding ring and used for fixing a dial gage. Through the hot rolling line tooth coupling alignment tool, the alignment precision of the concentricity of a coupling is improved, the roller table operation stability is greatly improved, and the surface quality of a plate is obviously improved; and accordingly, coupling tooth abrasion is reduced, the tooth coupling failure rate is decreased, and the construction cost is reduced to a certain extent.

Owner:SHANGHAI BAOYE GRP CORP

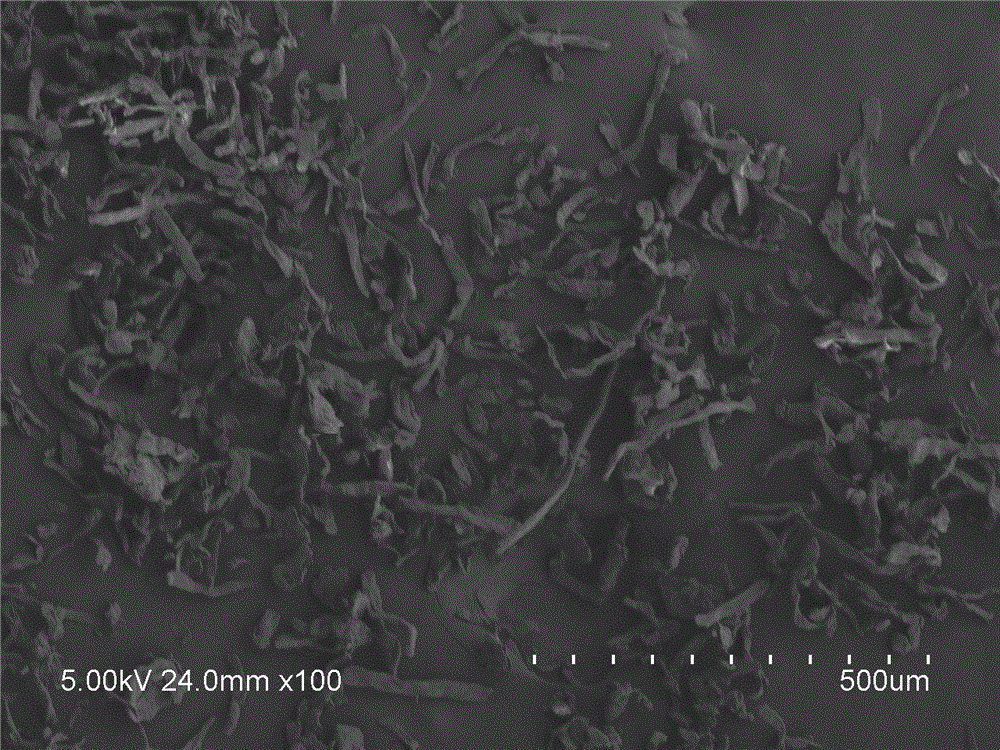

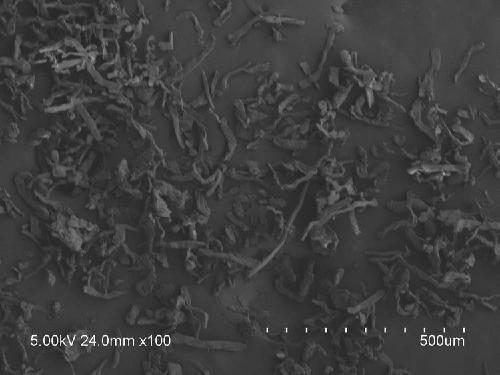

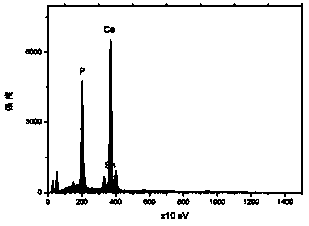

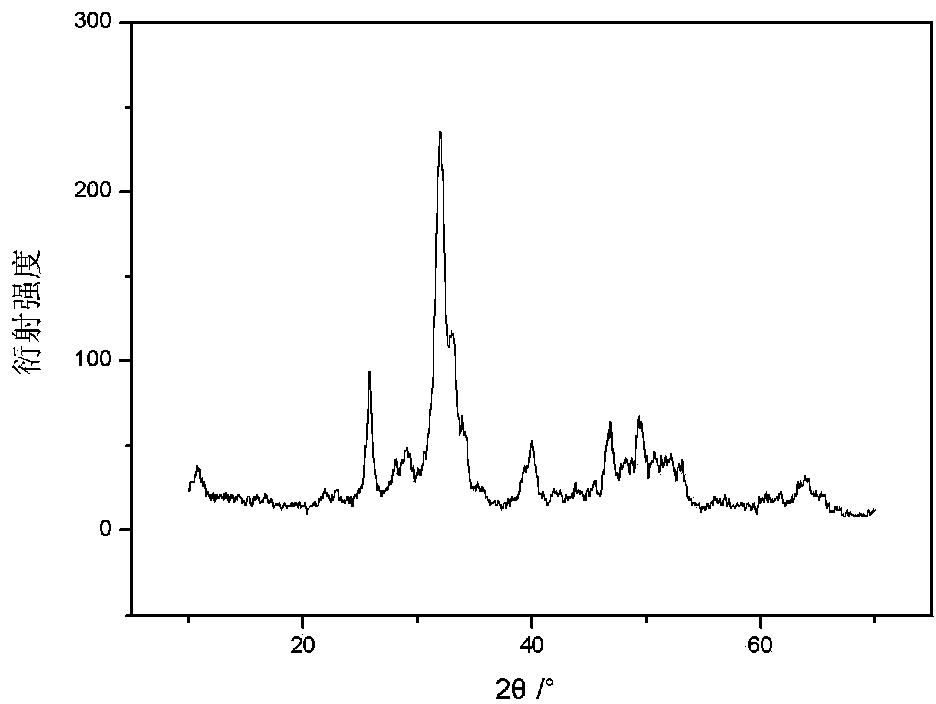

Preparation method of hydroxyapatite containing Sn(II)

The invention relates to a preparation method of hydroxyapatite containing Sn(II). The preparation method comprises the following steps of: firstly adding a solution containing Ca<2+> and Sn<2+> into a solution containing H3PO4 / H2PO<4-> / HPO4<2-> / PO4<3-> in mol ratio that (Ca+Sn) / P is equal to 10 / 6, adjusting a solution system to be alkaline, reacting for 12-48 hours at the temperature of 60-100 DEG C, and then washing to a pure phase; and carrying out suction filtering to obtain powder. A hydroxyapatite phase is observed by carrying out XRD (X-ray diffraction) on the prepared powder, particle diameter is observed to be in uniform distribution by utilizing an SEM (scanning electron microscope), granules are spherical, granular size is about 20nm, Ca<2+> is released in a dissolution process and Sn<2+> is also released, Ca<2+> can slow down a dissolution reaction on the surface of teeth, and Sn<2+> can inhibit activity of anaerobic bacteria in a mouth cavity; and hydroxyapatite powder can serve as a grinding material, has hardness similar to that of teeth, can effectively reduce tooth abrasion in a tooth brushing process and has a good characteristic of protecting mouth health.

Owner:SHAANXI UNIV OF SCI & TECH

Gear shaft with dust cover

InactiveCN107387535AReduce wearExtend your lifeShaftsGear lubrication/coolingCooling effectEngineering

