Pressure exchanger energy recovery cylinder

A technology for exchanging energy and recovering cylinders, which is used in fluid pressure actuation devices, fluid pressure actuation system components, seawater treatment, etc. Coaxiality requirements, unfavorable maintenance and adjustment, etc., achieve the effect of low manufacturing cost, low processing cost and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

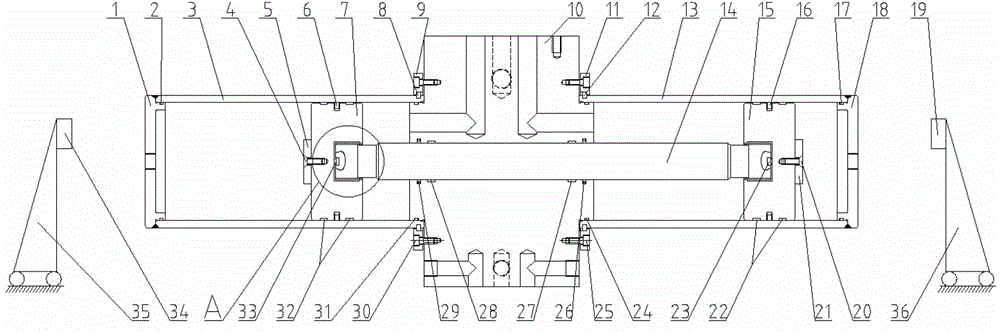

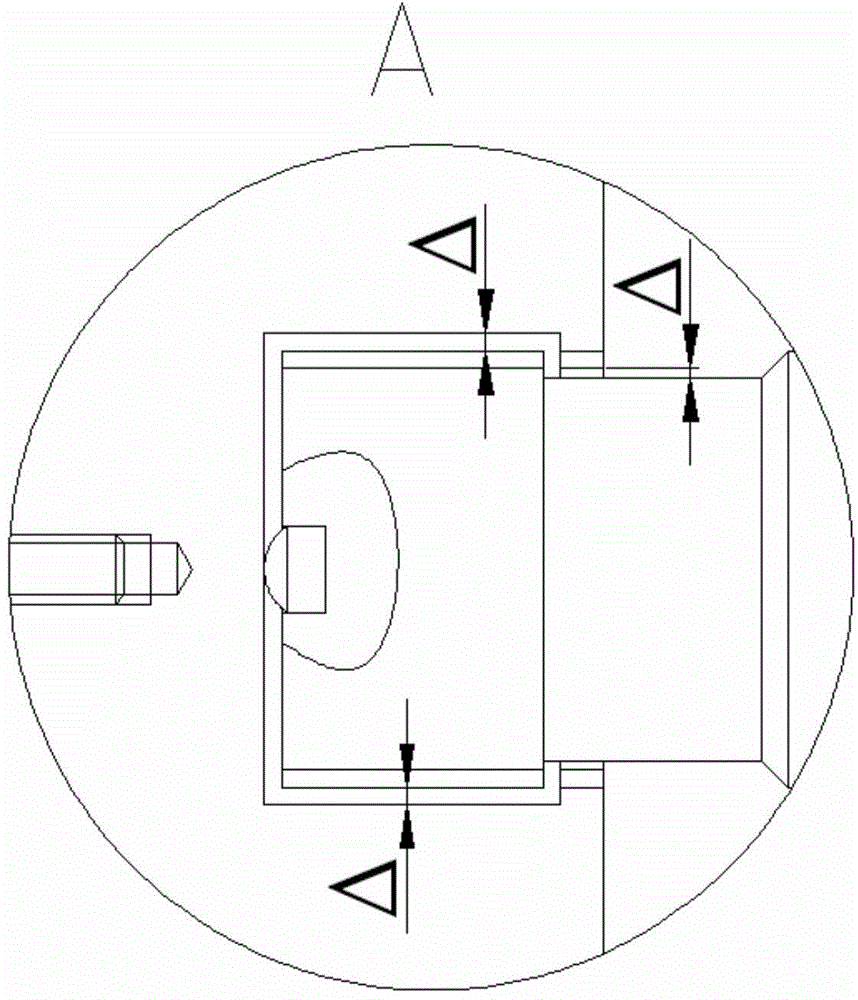

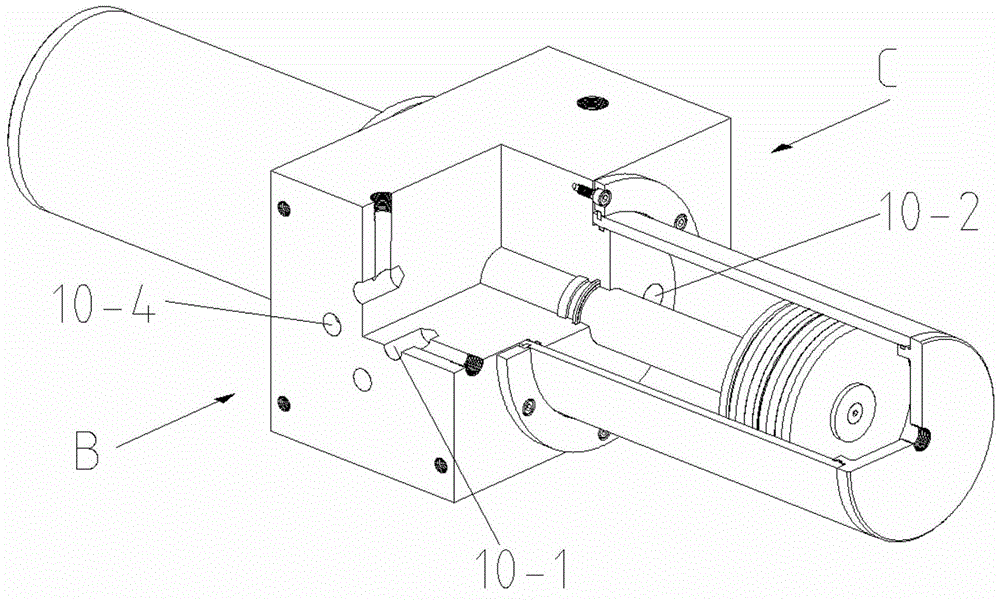

[0033] Such as figure 1As shown, a pressure exchange energy recovery cylinder of the present invention is mainly composed of a central block 10, a piston rod 14, a left piston 7, a right piston 15, a left cylinder 3, a left end cover 1, a right cylinder 13, and a right end cover 18. The left cylinder 3 and the right cylinder 13 are installed on the left and right sides of the center block 10 respectively and form a sealed connection, the piston rod 14 is installed on the center block 10, and the left and right ends of the piston rod 14 extend to the left cylinder 3 and the right The left piston 7 and the right piston 15 are respectively connected to the cylinder 13, and the left end cover 1 and the right end cover 18 are respectively installed on the outer ends of the left cylinder 3 and the right cylinder 13; the left end cover 1 and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com