Method and device for producing a screw connection point

A threaded connection and part technology, which is applied in the direction of welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problem of damage to the threaded connection part, etc., and achieve the effects of easy forming and processing, tight guidance, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

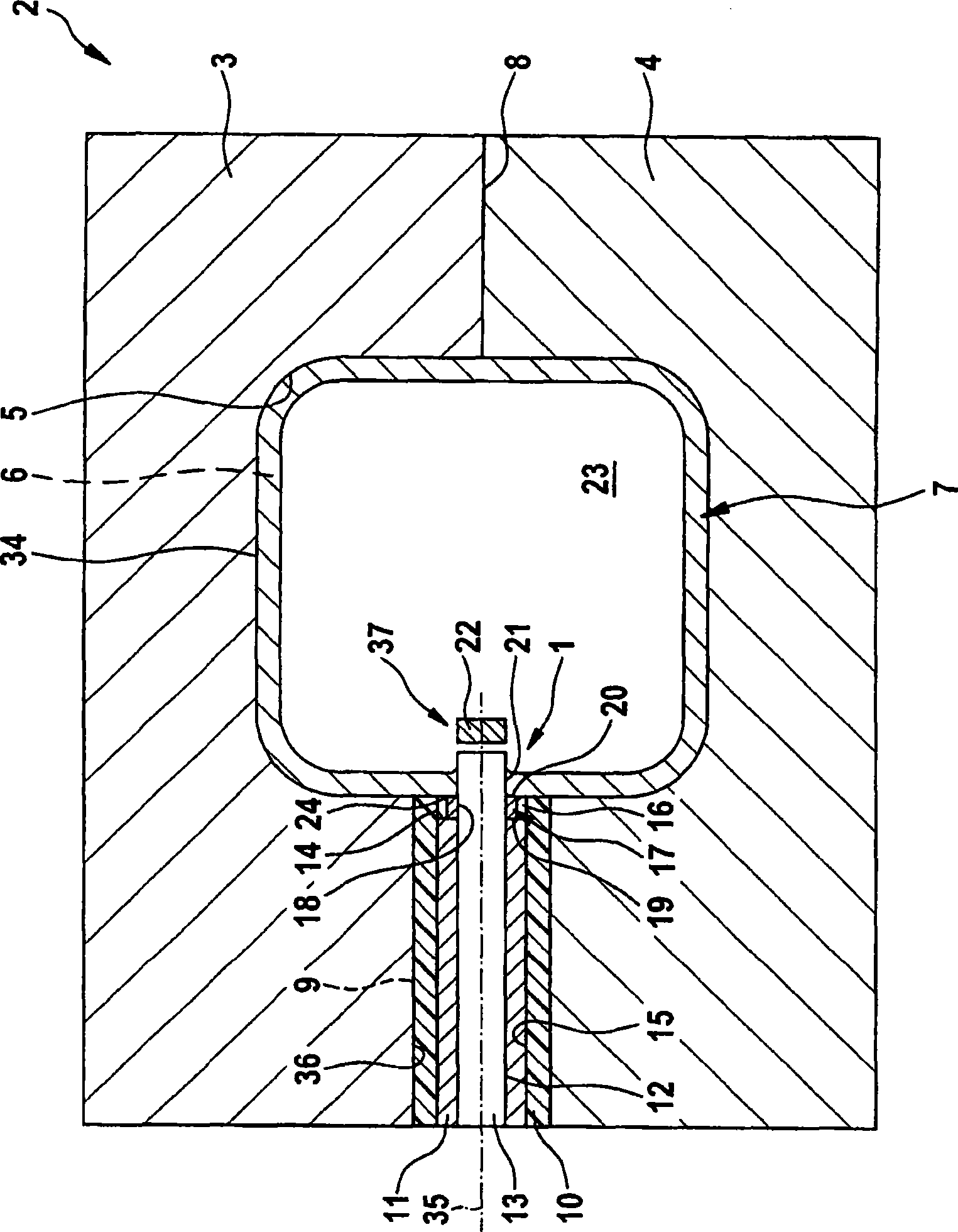

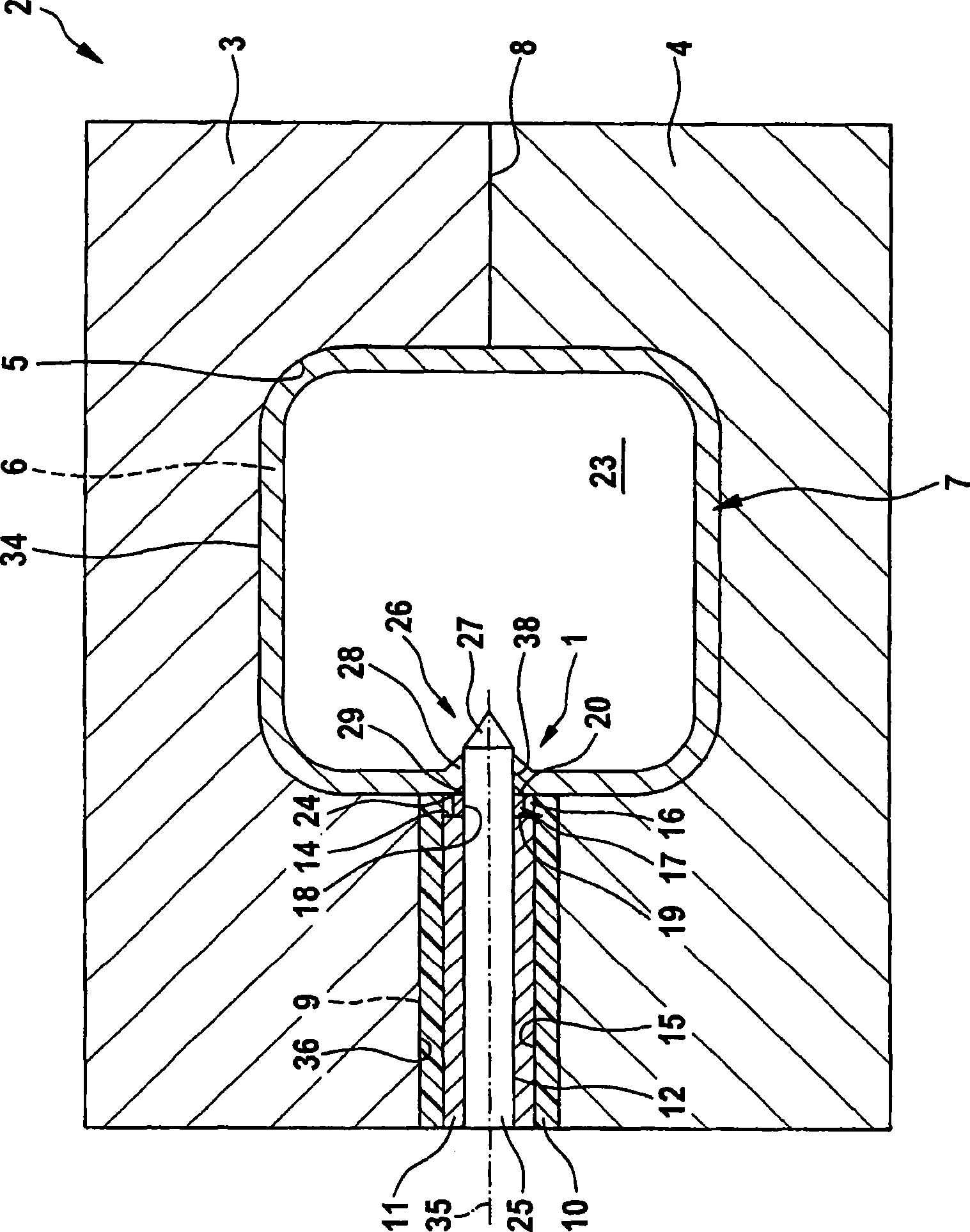

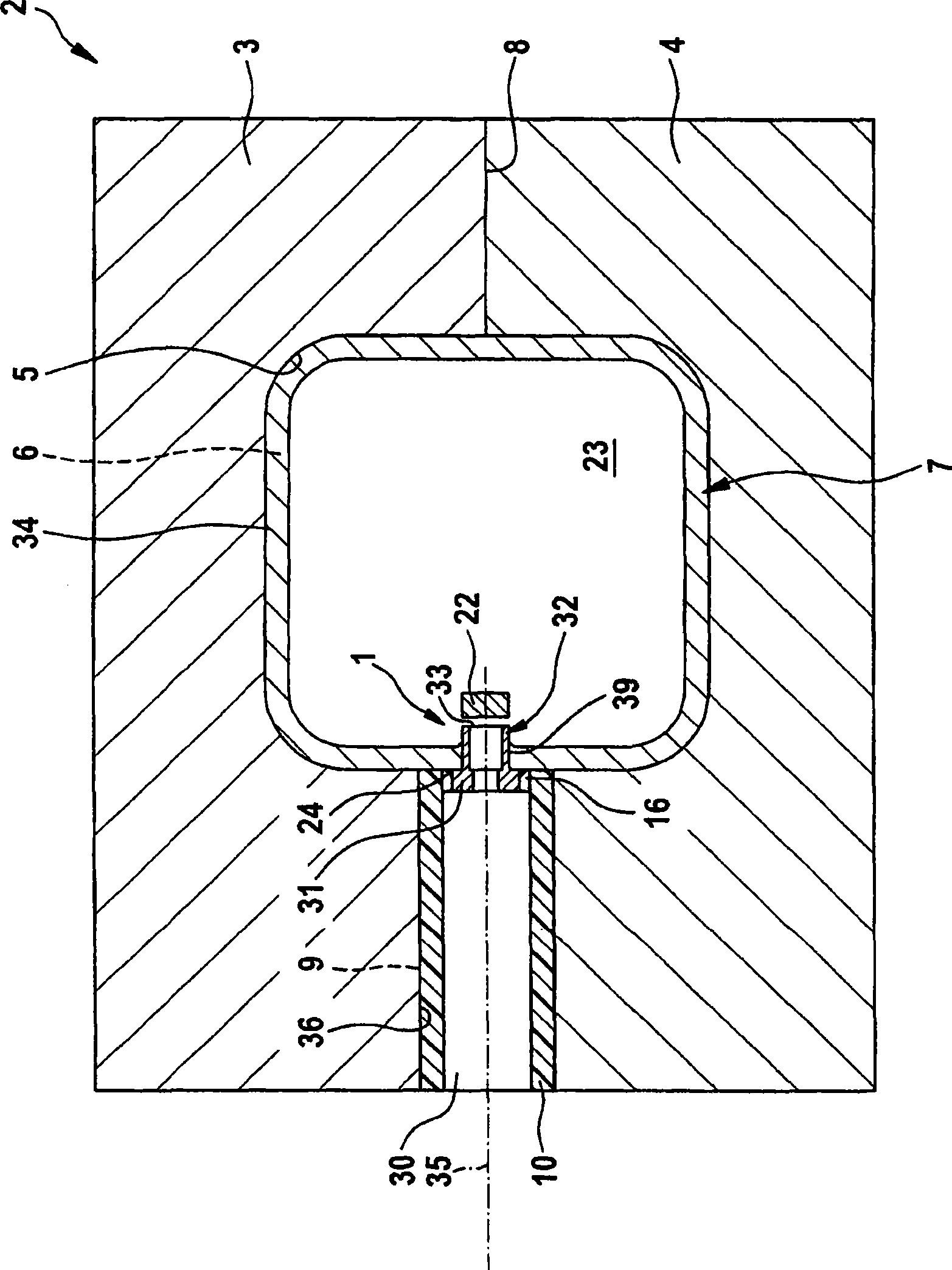

[0020] figure 1A device for producing the screw connection 1 on the periphery 34 of the hollow profile 7 is shown. The device includes a hydraulic forming tool 2, and the internal high pressure forming mold includes an upper mold 3 and a lower mold 4. On the sides of the molds 3 and 4 facing each other, a mold cavity 5 is processed, which defines a mold cavity 6 when the mold 2 is closed, that is, when the upper mold 3 and the lower mold 4 are attached. A hollow profile 7 is accommodated in this cavity 6 for forming and punching. Formed in the mutually facing sides of the upper mold 3 and the lower mold 4 is a guide hole 9 whose axis 35 lies in the plane of the boundary 8 of the two molds 3 and 4 . The guide bore 9 extends from the hydroforming tool 2 on the one hand and leads into the mold cavity 5 of the forming tool 2 on the other hand. Inserted into the guide hole 9 is an electrically insulating sleeve 10 which extends over the entire guide hole 9 and rests against its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com