Composite-structure track shoe and forming method thereof

A technology of composite structure and track shoe, which is applied in the field of track shoe manufacturing, can solve the problems of inability to meet wear resistance requirements, low hardness and wear resistance of aluminum alloy, etc., and achieve the effect of light weight, less machining and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through the description of the drawings and specific implementation examples.

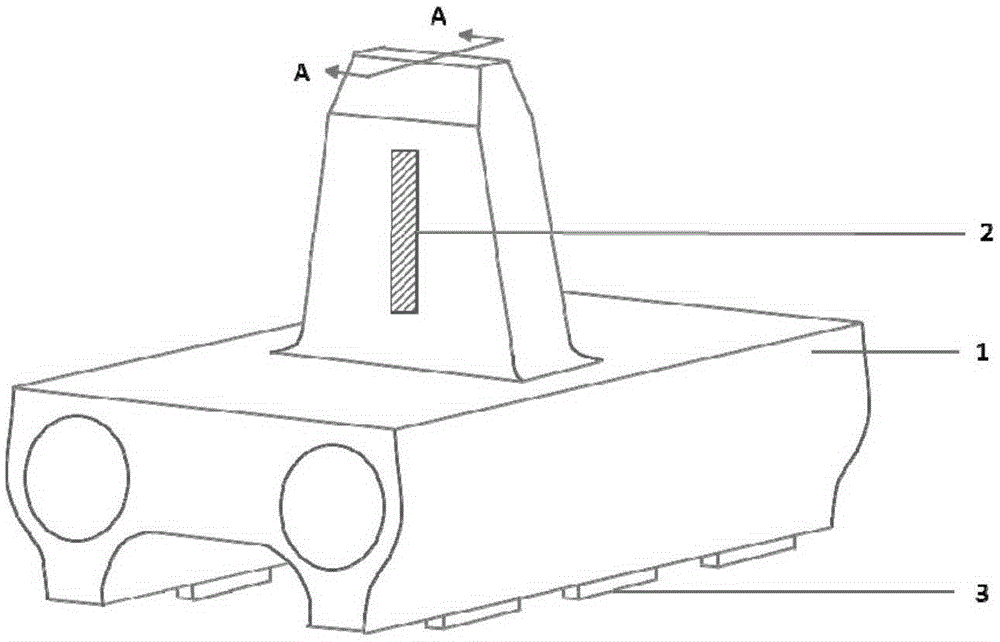

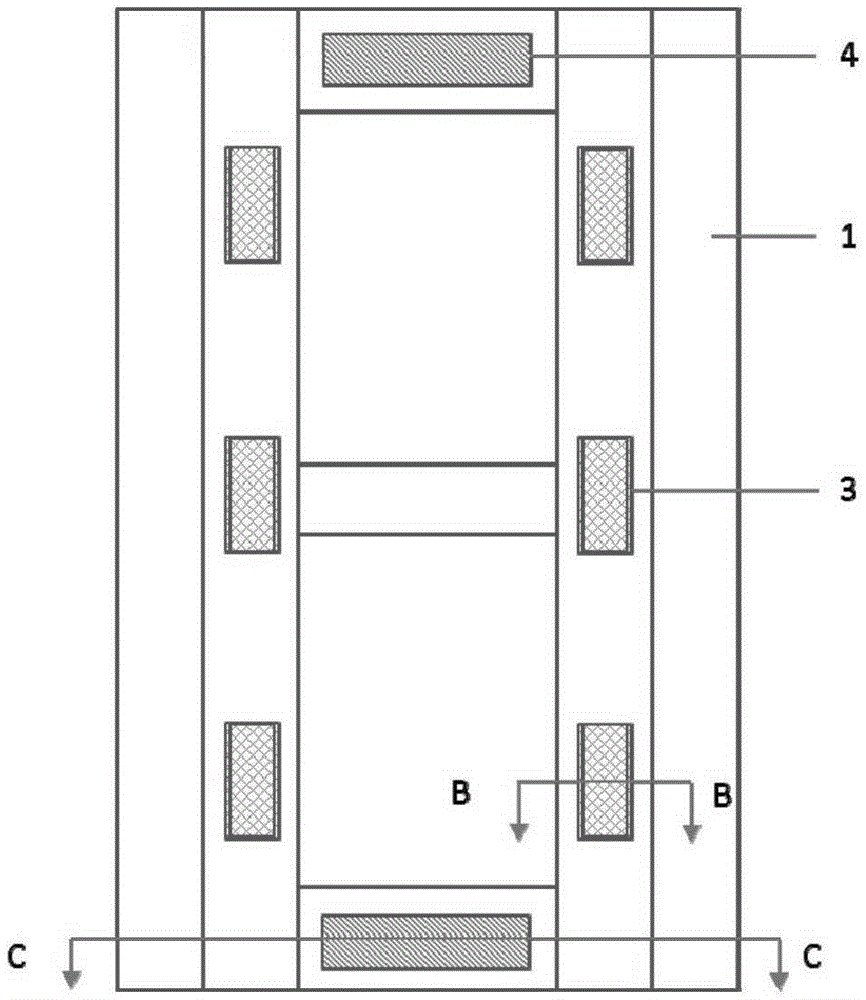

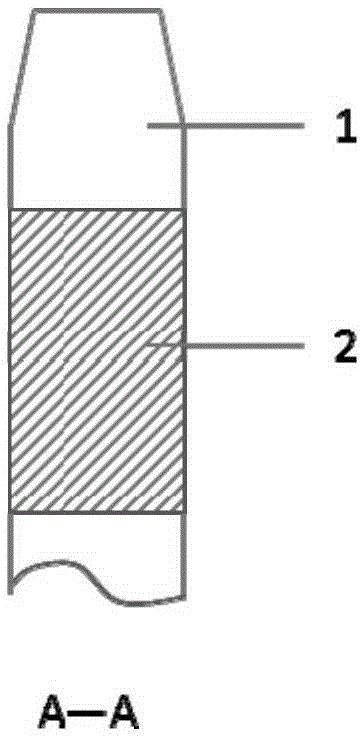

[0023] The structural schematic diagram of a kind of compound structure crawler shoe proposed by the present invention is as follows: figure 1 As shown, the induced tooth part on the upper part of the track shoe body 1 is provided with the induced tooth wear-resistant insert 2, figure 2 Schematic diagram of the bottom surface of the track shoe with a composite structure. The spur part on the ground under the track shoe body is provided with a spur wear-resistant insert 3, and the pin hole part in the middle of the track shoe body is provided with a pin hole reinforcement insert 4; image 3 Structural sectional view of the induced tooth insert of the composite track shoe, Figure 4 The cross-sectional view of the track insert struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com