Traction wheel of casing horizontal well tractor

A technology of horizontal wells and tractors, which is applied in the field of traction wheels, can solve the problems of decreased traction force, poor matching, and fast wear of the outer ring gear, and achieve the effect of reducing the contact area and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings.

[0033] See Figure 4 As shown, the present invention provides a traction wheel of a casing horizontal well tractor, which includes a body 1 and an outer ring gear 2.

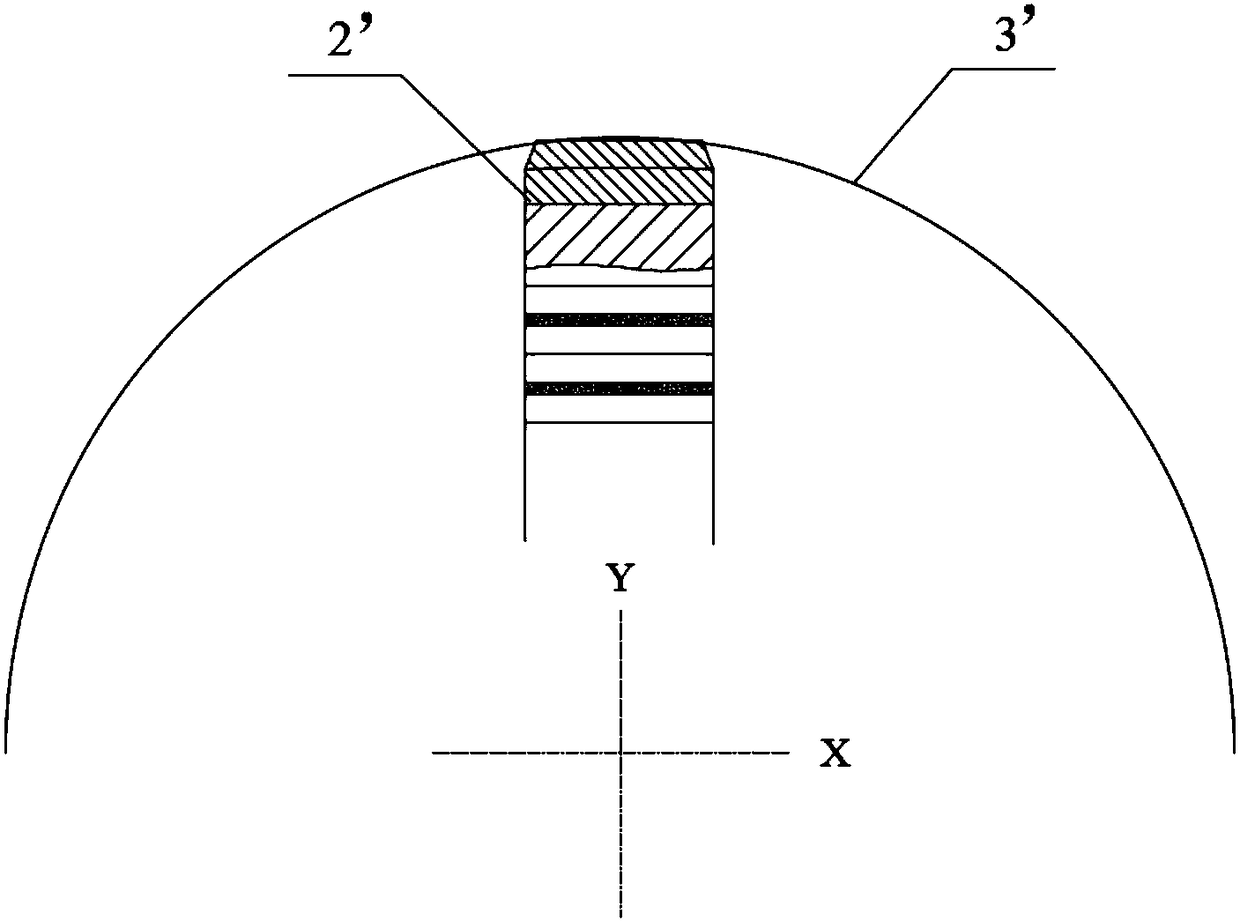

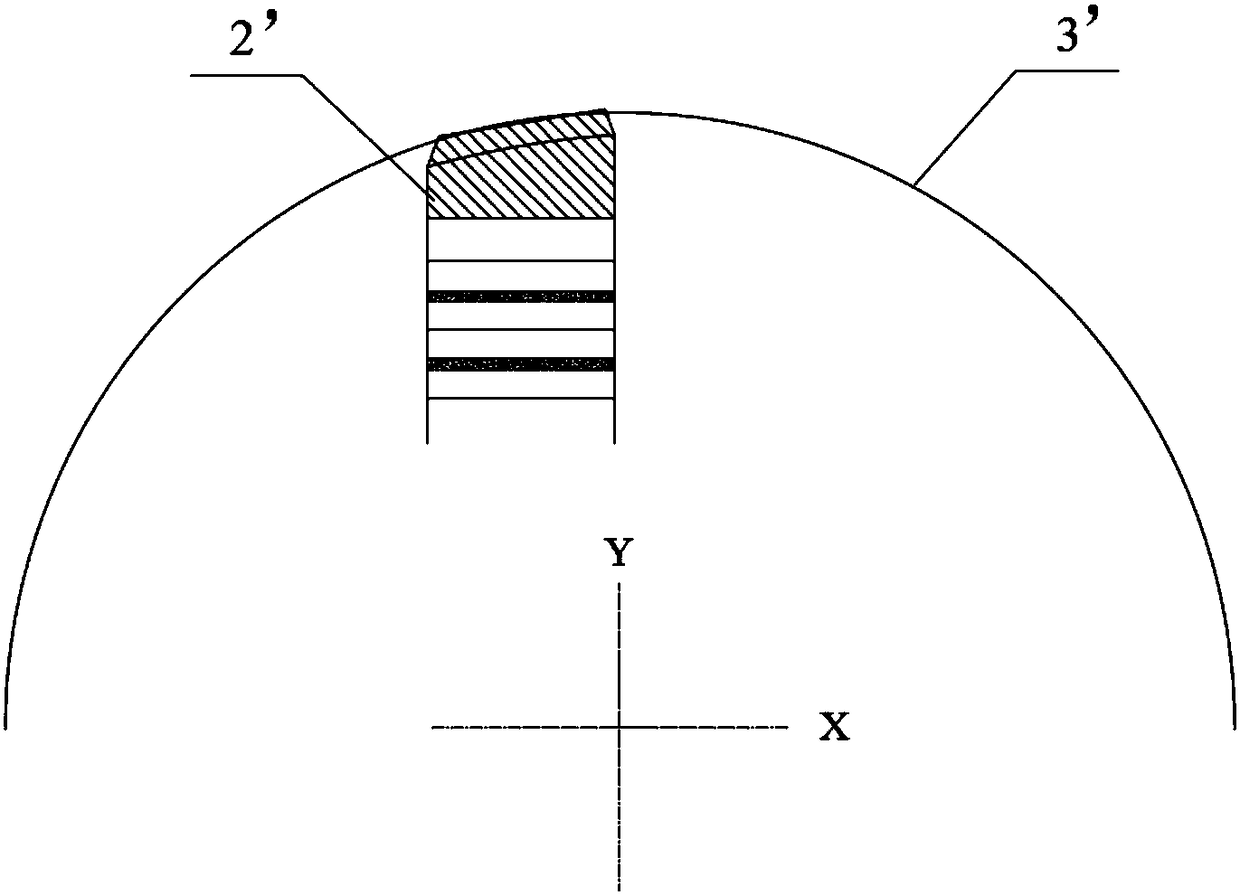

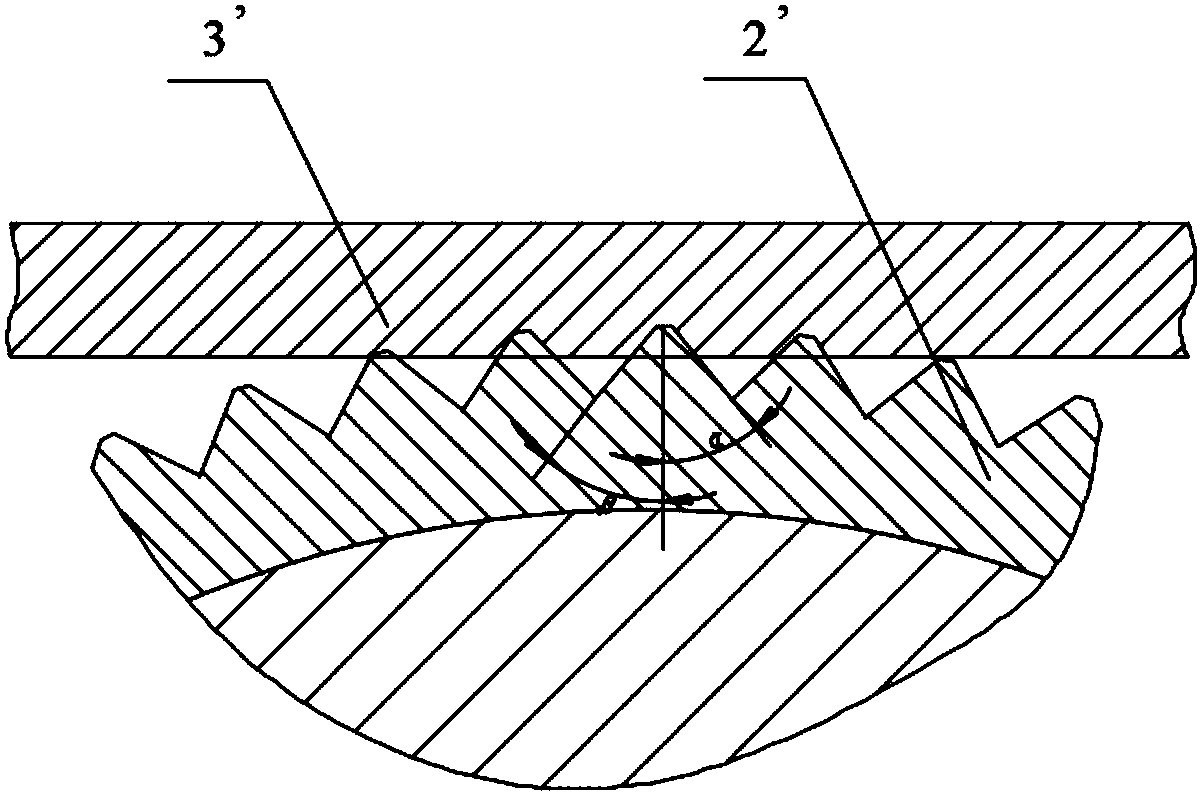

[0034] The outer gear ring 2 is detachably sleeved on the body 1. Because the outer gear ring 2 is a vulnerable part, it will be worn during use. It needs to be replaced after a period of use. It does not need to be replaced after being installed in a detachable manner. save costs. See Figure 5 As shown, the teeth of the outer gear ring 2 are provided with a plurality of mutually spaced annular grooves 21 along the axial direction of the outer gear ring 2, and the annular grooves 21 are arranged along the circumferential direction of the outer gear ring 2. 21. The outer gear ring 2 is divided into a plurality of gear rings 22, and the end points of the addendum lines of all the gear rings 22 share a circular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com