Backlight module and light guide plate thereof

A technology of light guide plate and light source, applied in the field of light guide plate, can solve the problems of difficult injection molding, bending deformation, high cost, etc., and achieve the effects of easy design and molding, enhanced uniformity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

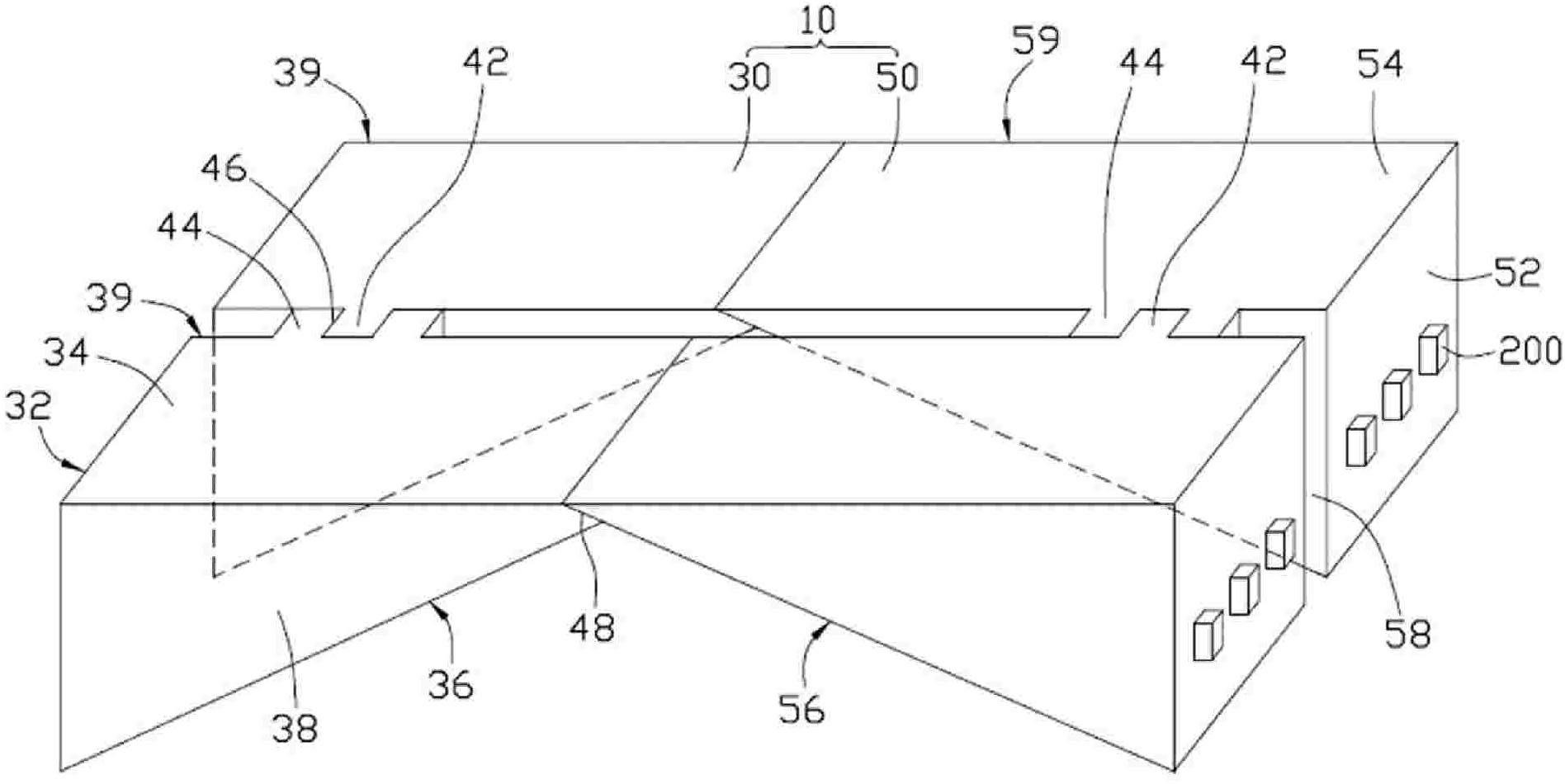

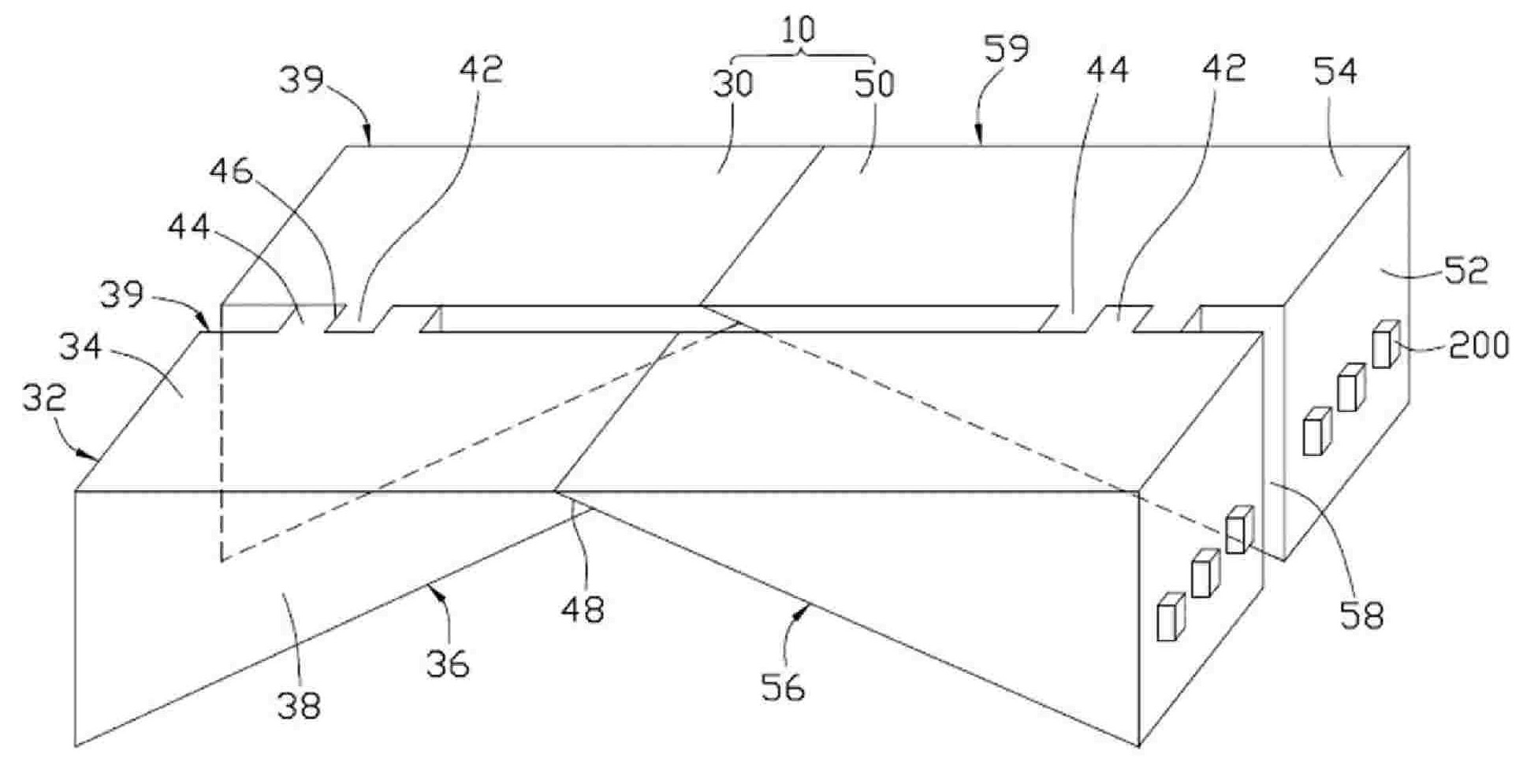

[0013] Such as figure 1 As shown, the backlight module of a preferred embodiment of the present invention includes several light sources 200 and a light guide plate. In this embodiment, the light source 200 is a light emitting diode for generating light.

