Mechanical-assisted chemical heat treatment method for metal surfaces

A chemical heat treatment, mechanically assisted technology, applied in surface polishing machine tools, metal processing equipment, metal material coating processes, etc., can solve the problems of difficult to control surface roughness, poor performance, complex process, etc., and achieve maintenance and processing costs. Inexpensive, low surface roughness, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

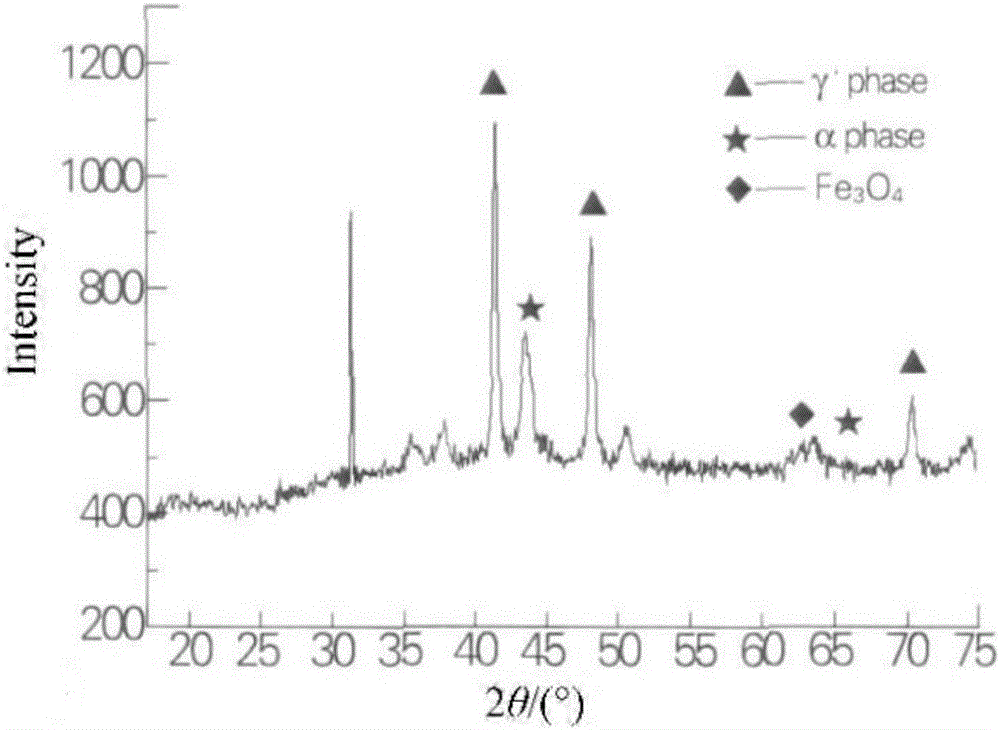

[0032] see figure 1 Shown, a metal surface mechanically assisted chemical heat treatment method, its operation steps are as follows:

[0033] Step 1. Pretreatment of the metal workpiece substrate to be treated with oxygen and nitrogen co-infiltration:

[0034] Φ100×2mm 304 stainless steel plate is used as the metal workpiece substrate for oxygen and nitrogen co-infiltration treatment, and the oil, scale and work-hardened layer on the surface of the 304 stainless steel plate are removed by sandblasting and grinding, and are ready for use;

[0035] Step 2. Electrode preparation for oxygen and nitrogen co-infiltration treatment:

[0036] Tungsten wire with a diameter of 0.2 mm and a high melting point is selected as the electrode material, and the tungsten wire is fixed on a conductive rod to make a density of 500 wires / cm 2 , Φ30mm bowl-shaped brush, ready for use;

[0037] Step 3. Oxygen and nitrogen co-infiltration treatment equipment assembly:

[0038] Connect the tapered...

