Aluminum alloy heavy heat treatment method

A heat treatment method and technology for large forgings, applied in the field of aluminum alloy forging, can solve the problems of high heat treatment cost, low utilization rate of heat treatment furnace, no large well-type electric furnace, etc., and achieve the effect of low processing and manufacturing cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example one:

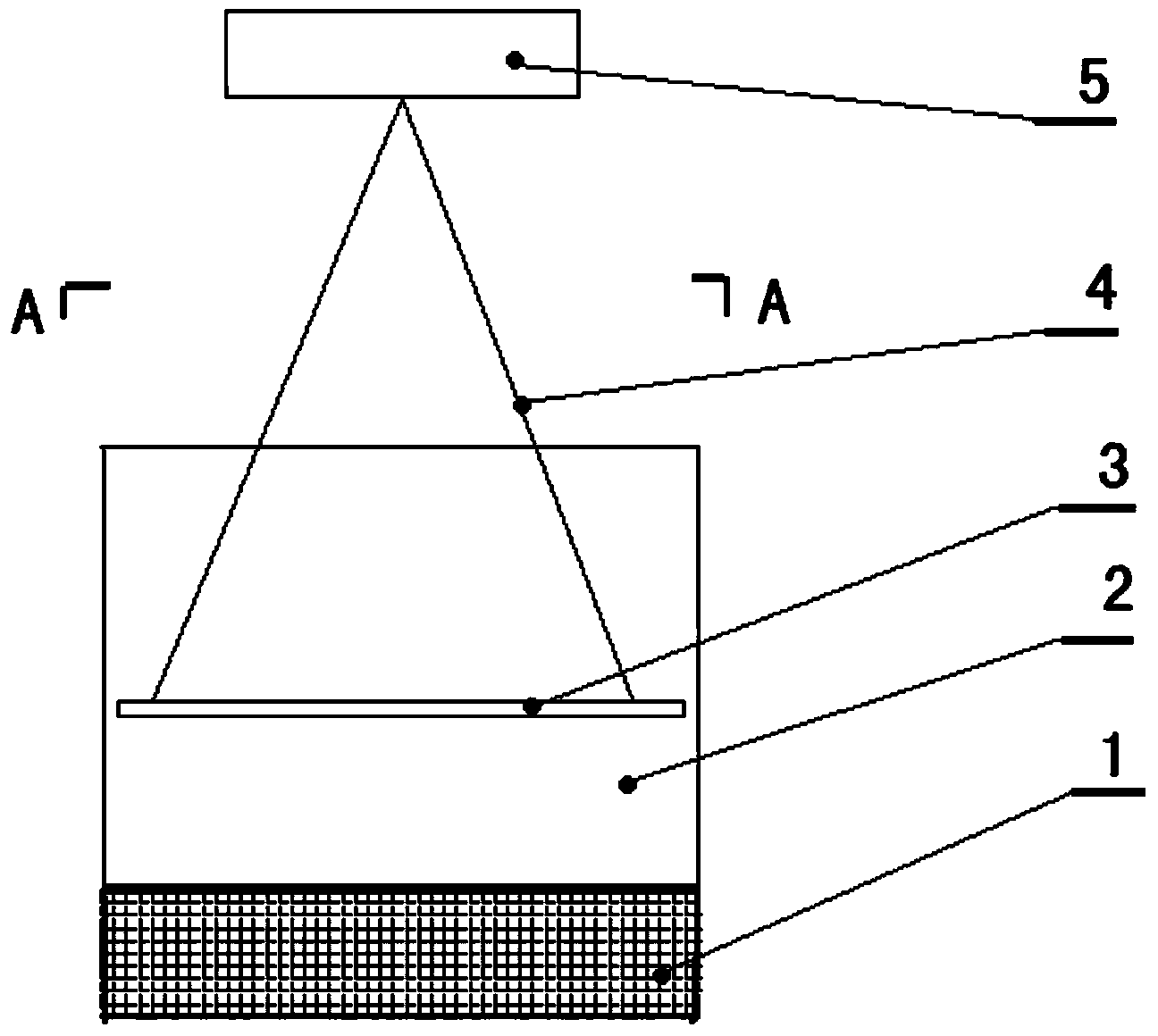

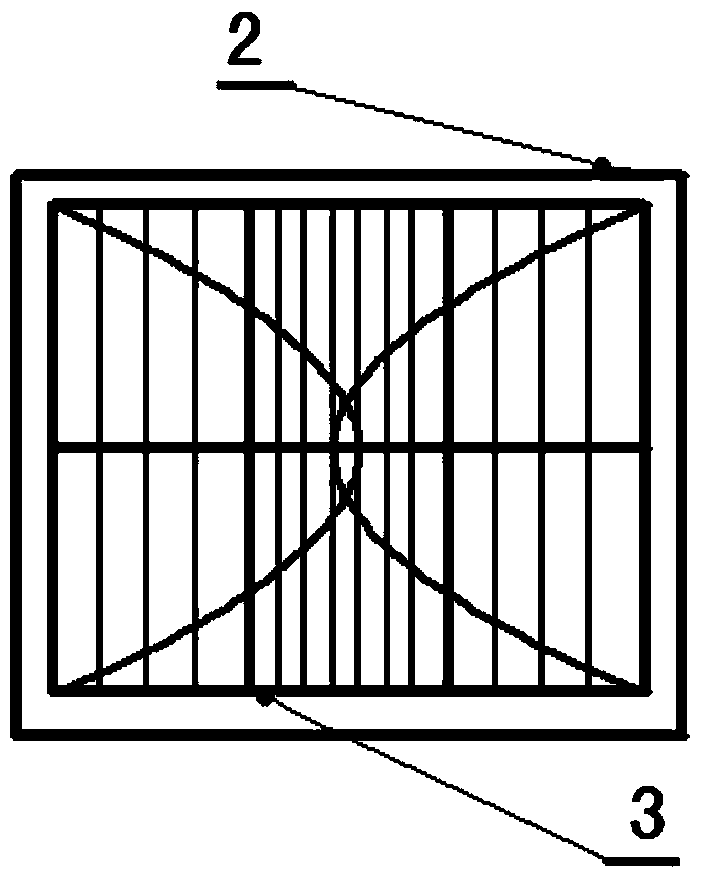

[0020] Such as figure 1 , figure 2 As shown, a heat treatment method for aluminum alloy large forgings is to first manufacture and process heat treatment heating devices, which are mainly composed of an open box body 2 and a shelf 3. The open box body 2 has a bottom and surrounding seal and an open top structure The open box 2 is set on the trolley of the trolley-type resistance furnace 1, and then the aluminum alloy forgings that need heat treatment are placed on the shelf 3. During the solution heat treatment, the open box The temperature in the body 2 rises to the heat preservation temperature, and then the shelf 3 and the forgings are put into the open box body 2 and heated to increase the temperature. After the solution heat preservation is completed, the shelf 3 is lifted out of the open box body 2. Carry out the next heat treatment process such as water cooling, air cooling, etc. If the forging needs to be aging, the temperature in the open box 2 is ...

Example Embodiment

[0024] Embodiment two:

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: A heat treatment method for frame forgings made of 2A14 (LD10). The forging dimensions are φ3010 mm×φ2725 mm×130mm. The heat treatment heating device described in Example 1 is used. The heat treatment process is solid solution plus cold deformation plus aging treatment (see image 3 ),Specifically:

[0026] Heating up: Use program control or manual control to heat up the open box 2 to the solid solution insulation temperature of the forging to 500℃. After the insulation temperature is stable, put the shelf 3 and the forging into the open box 2 and set The temperature of the car-type resistance furnace 1 is set to the lower limit of the holding temperature of 495°C, and the temperature is raised by program control or manual control. After the temperature rises to 495°C, the temperature is kept stable for a certain period of time and then rises to 500°C.

[0027] Heat preservation: heat preserva...

Example Embodiment

[0034] Embodiment three:

[0035] Such as figure 1 , figure 2 , Figure 5 , Image 6 Shown: a heat treatment method for ring-shaped forgings made of LY19, with dimensions of Φ1500mm×Φ1200mm×510mm, using the heat treatment heating device described in Example 1, and the heat treatment process is solid solution plus cold deformation plus aging treatment (see Figure 5 ),Specifically:

[0036] Heating up: Use program control or manual control to raise the temperature in the open box body 2 to the solid solution heat preservation temperature of the forging at 535℃. After the heat preservation temperature is stable, put the shelf 3 and the forging into the open box body 2 and set The temperature of the car-type resistance furnace 1 is set to the lower limit of the holding temperature of 530°C, and the temperature is raised by program control or manual control. After the temperature rises to 530°C, the temperature is kept stable for a certain period of time and then rises to 535°C.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com