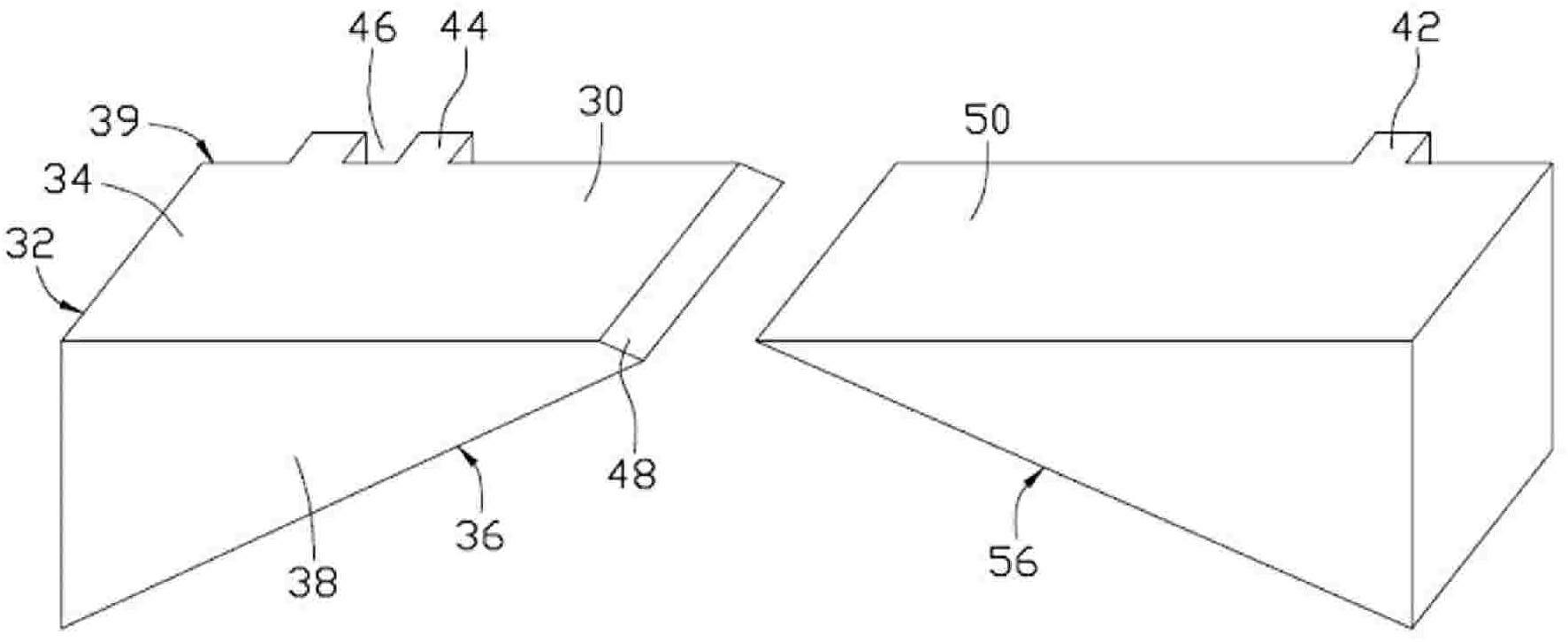

[0014] The light guide plate is used to guide the transmission direction of the light emitted by the light source 200. The light guide plate includes a number of closely arranged light guide units 10. The number of the light guide units 10 is determined by the size of the display screen. For different Display screens of different sizes have different numbers of light guide units 10 . In this embodiment, the light guide plate includes two light guide units 10 , and each light guide unit 10 includes a first wedge-shaped block 30 and a second wedge-shaped block 50 that cooperate with each other. The two wedge-shaped blocks 30, 50 are both made of light-transmitting materials, and their shapes are substantially the same, and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com