Embodiment 2

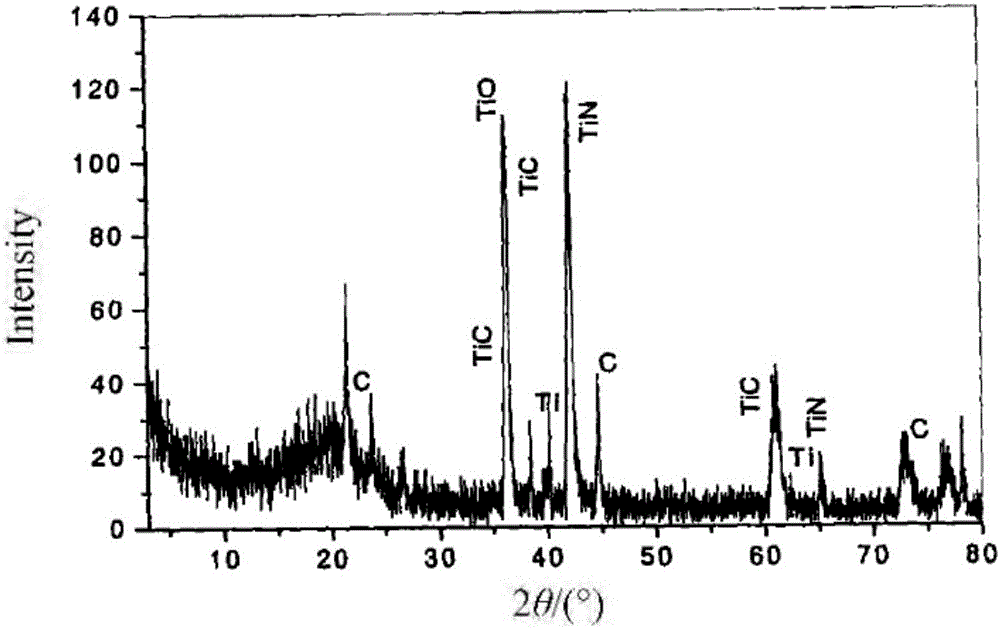

[0044] see figure 2 Shown, a metal surface mechanically assisted chemical heat treatment method, its operation steps are as follows:

[0045] Step 1. Pretreatment of the metal workpiece substrate to be treated with carbon, oxygen and nitrogen co-infiltration:

[0046] The Φ100×2mm pure titanium plate (TA1) plate is used as the carbon, oxygen, and nitrogen co-infiltrated metal workpiece substrate, and the oil, scale, and work-hardened layer on the surface of the pure titanium plate (TA1) are removed by sandblasting and grinding. use;

[0047] Step 2, carbon, oxygen, nitrogen co-infiltration treatment electrode preparation:

[0048] Tungsten wire with a diameter of 0.3 mm and a high melting point is selected as the electrode material, and the tungsten wire is fixed on a conductive rod to make a density of 100 wires / cm 2 , Φ30mm tapered brush, ready for use;

[0049] Step 3, carbon, oxygen, nitrogen co-infiltration treatment equipment assembly:

[0050] Connect the tapered ...

Embodiment 3

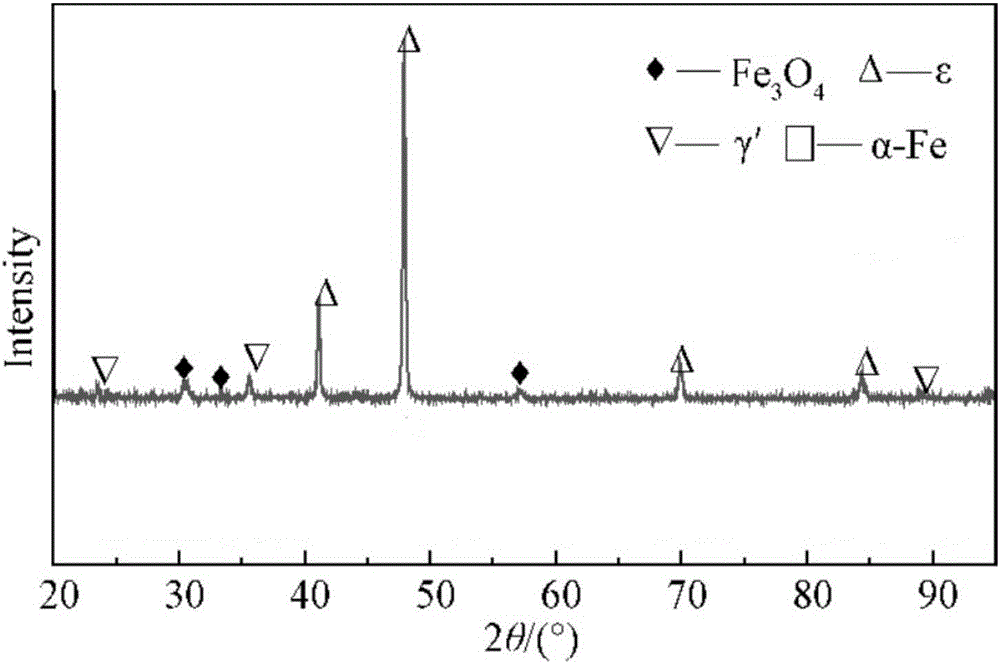

[0058] see image 3 Shown, a metal surface mechanically assisted chemical heat treatment method, its operation steps are as follows:

[0059] Step 1. Pretreatment of the substrate of the metal workpiece to be treated by one-sided oxynitriding treatment:

[0060] Use No. 45 steel plate of 100 × 20 × 2mm as the metal workpiece substrate for single-sided oxynitridation treatment, and remove the oil, scale and work-hardened layer on the surface of No. 45 steel plate by sandblasting and grinding, and set it aside for use;

[0061] Step 2. Electrode preparation for single-sided oxynitridation treatment:

[0062] Select Φ0.4mm diameter nickel wire with high melting point as the electrode material, fix the nickel wire on the conductive rod, and make it with a density of 300 wires / cm 2 , Φ100×30mm disc brush, ready for use;

[0063] Step 3. Assembly of single-sided oxynitride treatment equipment:

[0064] Connect the disc brush prepared in step 2 to the high-speed motion motor, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com