Steam iron

A steam and iron technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problem of outflow from the pressure balance system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

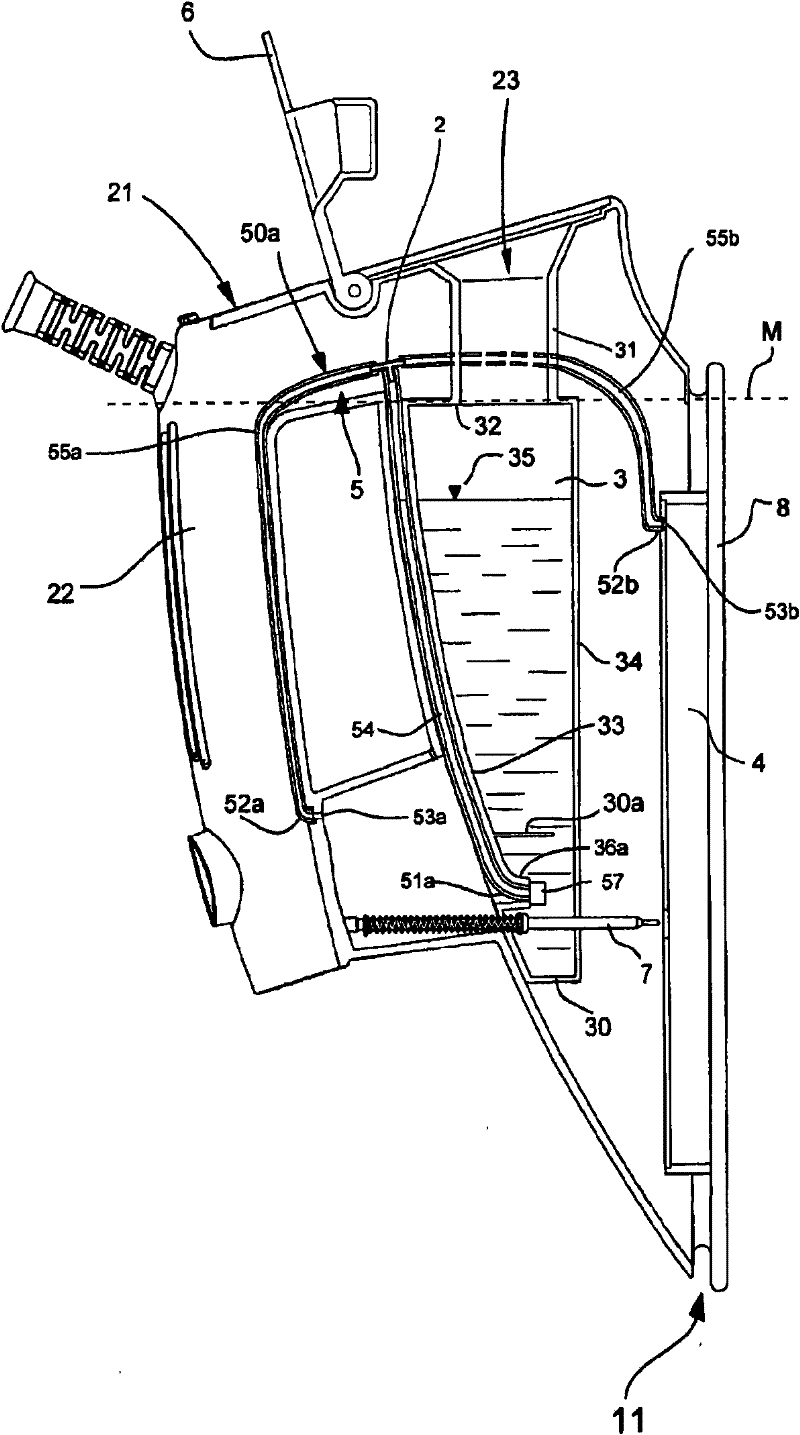

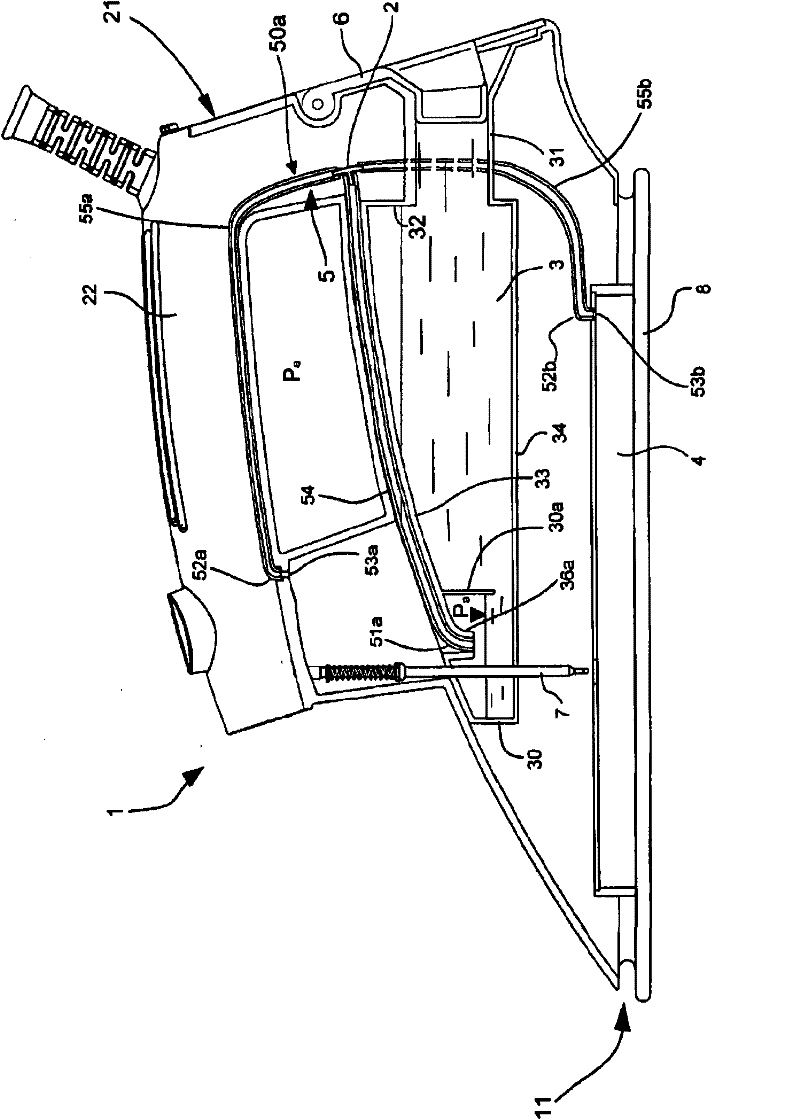

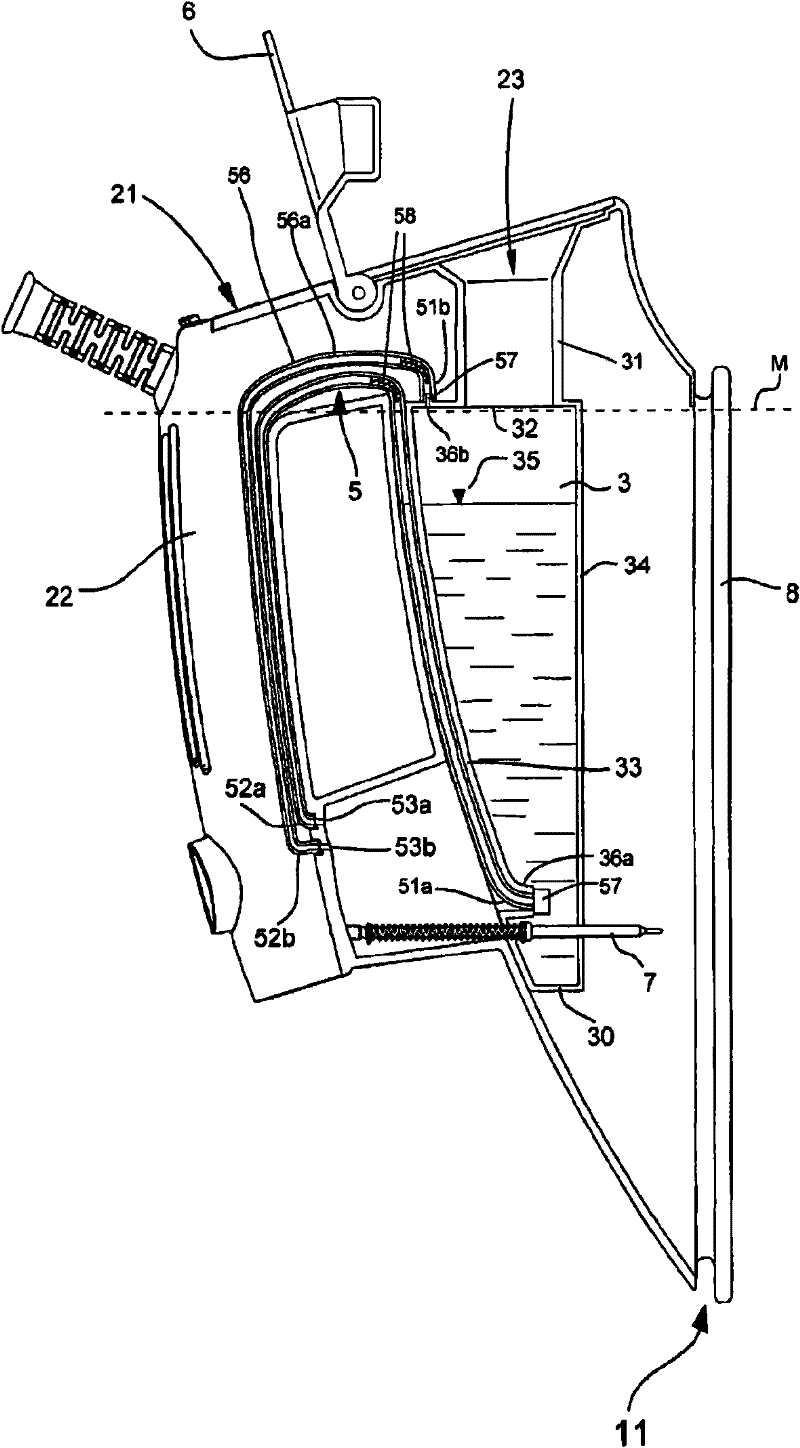

[0032] Identical or functionally identical components are provided with the same reference symbols in the figures.

[0033] exist figure 1 A cross-sectional view of a first embodiment of an iron according to the invention is shown in , which in this embodiment consists of a steam iron. Shows the state of the iron filling the iron water container. For this purpose the iron is oriented such that the front or tip 11 of the iron is oriented essentially vertically downwards.

[0034] The iron has a rear or rearward portion 21 and a handle portion 22 . Furthermore, there is a water container 3 in the iron. In the exemplary embodiment shown, the iron has in this rear part 21 a rear iron opening 23 through which the water container 3 can be filled with liquid, in particular water. For this purpose, the water container 3 is arranged in such a way that the filling opening 31 opens into the opening 23 of the iron body 2 and can be closed hermetically by means of a closure element or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com