Steel-aluminum mixed structure fence car

A hybrid structure and trolley technology, applied in the lower structure, the upper structure, the upper structure of the truck, etc., can solve the problems of weak strength and rigidity, reduced bearing capacity, and high overall weight, so as to achieve light weight and ensure structural strength. , the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

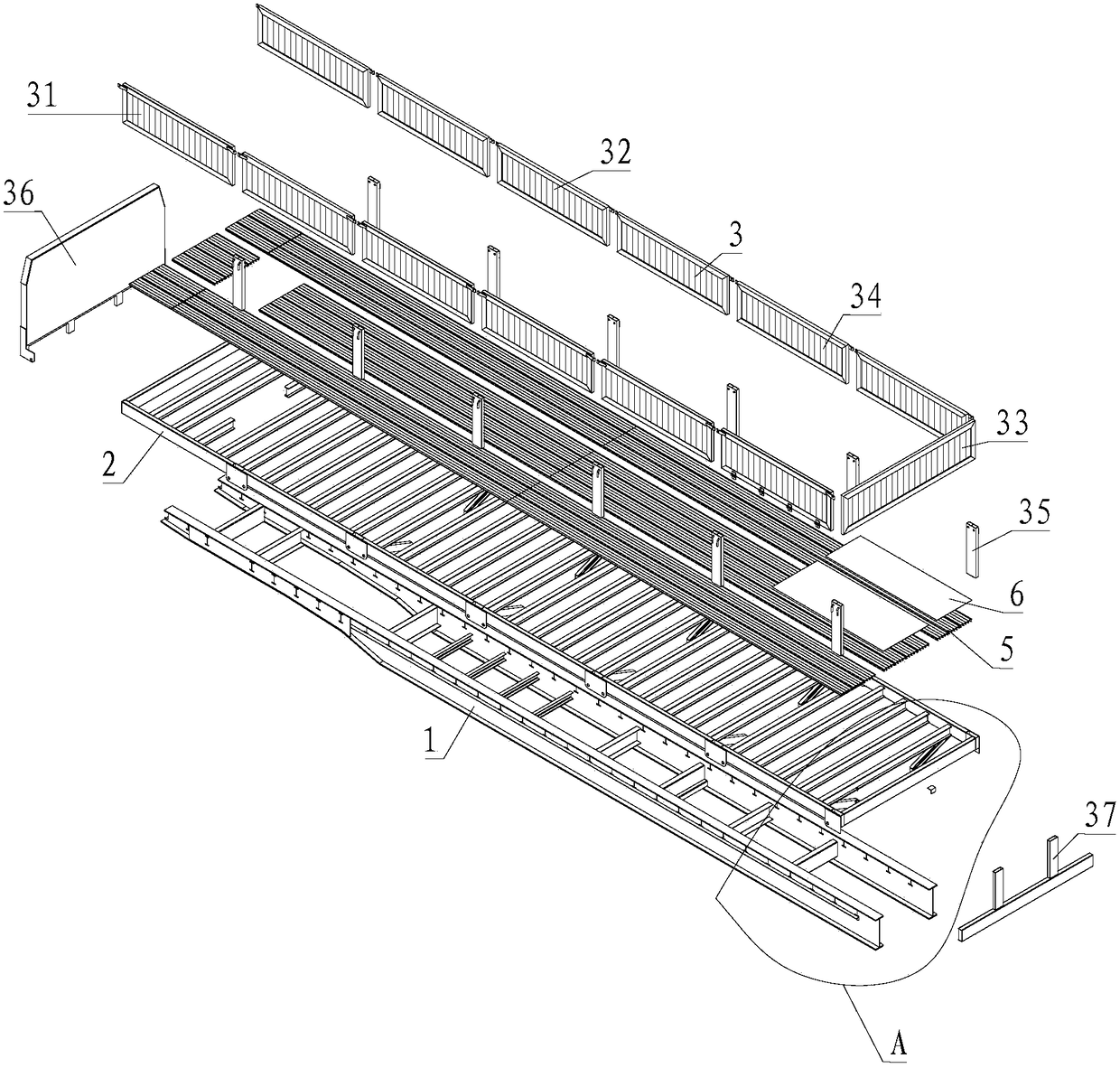

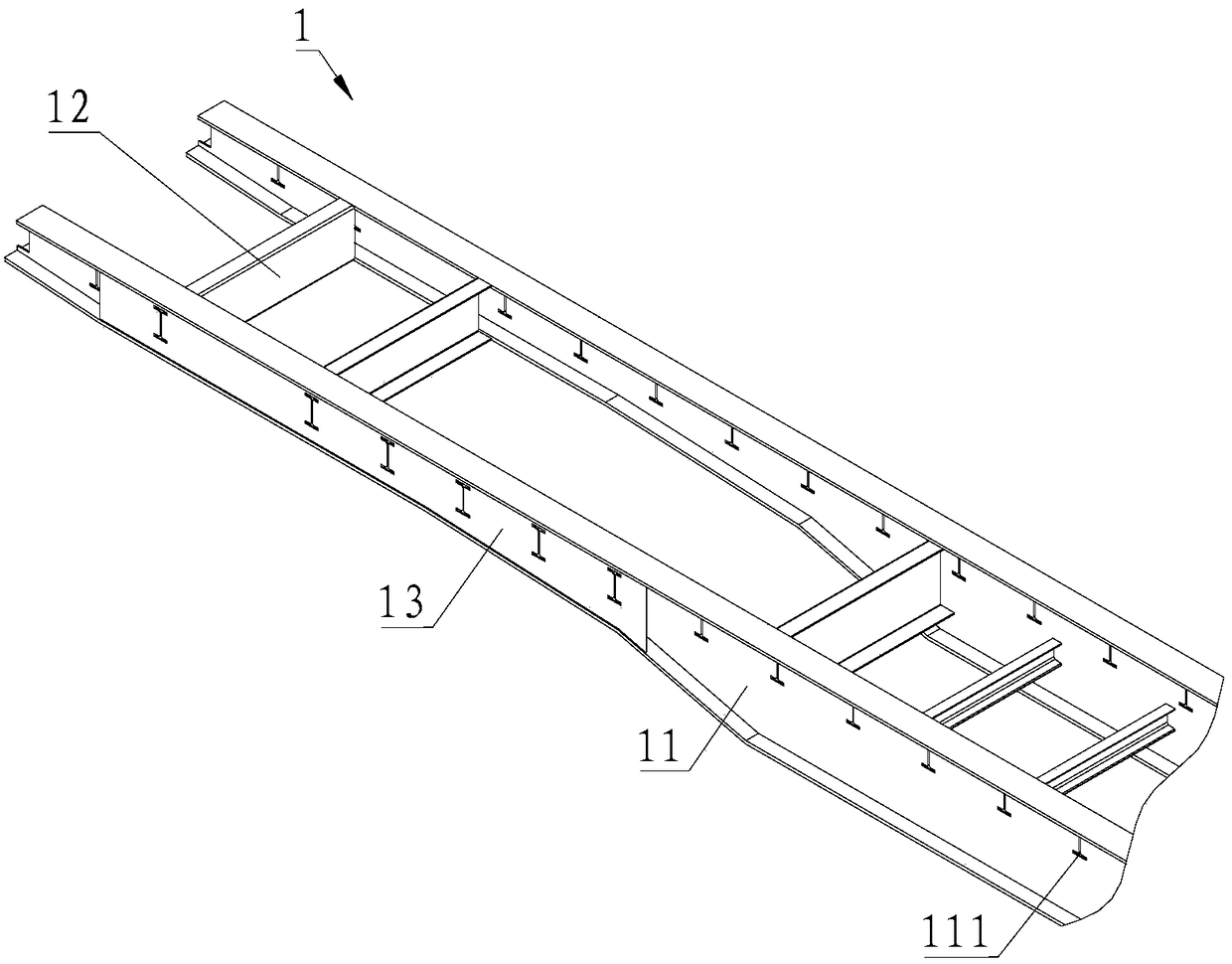

[0058] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

[0059] A steel-aluminum mixed structure curb car, comprising a main longitudinal beam underframe 1, a carriage base 2, a carriage side panel 3, and corner brackets 8, the carriage base 2 is fixed on the main longitudinal beam underframe 1, the The carriage side panel 3 is fixed on the carriage base 2, the main longitudinal beam underframe 1 is a steel structure, and the carriage base 2 and the carriage side panel 3 are aluminum structures;

[0060] The main longitudinal beam chassis 1 includes two first longitudinal beams 11 penetrating front and rear, at least two first cross beams 12, side support plates 13, and angle steels 14, and two ends of the first cross beams 12 are respectively connected to a The first longitudinal beam 11, the main longitudinal beam underframe 1 also includes, the cross-sectional shape of the first longitudinal beam 11 is I-shaped, and the side support plate ...