The invention discloses a gear shaft with a dustproof cover, which comprises a gear shaft body, one side of the gear shaft body is provided with a gear shaft rear end shaft body, and the other side of the gear shaft body is provided with a bearing sleeve, The side of the rear end shaft body of the gear shaft close to the bearing sleeve is provided with gear teeth, and the side of the gear teeth away from the rear end shaft body of the gear shaft is provided with the middle end shaft body of the gear shaft, and the middle end shaft of the gear shaft A pinion spline is embedded in the center of the pinion body, a cross-shaped oil groove is embedded in the surface of the pinion shaft body, and a pinion front end shaft body is set on the side of the pinion shaft body away from the pinion shaft spline. The present invention is different from the pinion on the market where the ordinary oil groove is embedded on the shaft surface, but a cross-shaped oil groove is embedded on the surface of the gear shaft shaft. When oil is injected through the cross-shaped oil groove, the lubricating oil can flow along the Add lubricating oil to the gear shaft to the maximum to lubricate, cool down, reduce gear wear and prolong the life of the gear shaft.

Owner:陈九凤

A tooth guard for treating bruxism and its application

The invention discloses a tooth protector for treating bruxism. The tooth protector is used for being worn on lower teeth. The tooth protector comprises a U-shaped sleeve of which the shape is designed according to the shapes of the lower teeth in the human oral cavity, a groove is formed in the middle of the U-shaped sleeve, the inner side face of the groove is attached to the lower teeth to hinder occlusion of upper teeth and the lower teeth, one end of the groove is open, and the open side face is used for sticking a traditional Chinese medicine patch. According to the tooth protector, modeling is simple, wearing is convenient, tooth abrasion can be effectively prevented, the traditional Chinese medicine patch with the effects of soothing the nerves and regulating qi is stuck to the open end of the groove, the trouble of directly drinking traditional Chinese medicine is avoided, a patient can be helped to regulate the sleep quality and improve the mental stress state, and then bruxism symptoms are relieved; the traditional Chinese medicine patch can be replaced every day, and the tooth protector is simple, convenient to use, clean and sanitary and cannot bring the oral bacterium problem.

