Grinding device for mechanical machining parts

A mechanical processing and grinding technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problem of poor surface grinding quality, poor shape tolerance, grinding accuracy that cannot meet the design requirements, and poor coordination requirements. High-level problems, to achieve the effect of improving the scope of application, improving dimensional retention and grinding surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

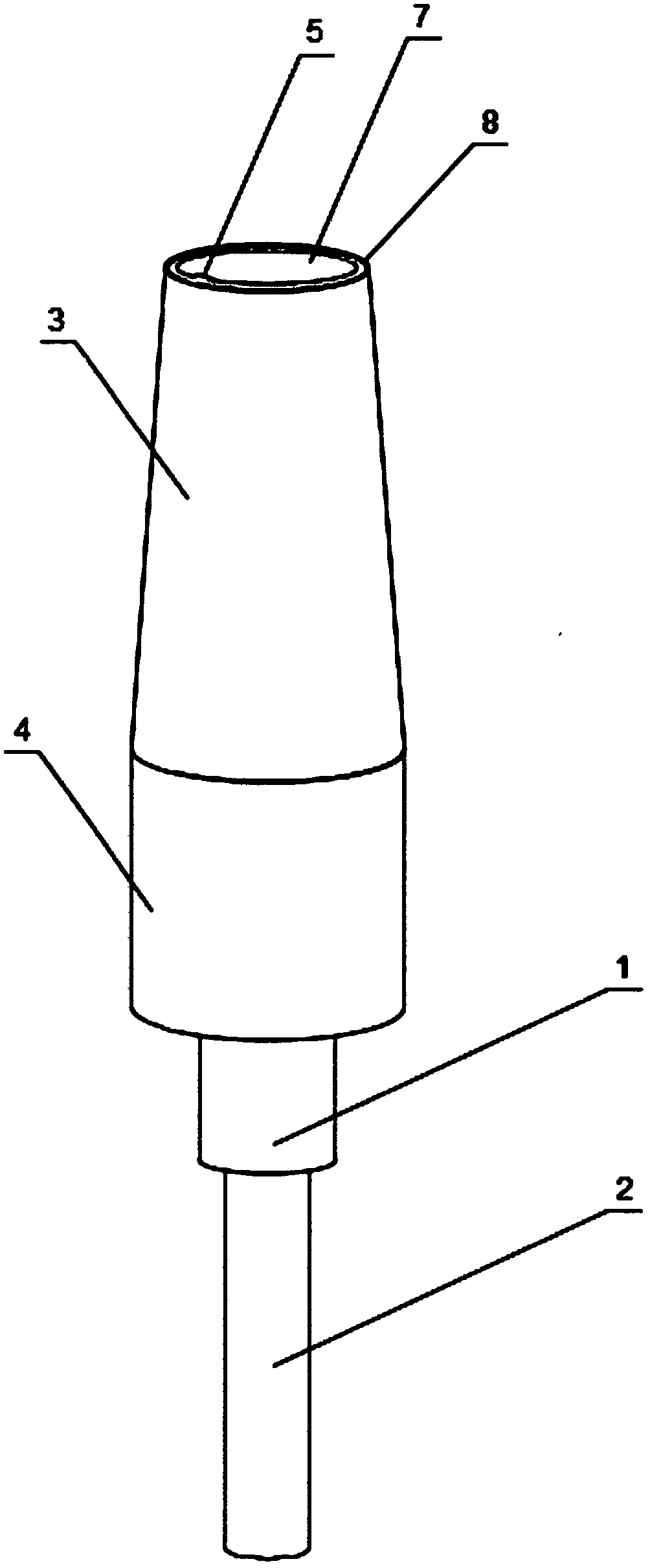

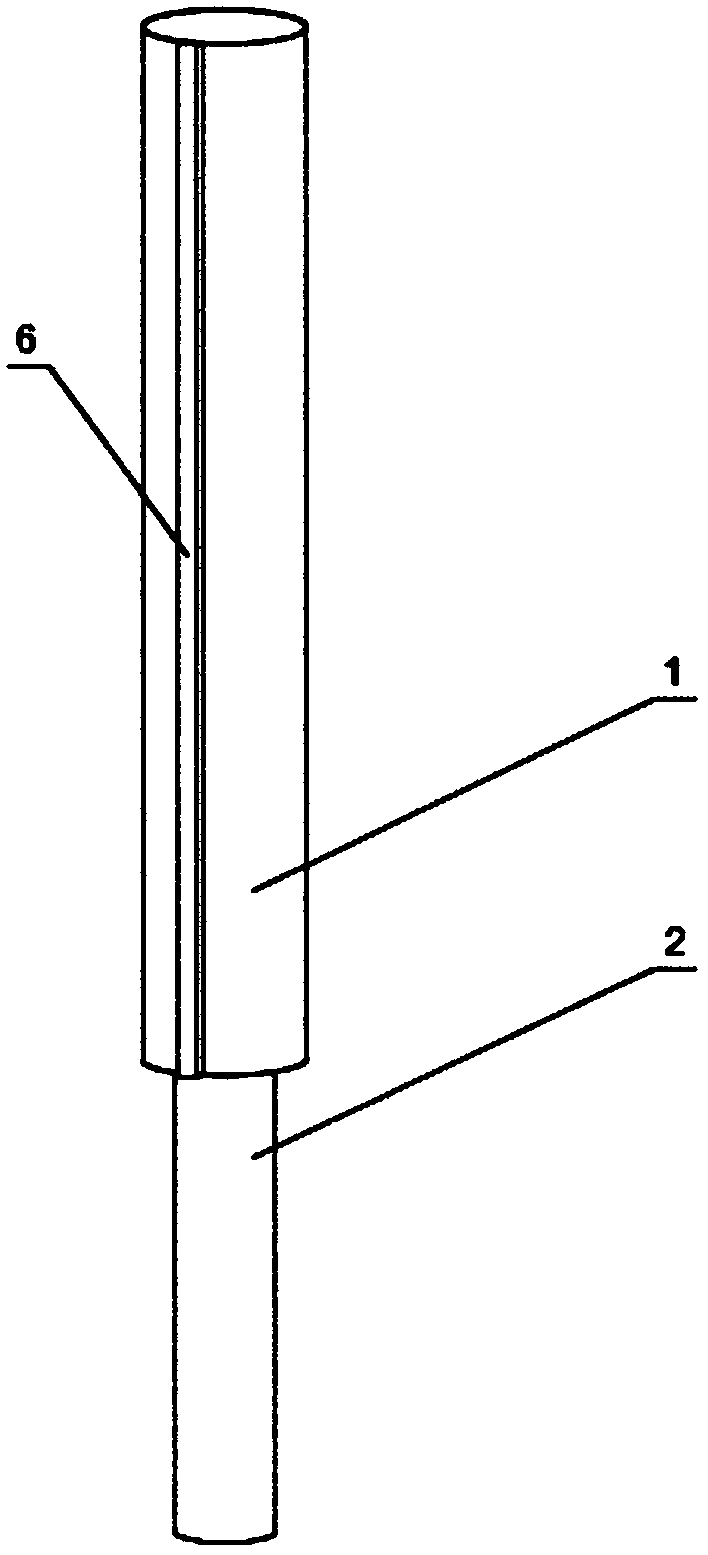

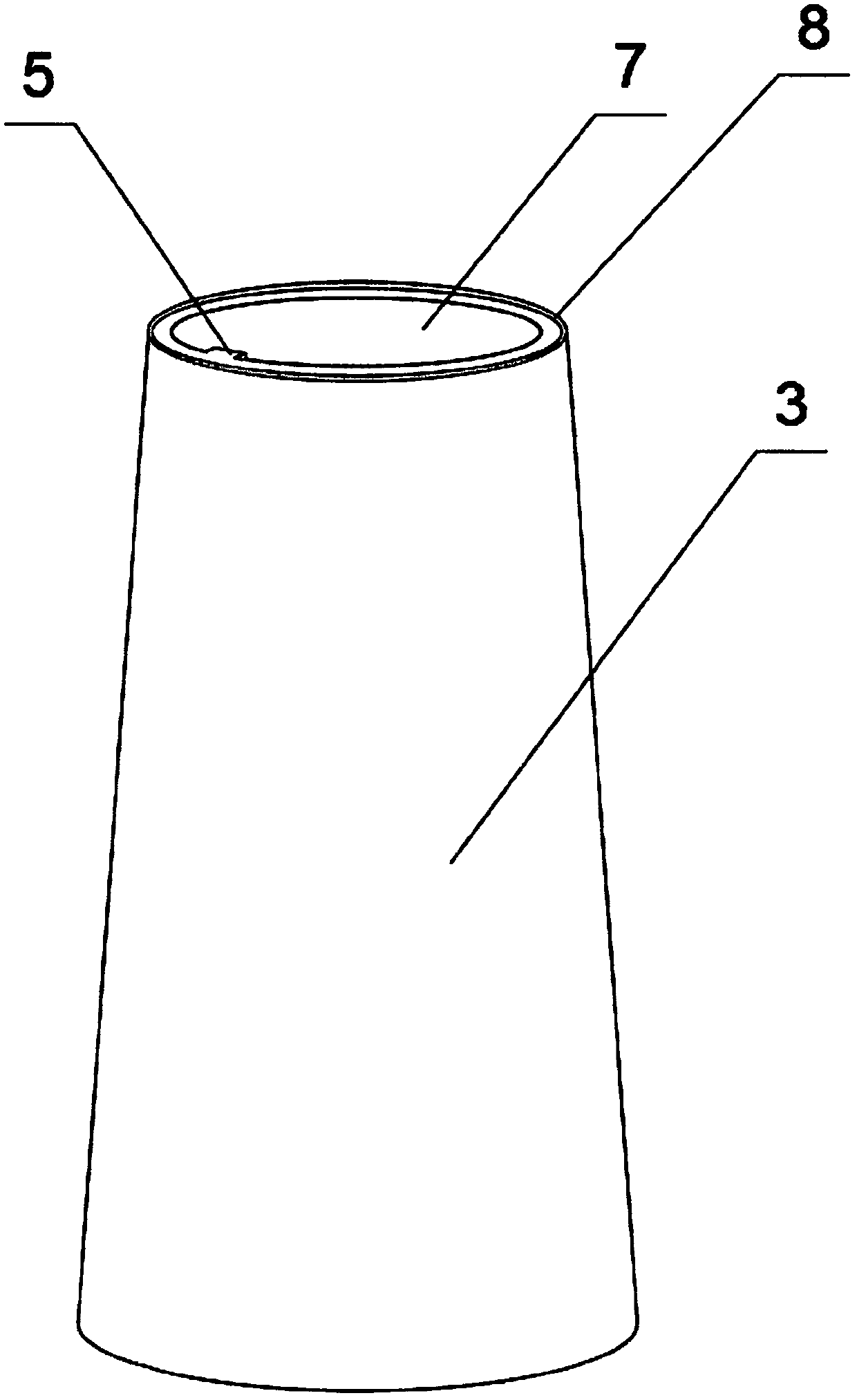

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a machined workpiece grinding device includes a tool bar 1 and a tool handle 2 connected to a machine tool. A grinding sleeve is provided on the tool bar 1. The grinding cover includes a conical grinding cover 3 and