Double-sprayer and dual-mode 3D printer and operation method thereof

A 3D printer, dual-mode technology, applied in the direction of additive processing, etc., can solve the problems of high time cost, low strength of parts, short life, etc., and achieve the effect of saving time, good inheritance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

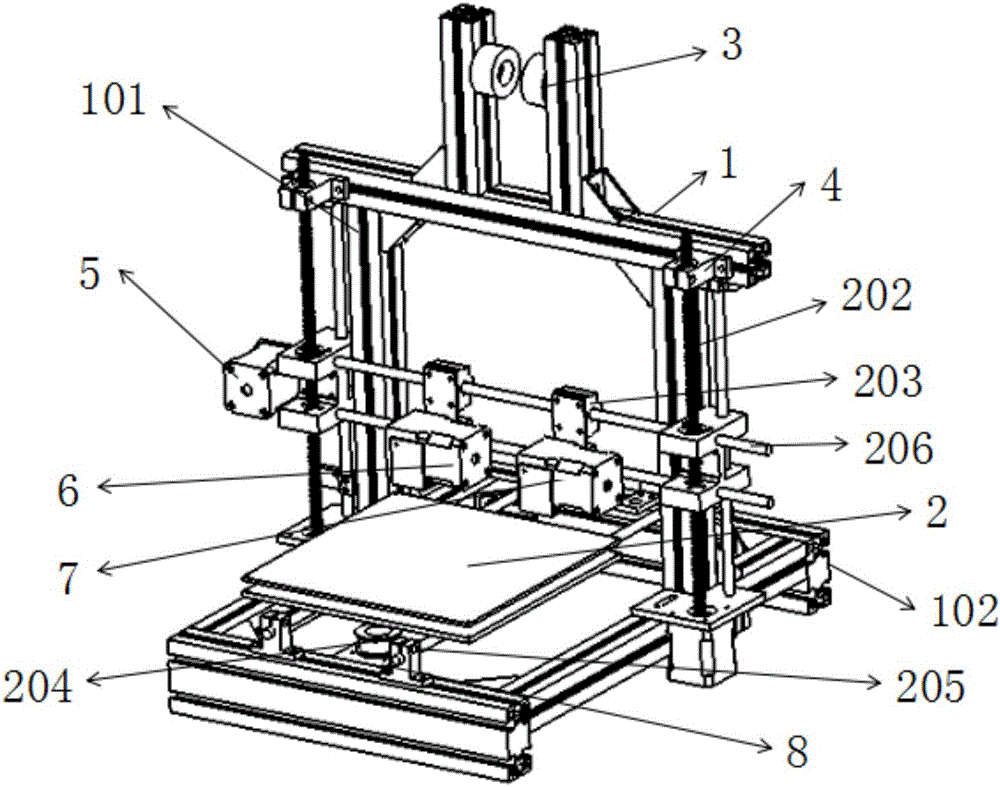

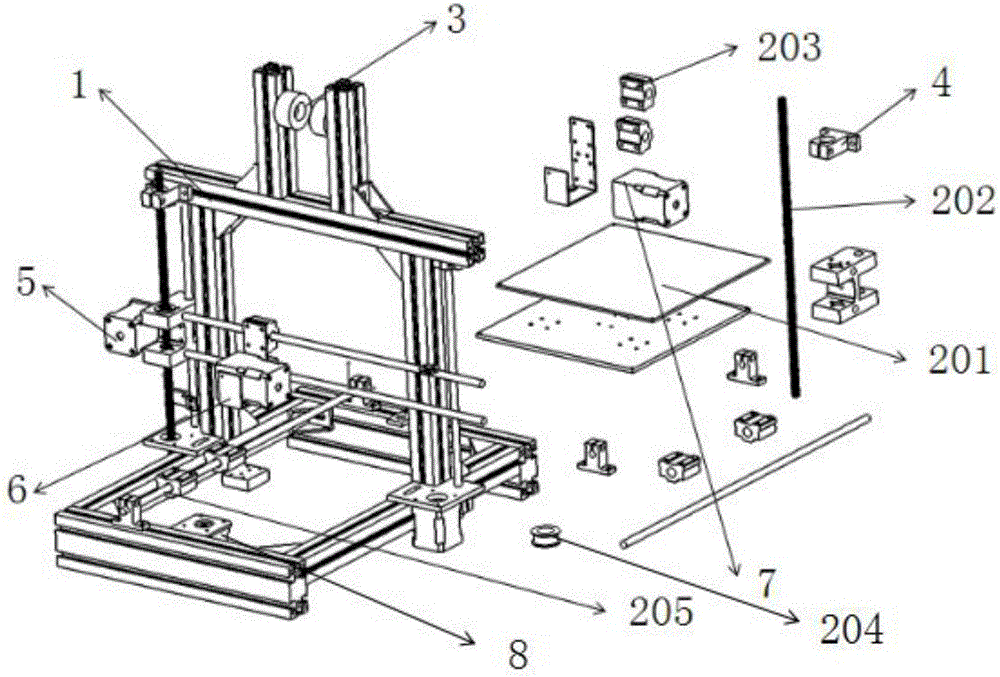

[0032] As shown in the figure, a double-nozzle dual-mode 3D printer, the main structure includes: bracket 1, bottom platform device 2, printing material fixing device 3, drive motor Ⅰ5, nozzle Ⅰ6, nozzle Ⅱ7, drive motor Ⅱ8 and central controller, etc. ,

[0033] Described support 1 comprises vertical support 101 and horizontal support 102, and vertical support 101 is fixedly connected with horizontal support 102;

[0034] The bottom platform device 2 includes a printing platform 201 and a mobile control device; the mobile control device includes a vertical lifting mobile device and a horizontal displacement mobile platform device; the vertical lifting mobile device includes a sliding screw 202, a slider 203 and Connecting rod 206; The horizontal displacement mobile platform device includes a synchronous wheel 204 and a synchronous belt guide rail 205;

[0035] The upper part of the vertical support 101 is fixedly installed with a printing material fixing device 3 through a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com