Polylactic acid/carbon dioxide polymer degradation type composite material

A technology of carbon dioxide and composite materials, applied in the field of composite materials, can solve problems such as poor impact strength, reduced physical properties, and application constraints, and achieve the effects of good thermal stability, excellent mechanical properties, and easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

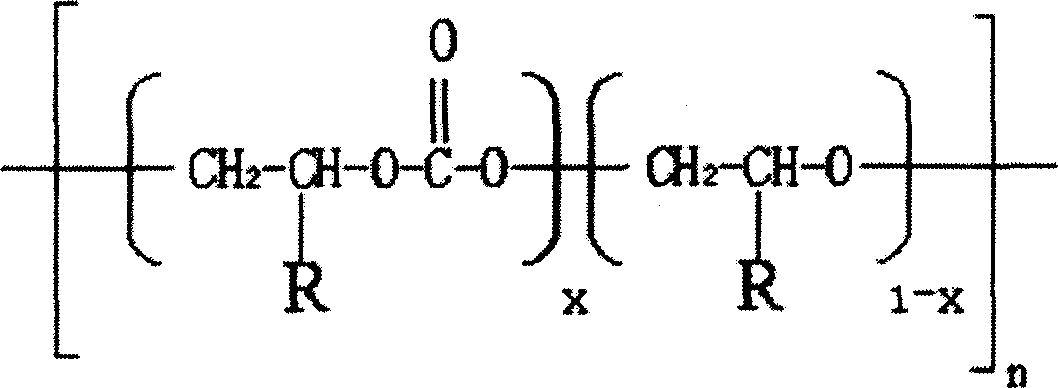

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: take each component by following formula (weight part):

[0019] carbon dioxide polymer 20

[0020] PLA 80

[0021] Plasticizer 15

[0022] Capping agent 1

[0023] The components are mixed in a high-speed mixer for 5 minutes, then cooled and stirred, discharged at 20-30°C, and then plasticized, extruded and granulated in a twin-screw or single-screw extruder. The temperature setting of the extruder is: 70-120°C in the feeding section, 130-155°C in the plasticizing section, and 130-150°C in the extrusion section. The screw speed is: 300 rpm. The film produced by this composite material has very good gloss, transparency and hand feeling, and can be used in the production of medical dressings and packaging materials. The tensile strength of the film made of the composite material is 30.50Mpa. Elongation at break: 402.25%, 45 days of intensive composting test, turned into small fragments that are difficult to pick up....

Embodiment 2

[0024] Embodiment 2: take each component by following formula (weight part)

[0025] carbon dioxide polymer 30

[0026] Polylactic acid 70

[0027] Acetyl tri-n-butyl citrate 15

[0028] Capping agent 1

[0029] The components are mixed in a high-speed mixer for 5 minutes, then cooled and stirred, discharged at 20-30°C, and then plasticized, extruded and granulated in a twin-screw or single-screw extruder. The temperature setting of the extruder is: 70-120°C in the feeding section, 130-155°C in the plasticizing section, and 130-150°C in the extrusion section. The screw speed is: 300 rpm. The film produced by this composite material has very good gloss, transparency and hand feeling, and can be used in the production of medical dressings and packaging materials. The tensile strength of the film made of the composite material is 32.28Mpa. Elongation at break: 423.36%, 60 days of intensive composting test, turned into small fragments that...

Embodiment 3

[0030] Embodiment 3: take each component by following formula (weight part)

[0031] carbon dioxide polymer 70

[0032] PLA 30

[0033] Acetyl tri-n-butyl citrate 10

[0034] Capping agent 1

[0035] The components are mixed in a high-speed mixer for 5 minutes, then cooled and stirred, discharged at 20-30°C, and then plasticized, extruded and granulated in a twin-screw or single-screw extruder. The temperature setting of the extruder is: 70-120°C in the feeding section, 130-155°C in the plasticizing section, and 130-150°C in the extrusion section. The screw speed is: 300 rpm. The film produced by this composite material has very good gloss, transparency and hand feeling, and can be used in the production of medical dressings and packaging materials. The tensile strength of the composite material is: 28.32Mpa. The elongation at break is 512%, and the degradation rate is 26.35% in the 45-day intensive composting test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com