Pitched cable having a flexible core around which a coil is wrapped

A helical wire and helical cable technology, applied in the field of helical cables, can solve problems such as unsuitable welding and achieve the effect of small heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

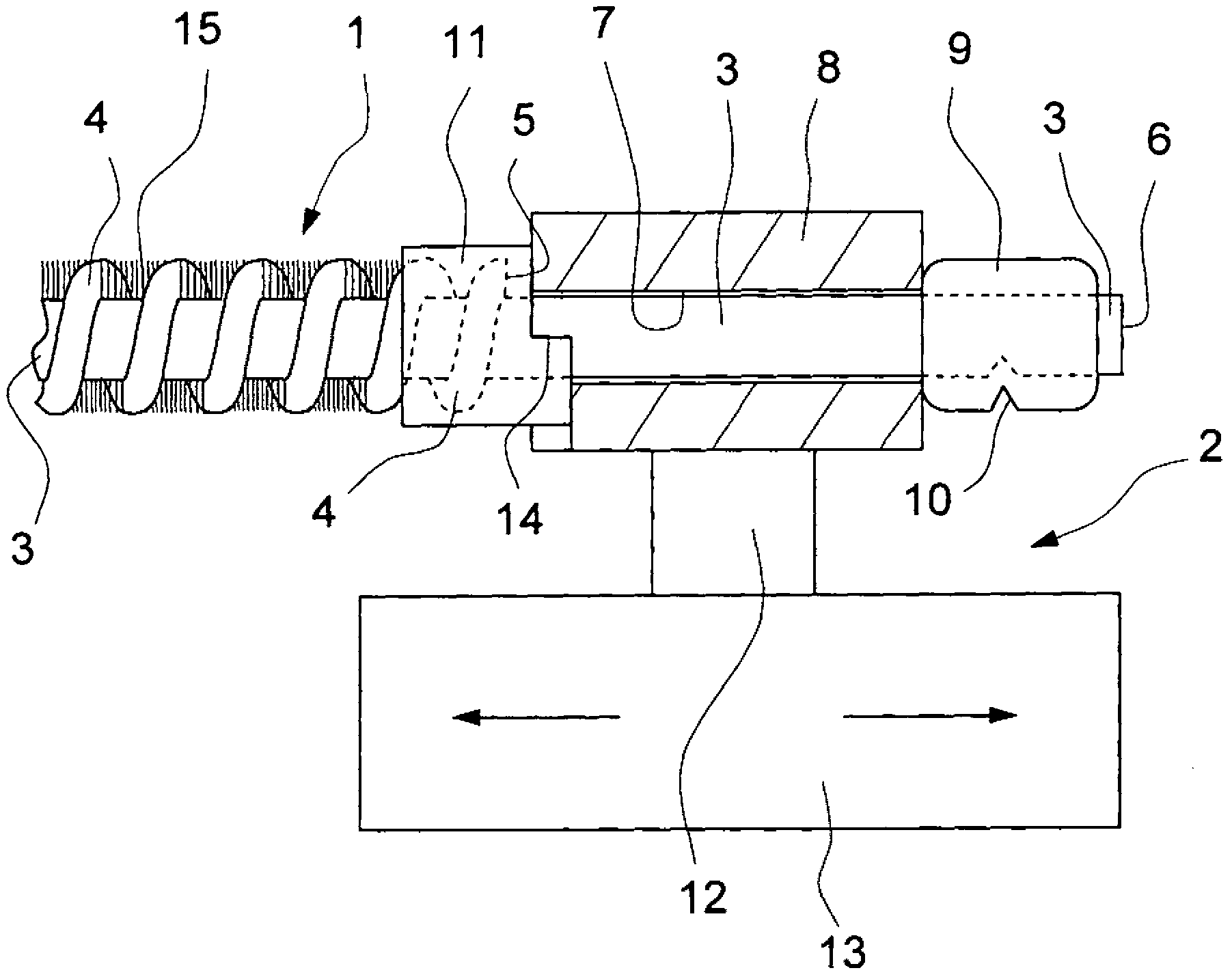

[0013] figure 1 The end region of the spiral cable 1 is shown, including the entraining body 2 fastened thereto.

[0014] The spiral cable 1 has a core 3 made of twisted wire. The core 3 is wound with a helix 4 which is wound very firmly around the core 3 and can thus absorb high forces in the axial direction of the core 3 .

[0015] The helix 4 ends at 5 , ie before the end 6 of the core 3 . The in-between end regions of the core 3 are not occupied.

[0016] This unoccupied end region of the core 3 passes through the bore 7 in the bore part 8 of the entraining body 2 . Arranged at the end of the core 3 is a stop body 9 which is fastened to the core 3 . In the exemplary embodiment shown, the stop body 9 consists of deformable metal and is fastened to the core 3 by impacting on the notches 10 . The stop body bears with one side against the end of the hole part 8 , while the other end of the hole part 8 rests against the end 5 of the helix 4 .

[0017] In order to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com