High-performance colloid for aluminum-based copper-clad plate and preparation method of high-performance colloid

An aluminum-based copper clad laminate, high-performance technology, used in adhesives, epoxy resin adhesives, polymer adhesive additives, etc. The problem of high raw materials and production costs, to achieve the effect of simple processing and production technology, high thermal coefficient improvement, low raw materials and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

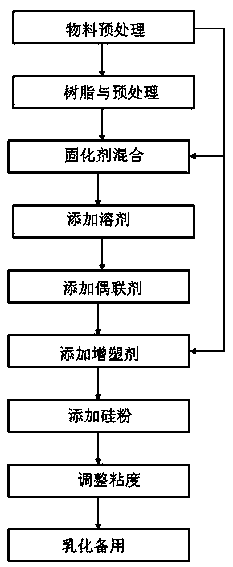

Image

Examples

Embodiment 1

[0027] A high-performance colloid for aluminum-based copper-clad laminates is composed of the following substances in mass percentage: 25% resin matrix, 11% curing agent, 16% plasticizer, 1.4% coupling agent, 47% filler, and the balance is organic solvent.

[0028] In this embodiment, the resin matrix includes acrylic resin and epoxy resin, and the acrylic resin and epoxy resin are mixed in a ratio of 1:4.

[0029] In this embodiment, the curing agent is Moka.

[0030] In this embodiment, the plasticizer is polyvinyl alcohol.

[0031] In this embodiment, the coupling agent is KH560.

[0032] In this embodiment, the filler is composite silica powder.

[0033] In this embodiment, the organic solvent is dimethylformamide.

[0034] A method for preparing high-performance colloid for aluminum-based copper-clad laminates, comprising the following steps:

[0035] The first step is material pretreatment. First, the organic solvent is divided into two parts according to the amount ...

Embodiment 2

[0047]A high-performance colloid for aluminum-based copper-clad laminates, which is composed of the following substances in mass percentage: 30% of resin matrix, 15% of curing agent, 21% of plasticizer, 1.8% of coupling agent, 50% of filler, and the balance is organic solvent.

[0048] In this embodiment, the resin matrix includes acrylic resin and epoxy resin, and the acrylic resin and epoxy resin are mixed at a ratio of 1:5.

[0049] In this embodiment, the curing agent is bisamide.

[0050] In this embodiment, the plasticizer is carboxybutyraldehyde.

[0051] In this embodiment, the coupling agent is KH560.

[0052] In this embodiment, the filler is composite silica powder.

[0053] In this embodiment, the organic solvent is a mixture of dimethylformamide and acetone, wherein the total amount of acetone is 1% of the total amount of dimethylformamide.

[0054] A method for preparing high-performance colloid for aluminum-based copper-clad laminates, comprising the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com