Composite sandwich structure and making method thereof

A composite material, sandwich structure technology, applied in the field of composite materials, can solve problems such as difficult maintenance and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

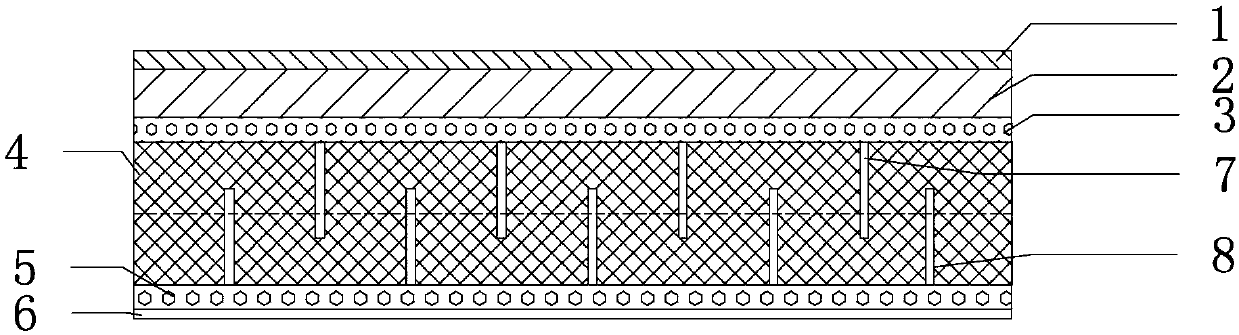

[0031] Embodiments of the present invention provide a composite material sandwich structure and a manufacturing method thereof, which can simultaneously meet the requirements of corrosion resistance, light weight, easy molding and impact resistance of the hull.

[0032] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

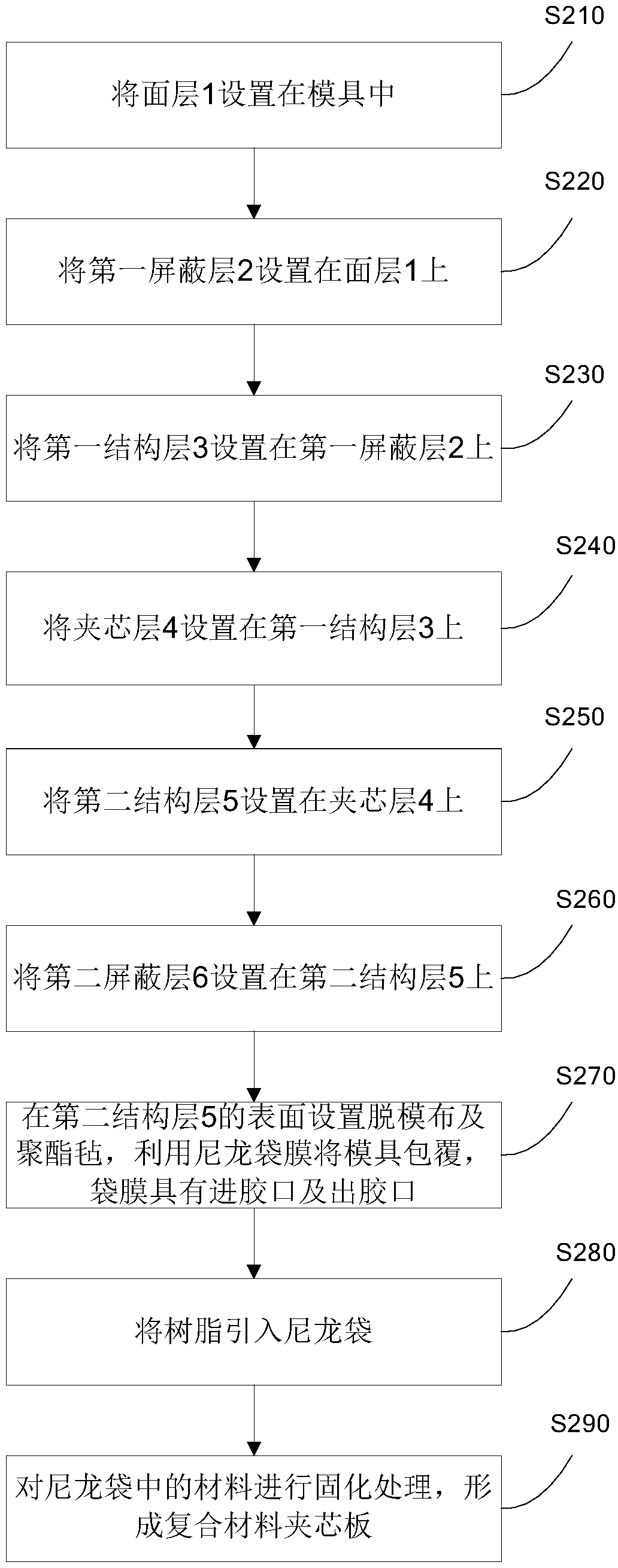

[0033] A multi-layer structure composed of a surface layer, a first shielding layer, a first structural layer, a sandwich layer, a second structural layer and a second shielding layer is provided. If the surface layer and the first shielding layer are waterproof and anti-corrosion materials, the waterproof and corrosion resistance of the sandwich structure can be improved; if the first and second structural layers are mixed with ultra-high molecular weight polyethylene fibers with lighter weight And carbon fiber, and can be laid on any curved surface, it can have exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com