Cold Extrusion Forming Technology of Pinion Shaft in Power Steering Gear

A power steering gear, pinion shaft technology, applied in the direction of shafts, shafts and bearings, mechanical equipment, etc., can solve the problems of difficult to ensure product consistency, difficult to control machining accuracy, high production costs, improve internal quality and reduce waste. rate, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

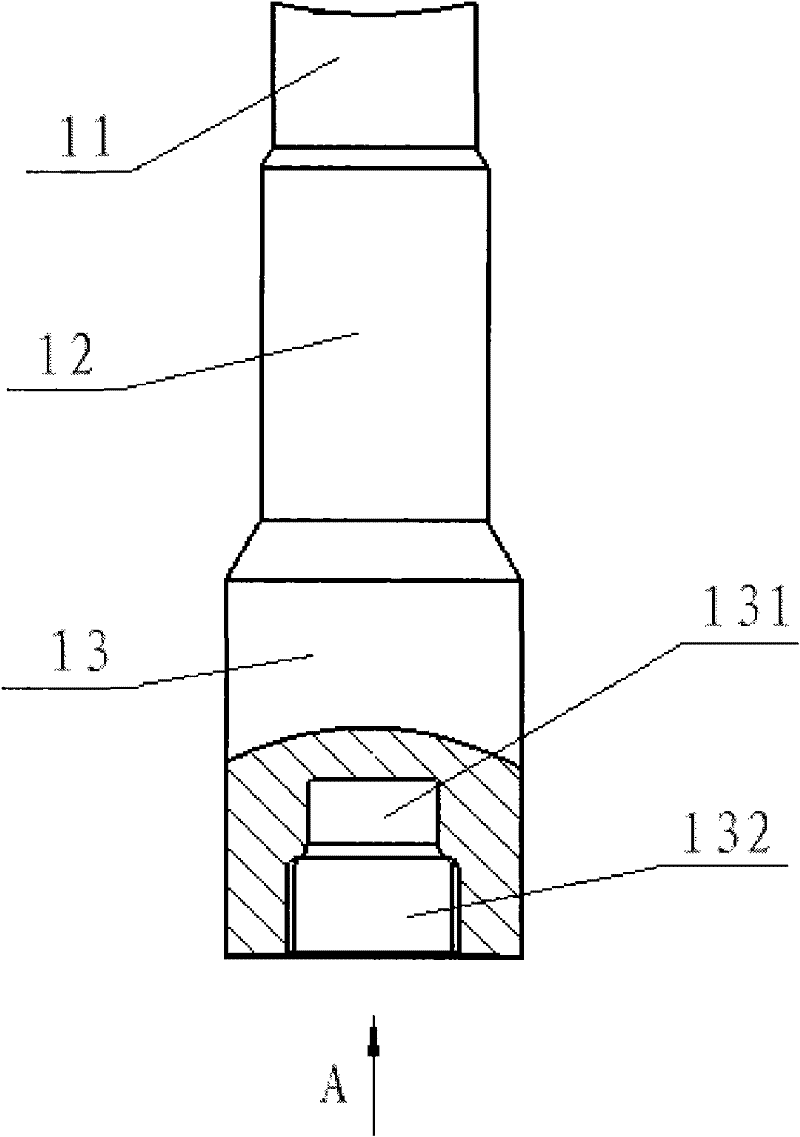

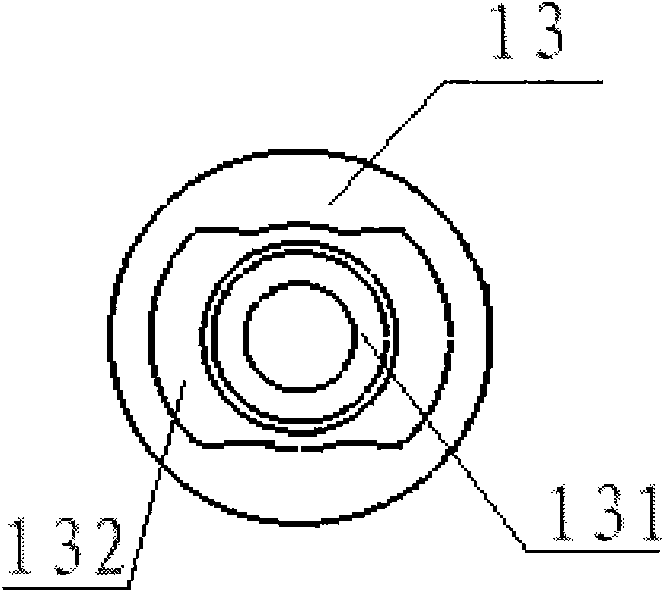

[0018] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0019] The cold extrusion molding process of the pinion shaft in the power steering gear of the present invention comprises the following steps:

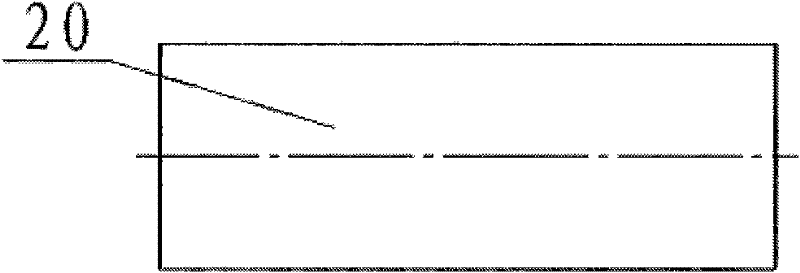

[0020] Step 1, saw a cylindrical blank 20 of required length on a disc according to product requirements (see Figure 3a ), to ensure that the length tolerance of the cylindrical blank is 0-0.1mm, and the perpendicularity between the two ends of the cylindrical blank and the outer peripheral surface of the cylindrical blank is 0.10mm;

[0021] Step 2, grinding the outer circle of the cylindrical blank to ensure that the cylindrical blank 21 after grinding (see Figure 3b ) diameter tolerance is controlled within 0~0.05mm, and the weight error of the single-piece ground cylindrical blank is controlled within ±1g;

[0022] Step 3: Perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com