Large-diameter steel ball hard-turning method

A processing method and large-diameter technology, applied in the field of steel ball processing, can solve the problems of low precision, high cost, grinding burns, etc., and achieve high processing efficiency, reduce processing costs, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

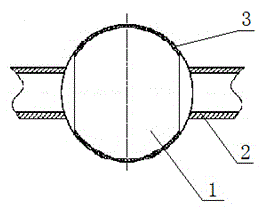

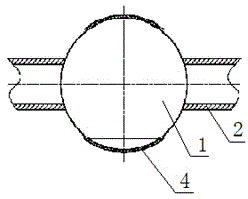

[0012] like figure 1 , figure 2 As shown, the precision CNC lathe is used for turning in two directions. The spherical error and roundness tolerance are easy to control and do not require repeated grinding, which solves the dual problems of uncontrollable quality and low efficiency; use double hollow fixtures to limit all degrees of freedom and repeat positioning. High precision, the hollow fixture is self-carrying on the machine tool, the clamping error is extremely small and negligible, the spherical error and roundness of the processed steel ball are within 0.02mm, which lays a good foundation for the subsequent grinding and solves the problem of long-term grinding Grinding burns, grinding wheel chipping, and vibration of machine tools caused by out-of-roundness and uneven allowance.

[0013] After process verification, it not only easily meets the accuracy requirements of this process, but also solves the problems of low rough grinding efficiency, high cost, uneven reten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com