Owner:崔艳

An Improved Electroplating Device for Zinc Alloy Zipper

InactiveCN105755515BWon't wear outWill not depositSlide fastenersElectrodesZinc alloysElectroplating

The invention relates to an improved zinc alloy zipper electroplating device and belongs to the field of zipper electroplating devices.The improved zinc alloy zipper electroplating device comprises a plating tank, an anode device, a cathode device electrically in contact with a zipper and a zipper driving device for driving a zipper to move in the length direction of the plating tank, wherein the anode device comprises an anode plate, the anode plate is provided with a channel formed in the length direction of the anode plate, and the zipper penetrates through along the central axis of the channel.After the technical scheme is adopted, the zipper penetrates through the channel formed in the anode plate, zipper teeth on the zipper are electroplated when the zipper passes through the channel formed in the anode plate, the zipper teeth of the zipper in the channel do not produce friction with other devices in the electroplating process, and zipper tooth abrasion is not caused.The zipper located outside the channel cannot reach the deposition potential due to the fact that the current density is very small, so that a plating layer does not deposit basically.In addition, the zipper penetrates through along the central axis of the channel, the zipper teeth located in the channel are basically consistent in current density during electroplating, and it can be ensured that the plating layer is uniform during electroplating.

Owner:陈远婷

Drill buckets and rotary drilling rigs

ActiveCN103967419BImprove drilling efficiencyReduce wearConstructionsBorehole/well accessoriesMechanical engineeringTooth abrasion

The invention discloses a drilling bucket and a rotary drilling rig. The drilling bucket comprises a barrel and a base arranged at the bottom of the barrel. Drilling teeth and rotary cutting portions are arranged on the bottom face of the base. The rotary cutting portions are arranged on the base in a rotatable mode, and rotation axes are distributed in the radial direction of the barrel. The rotary cutting portions are provided with cutting teeth, and the top end of each cutting tooth is higher than that of the corresponding drilling tooth. The drilling bucket is wide in application range, and has high drilling efficiency to hard soil and decayed rocks. In addition, the drilling bucket further has the advantages that the drilling tooth abrasion degree is low, and service life is long.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Traction wheel of casing horizontal well tractor

The invention discloses a traction wheel for a casing pipe horizontal well tractor and relates to the field of wireline logging.The traction wheel comprises a body and an external gear ring, wherein the body is detachably sleeved with the external gear ring, a plurality of annular grooves are formed in teeth of the external gear ring in the axial direction of the external gear ring at intervals, the annular grooves are formed in the circumferential direction of the external gear ring and divide the external gear ring into a plurality of toothed rings, and the endpoints of tooth-tip lines of the toothed rings are located on the same arc.On one hand, the external tooth form is better matched with the inner wall of the sleeve in the circumferential direction of the sleeve, and external tooth abrasion is more uniform; on the other hand, the condition of external teeth being meshed with the inner wall of the sleeve is improved in the axial direction of the sleeve, and greater traction force can be provided compared with traditional traction wheels.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

Method for solving zero tooth abrasion of variable pitch bearing of wind generating set

ActiveCN111963392ASolve wear and tearExtended service lifeWind motor assemblyMachines/enginesButt jointEngineering

The invention discloses a method for solving zero tooth abrasion of a variable pitch bearing of a wind generating set. The method comprises the following steps that (1) a plurality of high-strength bolts are used for replacing connecting bolts with the corresponding number between the variable pitch bearing and blades in the high altitude, and then the remaining connecting bolts between the variable pitch bearing and the blades are removed; (2) the high-strength bolts are adjusted to enable the blades to move downwards; (3) two connecting plates are symmetrically installed on the blades, a lifting device is connected with the two connecting plates, and all the high-strength bolts are removed to enable the blades to be completely separated from the variable pitch bearing; (4) the variable pitch bearing is driven to rotate through a variable pitch of the wind generating set, and non-abraded teeth of the variable pitch bearing are rotated to the zero tooth position; (5) the lifting deviceand the two connecting plates are removed, and the blades and the variable pitch bearing are in butt joint; and (6) zero adjustment and debugging are conducted on the blades and the variable pitch bearing through a zero pointer. According to the method, the zero tooth abrasion problem of the variable pitch bearing is solved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

A Combined Crushing System of Coal and Rock Pre-splitting and Picks

ActiveCN106677774BEffective protectionReduce wearDriving meansCutting machinesRelative pressureRock cutting

A coal and rock pre-splitting and pick combined crushing system, including a computer electric control part set in the electric control box of the shearer, and an action set inside the shearer drum and on the shearer pick In the execution part, the computer electronic control part monitors and calculates relevant data such as pressure, flow and plunger displacement in real time through relevant sensors, controls the opening and closing of the valve in the action execution part, and makes the hydraulic system supply oil to the hydraulic impact cylinder, thereby driving the hydraulic impact pick to impact and retraction, the impact frequency, impact pressure and oil supply of the hydraulic impact pick are intelligently controlled by the electronic control part of the computer. The hydraulic impact pick can quickly provide a certain depth of impact hole in the pre-contact area before cutting the coal seam surface. In this way, a local unloading area is formed, which is combined with the fixed pick on the original drum to break the rock formation, effectively protects the pick, reduces wear of the pick, and can achieve high-efficiency cutting of coal and rock.

Owner:苏州市骞熙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com