a cylindrical grinding Set 4, the conical grinding set 3 and the cylindrical grinding set 4 are coaxially arranged, the conical grinding set 3 and the cylindrical grinding set 4 are tightly connected, the conical grinding set 3 and the cylindrical grinding set The inner sides of 4 are provided with connecting key 5, and the knife bar 1 is provided with the key groove 6 that cooperates with connecting key 5. The middle part of the conical grinding sleeve 3 is a cylindrical through hole 7 with the same diameter as the cutter bar 1 . The outer sides of the conical grinding sleeve 3 and the cylindrical grinding sleeve 4 are provided with a grinding layer 8, and the grinding layer 8 is connected...

Embodiment 2

[0025] Such as Figure 5 As shown, the difference between this embodiment and the above embodiments is that the conical grinding sleeve 3 includes a plurality of sub-grinding sleeves 301 , and the sub-grinding sleeves 301 are sequentially connected to form a conical grinding sleeve 3 .

[0026] When in use, the tool handle 2 is connected with the machine tool, and the tool handle 2 drives the conical grinding sleeve 3 and the cylindrical grinding sleeve 4 to rotate, passing through the two grinding areas on the conical grinding sleeve 3 and the cylindrical grinding sleeve 4 Grinding the plunger sleeve, the outer surface of the cylindrical grinding sleeve 4 and the conical grinding sleeve 3 are closely connected, the workpiece is first ground through the conical grinding sleeve 3, and then through the cylindrical grinding sleeve 4 Carry out precision grinding, through two combined grinding methods, the shape and surface quality of the plunger bushing can meet high-quality requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com