Embodiment 2

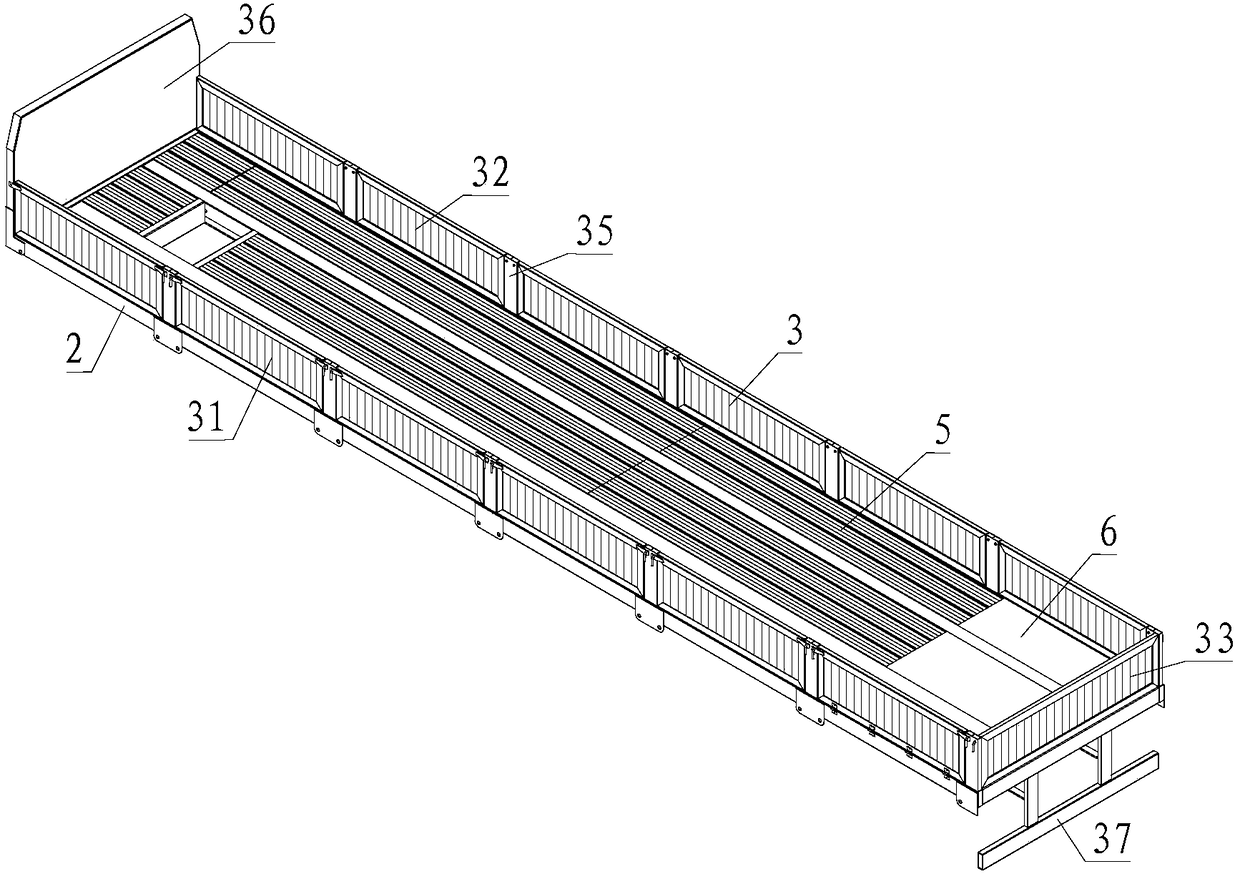

[0061] Please refer to Figure 1 to Figure 8 , the second embodiment of the present invention is:

[0062] A steel-aluminum mixed structure panel car, on the basis of the first embodiment, the side panel 3 of the vehicle box includes a left side panel 31, a right side panel 32, a rear side panel 33, a column 35, a front side panel 36, and a tail lamp holder 37. The left side panel 31, the right side panel 32 and the rear side panel 33 include at least one side panel 34, and the side panel 34 is hingedly connected with the trunk base 2; the side panel 34 includes At least two plug-in aluminum profiles 341 and frame aluminum profiles 342 located around the plug-in aluminum profiles 341, the two opposite sides of the plug-in aluminum profiles 341 are respectively provided with plug-in protrusions 3411 and plug-in grooves 3412, the insertion protrusion 3411 of the plug-in aluminum profile 341 is plugged into the plug-in groove 3412 of the adjacent plug-in aluminum profile 341, an...

Embodiment 3

[0063] Please refer to Figure 1 to Figure 11 , Embodiment three of the present invention is:

[0064] A steel-aluminum mixed-structure panel car, on the basis of Embodiment 1 or Embodiment 2, further includes a carriage floor 5 and a thin steel plate 6, the carriage floor 5 includes at least one aluminum profile plate 51, and the aluminum profile The plate 51 includes an upper end plate 511 and at least two T-shaped support frames 512 integrally connected with the lower surface of the upper end plate 511, adjacent aluminum profile plates 51 are welded and connected, and the carriage floor 5 is welded on the carriage base 2 The upper surface of the upper end plate 511 of the aluminum profile plate 51 is provided with a horizontal concave bending edge 513, and the upper surface of the horizontal concave bending edge 513 is flush with the lower surface of the upper end plate 511 The lower surface of the upper end plate 511 of the adjacent aluminum profile plate 51 is overlapped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com